Transcription

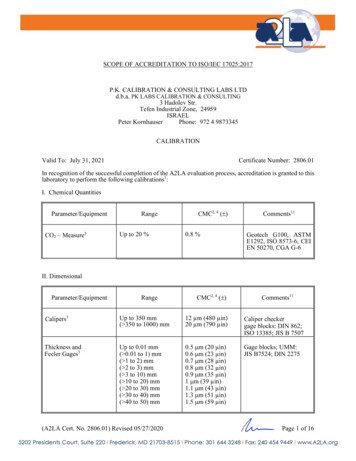

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2017P.K. CALIBRATION & CONSULTING LABS LTDd.b.a. PK LABS CALIBRATION & CONSULTING3 Hadolev Str.Tefen Industrial Zone, 24959ISRAELPeter KornhauserPhone: 972 4 9873345CALIBRATIONValid To: July 31, 2021Certificate Number: 2806.01In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to thislaboratory to perform the following calibrations1:I. Chemical QuantitiesParameter/EquipmentCO2 – Measure3RangeUp to 20 %CMC2, 4 ( )0.8 %Comments11Geotech G100, ASTME1292, ISO 8573-6, CEIEN 50270, CGA G-6II. DimensionalParameter/EquipmentRangeCMC2, 4 ( )Comments11Calipers3Up to 350 mm( 350 to 1000) mm12 µm (480 µin)20 µm (790 µin)Caliper checkergage blocks: DIN 862;ISO 13385; JIS B 7507Thickness andFeeler Gages3Up to 0.01 mm( 0.01 to 1) mm( 1 to 2) mm( 2 to 3) mm( 3 to 10) mm( 10 to 20) mm( 20 to 30) mm( 30 to 40) mm( 40 to 50) mm0.5 m (20 µin)0.6 m (23 µin)0.7 m (28 µin)0.8 m (32 µin)0.9 m (35 µin)1 m (39 µin)1.1 m (43 µin)1.3 m (51 µin)1.5 m (59 µin)Gage blocks; UMM:JIS B7524; DIN 2275(A2LA Cert. No. 2806.01) Revised 05/27/2020Page 1 of 16

RangeCMC2, 5 ( )Micrometers3,14Up to 500 mm(1.2R 6L) µmGage blocks:ISO 3611; DIN 863 Part1-4; JIS B 7502; JIS B7520Length Indicators (Dial,Lever, Dial Gauge,Test,LVDT)3Up to 100 mm(1 0.5R) µmIndicator calibrator;UMM: DIN 879; DIN879-1; DIN 879-3;DIN 878; DIN 2270;JIS B7503; JIS B 7533;ISO 13102Height Gages3Up to 500 mm( 500 to 1000) mm2 µm (79 µin)3 µm (360 µin)Gage blocks:JIS B7517; BS 1643; BSEN ISO 13225Bore Gages(2 to 200) mm0.9 µm (35 µin)Gage blocks; ring gages;UMM: JIS B7515Pins and Plain Plugs10Up to 100 mm( 100 to 300) mm( 300 to 550) mm1 µm (39 µin)2 µm (79 µin)2.8 µm (110 µin)Plain Rings10Up to 100 mm( 100 to 300) mm( 300 to 450) mm1 µm (39 µin)2 µm (79 µin)2.5 µm (98 µin)UMM, gage blocks:ISO 594/1; ISO 80369-7;ASME B1.20.5; ISO286;ISO 286-1; ISO 286-2DIN 7162; DIN EN ISO1938-1; DIN 7163;DIN 7164Length Standards(Micrometer Settings,End Rods, Length Bars)Up to 100 mm( 100 to 500) mm1.5 µm (59 µin)2.7 µm (110 µin)UMM, gage blocks:BS 870; BS EN ISO3611; JIS B 7502Thread WiresUp to 7 mm0.6 µm (24 µin)UMM, gage blocks:BS 5590; ASME B1.2Bevel Protractors3,Clinometers, Bubble LevelsUp to 5 9 µm/m (1.8arcsec)Angle blocks6, gageblocks, sine bars:BS 1685; BS 958;DIN 877; JIS B 7510;Parameter/EquipmentComments11Cylindrical and TaperGages –( 5 to 180) (A2LA Cert. No. 2806.01) Revised 05/27/20200.6RPage 2 of 16

Parameter/EquipmentRangeCMC2, 5 ( )Comments11Measuring Rules3Up to 0.2 m( 0.2 to 0.5) m( 0.5 to 1) m0.5 mm (0.02 in)0.9 mm (0.035in)1.2 mm (0.047in)Length standards:JIS B 7516Measuring Tapes3Up to 5 m( 5 to 10) m( 10 to 20) m( 20 to 30) m( 30 to 40) m( 40 to 50) m1.8 mm (0.071in)2 mm (0.079 in)2.3 mm (0.091in)2.9 mm (0.11 in)3.1 mm (0.12 in)3.6 mm (0.14 in)Length standards:JIS B 7512; JIS B 7522;BS 4035; BS 4484-1Cylindrical and TaperThread Plug Gage –Pitch DiameterUp to 100 mm( 100 to 300) mm( 300 to 550) mm1.5 µm (59 µin)2.1 µm (75 µin)3.4 µm (140 µin)Major Diameter9Up to 100 mm( 100 to 300) mm( 300 to 550) mm1 µm (39 µin)2 µm (79 µin)2.8 µm (110 µin)(A2LA Cert. No. 2806.01) Revised 05/27/2020Thread wires; UMM:ISO 7-1; ISO 7-2;ISO 965; ISO 1502;ISO 228; ISO 11363; ISO15872;DIN 477; DIN 2999; DIN103; DIN 40431; DIN 513;DIN 40430;DIN 158; DIN158-1; DIN EN 10226; EN10226;DIN 405; DIN EN 144-1;BS 93; BS 811; BS 84;BS 919; BS 21; BS EN10226-1; DIN EN 102261;DIN EN 10226-2; DINEN 10226-3;BS 3409; BS 4377;BS 1657; BS 1104;DIN 7756;MIL-T-21309;A-A-59158;FED STD H28;ASME B1.2; ASME B1.5;ASME B1.8; ASME B1.9; ASME B1.12;ASME B1.15; ASMEB1.20.1; ASME B1.20.3;ASME B1.20.5; ASMEB1.20.7; ASME B1.13M;ASME B1.16M; ASMEB1.21M; ASME B1.22M;ASME B18.29.1; ASMEB 1.1; BS 1580;API Spec 5B;API Spec 7-2;AWWA C800-05;SAE MA 1696.Page 3 of 16

Parameter/EquipmentSolid and Tapered ThreadRing Gage –RangeCMC2 ( )Pitch Diameter(0.5 to 100) mm( 100 to 300) mm( 300 to 450) mm1.5 µm (59 µin)3.9 µm (150 µin)4.3 µm (170 µin)Minor Diameter9(6 to 50) mm( 50 to 100) mm2.4 µm (94 µin)2.9 µm (110 µin)Extensometers3 –Displacement(0.01 to 500) mm(A2LA Cert. No. 2806.01) Revised 05/27/20202.6 µm (100 µin)Comments11Ball probe, micrometerTri-O-Bor,UMM:ISO 7-1; ISO 7-2;ISO 228 ; ISO 965;ISO 1502; ISO 11363;ISO 15872; DIN 477;DIN 2999; DIN 103;DIN 40431; DIN 513;DIN 40430;DIN 158;DIN 158-1; DIN EN10226; EN 10226;DIN 405; DIN EN 1441; BS 93;BS 811;BS 84; BS 919;BS 21; BS EN 10226-1;DIN EN 10226-1;DINEN 10226-2; DIN EN10226-3;BS 3409; BS 4377; BS1657; BS 1104; BS1580-1; BS 1580-3;DIN 7756;MIL-T-21309;A-A-59158;FED STD H28;ASME B1.3; ASMEB1.5; ASME B1.8;ASME B 1.9; ASMEB1.12; ASME B1.15;ASME B1.20.1;ASME B1.20.3;ASME B1.20.5;ASME B1.20.7;ASME B1.13M;ASME B1.16M;ASME B1.21M;ASME B1.22M;ASME B1.1;API Spec 5B;API Spec 7-2;AWWA C800-05;SAE MA 1696.Micrometers; indicators,gage blocks:ASTM E83; ASTME2309; ASTME2309/E2309M; ISO5893; ASTM E8/E8MISO 9513, ASTMD5311; ASTMD5311/D5311MPage 4 of 16

Parameter/EquipmentRangeCMC2 ( )Comments11Length MeasuringInstruments – UMMs, BenchMicrometers, Indicators,Calibrators, Caliper CheckersUp to 1 mm( 1 to 20) mm( 20 to 50) mm( 50 to 100) mm( 100 to 200) mm( 200 to 300) mm0.12 m (4.7 µin)0.18 m (7.1 µin)0.2 m (7.9 µin)0.24 m (9.5 µin)4 m (160 µin)5.6 m (220 µin)Gage blocks,LVDTLine Standard ScalesUp to 1 mm( 1 to 10) mm( 10 to 50) mm( 50 to 200) mm0.7 µm (28 µin)1.3 µm (51 µin)1.7 µm (67 µin)2.5 µm (98 µin)UMM: JIS B 7541Measuring Projectors andMicroscopes3 –Line standard scales:JIS B7184; JIS B7153;ASTM 1951;ASTM 112DisplacementUp to 10 mm( 10 to 50) mm( 50 to 100) mm1.7 µm (67 µin)2.3 µm (91 µin)3.5 µm (140 µin)Angle(0 to 90) 3.5" (0.000 017rad)Angle blocksUp to 2.5 m x 1.6 m0.001 mmISO 8512-2, DIN 876,GGG-P-463cc, BS 817To Manufacturer orcustomer requirementsSurface (Granite) Plates MeasureFlatness OnlyIII. Dimensional Testing/CalibrationParameter/EquipmentLinear Measurement(Single Axis)3, 7RangeCMC2 ( )Comments11Up to 0.2 m( 0.2 to 0.5) m( 0.5 to 1.0) m( 1.0 to 5.0) m( 5.0 to 10.0) m0.15 mm (0.0059 in)0.7 mm (0.028 in)0.9 mm (0.035 in)2 mm (0.079 in)3.3 mm (0.13 in)Length standardsUp to 50 mm3.0 µm (120 µin)Measuring projector(A2LA Cert. No. 2806.01) Revised 05/27/2020Page 5 of 16

Parameter/EquipmentInspection Fixtures –Length, Single Axis(Straight Edges, KnifeEdges)12RangeUp to 500 mmCMC2 ( )2.6 µm (79 µin)Comments11LVDT; DIN 874;JIS B 7514BS 3731; BS 3064;JIS B 7523; JIS B 7526;JIS B 7539; JIS B 7540;JIS B 7514;DIN 875; DIN 875-1; DIN874; DIN 2273; DIN 2274Inspection Fixtures –Length, Two Axis (VBlocks, Bar Parallels, 1-2-3Blocks, Squares, Sine Bars,Sine Plates, Angle Irons)12FlatnessUp to 500 mm5.6 µm (220 µin)LVDT, granite plateAngleUp to 60 (5 to 60) ( 60 to 180) (0.5 to 60) 4" (0.000 019 rad)0.6R1.0R36" (0.000 17 rad)Sine bar, granite platebevel protractorParallelismUp to 200 mm3.0 µm (120 µin)LVDT, granite platePerpendicularityUp to 600 mm2.8 µm (110 µin)Square, granite plate, gageblocksMeasuring projectorIV. Electrical – DC/Low FrequencyParameter/EquipmentRangeCMC2 ( )Comments11Electrical Simulationof RTDs3 –Pt 50 Ω, Pt 100 Ω,Pt 200 Ω, Pt 500 ΩPt 1000 Ω(-190 to 830) C(A2LA Cert. No. 2806.01) Revised 05/27/20200.12 CProcess calibrator:EURAMET/cg-11;AMS 2750Page 6 of 16

Parameter/EquipmentRangeCMC2 ( )Comments11Electrical Simulationof Thermocouples3 –Type B(250 to 900) C( 900 to 1800) C1.0 C0.31 C(250 to 900) C( 900 to 2250) C0.32 C0.40 CType E(-200 to 0) C( 0 to 990) C0.20 C0.25 CType J(-200 to 0) C( 0 to 1190) C0.19 C0.20 CType K(-200 to -100) C( -100 to 0) C( 0 to 900) C( 900 to 1360) C0.26 C0.20 C0.21 C0.23 CType N(-200 to 0) C( 0 to 1240) C0.21 C0.21 CType S(-40 to 600) C( 600 to 1730) C0.77 C0.34 CType T(-200 to -180) C( -180 to 0) C( 0 to 390) C0.41 C0.21 C0.20 CType CProcess calibrator:EURAMET/cg-11;AMS 2750V. MechanicalParameter/EquipmentRangeCMC2 ( )Comments11Force3 –ASTM E74;ISO 376Load Cell (ForceTransducer)Compression and TensionCompression(0.001 to 1) kN( 1 to 10) kN0.04 % of reading0.05 % of readingDead weights(10 to 50) kN( 50 to 100) kN0.057 % of reading0.088 % of readingLoad cell standards(100 to 500) kN( 500 to 5000) kN0.073 % of reading0.09 % of readingLoad cell standards(A2LA Cert. No. 2806.01) Revised 05/27/2020Page 7 of 16

Parameter/EquipmentRangeCMC2 ( )Comments11Force3 –(cont)Testing MachinesForce Push/Pull GagesDynamometersUp to 50 kN(50 to 100) kN(100 to 200) kN(200 to 500) kN(500 to 1000) kN0.052 % of reading0.039 % of reading0.063 % of reading0.057 % of reading0.033 % of reading(500 to 1000) kN(1000 to 5000) kN0.041 % of reading0.039 % of readingRate of Stress(0.05 to 2) MPa/sec0.07 MPa/sRate of Straining(0.5 to 12) MPa/sec(0.05 to 0.8)mm/mm/min0.3 MPa/s0.02 mm/mm/minCompression and TensionCompressionPressure Gages3–ASTM E4; ISO 7500-1;ISO 7500-2; BS 123904 (Israeli standard 26part 4-1) 13Dead weightsLoad cell standardsBS EN 12390-3;load cell, stop watchASTM E2658;load cell, stop watchOIML/R 101;Israeli standard 697;EA-10/17Pneumatic –Druck, LPE 9400Druck, DPI 610Druck, DPI 610Gage & Differential(-1250 to 1250) kPa 0.8 Pa3 Pa(-15 to 15) kPa0.14 kPa(-100 to 100) kPaAbsolute(13 to 1250) Pa(0.04 to 200) kPa0.73 Pa0.53 kPaDruck, LPE 940Druck, DPI 104(0 to 7) MPa( 7 to 70) MPa( 70 to 200) MPa0.4 kPa10 kPa32 kPaDruck, DPI 104Druck, DPI 104AEP Transducers LABDMMHydraulic & Pneumatic(A2LA Cert. No. 2806.01) Revised 05/27/2020Page 8 of 16

Parameter/EquipmentRangeCMC2 ( )CommentsPressure Testers, Pressuretransducers, Pressureindicators–Pneumatic –Hydraulic(-100 to 100) kPa2 PaDeadweight testerYANTRIKA, REW401HAA/1(0 to 7) MPa150 PaDeadweight testerYANTRIKA, REW417HAA/1(0 to 7) MPa( 7 to 140) MPa170 Pa1 kPaDeadweight testerYANTRIKA, REW309HAO/ASTM D 2240; ISO 868;DIN 53505; DIN ISO7619-1Durometers Calibration –Indenter – Extension andShapeDiameterDiameter of the baseof the cone0.79 mm (A, C)4 µm (160 µin)RadiusTip radiusR 0.1 mm (B, D),R 1.19 mm (O, DO)3 µm (120 µin)10 µm (390 µin)AngleCone angle35º (A, C), 30º (B, D)Extension2.5 mm (A, B, C, D, O,DO)8 µm (320 µin)A, B, E, OC, D, DO0.04 N0.4 NSpring Calibration Force(A2LA Cert. No. 2806.01) Revised 05/27/2020Optical inspectionunder magnification51" (0.00025 rad)Load cell standards;dead weightsPage 9 of 16

Parameter/EquipmentRangeCMC2 ( )Comments11Scales and Balances3(Includes Analytical Balances)Up to 20 mg( 20 to 100) mg( 100 to 1000) mg( 1 to 10) g( 10 to 20) g( 20 to 100) g( 100 to 200) g( 200 to 500) g( 500 to 1000) g( 1 to 10) kg( 10 to 200) kg( 200 to 1000) kg(1000 to 2400) kg0.002 mg0.003 mg0.004 mg0.009 mg0.014 mg0.092 mg0.169 mg0.8 mg0.9 mg0.08 g1.3 g15 g23 gMass standards: ClassE2, M1,M3, OIML R76-1,OIML R 111-1EURAMET/cg-18,USP 41Calibration of StandardWeights10 kg20 kg50 kg0.15 g0.30 g0.78 gOIML R101OIML R 111-1Accuracy grades:M1, M2, M3MassFrom 10 g to 100 g( 100 to 1000) g( 1 to 10) kg( 10 to 30) kg0.092 mg0.9 mg0.08 g1.3 gPrecision scales6OIML R 111-1VolumeFrom 1 ml to 5 ml( 5 to 20) ml( 20 to 150) ml( 150 to 200) ml0.001 ml0.002 ml0.003 ml0.004 mlDerived value(0 to 0.25) N m(0.25 to 0.7) N m(0.7 to 2.5) N m(2.5 to 25) N m(25 to 250) N m(150 to 1500) N m0.066 N m0.068 N m0.11 N m0.009 N m0.13 N m0.48 N mTorque calibrators,ISO 6789; ISO 6789-1;ISO 6789-2Custom Weights/Fixtures3, 8 –Torque –Torque Wrenches and TorqueDrivers3(A2LA Cert. No. 2806.01) Revised 05/27/2020Torque MeterPage 10 of 16

Parameter/EquipmentIndirect Verification ofRockwell Hardness Testers3RangeCMC2 ( )Comments11HRA:LowMediumHigh0.24 HRA0.24 HRA0.18 HRAHRBW:LowMediumHigh0.58 HRBW0.39 HRBW0.40 HRBWHRC:LowMediumHigh0.29 HRC0.24 HRC0.40 HRCHREW:LowMediumHigh0.19 HREW0.28 HREW0.18 HREWHR15TW:LowMediumHigh0.28 HR15TW0.25 HR15TW0.31 HR15TWIndirect Verification of VickersHardness Testers3(0.1, 0.5, 1 and 10) kg( 100 to 240) HV( 240 to 600) HV 600 HV3.3 HV6.1 HV8.1 HVHardness standards:ASTM E384, ASTME92; ISO 6507-2Indirect Verification of KnoopHardness Testers3( 100 to 250) HK( 250 to 650) HK 650 HK4.7 HK5.6 HK9.6 HKHardness standards:ASTM E384; ISO 45452Indirect Verification of BrinellHardness Testers3, (10/3000,10/1000, and 2.5/187.5) 125 HBW(125 to 225) HBW 225 HBW1.9 HBW2.9 HBW4.4 HBWHardness standards:ASTM E10; ISO 6506-2(A2LA Cert. No. 2806.01) Revised 05/27/2020Hardness standards:ASTM E18;ISO 6508-2Page 11 of 16

Parameter/EquipmentRangeCMC2 ( )Comments11Volume – Fixed Points(Volumetric Apparatus,Pipettes)1 µl2 µl5 µl10 µl20 µl50 µl100 µl200 µl500 µl1 ml2 ml5 ml10 ml20 ml50 ml100 ml0.016 µl0.016 µl0.016 µl0.016 µl0.016 µl0.017 µl0.017 µl0.017 µl0.017 µl0.018 µl0.021 µl0.40 µl0.49 µl0.66 µl1.87 µl2.42 µlGravimetric methodwith analytical balance:ISO 8655-1; ISO 86552; ISO 8655-3; ISO8655-4;ISO 8655-5; ISO 8655-6SievesStandard sievedesignation(Customer definedparameters)7 µm (280 µin)Measuring projector;caliper; ASTM E11;ISO 3310-1; ISO 33102;ISO 3310-3; ISO 2395;ISO 565Defined by Standard2 LSVDDefined by Standard0.9 mm (0.035in)ASTM D 1557;ASTM D 698;ASTM D 2168;ASTM D 1883Hammers3 –WeighingHeight of Free Fall(A2LA Cert. No. 2806.01) Revised 05/27/2020Page 12 of 16

Parameter/EquipmentRangeCMC2, 4 ( )Comments11Impact Testing Devices3(Direct Method Only) –Energy(1 to 5.5) J( 5.5 to 150) J( 150 to 406) J0.21 J0.51 J3.2 JVelocity(3 to 6) m/s0.004 m/sASTM D 256;ASTM E 23;AS 1146.3; EN10045;ISO 148; ISO 148-1;ISO 148-2; BS 131;BS 131-1; BS 131-5;BS 131-6; BS 131-7;VI. ThermodynamicsParameter/EquipmentRangeCMC2 ( )Comments11ThermocoupleCalibration –Type E(190 to 0) C( 0 to 960) C0.24 C0.24 CType J(-190 to 0) C( 0 to 960) C0.18 C0.24 CType K(-190 to 0) C( 0 to 230) C( 230 to 660) C( 660 to 960) C( 960 to 1250) C0.19 C0.18 C0.22 C0.28 C2.5 C(-190 to 0) C( 0 to 230) C( 230 to 660) C( 660 to 960) C( 960 to 1250) C0.28 C0.28 C0.22 C0.22 C2.5 C(-40 to 0) C( 0 to 600) C( 600 to 960) C( 960 to 1250) C0.96 C0.43 C0.46 C2.6 CType NType R(A2LA Cert. No. 2806.01) Revised 05/27/2020AMS 2750;ASTM E220Page 13 of 16

Parameter/EquipmentRangeCM

ASME B1.20.5; ISO 286; ISO 286-1; ISO 286-2 DIN 7162; DIN EN ISO 1938-1; DIN 7163; DIN 7164 Length Standards (Micrometer Settings, End Rods, Length Bars) Up to 100 mm ( 100 to 500) mm 1.5 µm (59 µin) 2.7 µm (110 µin) UMM, gage blocks: BS 870; BS EN ISO 3611; JIS B 7502 Thread Wires Up to 7 mm 0.6 µm (24 µin) UMM, gage blocks: BS 5590; ASME B1.2 Bevel Protractors3, Clinometers,