Transcription

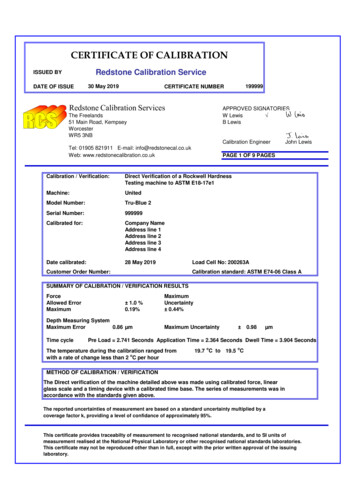

CERTIFICATE OF CALIBRATIONRedstone Calibration ServiceISSUED BYDATE OF ISSUE30 May 2019199999CERTIFICATE NUMBERRedstone Calibration ServicesAPPROVED SIGNATORIESW Lewis B LewisThe Freelands51 Main Road, KempseyWorcesterWR5 3NBCalibration EngineerTel: 01905 821911 E-mail: info@redstonecal.co.ukWeb: www.redstonecalibration.co.ukJohn LewisPAGE 1 OF 9 PAGESCalibration / Verification:Direct Verification of a Rockwell HardnessTesting machine to ASTM E18-17e1Machine:UnitedModel Number:Tru-Blue 2Serial Number:999999Calibrated for:Company NameAddress line 1Address line 2Address line 3Address line 4Date calibrated:28 May 2019Load Cell No: 200263ACustomer Order Number:Calibration standard: ASTM E74-06 Class ASUMMARY OF CALIBRATION / VERIFICATION RESULTSForceAllowed ErrorMaximum 1.0 %0.19%Depth Measuring SystemMaximum Error0.86 µmTime cycleMaximumUncertainty 0.44%Maximum Uncertainty 0.98µmPre Load 2.741 Seconds Application Time 2.364 Seconds Dwell Time 3.904 SecondsThe temperature during the calibration ranged fromwith a rate of change less than 2 oC per houroo19.7 C to 19.5 CMETHOD OF CALIBRATION / VERIFICATIONThe Direct verification of the machine detailed above was made using calibrated force, linearglass scale and a timing device with a calibrated time base. The series of measurements was inaccordance with the standards given above.The reported uncertainties of measurement are based on a standard uncertainty multiplied by acoverage factor k, providing a level of confidance of approximately 95%.This certificate provides traceabilty of measurement to recognised national standards, and to SI units ofmeasurement realised at the National Physical Laboratory or other recognised national standards laboratories.This certificate may not be reproduced other than in full, except with the prior written approval of the issuinglaboratory.

CERTIFICATE OF CALIBRATIONUKAS ACCREDITATION CALIBRATION LABORATORY No.CERTIFICATE NUMBER199999PAGE 2 OF 9 PAGESRESULTS OF FORCE VERIFICATION k(95%) 23Force (kgf)10150101010010106010Decreasing loads0 Degrees 9Increasing loads Decreasing loads0 Degrees (kgf) 180 Degrees (kgf) Mean 0430.00053.00083.000414.99943.0008Bias (kgf) Unc 8##% 3%0.01%0.00%0.03%-0.0010.00464499Force Readings during indentation of Reference BlocksBlockHard BlockSoft Block0 Degrees (kgf)150.220150.2890 Degrees (kgf)150.142150.297180 Degrees (kgf) Mean (kgf)150.226150.1960150.278150.2880Bias (kgf) Unc (kgf)0.19600.23110.28800.2250RESULTS OF DEPTH MEASURING SYSTEM VERIFCATIONBlock Depth15.3060.64100.44131.42179.90Machine Depth16.1260.12100.56132.28180.68Bias (µm)0.82-0.520.120.860.78Unc (µm)0.680.680.980.730.71Veff444440.00%INDENTER INFORMATION (FROM CALIBRATION CERTIFICATE)Lab NameIndenter Angle α119.82 Lab No.Uncertainty (k 2)0.030 Diamond Serial Number99999Indenter Radius0.2070 mmCertificate Number99999Uncertainty (k 2)0.003 mmDate of calibration20-May-19Calibration LaboratoryUKAS laboratory No####COMMENTSHysterisisAverage of the last three readings performed 99.82% Error0.13%0.19%###0

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 3 OF 9 PAGESRESULTS OF TIME VERIFICATION @ 150Kg FORCESummary of Time Graph ResultsForceMeasured TimeStandard Time RequirementPre Load:2.741 seconds0.1 to 4 secondsLoad Application:2.364 seconds1 to 8 secondsFull Load:3.904 seconds2 to 6 secondsFinal Load:2.856 seconds0.2 to 5 seconds

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 4 OF 9 PAGESRESULTS OF TIME VERIFICATION @ 100Kg FORCESummary of Time Graph ResultsForceMeasured TimeStandard Time RequirementPre Load:2.960 seconds0.1 to 4 secondsLoad Application:2.630 seconds1 to 8 secondsFull Load:4.054 seconds2 to 6 secondsFinal Load:3.172 seconds0.2 to 5 seconds

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 5 OF 9 PAGESRESULTS OF TIME VERIFICATION @ 60Kg FORCESummary of Time Graph ResultsForceMeasured TimeStandard Time RequirementPre Load:2.847 seconds0.1 to 4 secondsLoad Application:1.809 seconds1 to 8 secondsFull Load:3.843 seconds2 to 6 secondsFinal Load:3.165 seconds0.2 to 5 seconds

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 6 OF 9 PAGESRESULTS OF TIME VERIFICATION @ 30Kg FORCESummary of Time Graph ResultsForceMeasured TimeStandard Time RequirementPre Load:2.958 seconds0.1 to 4 secondsLoad Application:1.564 seconds1 to 8 secondsFull Load:3.851 seconds2 to 6 secondsFinal Load:3.061 seconds0.2 to 5 seconds

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 7 OF 9 PAGESRESULTS OF TIME VERIFICATION @ 15Kg FORCESummary of Time Graph ResultsForceMeasured TimeStandard Time RequirementPre Load:2.614 seconds0.1 to 4 secondsLoad Application:1.188 seconds1 to 8 secondsFull Load:3.828 seconds2 to 6 secondsFinal Load:2.959 seconds0.2 to 5 seconds

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 8 OF 9 PAGESRESULTS OF INDENTER CONTACT VELOCITY VERIFICATIONSummary of Time Graph ResultsDepthMeasured TimeMaximum µm607.30Minimum µm0.00Range µm607.30Standard Velocity Requirement 999 µm per secondMeasured Velocity3.92 Seconds154.92 µm per second

CERTIFICATE OF CALIBRATIONCERTIFICATE NUMBER199999PAGE 9 OF 9 PAGESRESULTS OF INDENTER CONTACT VELOCITY VERIFICATIONSummary of Time Graph ResultsDepthMeasured TimeMaximum µm261.30Minimum µm0.00Range µm261.30Standard Velocity Requirement 999 µm per secondMeasured Velocity1.43 Seconds183.37 µm per second

CERTIFICATE OF CALIBRATIONRedstone Calibration ServiceISSUED BY30 May 2019DATE OF ISSUECERTIFICATE NUMBERRedstone Calibration ServicesThe Freelands51 Main Road, KempseyWorcesterWR5 3NB199999AAPPROVED SIGNATORIESW Lewis B LewisCalibration EngineerTel: 01905 821911 E-mail: info@redstonecal.co.ukWeb: www.redstonecalibration.co.ukJohn LewisPAGE 1 OF 2 PAGESCalibration / Verification:Indirect Verification of a Rockwell HardnessTesting machine to ASTM E18-17e1Machine:UnitedStart Temp.19.5 CModel Number:Tru-Blue 2End Temp.19.7 CSerial Number:999999Calibrated for:Company NameAddress line 1Address line 2Address line 3Address line 4Date calibrated:28-May-19Customer Order Number:METHOD OF CALIBRATION / VERIFICATIONThe above Rockwell hardness testing machine has been indirectly verified to the standard requirements ofASTM E18.The hardness tests were made using certified indenters. Certified hardness reference blocks were alsoused. The serial numbers and assigned hardness values of the reference blocks together with themeasurements obtained are given in the table on page 2 of this certificate.A direct verification was carried out to ASTM E18. Reference certificate number 199999Dated :- 28 May 2019The reported uncertainties of measurement are based on a standard uncertainty multiplied by acoverage factor k, providing a level of confidance of approximately 95%.This certificate provides traceabilty of measurement to recognised national standards, and to SI units ofmeasurement realised at the National Physical Laboratory or other recognised national standards laboratories.This certificate may not be reproduced other than in full, except with the prior written approval of the issuinglaboratory.

CERTIFICATE OF CALIBRATIONUKAS ACCREDITATION CALIBRATION LABORATORYCERTIFICATE NUMBER199999APAGE 2 OF 2 PAGES200RESULTS OF REFERENCE BLOCK VERIFICATION86.8 HRA73.8 HRA38.8 HRA93.0 HRB(w)69.6 HRB(w)46.2 HRB(w)64.4 HRC47.3 HRC27.2 HRC81.1 HR30N65.3 HR30N50.9 HR30N92.7 HR15N82.7 HR15N74.4 3.174.8Mean of Uncertaintytheof the Meanreadings 0.700.400.300.500.200.500.500.20#REF!Note! The readings above have not been corrected for the BIAS of the machine obtained during the direct verification.INDENTER INFORMATION (FROM CALIBRATION CERTIFICATE)Diamond IndentorBall IndentorLab NameIndenterAngle α119.82ºCalibrationLaboratoryLab NameBall SerialNumber999999Lab No.Uncertainty(k 2)0.03ºUKASlaboratoryNumberLab No.BallCertificateNumber99999Diamond SerialNumber99999IndenterRadius0.207 mmBall holderSerialNumber99999Date ofCalibration20-May-19Certificate Number99999Uncertainty(k 2)0.003 mmCertificateNumber99999Ball Diameter0.062513 InchDate ofCalibration20-May-19Uncertainty(k 2)0.00002 InchCalibrationLaboratoryUKAS laboratoryNumberDate ofCalibration20-May-19COMMENTS0Allowed errorReading Reading Reading Reading Reading12345RepeatabilitySerialNumberError3Block Scale& Value0.51.01.01.0 Max Unc1.01.50.51.01.00.7 Max Unc1.01.00.71.01.0

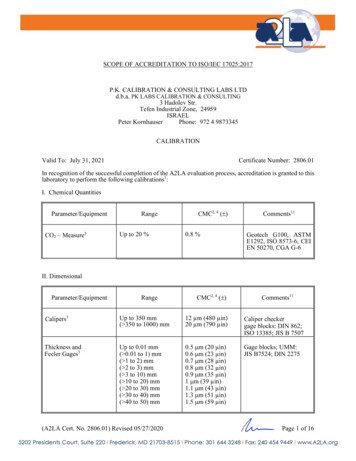

ASTM E18. PAGE 1 OF 2 PAGES The hardness tests were made using certified indenters. Certified hardness reference blocks were also used. The serial numbers and assigned hardness values of the reference blocks together with the measurements obtained are given in the table on page 2 of this certificate. 28-May-19 A direct verification was carried out to ASTM E18. Reference certificate number .