Transcription

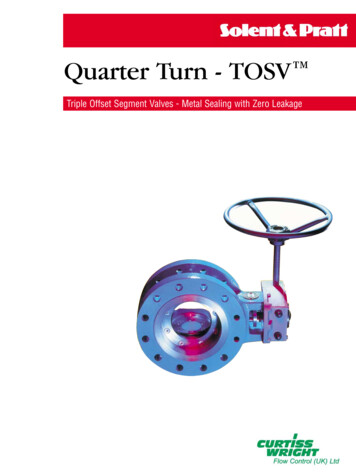

Quarter Turn - TOSV Triple Offset Segment Valves - Metal Sealing with Zero Leakage

TOSV Design FeaturesFor over 40 years Solent & Pratt hasbeen at the forefront of the design,development and manufacture ofhigh quality butterfly valves forengineering projects around theworld. An absolute commitment tooutstanding quality and reliability isthe key of our success, particularlyin environments such as the oil andgas, chemical, petro-chemical andpower generation industries. FiresafeCertified to API 607 4th editionBS6755 Part 2 and API 6FA Sizes3” (750mm) to 84” (2100mm) Body styles availableWafer flangeless, Wafer lugged, DoubleFlanged (short and long patterns), andButt Weld. Anti-blowout stemInternal is standard.External to API 609 optional Triple Offset GeometryProvides non-rubbing motion throughoutfull 90 rotation elimination unnecessarywear and prolongs life of seat and seal. Pressure ratingsANSI 150 through 2500 Ib.Valve design illustrated is Wafer Lugged design. TOSV and Triple Offset Segment Valve are trademarks of Solent & Pratt.1

TOSV Design Features Zero leakageBi-directional shut-off to API 598, ZeroLeakage Capability. Ease of maintenanceField replaceable seat and seal ringreduces maintenance costs. Ease of material selectionNon-galling design enables a widevariety of material options. Bearing protectorsBearing protectors are available forthe more arduous duties. Live loaded packingIs available as an option. OperatorsValves can be supplied with manual, electric,pneumatic or hydraulic operator. Fail-safe systemsfor emergency operation are also available. Quality assurance systemApproved by Lloyds to ISO 9001.2

TOSV Geometry & ConstructionThe Solent & Pratt Triple Offset Segment Valve utilises thewell established patented valve geometry where the shaft isoffset from the body in two directions (1) and (2), whilst thedisc is a segment taken from a cone where the apex is offsetfrom the centre line of the valve (3).The disc (segment) of the valve houses a field replaceablemetal laminate seal whilst the field replaceable seat ring ishoused in the body of the valve.% of Segment InterferenceZeroInterferenceDegrees of rotationDue to the valve geometry there is no interference or rubbingbetween seat and seal as the valve strokes through it’s full 90 .Results of Computational Fluid Dynamics (CFD) analysis showing velocity contours.3

TOSV Method of Operation & SealingBi-directional zero leakage is achievedby a unique principle in which the torquegenerated by the actuating mechanism isallowed to flex the metal seal within it’selastic limits, compressing the seal, thusensuring that both seal and seat areperfectly matched. This seal resiliencyresults in zero leakage.Torque generatedresilient sealingDisc ClosingThe resiliency of the seal ring and it’s abilityto flex makes the valve ideal for Hot, Coldor Thermal Cycle applications where thebody is able to expand or contract withoutthe risk of the valve jamming.The Triple Offset Segment valve’s cammingaction of the disc as the valve strokesensures that the metal seat and metallaminate seal are never in contact with eachother whilst the valve is stroking. Contact ismade between seat and seal only as finalshut off position is reached. The tilted coneangle of seat and seal combined with theellipsoidal geometry allows the seal totouch the seat with a uniform contact anglearound it’s circumference with a slightwedging action being achievable.Disc ClosedThis camming motion obtained by the TripleOffset Geometry extends the life of the valveby designing out the continual rubbing ofseat and seal as is inherent in conventionalrotary valve designs. This geometry makesthe TOSV ideal for either control orisolation applications.4

TOSV Standards & SpecificationsSolent & Pratt utilises the latest computer aideddesign systems and software enabling special designrequirements, dimensions and specification to beaccommodated.Our standard valve range however is built and testedto the following standards: Quality assuranceCertified by Lloyds to ISO 9001 Valve designANSI B16.34 Fire testAPI 607 4th edition, BS 6755 Part 2 and API 6FA Face to faceAPI 609, BS 5155, ISO 5752, ANSI B16.10 FlangeANSI B16.5 (3” to 24”), ANSI B16.47(28” and larger). TestingBS 6755 Rate A, API 598, API 6DOur flexibility in design enables us to consider anyspecial requirements, please consult our sales officewith your needs.Double Flanged TOSVOptions Available Bearing protector - recommended forarduous duty applications where solids maybe present in the flow media. Live loaded packing - a set of Bellevillespring washers fitted to the gland followerprovides automatic adjustment to packing. Lantern ring - available for the packing box. Steam jacket - integral steam jackets areavailable on the double flanged body design.5

TOSV Comparison of FeaturesFeaturesGate Ball Gate SolentValve Valve Valve & Pratt Replaceable seat and seal Zero Leakage Bi-Directional Resilient metal seat Inherently fire safe Triple Offset Geometry with field replaceable seatand seal rings (patent design). Solent & Pratt TOSV Range is able to meet shut offStandards API 598 and API 6D. Zero Leakage Capability. The TOSV range can provide zero leakage bi-directionalshut off with metal sealing. Torque generated resilient metal sealing providesrepeatable long term sealing performance.Tested and certified firesafe to BS 6755 Pt.2, API 607 4thedition and API 6FA, the TOSV range is an all metal constructionit’s performance is not affected by fire, it is inherently fire safe.The Triple Offset Geometry of the TOSV range eliminatesall rubbing between seat and seal thus extending theperformance and life expectancy of the valve. Non-rubbing design Wafer body designs Double Flanged body designs Flanged body designs DescriptionWafer and lugged body design available to API 609. Double Flanged designs available to BS5155 (ISO 5752). TOSV is available with face to face to ANSI B16.10enabling easy replacement of ball, plug and gate valves. Lightweight construction Lower piping stresses and construction costs areassociated with this design. Ease of material selection No galling is possible with this design making materialselection simple. Cryogenic design Double Block and Bleed design Full Cryogenic designs down to -320 F (-196 C) are available. Double Block and Bleed design available within single valve body. Non-standard sizes are available on request. ANSI 150, 300, 600, 900 and 1500 with full rated trims.ANSI 2500Ib rating available on request. Lower operating torques compared to comparable designs. Temperature applications up to 1292 F (700 C) arewith this all metal design. Rotary action of the valve enables ease of actuation andsuitability for either control or isolation.Rotary motion valves greatly reduce fugitive emissionsfrom gland packing. In addition gland packing life isconsiderably improved. Sizes 3” (80mm) to 84” (2100mm) Wide pressure rating available Low torque High temperatureavailable Ease of actuation Superior gland performance 6

ComponentsWafer Lugged body illustrated.7

MaterialsMaterials tabulated are for standard firesafe applications up to 842 F (450 C)All materials can be certified to NACE requirements.ItemDescriptionQtyMaterial (Carbon steel valve)1Body1Steel ASTM A216 WCB2Disc (Segment)1Steel ASTM A216 WCB3Through shaft1Stainless steel ASTM A564 type 630 H1100 (17 - 4ph)4Thrust ring2Stainless steel type 316/chrome plated5Seat ring1Stainless steel type 3166Laminated seal1Stainless steel type 316/Supagraph sheet7Clamp ring1Stainless steel UNS S32760 Super Duplex8End cover1Stainless steel type 3169Gland plate1Stainless steel type 31610Drive end bearings2Stainless steel type 316/chrome plated11Non drive end bearing2Stainless steel type 316/chrome plated12Shaft pin3Stainless steel ASTM A564 type 630 H110 (17-4ph)13Seat ring gasket1Supagraph laminated14End cover gasket1Supagraph laminated15Gland packing3Supagraph passivated P616Gland packing (braided)2Supagraph Grafpack17Seat ring screw4-24Stainless steel grade 304 A2 class 7018Clamp ring screw4-24Stainless steel grade 304 A2 class 7019Gland plate stud2Stainless steel type 31620Gland plate retaining nut2Stainless steel grade 30421Key1Stainless steel ASTM A564 type 630 H110022Rollpin1Stainless steel grade 30423Bearing protectors2Graphoil24End plate screw4Stainless steel grade 304 A2 class 70Special applicationsValve design range is available inmost other materials including: 316 stainless steel Duplex stainless steels 6 Mo stainless steel Bronze Monel Incoloy Hastelloy B and C Titanium ZirconiumFiresafe test certificationThe valve design range is certified firesafe to BS 6755 : Part 2 and API 6FA :API 607 4th editions.Summary from SGS Yarsley Fire Test Report FT/92197/2 for a Solent & Pratt14 inch class 150 valve for fire testing to BS 6755 : Part 2 : 1987. The leakagerates were as follows:1. Valve in the non-preferred directionLeakage rate inml/minThroughleakage rateMaximumallowedExternalleakage rateBurn ol downLow hydrostaticpressure testHigh hydrostaticpressure testMaximumallowed14008Under high pressure (14.5Bar/210psi) thetorque required to operate the valve was 160N.M. These results show that even duringthe fire test burn period, where temperaturesreached 1652 F (900 C) the high integritymetal/metal seal still ensured tight shut off.

DimensionsDF - Double Flange designWL - Wafer Lugged body design9

DimensionsTOSV ANSI Class 150# range (dimensions in mm)Double Flange DesignValve size Dim.Inches mmAWafer Lugged 229146515535275630 5 3 000 085 0 2750401000 410205695725325155034103001506957253251390 3058421050 410205725755325166036523001507257553251490 3278441100 410205750780325183040263001507507803251645 3619461150 470235780810340202044443501757808103401815 3993481200 470235815855340226549833501758158553502035 4477501250 470235845885340255056103501758458853402295 5049521300 530265465505350280561713501754655053502520 5544541350 530265900940350318069963901959009403502860 6292561400 530265935975360354077883901959359753603185 7007581450 60030069510053603750825039019596510053603375 7425601500 60030099010503704030886644022099010503703625 7975641600 600300103511253705125 11275440220103511253704600 10120721800 670335117012303705975 13145490245117012303705375 11825802000 760380124512503908200 18040540270124513253907380 16236842200 7603801340142039011050 24310540270134014203909945 21879All dimensions are approximate and subject to change. Consult sales offices for other size requirements.10

DimensionsDF - Double Flange designWL - Wafer Lugged body design11

DimensionsTOSV ANSI Class 300# range (dimensions in mm)Double Flange DesignValve size Dim.Inches mmAWafer Lugged 732539586914973431407325490 7 95 28700292146580610375121526732291465806103751090 95 490 620 863 0 5060401000 410205695725410237552253001506957254102135 5654421050 410205725755410285062703001507257554102565 6160441100 410205750780410317069743001507507804102850 6600461150 470235780810420350077003501757808104203150 7150481200 470235815855420399087783501758158554203590 7832501250 470235845885430425093503501758458854303825 8470521300 5302654655054304700 103403501754655054304230 9570541350 5302659009404305200 114403901959009404304680 11000561400 5302659359754505800 127603901959359754505800 12540581450 60030096510054506500 1430039019596510054505850 13662601500 60030099010504708500 1870044022099010504706800 14960641600 6003001285138047010200 22440440220128513804708650 19030All dimensions are approximate and subject to change. Consult sales offices for other size requirements.12945

DimensionsDF - Double Flange designWL - Wafer Lugged body design13

DimensionsTOSV ANSI Class 600# range (dimensions in mm)Double Flange DesignValve size Dim.Inches mmAWafer Lugged 1435029014536038022548

Standards API 598 and API 6D. Zero Leakage Capability. Bi-Directional The TOSV range can provide zero leakage bi-directional shut off with metal sealing. Resilient metal seat Torque generated resilient metal sealing provides repeatable long term sealing performance. Inherently fire safe Tested and certified firesafe to BS 6755 Pt.2, API 607 4th edition and .