Transcription

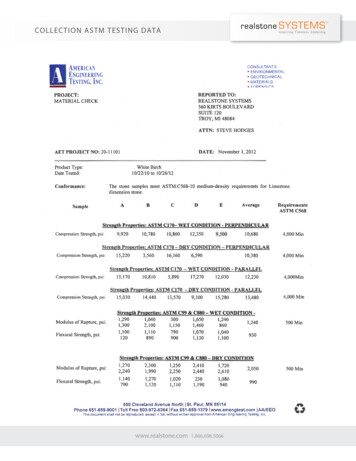

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

realstone SYSTEMSCOLLECTION ASTM TESTING DATAInspiring. Timeless. Endurin g.CONSULTANTS· ENVIRONMENTAL· GEOTECHNICAL· MATERIALS· FORENSICSREPORT OF FREEZE-THAW TESTING OF STONEPROJECT:REPORTED TO:FREEZE-THAW TESTINGWHITE BIRCH STONEREALSTONE SYSTEMS560 KIRTS BOULEVARDSUITE 120TROY, MI 48084AET JOB NO: 29-01290TMATTN:KURT FEINDATE:OCTOBER 11, 2013INTRODUCTIONThis report presents the results of testing performed on five stone units. Samples were submittedto our laboratory by you. The scope of our work consisted of performing freeze-thaw testing andreporting our results. Testing was conducted in accordance with ASTM C67 “Standard TestMethods for Sampling and Testing Brick and Structural Clay Tile” and evaluated according toASTM C 216 “ Standard Specification for Facing Brick (Solid Masonry Units Made from Clayor Shale)”. Our work was authorized by you on June 14, 2013.SAMPLE INFORMATIONAmerican Engineering Testing, Inc. received 1 box of 5 samples of stone from RealstoneSystems labeled as White Birch on June 19, 2013.TESTING METHODSThe specimens were subjected to freeze-thaw cycling in accordance with ASTM C67.1. The samples were placed in a pan with water at a depth of ½” and frozen for 20 hours. Nextthe samples were immersed in a thawing tank for 4 hours. This process is continued for 50cycles or until the specimens develop a crack or appears to have lost more than 3% of itsoriginal weight by disintegration as judged by visual inspection.2. Final weight loss percentages are calculated by dividing the oven dry weight of dislodgedmaterials by the final oven dried sample weight, plus the total dislodged materials.www.realstone.com 1.866.698.5066

realstone SYSTEMSCOLLECTION ASTM TESTING DATAInspiring. Timeless. Endurin g.TEST RESULTSCycles12345AverageTMWHITE BIRCH STONERatingWeightFullLoss %WidthCrackingNo0.0See RemarksNo0.0See RemarksNo0.0See RemarksNo0.0See RemarksNo0.0See Remarks0.0REMARKSThe samples were tested to 50 freeze thaw cycles and found to meet the specifications of ASTMC216 “Standard Specification for Facing Brick (Solid Masonry Units Made from Clay or Shale)”for SW facing material. This report represents specifically the samples tested. According toASTM C216 section 6.1.3.1 No individual unit separates or disintegrates resulting in a weightloss greater than 0.5% of its original dry weight. Also section 6.1.3.2 No individual unit developsa crack that exceeds, in length, the units least dimension. If you have any questions, please feelfree to call us.Report Prepared By:American Engineering Testing, Inc.Report Reviewed By:American Engineering Testing, Inc.Joseph T. JohnsonConcrete Technician IIIPhone: 651-659-1354Fax: 651-647-2744jtjohnson@amengtest.comDaniel M. Vruno, P.E.Principal EngineerMN Lic. No. 42037Phone: 651-659-1334Fax: 651-647-2744dvruno@amengtest.comwww.realstone.com 1.866.698.5066

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

realstone SYSTEMSCOLLECTION ASTM TESTING DATAInspiring. Timeless. Endurin g.CONSULTANTS· ENVIRONMENTAL· GEOTECHNICAL· MATERIALS· FORENSICSREPORT OF FREEZE-THAW TESTING OF STONEPROJECT:REPORTED TO:MATERIAL EVALUATIONLATTE-STONE UNITSREALSTONE SYSTEMS560 KIRTS BLVDSUITE 120TROY, MI 48084AET JOB NO: 20-11101TMATTN:STEVE HODGESDATE:JANUARY 29, 2013INTRODUCTIONThis report presents the test results on five stone units. Samples were submitted and identifiedby you. The scope of our work consisted of conducting freeze-thaw testing in accordance withASTM C67-12, “Standard Test Methods for Sampling and Testing Brick and Structural ClayTile” and evaluated according to ASTM C 216-12a “Standard Specification for Facing Brick(Solid Masonry Units Made from Clay or Shale).” Our work was authorized by you on February20, 2012.SAMPLE INFORMATIONAmerican Engineering Testing, Inc. received 5 stone samples identified as Latte #1 through #5from Realstone Systems.TESTING METHODSThe specimens were subjected to freeze-thaw cycling in accordance with ASTM C67, Section 9.1. The samples were placed in a pan with water at a depth of ½” and frozen for 20 hours. Nextthe samples were immersed in a thawing tank for 4 hours. This process continued for 50cycles or until the specimens develop a crack or appears to have lost more than 3% of itsoriginal weight by disintegration as judged by visual inspection.2. Final weight loss percentages are calculated by dividing the oven dry weight of dislodgedmaterial by the final oven dried sample weight, plus the total dislodged material.www.realstone.com 1.866.698.5066

realstone SYSTEMSCOLLECTION ASTM TESTING DATATMInspiring. Timeless. Endurin g.AET Project No. 20-11101 - Page 2 of 2TEST RESULTSSampleWeightLoss 006%FullWidthCrackingNoNoNoNoNoRatingSee RemarksSee RemarksSee RemarksSee RemarksSee RemarksREMARKSThe samples were tested for 50 freeze thaw cycles. The test results meet the specifications ofASTM C216-12a “Standard Specification for Facing Brick (Solid Masonry Units Made fromClay or Shale)” for SW facing material. This report represents specifically the samples tested.The ASTM C216 requirements for freeze-thaw durability in section 6.1.3.1 state that noindividual unit separates or disintegrates resulting in a weight loss greater than 0.5% of itsoriginal dry weight. Additionally, ASTM C216, Section 6.1.3.2 states that no individual unitdevelops a crack that exceeds, in length, the units least dimension. If you have any questions,please feel free to call us.Report Prepared By:American Engineering Testing, Inc.Report Reviewed By:American Engineering Testing, Inc.Joseph T. JohnsonConcrete Technician IIIPhone: 651-659-1354Fax: 651-647-2744jtjohnson@amengtest.comDaniel M. Vruno, P.E.Principal EngineerMN Lic. No. 42037Phone: 651-659-1334Fax: 651-647-2744dvruno@amengtest.comFor additional help or with questions please contact usat 1-866-698-5066 or at realstonesystems.comwww.realstone.com 1.866.698.5066

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

realstone SYSTEMSCOLLECTION ASTM TESTING DATAInspiring. Timeless. Endurin g.CONSULTANTS· ENVIRONMENTAL· GEOTECHNICAL· MATERIALS· FORENSICSREPORT OF FREEZE-THAW TESTING OF STONEPROJECT:REPORTED TO:MATERIAL EVALUATIONMOCHA-STONE UNITSREALSTONE SYSTEMS560 KIRTS BLVDSUITE 120TROY, MI 48084AET JOB NO: 20-11101TMATTN:STEVE HODGESDATE:JANUARY 29, 2013INTRODUCTIONThis report presents the test results on five stone units. Samples were submitted and identifiedby you. The scope of our work consisted of conducting freeze-thaw testing in accordance withASTM C67-12, “Standard Test Methods for Sampling and Testing Brick and Structural ClayTile” and evaluated according to ASTM C 216-12a “Standard Specification for Facing Brick(Solid Masonry Units Made from Clay or Shale).” Our work was authorized by you on February20, 2012.SAMPLE INFORMATIONAmerican Engineering Testing, Inc. received 5 stone samples identified as Mocha #1 through #5from Realstone Systems.TESTING METHODSThe specimens were subjected to freeze-thaw cycling in accordance with ASTM C67, Section 9.1. The samples were placed in a pan with water at a depth of ½” and frozen for 20 hours. Nextthe samples were immersed in a thawing tank for 4 hours. This process continued for 50cycles or until the specimens develop a crack or appears to have lost more than 3% of itsoriginal weight by disintegration as judged by visual inspection.2. Final weight loss percentages are calculated by dividing the oven dry weight of dislodgedmaterial by the final oven dried sample weight, plus the total dislodged material.www.realstone.com 1.866.698.5066

realstone SYSTEMSCOLLECTION ASTM TESTING DATATMInspiring. Timeless. Endurin g.AET Project No. 20-11101 - Page 2 of 2TEST RESULTSSampleWeightLoss 005%FullWidthCrackingNoNoNoNoNoRatingSee RemarksSee RemarksSee RemarksSee RemarksSee RemarksREMARKSThe samples were tested for 50 freeze thaw cycles. The test results meet the specifications ofASTM C216-12a “Standard Specification for Facing Brick (Solid Masonry Units Made fromClay or Shale)” for SW facing material. This report represents specifically the samples tested.The ASTM C216 requirements for freeze-thaw durability in section 6.1.3.1 state that noindividual unit separates or disintegrates resulting in a weight loss greater than 0.5% of itsoriginal dry weight. Additionally, ASTM C216, Section 6.1.3.2 states that no individual unitdevelops a crack that exceeds, in length, the units least dimension. If you have any questions,please feel free to call us.Report Prepared By:American Engineering Testing, Inc.Report Reviewed By:American Engineering Testing, Inc.Joseph T. JohnsonConcrete Technician IIIPhone: 651-659-1354Fax: 651-647-2744jtjohnson@amengtest.comDaniel M. Vruno, P.E.Principal EngineerMN Lic. No. 42037Phone: 651-659-1334Fax: 651-647-2744dvruno@amengtest.comFor additional help or with questions please contact usat 1-866-698-5066 or at realstonesystems.comwww.realstone.com 1.866.698.5066

COLLECTION ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

COLLECTION ASTM TESTING DATAFor additional help or with questions please contact usat 1-866-698-5066 or at realstonesystems.comwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

realstone SYSTEMSCOLLECTION ASTM TESTING DATAInspiring. Timeless. Endurin g.CONSULTANTS· ENVIRONMENTAL· GEOTECHNICAL· MATERIALS· FORENSICSREPORT OF FREEZE-THAW TESTING OF STONEPROJECT:REPORTED TO:MATERIAL EVALUATIONROMAN BEIGE-STONE UNITSREALSTONE SYSTEMS560 KIRTS BLVDSUITE 120TROY, MI 48084AET JOB NO: 20-11101TMATTN:STEVE HODGESDATE:JANUARY 29, 2013INTRODUCTIONThis report presents the test results on five stone units. Samples were submitted and identifiedby you. The scope of our work consisted of conducting freeze-thaw testing in accordance withASTM C67-12, “Standard Test Methods for Sampling and Testing Brick and Structural ClayTile” and evaluated according to ASTM C 216-12a “Standard Specification for Facing Brick(Solid Masonry Units Made from Clay or Shale).” Our work was authorized by you on February20, 2012.SAMPLE INFORMATIONAmerican Engineering Testing, Inc. received 5 stone samples identified as Roman Beige #1through #5 from Realstone Systems.TESTING METHODSThe specimens were subjected to freeze-thaw cycling in accordance with ASTM C67.1. The samples were placed in a pan with water at a depth of ½” and frozen for 20 hours. Nextthe samples were immersed in a thawing tank for 4 hours. This process continued for 50cycles or until the specimens develop a crack or appears to have lost more than 3% of itsoriginal weight by disintegration as judged by visual inspection.2. Final weight loss percentages are calculated by dividing the oven dry weight of dislodgedmaterial by the final oven dried sample weight, plus the total dislodged material.www.realstone.com 1.866.698.5066

realstone SYSTEMSCOLLECTION ASTM TESTING DATATMInspiring. Timeless. Endurin g.AET Project No. 20-11101 - Page 2 of 2TEST RESULTSSampleWeightLoss 24.14%FullWidthCrackingYesYesYesYesYesRatingSee RemarksSee RemarksSee RemarksSee RemarksSee RemarksREMARKSThe samples were tested for 50 freeze thaw cycles and did not to meet the specifications ofASTM C216-12a “Standard Specification for Facing Brick (Solid Masonry Units Made fromClay or Shale)” for SW facing material. This report represents specifically the samples tested.The ASTM C216 requirements for freeze thaw durability in 6.1.3.1 state that no individual unitseparates or disintegrates resulting in a weight loss greater than 0.5% of its original dry weight.Additionally, ASTM C216, Section 6.1.3.2 states that no individual unit develops a crack thatexceeds, in length, the units least dimension. All samples exhibited unsatisfactory weight loss,full width cracking or both. If you have any questions, please feel free to call us.Report Prepared By:American Engineering Testing, Inc.Report Reviewed By:American Engineering Testing, Inc.Joseph T. JohnsonConcrete Technician IIIPhone: 651-659-1354Fax: 651-647-2744jtjohnson@amengtest.comDaniel M. Vruno, P.E.Principal EngineerMN Lic. No. 42037Phone: 651-659-1334Fax: 651-647-2744dvruno@amengtest.comFor additional help or with questions please contact usat 1-866-698-5066 or at realstonesystems.comwww.realstone.com 1.866.698.5066

ESTATE STONE ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

ESTATE STONE ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

ESTATE STONE ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

ESTATE STONE ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

ESTATE STONE ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

C ARBON ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

CHARCOAL ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

CHARCOAL ASTM TESTING DATAwww.realstone.com 1.866.698.5066realstone SYSTEMSTMInspiring. Timeless. Endurin g.

CHARCOAL ASTM TESTING DATAwww.realstone.

ASTM C67-12, “Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile” and evaluated according to ASTM C 216-12a “Standard Specification for Facing Brick (Solid Masonry Units Made from Clay or Shale).” Our work was authorized by