Transcription

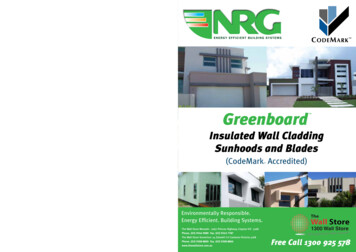

E n v i r o n m e n ta l ly r e s p o n s i b l e . E n e r gy E f f i c i e n t . B u i ld i n g Syst e m s .Greenboard Insulated Wall CladdingSunhoods and Blades(CodeMark Accredited) NRG Provides you with seasonalcomfort all year roundEnvironmentally Responsible.Energy Efficient. Building Systems.The Wall Store Monash: 2067 Princes Highway, Clayton VIC 3168Phone. (03) 9544 9989 Fax. (03) 9543 7787The Wall Store Somerton: 14 Zakwell Crt Coolaroo Victoria 3168Phone. (03) 9308 8800 Fax. (03) 9308 8866www.thewallstore.com.auFree Call 1300 925 578

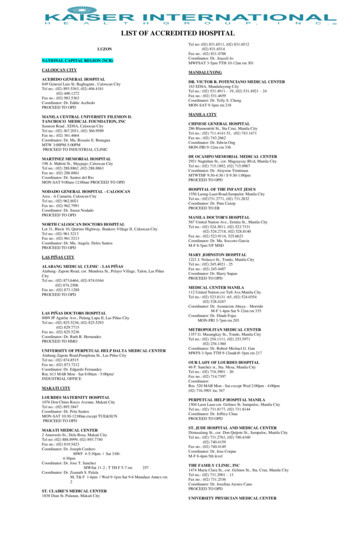

NRG GREENBOARD and the ENVIRONMENT NRG Greenboard Energy Efficient Insulative Walling System Product Information. NRG Greenboard is comprised of 98% air and therefore only 2% polystyrene making it a highlyefficient use of raw material. NRG Greenboard remains inert, is non toxic, odour free and nonbiodegradable. No CFC’s or HCFC’s foam agents are used in its manufacture, so NRG Greenboard causes no damageto the ozone layer. Effective installation of NRG Greenboard can cut carbon dioxide emissions by up to 50%. The R-value of NRG Greenboard does not deteriorate during its life time; therefore the reduction inemissions lasts the full lifetime of the building. The energy used to manufacture NRG Greenboard is recovered within six months by the energysaved in the building in which NRG Greenboard is installed. Typically, for every kg of oil used in NRG Greenboard manufacturing, about 200kg will be saved inGM-09-CM30005CODEMARK ACCREDITATIONNRG Greenboard is CodeMark Accreditated andcomplies with the Building Code of Australia (BCA)reduced heating demands. All NRG Greenboard waste is recycled. Either through installation of off-cuts in the wall cavity or itcan be granulated and mixed with virgin material to make new products.

CodeMark CertificateChanges to the 2010 version of Building Code of Australiaare that all building products must comply with the BCA.CodeMark certified products comply with the BCA.NRG Greenboard has achieved CodeMark Certification.Each state has regulations, ensuring that a CodeMark building solution can not be rejected.For their own protection, local authorities (certifiers, councils,surveyor, designers, home insurance companies) are insistingon CodeMark Certification.NRG Specification May 2010 6th EDITION1

TABLE OF CONTENTS2Greenboard Insulated Wall Cladding3Greenboard Product Data4NRG Greenboard Insulative Walling System4Properties and Advantages of the NRG Greenboard Walling System4Design Information General6NRG Greenboard Installation Procedure8NRG Greenboard Bead and Sealant Procedure11NRG Greenboard Texture Coating System: - Procedure12Applied Finish Specification13NRG Accessories15NRG Check List29NRG Warranty30Thermal Rating for Greenboard Wall System32NRG Specification May 2010 6th EDITION

GREENBOARD Insulated wall claddingGreenboard is an Insulated Wall Panel that combinesexterior cladding with insulation so designers can achievethe 6 star energy ratings that have been introduced into thebuilding code. Greenboard ‘s insulated core of high qualityexpanded polystyrene puts the Greenboard insulated panelin the best place of the building, as far towards the outer sideas possible.Greenboard Insulated Wall Panel is a lightweight, energyefficient product and once coated the system provides aweather resistant, seam free rendered finish.Greenboard AdvantagesCodeMark CertificationAll building products must comply with the BCA (Building Codeof Australia). NRG Building Systems has achieved CodeMark onGreenboard Insulated Wall Cladding meaning Greenboard complies to the BCA.Insulation QualitiesAll insulation materials are rated for their performance inrestricting heat transfer. This rating is expressed as anR-value which is a measure of the material’s resistance toheat transfer (thermal resistance). The higher the R-value thegreater insulating effect.Total Wall R-value for using Greenboard Thickness (mm)50mm60mm75mm100mmR-value on total wall2.18 R2.44 R2.83 R3.48 RSound RatingNRG Building Systems has tested 60mm Greenboard total wall system and the acoustic performance result wasRw35,Ctr-6. Please refer to NRG test results. The Greenboard walling system can be further enhanced by using a “soundrated” insulation batt. Please refer to insulation manufacture’sspecifications.Grooved PanelThe surface of the Greenboard panel is Grooved bothsides allowing the inside surface to breathe and channel anypossible condensation away through the Grooves, downwardsto the base of the wall. This is particularly important where“insulation” or “breather sarking” is used. The additionaladvantage being that when theGrooved face of Greenboard is rendered the systembecomes stronger as the render gets into the Groove to forma core shape for better adhesion and a stronger more rigidGreenboard system.Easy to UseGreenboard ‘s lightweight panel size is 2500 x 1200 allowinginstallers to cover the external walls quicker and easier. For thebuilder and their client, Greenboard gets the project to lockup stage quicker allowing other trades to start and completetheir tasks.Environmentally FriendlyGreenboard requires less energy to produce than othertraditional building materials and contains no CFC’s nor HCFC’s.Greenboard does not contain ozone depleting substancesand none are used in the manufacturing of this product.Greenboard can be recycled or NRG recommends left overGreenboard can be placed in the walls as extra insulation.Termite RetardantGreenboard contains a termite retardant (Bifenthrin)and NRG uses 62% more in their product than theminimum required.Render Levels of FinishReinforced render is applied to the Greenboard substrateat approximately 4-8mm in thickness which allows qualifiedapplicators to screed out usual imperfections and form a seamfree level 5 finish. NRG recommends render over Greenboard should be specified by a coating manufacturer.Fire RetardantGreenboard contains a flame retardant additive and will notsupport fire, it has a spread of flame index of zero. If in a firesituation the toxic fumes are no greater than that of timber andother building materials.NRG Specification May 2010 6th EDITION3

Greenboard Product DataGreenboard Energy Efficient Insulative Walling System Product Information.NRG Greenboard is an insulative walling system suitable for external cladding of timber or steel framed buildings as well as solidconcrete and masonry walls. The system provides a weather resistant, seam free rendered finish in a wide range of textures andcolours. It also provides continuous thermal insulation over the entire wall. Developed in Germany in 1973, these systems have beenextensively used throughout Western Europe and North America where strict environmental laws are in place governing the energyefficiency of both private and commercial buildings. The system is now well established in Australia ranging from dry arid areas, totropical and alpine regions, whilst proving energy efficiency, cost effective and flexible construction alternative. The NRG Company isproviding and increasing research and development of the system to improve the product.NRG Greenboard Insulative WallingSystem consists of:14.1.1An enhanced expanded polystyrene (EPS) insulationboard impregnated with an insect repellent compoundand flame retardant. The board is mechanically fixedto timber/steel stud framing or reinforced concreteor masonry wall. The surface of the Greenboard panel is grooved both sides allowing the insidesurface to breath and channel any possiblecondensation away through the grooves, downwardsto the base of the wall. This is particularly importantwhere 'insulation' or 'breather sarking' (refer 16.1.9) isused. The additional advantage being that the grooved'face' surface of the Greenboard panel provides anexcellent 'key' to accept the reinforced render system.14.1.2 NRG Greenboard Washers and Screws (Class 3) areused for fixing to timber or steel framing, while specialanchors are used for fixing to masonry wall surfaces.14.1.3 External PVC (UV Stabilised) angle beads andwindow trims.14.1.4 A polymer modified cement render reinforced with analkali resistant fiberglass mesh.14.1.5 Acrylic texture coating and or pigmented membranefinished in your selected colour.14.1.6 The NRG Walling System incorporating reinforcedrenders and textured finish coatings form a completecladding system from the frame to the finishedsurface.14.1.7 Vermin Retardant.14.1.84A high impact strength finish.NRG Specification May 2010 6th EDITION14.1.9 NRG Greenboard Insulative Walling System: Soundinsulation value - 60mm Greenboard Refer (16.1.5 Acoustic Values (Table D)) Rw 35, Ctrr -614.1.10 NRG Greenboard Insulative Walling System: is anextremely high-energy, efficient product reducingheating costs in winter and cooling costs in summer.14.1.11 NRG Greenboard Insulative Walling Systems uniquegrooved surface provides strength and flexibility offinish, allowing a vast range of architectural designs,finishes and colours to complement any surroundings.14.1.12 NRG Greenboard Insulative Walling Systems isthe ideal substrate for lightweight construction, 2ndstorey additions, reactive soil and mine subsidenceareas are concerned.Properties and Advantages of theNRG Greenboard Walling SystemNRG Greenboard panel is manufactured from high density,rigid, expanded polystyrene. The raw material is gained as aby-product of the manufacture of oil.Greenboard is manufactured without the use of CFC’s anddoes not contain or emit any poisonous gas. In fact, NRGGreenboard is made up of 98% air entrapped in a closedcellular structure of polystyrene. This entrapped air accountsfor the extremely good insulation propertiesof the Greenboard .The off cuts of NRG Greenboard can be glued within thewall cavity prior to the installation of the internal liningsas additional insulation. This cuts down on the impact toour environment as all the material is being used, leaving aminimal amount of material to be removed from site.

98% ENTRAPPED AIR SUPPORTING THE ENVIRONMENT NO CFC’S USED IN THE MANUFACTURING PROCESS NO SITE WASTAGE - USING ALL OFF-CUTS ASADDED INSULATION SUPPORTING THE CONSUMER BY REDUCINGHOME AND BUSINESS GREENBOARD RENDER, REINFORCED WITH 150G/m2FIBERGLASS MESH FOR HIGH IMPACT STRENGTH. ADDED FIRE RETARDANT WILL NOTSUPPORT COMBUSTION DESIGN FLEXIBILITY. FULL RANGE OF COLOURED FINISHES AND STYLES EXCEPTIONAL THERMAL QUALITIES acoustic values VERMIN RETARDENTNRG Specification May 2010 6th EDITION5

15.1.1Insulation for Energy Efficient BuildingsThe Greenboard system is the most cost efficientmethod of insulation in terms of R-value per dollar.Unlike some other methods of insulation that allowthermal bridging across the timber or steel studsframing. NRG Greenboard provides a continuousinsulative sheath around the entire building.15.1.2 Warranty - 10yri. NRG warrants that the Greenboard sheets(the "Product") will be free from defects due todefective factory workmanship or materials priorto the installation of the Product for a periodof 10 years from the date of purchase, subject tocompliance with the conditions published in NRGProduct Warranty 2007 - Free Call 1800 674 001www.nrggreenboard.comDesign Information GeneralThe NRG Greenboard Insulative Walling System forms acontinuous weather-resistant thermal envelope around theexternal walls of the building. The versatility of the buildingand the workable nature of the Greenboard compositepanel permits greater design freedom. This system allows thedesigner to economically provide a fashionable, long lastingrender finish as well as comply with the strictest energy ratingsrequired in modern building codes.Tests show that a properly insulated building can reduceenergy costs by up to 75%. This greatly reduces the runningcosts of the building in terms of energy savings and reducesthe amount of green house gases released into the atmosphere16.1.115.1.3 Easy to RenderThe surface of the NRG Greenboard is groovedproviding an excellent substrate forReinforced Render Systems.15.1.4 Energy Efficient ProductionGreenboard uses much less energy in its productionthan conventional building materials such as concreteand masonry.15.1.5 Fashionable Render FinishesAvailable in a wide range of Architectural colours andstyles (Refer to your selected manufacturers, texturecoating specifications).15.1.6 Design FreedomCurved walls, rounded corners, embossed patterns,raised wall areas, mouldings and other architecturalfeatures are simple to achieve and cost-effectively withthe versatile NRG Walling System.15.1.7Vermin RetardantNRG Greenboard is impregnated with a naturalinsect retardant, (Bithentrin)16.1.2 Building - Wind Zones (Table A)When mechanically fixed to a variety of substrates inaccordance with the "NRG Greenboard WallingSystem – Installation Manual for use in thefollowing categories.IntermediateRegionDescriptionpd Type B - W33Sheltered Suburban0.990 kPaType B - W41Exposed Suburban1.485 kPaType C - W50Open Rural (Tropical Cyclone)3.289 kPaType D - W65Open Rural (Severe Tropical Cyclone)4.719 kPa16.1.3 Minimum Stud & Fastener Spacing’s (Table B)NRG Greenboard Minimum Stud & Fastener Spacing’sRegions Wind CategoryCyclonicNon Cyclonic15.1.8 Biologically InertThe board will not rot and provides no nutritive valuefor insects or micro-organisms.StructureNRG Greenboard 50mm, 60mm, 75mm and 100mmthick has sufficient strength and rigidity to besupported by wall framing spaced at 450mm maximumcentres. NRG Greenboard can be installed overmasonry walls (e.g. 40mm Greenboard ) to increasethe "R–value" of the masonry wall system or brickveneer ertically)Number ofFasteners 24C145020018C245015024C345010037* In accordance with AS1684 – 2006 / AS4005 – 19926NRG Specification May 2010 6th EDITION

16.1.4 Insulation Values (Table C)All insulation materials are rated for their performanceIn restricting heat transfer. This rating is expressed asAn R-value which is the measure of material’sresistance To heat transfer (thermal resistance).The higher the R-value, the greater theinsulating effect.Thickness5060Thermal conductivity at23oC (W/m2.k)R-value of insulationmaterialTotal R-value ofwall from RenderedGreenboardTMReflective sarking,cavity plasterboard751000.0371.301.92R1.561.952.44R 2.83R2.603.48R16.1.7 Hazardous Building MaterialsWhen installation is complete the NRG Greenboard Walling System and the Greenboard ReinforcedRender System is non-hazardous.16.1.8 External MoistureThe "NRG Specifications & Installation Manual”contains specific details and instructions for flashingaround windows, finishing to edges and sealingpenetrations. Head, sill and jamb flashings must beused as specified. The NRG Greenboard WallingSystem must not be allowed to come into contactwith the ground.16.1.9 SarkingNRG Building Systems highly recommends the useof vapor permeable sarking, equivalent to Sisalation Wall Wrap (Breather) or similar, fixed directly behindthe NRG Greenboard Walling System.16.1.5 Acoustic Values - NRG Greenboard (Table D)Summary of Acoustic Test Results: 60mm NRG Greenboard Side 16mm concrete render appliedto 60mm thick expandedpolystyrene foam.The polystyrene applied withsheet lengths vertical.AcousticPerformanceRw 35,Ctr -6Framing 90mm timber studs at 450mmSide 2centres 10mm Plasterboardapplied with sheet lengthsvertical. Edges caulked withexpanding polyurethane foam.Ron Rumble Pty Ltd, Consulting Acoustical & Vibration Engineers - 28th August 2006The NRG Greenboard walling system can be furtherenhanced by using a ‘sound rated’ insulation batt (Refer toInsulation manufacturer’s specifications).16.1.6 Impact ResistanceThe Greenboard Walling System when installedin accordance with "NRG Specifications & InstallationManual" will have adequate resistance to impact loadslikely to occur in normal residential and commercialuse. The likelihood of damage in public areas in oraround residential, commercial or industrial buildingswhere heavy impacts could occur should be consideredat the design stage. Heavier grade fibreglassreinforcing mesh or multiple layers should be used andappropriate protection or barriers should be providedin vulnerable areas.NRG Specification May 2010 6th EDITION7

16.1.10 Early Fire Hazard Properties (Table E)NRG Greenboard contains a flame retardant additiveto inhibit accidental ignition from small flame source.Note:NRG Greenboard System must be separatedfrom heat sources such as fireplaces, chimneys orflues. NRG Greenboard System Does not provide afire rated wall.NRG Greenboard IndexRatingIgnitability(0-20)6Spread of Flame Index(0-10)0Heat Evolved(0-10)1Smoke Developed(0-10)4NRG Greenboard Installation Procedure17.1.1Installation Procedures NRG Greenboard Walling SystemThis manual provides information on the correctprocedures and materials to be used for theinstallation of NRG Greenboard Walling Systemover standard framed and solid structures. Thedrawings and details are provided to assist buildingdesigners in specifying the correct design and detailof the NRG Walling System. These details cover mostcommon applications. If the details are to be alteredor new ones proposed please contact NRG to discussthe changes. Failure to do so may void thesystems warranty.person, to identify any deterioration or infestationby wood boring insects. Although NRG Greenboard is impregnated with an effective insect repellent, it willnot arrest or prevent further infestations of the timberframing structure. Where necessary, repairs must beundertaken to ensure that the timber substrate issound, straight and true.17.1-4 Back Blocking (Off Stud Joints)Where horizontal fixing of sheets ‘off stud’ join are tobe made, it is necessary to back block as follows.i. By fixing an ‘off cut’ of stud material vertical,(widest face facing outwards) and securelynailing to bottom plate and noggin. Alternatively,between noggin and top plate, making sure toglue both Greenboard sheet edges with BostikNo-More Nails and fixing through each sheet intothe ‘black block’ with washers and screws atmaximum 300mm centre’s.ii. Alternatively, horizontal ‘back block’ using ‘offcuts’ can be placed at maximum 300mm centre’s,following the above procedure except that,with the two sheets in place, take ‘off cuts’,smear with Bostik No-More Nails over one face,place ‘off cuts’ against the Greenboard sheetsand screw through face of Greenboard into ‘offcuts’, pulling both sheets into alignment.(Refer to DWG 08 )17.1.5These components that make up the NRG Greenboard Insulative Walling System are. Screws and washersVapor permeable sarkingNRG Greenboard NRG PVC beadsPolymer modified renderReinforced meshTexture top coatThese components form part of the complete systemand must not be substituted with other possible nonconforming materials.17.1.2 Timber and Steel FramingAll timber and steel framing should conform to therelevant Australian Standards, as well as the localstandards for structural requirements including windloadings and bracing.NRG GreenboardTM is not a structural material and thereforeshould not be considered or used as a bracing material.17.1.38Existing framingWhen ‘over-cladding’ existing timber buildings,inspection should be carried out by a fully qualifiedNRG Specification May 2010 6th EDITIONSolid Blocking of Fitting and AccessoriesConsideration should be given to the installation ofwall mounted accessories i.e. taps, electrical fittings,etc. It is important to allow for adequate backblocking for these items prior to the installation of theNRG Greenboard .17.1.6 Electrical Cables and PVCCables penetrating the NRG Greenboard WallingSystem must be installed in conduit or ducts sealed tothe cladding or have a sheathing containing migrationresistant plasticizer. Cable manufacturers should becont

nrg check list 29 nrg warranty 30 . home and business greenboard render, reinforced with 150g/m2 fiberglass mesh for high impact strength. added fire retardant will not support combustion design flexibility. full range of coloured finishes and styles