Transcription

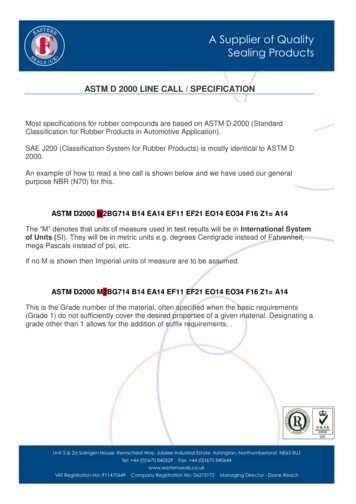

ASTM D 2000 LINE CALL / SPECIFICATIONMost specifications for rubber compounds are based on ASTM D 2000 (StandardClassification for Rubber Products in Automotive Application).SAE J200 (Classification System for Rubber Products) is mostly identical to ASTM D2000.An example of how to read a line call is shown below and we have used our generalpurpose NBR (N70) for this.ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14The “M” denotes that units of measure used in test results will be in International Systemof Units (SI). They will be in metric units e.g. degrees Centigrade instead of Fahrenheit,mega Pascals instead of psi, etc.If no M is shown then Imperial units of measure are to be assumed.ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14This is the Grade number of the material, often specified when the basic requirements(Grade 1) do not sufficiently cover the desired properties of a given material. Designating agrade other than 1 allows for the addition of suffix requirements. .

ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14This is the type of material and is used to classify materials by temperature resistance.ASTM D2000 requires rubber materials must meet the following requirements after 70hours of heat aging at various temperatures, according to type.1. Change in tensile strength: 30%2. Change in hardness: -50% max.3. Change in hardness: 15 pointsThe test temperatures by type are as follows:Type Test Temp, CA70B100C125D150E175F200G225H250J275K300

ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14This is the class of material. Class is used to differentiate materials on the basis ofresistance to swelling in IRM No. 903 Oil, after 70 hours at the temperatures per theimmediately preceding table. However, a maximum of 150 C has been established, whichis the limit of stability of the test oil. The maximum allowable volume swell by class is setforth in the table below:ClassMax. Swell, %ANo RequirementB140C120D100E80F60G40H30J20K10ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14Durometer hardness and tensile strength are defined by a three-digit number. In the aboveexample, 714, the “7” denotes a material of with a durometer hardness, in A units, of 70 5. The “14” means that the tensile strength must be at least 14 mega Pascals, or 2031psi.

ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14The remainder of the specification consists of suffix requirements. These are specifiedwhen the basic requirements as detailed in ASTM D 2000 for a particular type and class ofmaterial are not sufficient to achieve the desired properties in the finished product. Suffixrequirements always consist of one or two of both alpha and numeric characters. Themeaning of these is explained in the following table:SuffixRequired TestAHeat ResistanceBCompression SetCOzone or Weather ResistanceDCompression-Deflection ResistanceEAWater ResistanceEFFuel ResistanceEOOil and Lubricant ResistanceFLow Temperature ResistanceGTear ResistanceHFlex ResistanceJAbrasion ResistanceKAdhesionMflammability ResistanceNImpact ResistancePStaining ResistanceRResilienceWhen there is a special requirement not covered by the tests in the tables above, they aredesignated as “Z” requirements. They are user defined, should always be clearly specified,and agreed upon by the customer and manufacturer in advance.

The numeric characters in suffix requirements serve two purposes. The first numberspecifies the duration of the test, and the test method to be used. The second numberindicates the temperature at which the test is to be run. In the example, “B14” means thatthe compression set test must be run using Test Method D 395 for a period of 22 hours.The test temperature is 100 C. For a complete listing of the meaning of numericcharacters in ASTM specifications, please consult Tables 4 and 5 in ASTM D 2000.With the exception of type/class FC, FE, FK, and GE, all materials are assumed to beblack. Any change in colour of a rubber material almost always has an effect on itsphysical properties, and the same performance cannot always be obtained. It is alsoimportant that suffix requirements are only specified when needed to achieve the desiredproperties in the end product. It is not necessary to specify all available suffix requirementsfor a given grade number.

ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 A14 Durometer hardness and tensile strength are defined by a three-digit number. In the above example, 714, the “7” denotes a material of with a durometer hardness, in A units, of 70 5. The “14” means that the tensile strength must be at least 14 mega Pascals, or 2031psi. ASTM D2000 M2BG714 B14 EA14 EF11 EF21 EO14 EO34 F16 Z1 .