Transcription

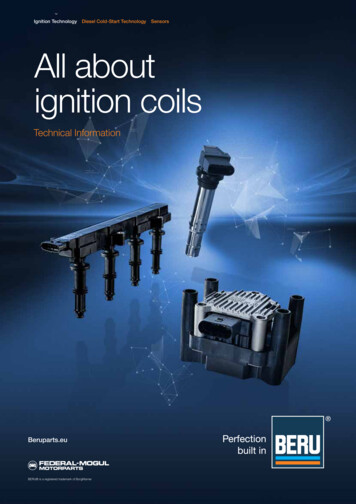

Ignition TechnologyDiesel Cold-Start Technologyn BERU UltranBERU Ultra X TitannBERU PlatinCoolingSensorsAll About Spark PlugsTechnicalInformationNo. 02 Perfectionbuilt in

2ContentsThe spark-ignition engineFunction of the spark plug in a spark-ignition engineDemands placed on a modern spark plugSpark plug design and typesMaterialsElectrode gapThe spark plug in detailSpark position and sparking distanceSeat SealingThermal rating and thermalconductionThermal rating/influencesThermal conductionBERU spark plug rangeBERU Ultra X Titan. The range for X-treme demandsBERU Ultra – the Manufacturers‘ choiceSpecial spark plugs3334444556667777Workshop tips8Spark plug testingOperating Faults and wearSpark plug installationBERU assembly aids8/9101111The FutureThe future of the spark plugHigh demands placed on the new generations of spark plugsNew spark plug geometries for even longer lifeNew high voltage connector for increasedflash-over resistanceHigh-frequency ignition technology:the solution for the futureThe latest measurement and applications systemsSpark plug productionFrom blank to precision componentBERU endurance testsHighest quality standardsBERU services121212131313141414151515Starting characteristics,service life, performance, fuelconsumption, and exhaustperformance – these criticalengine parameters are allinfluenced by the sparkplug. The functional part ofthe spark plug is concealedwithin the engine’s combustion chamber; only a part ofthe insulator and connectorare visible from outside.During operation, sparkplugs have to deliver outstanding performance: in allsituations they must producea spark reliably, ensure correct cold starts, and preventmisfiring – even underextreme conditions – playingtheir part in ensuring optimum combustion with lowemissions.They have to cope withtemperatures in the combustion chamber of up to3,000 C and pressures of upto 100 bar, not to mentionignition voltages of up to40,000 volts, with transientpower peaks of up to 300 A.Chemical influences alsomake high demands onquality. So this is extremelytough work , that the sparkplug has to maintain for manythousands of kilometers.BERU spark plugs are highlyspecialized, precision components, which have beendeveloped to meet vehiclemanufacturers’ specificationsand are produced on up todate production lines.

3The spark ignition engineThe function of a spark plugThe ignition system on petrol-driven engines – in contrast todiesel engines – is external: during the compression cycle thecombustion of the compressed fuel-air mixture is triggered byan electrical spark produced by the spark plug. It is the taskof the spark plug to generate this spark. Created by the highvoltage produced by the ignition coil, it leaps between theelectrodes. A flame front spreads from the spark and fills thecombustion chamber until the mixture has been burned. Theheat released increases the temperature, there is a rapid buildup of pressure in the cylinder and the piston is forced downwards ( Power stroke). The movement is transferred via theconnecting rod to the crankshaft; this drives the vehicle viathe clutch, the gears and the axles.The demands placed on a modern spark plugIn order for the engine to operate smoothly, powerfully and inan environmentally friendly manner, a number of requirementshave to be met: the correct amount of perfectly balanced fuel/air mixture must be present in the cylinder, and the high-energyignition spark must leap between the electrodes precisely at thepredetermined moment. For this purpose spark plugs have tomeet the highest performance requirements : they must delivera powerful ignition spark between around 500 and 3,500 timesa minute (in 4-stroke operation) - even during hours of driving athigh revs or in stop-and-go traffic conditions. Even at -20 C, theyhave to ensure a completely reliable ignition. High-tech sparkplugs provide low-emission combustion and optimum fuel efficiency – without misfiring, which can cause unburnt fuel to getinto the catalytic converter, and destroying it. A modern sparkplug must meet the following requirements:Electrical requirementsn Reliable high-voltage transmission, even atignition voltages of up to 40,000 voltsn Good insulation capability, even attemperatures of 1,000 C, prevention ofarcing and flashoverMechanical requirementsPressure-tight and gas-tight sealing of thecombustion chamber, resistance tooscillating pressures up to approx. 100 barn High mechanical strength for reliableinstallationnThe spark from the spark plugtriggers the combustion of thecompressed fuel-air mixtureduring the compression cycleThermal requirementsResistance to thermal shock (hot exhaustgases – cold intake mixture)n Good thermal conduction by insulator tipand electrodesnElectrochemical requirementsResistance to spark erosion, combustiongases and residuesn Prevention of build-up of deposits on theinsulatornBERU spark plugs are designed and manufactured using highquality materials to consistently meet these extreme requirements. Even at the engine development stage, BERU engineerswork closely with the motor industry to ensure that the sparkplugs are precisely adapted to specific conditions in the combustion chamber.

4Spark plug design and typesMaterialsBERU offers a wide range of spark plugs to ensure that theoptimum spark plug is always available for the many differentengine types and applications. Diverse materials are used for thecenter electrodes. Special nickel-based alloys and copper-coreelectrodes offer good thermal conductivity and high corrosionresistance. Silver has even higher thermal conductivity. Platinumand Iridium offer excellent resistance to erosion, so it extends thelength of time between replacements. The design of the earthingelectrode is just as important. Its geometry influences mixtureaccessibility, wear, heat dissipation and ignition voltage requirement, among other things. Titanium, platinum and iridium offerparticularly long operating lives, for the same electrode gap.Electrode gap1 Connector for the spark plug ( The illustra-tion shows an SAE connector , older vehiclesare fitted with connectors with M4 threads ).Feeds the ignition voltage to the centralelectrode.2 The steel pin (ignition pin) enclosed in agas-tight fit within the conductive glass melt,forming a link with the central electrode.3 The insulator is made of an aluminium oxideceramic and insulates the central electrodeagainst earth at up to 40,000 Volts. Theinsulator can be produced in a plain formor with profiles to prevent flashover.4 Nickel-plated spark plug body forms a gas-tightconnection with the insulator through a heatshrinkage method, which is why the shrinkagezone shows the blue oxydation colour. Threadserves to secure the spark plug in the engineblock.5 Captive outer sealing washer, for sealing andheat dissipation.The shortest distance between the central and earth electrode(s)on the spark plug is called the electrode gap. This is what theignition spark must jump across. The optimum electrode gapin any particular situation depends partly on the engine, andit is determined in close collaboration with the vehicle manufacturer. Maximum precision in maintaining the electrode gapis important since an incorrect gap can have a considerabledetrimental effect on spark plug function and consequentlyon engine performance.Ultra XTitannnnIf the electrode gap is too small this may cause misfiring,noisy idling and poor exhaust gas quality levels.If the electrode gap is too large, this may lead to misfiring.The co-ordinated spark positioning on multi-electrode plugsmeans the electrode gaps does not have to be adjusted(for example Ultra X Titan, air/glide spark technology).6 Electrical connection of spark pin and centralelectrode. On suppressed (R types) glass meltresistors. By means of appropriate additivesthe glass melt can be given a defined degreeof resistance in order to ensure the requirederosion resistance and suppression chracteristics.7 The inner sealing ring forms the gas-tightjunction between the insulator and themetallic body and provides heat conduction.8 The center electrode consists of a copper coreenclosed in nickel. Depending on the type,the central electrode can be in platinum oriridium.9 The insulator tip extends into the combustionchamber. It has a fundamental influence onthe thermal rating.10 The lead-in chamfer makes it easier to screwthe spark plug into engine block.11 The clearance volume influences selfcleaning action.12 One or more earth electrode are weldedElectrode GapPlatinum central electrodeEAonto the body of the spark plug, and withthe central electrode form the spark path.Specially developed nickel-based alloys (orplatinum or titanium reinforcements) increasethe erosion resistance of the electrodes.EAThe spark plug in detail4 Spark plug body1 SAE terminal nut(cable connector nut)2 Ignition pin3 Aluminum oxide insulator

5Spark plug design and typesSpark position and Spark distanceSparking air distanceThe function of the spark plug in the combustion chamber isinfluenced by three main factors: the spark position, the sparkdistance and the electrode gap for spark plugs using variable sparktechnology.Spark position is the name given by engine developers to the sparkpath geometry , the extent to which the spark path extends intothe combustion chamber.Spark pathWith regard to the spark distance, a distinction is made between:The air spark distance which denotes the path the sparktakes between central and earth electrode in order toignite the fuel-air mixture in the combustion chamber.n The variable spark distance which denotes the path whichthe spark takes if it first passes over the surface of theinsulator tip before then jumping across to the earthelectrode. Taking this path burns off harmful deposits andcombustion residues.n Air spark distance/variable spark distance: spark distances,that can pass via air and the insulator. By combining themutually independent air spark and variable spark distances,electrode burn-off can be reduced, leading to a significantlyincreased service life for spark plugs.nThe innovative Poly-V design :5 ignition points are targetted bythe spark in a contuinually changingsequence – thus ensuring greatreliability for the ignition and consequently fuel-saving combustion withan ignition performance that remainsconstant over long periods.Variable sparking distanceSeat sealingThe spark plug must be screwed into the cylinder head so that itis gas-tight. Depending on engine construction features , thereare two different types of seal:nnWrenchsize SW 16Flat seat or level seat: a captive outer gasket acts as a sealaround the plug body.Taper seat or conical seat: the conical surface of the plugbody fits into a correspondingly shaped contact surfacein the cylinder head to create a seal.In restricted spaces (e.g. multi-valve engines), FineLine orBiHex spark plugs are commonly used, which require smallerwrench sizes and have more miniaturised dimensions.75 Captive outer gasketInnergasket10Lead-in section11Clearance volume91286Flat sealing seatwith gasketInsulator tipEarth electrodeCenter electrodeElectrically conductive glass meltConical seatwithout gasket

6Thermal rating and thermal conductionThermal ratingThe thermal rating is a measure of the thermal structure of a spark plug.It indicates the maximum thermal loading on the spark plug in equilibriumbetween heat absorption and heat dissipation.Auto-ignition1.000 OC area850 OCSevere electrodewearIt is vital to choose the correct thermal rating when selecting a spark plug:nn600-700 OCIf the thermal rating characteristic is too high (for example thermalrating 9) the plug is unable to dissipate the resultant heat quicklyenough. This leads to incandescent ignition; in other words it is not theignition spark that ignites the mixture but the overheated plug.400 OCOperating rangeSelf-cleaning limitSootingIf the thermal rating characteristic is too low (for example thermalrating 5) then the free burning temperature required in the lowerpeformance range for self-cleaning the plug, is not reached.Result: misfiring, increased fuel consumption and higher exhaustemissions. (For pictures of faults, see Pages 8 and 9).The influences on thermal ratingThe higher the engine output, the higher in most cases is the combustionchamber temperature. The size of the insulator base has a critical influenceon heat absorption; heat dissipation takes place through the insulatortip, via the center electrode and the inner gasket on the plug body to thecylinder head.nnHeat conduction path of a spark plugapprox. 2%Spark plugs with a long insulator tip absorb more heat. However, sincethey emit less heat on the long path to the plug body they are calledhot plugs.Spark plugs with a small insulator tip absorb less heat. However, sincethey are able to emit a lot of heat on the short route to the plug bodythey are called cold spark plugs.approx. 20%The thermal conductionCylinder temperatures of up to 3,000 C are generated for short periodsduring the combustion process and these temperatures also cause thespark plugs themselves to heat up. The spark plugs give off around 80 percent of this absorbed heat tot he surroundings through various methods ofheat conduction (illustration). The vast majority of the heat is transferredfrom the plug thread directly to the cylinder head. The spark plug musttherefore always be screwed in with the correct torque. Only about 20per cent of the heat is absorbed and dissipated by the passing fuel-airmixture.The use of composite electrodes , e.g. copper-cored Ni-electrodes,enablesa considerable improvement in heat conduction. If the spark position isextremely far forward in the combustion chamber, the self-cleaning temperature is quickly reached - thanks to a special adjustment of the cross-sectionand the heat-absorbing surface of the insulator tip – and the upper cut-offtemperature at the insulator is kept to below 900 C. This type of spark plugis therefore suitable for combustion chambers with both relatively low andvery high temperatures.approx. 30%approx. 30%approx. 18%

7BERU spark plug rangeBERU Ultra X Titan. The range for X-treme demands.ULTRA X TITAN15 types of spark plugs90% market coverage100% fit for the workshopThe successful Ultra X range is nowcalled Ultra X Titan – and consistsof a total of 15 spark plug types:6 of the well established Ultra X sparkplugs and 9 new ones. Together theymake up the Ultra X Titan Series –offering you a market coverage ofalmost 90% !BERU Ultra X. Titan.Center electrode withplatinum ignition tipfor outstanding coldstart performance.Corona ring for targetted pre-dischargeand stable flamepropagation.For more spark power at higher combustion chamberpressures – giving highly efficient combustion.The higher the combustion chamber pressure, the greater mustbe the power of the spark. This is where the innovative sparkplug BERU Ultra X Titan sets new standards : with its burnoff resistant nickel-titanium alloy and intelligently designedearthing electrodes – for increased ignition reliability and anda highly effective, and therefore fuel-saving cmbustion, withcorrespndingly low emmissions figures.BERU Ultra – the car manufacturers‘ choice.BERU Ultra.BERU Bi-Hex.Top-quality spark plugs in OEM quality – for the many different enginetypes and applications.nDA N F IN„YOU C LUGSPSPARK -FUELLEDSAGR06“FOS IN T IEINGNEnnnEnvironment-friendly combustion:saves fuel and protects the catalyticconverterReliable ignition, even at lowtemperaturesLong service life, good durabilityProven materials: two-elementcenter electrode with nickel-sheathedcopper corennnnTwelve millimeter technologywith wrench size 14Reduced thread diameterThread length 26,5 millimetersReliable ignition via coronapre-dischargeSpecial spark plugsThe BERU range of spark plugs included special applications for:1. Compact spark plugs for the particularly confined spaces onpower saws or lawnmowers2. Fully screened spark plugs with steel jacket where verystringent demands are placed on suppression, for examplein official vehicles3. Spark plugs for gas powered engines on gas driven vehiclesand stationary engines for industrial and domestic use4. Measurement spark plugs specially for test and trial engines

8Workshop tips1Spark Plug ChecksA visual inspection of a spark plug can reveal a wide variety ofdamage patterns. Some of them are listed below, with a description of causes, effects and solutions:NormalMinimal electrode burn-off and a grayish white/grayishyellow to russet colored insulator base: Engine settingsare OK, thermal rating is correct.2345SOOT DEPOSITSThe insulator tip, electrode and plug are covered withvelvety black soot.Cause: Incorrect mixture setting (Injection unit). Mixture too rich.Air filter very dirty. Defective cold start system (injection). Defectivetemperature sensor. Used predominantly on short journeys.Thermal rating of plug too high. Defective lambda sensor.Effect: Due to leakage currents, cold starting behaviour is poorand misfiring occurs.OILED-UPInsulator tip, electrode and plug covered in black oil film.Cause: Too much oil in combustion chamber. Oil level too high,heavily worn piston rings, cylinders and valve guides.Defectiveturbo charger.Effect: Misfiring or even shorting of the spark plug, completefailure.GLAZE FORMATIONInsulator tip shows signs of brownish yellow glazing whichcould also take on a greenish tint.Cause: Additives in fuel and oil forming ash-like deposits.Effect: During sudden full loading of engine, the glaze liquifiesand becomes electrically conductive.EXCESSIVE DEPOSITSHeavy deposits of fuel and oil additives on the insulator tipand earth electrode. Slag type deposits (oil coke).Cause: Additive residues , especially from the oil, which thensettle in the combustion chamber and onto the plug.Effect: Can lead to pre-ignition with loss of performance andengine damage.Solution: Checking and ifpossible correction of mixtureand start system. Also examinetemperature sensor. Check airfilter, use a spark plug withcorrect heat rating.Solution: Overhaul engine,correct fuel-air mixture, fitnew, original BERU sparkplugs.Solution: Check whole engine,fit new, original BERU sparkplugs.Solution: Check engine.Fit new, original BERU sparkplugs, possibly change thetype of oil used.

9Workshop tips678910CENTRE ELECTRODE MELTEDCenter electrode melted, end of insulator tip burnt.Cause: Thermal overload due to “glow ignition“ , combustionresidues in chamber, defective valves, inadequate fuel quality,thermal rating of plug too high , tightening torque notobserved.Effect: Misfiring, drop in output (engine damage).Broken insulator tipSurface break up on the insulator nose.Cause: Mechanical damage due to incorrect use. Initiallyoften only discernible as a hairlike crack, sometimes causedby pinking. In extreme cases, deposits can from between themiddle electrode and the insulator, causing the insulator toshatter. Pinking.Effect: Misfire, spark “wonders“, not guaranteeing ignition.Excessive wear of the electrodeCentre or earth electrode shows visible signs of material loss.Cause: Aggressive fuel or oil additives. Poor flow in thecombustion chamber, possibly due to carbon build up. Pinking,overheating.Effect: Misfire, especially during acceleration (ignition voltageno longer sufficient, with large electrode gap). Poor startingperformance.PARTLY MELTED ELECTRODESCauliflower-like deposits on the electrode , possible depositsof materials not originating from the spark plug.Cause: Thermal overload due to “glow ignition, combustionresidues in chamber, defective valves, inadequate fuel quality,possibly too high heat rating, spark plugs were not tightenedas prescribed.Effect: Prior to total engine failure (engine damage) , efficiency willdrop.EMBRITTLEMENT OF SPARK PLUG CONNECTORCause: Thermal overload, old connectors.Effect: Misfiring.Solution: Check engine,ignition, mixture, tighteningtorque of the spark plugs.Fit new, original BERU sparkplugs with the correct thermalvalue.Solution: Fit new, originalBERU spark plugs.Solution: Fit new, originalBERU spark plugs.Solution: Check engine,ignition and mixture; checktightening torque of thespark plugs. Fit new, originalBERU spark plugs with correctheat rating.Solution: Fit new, originalBERU connectors and sparkplugs, grease spark plugconnector with BERU specialgrease (see p. 11).

10Workshop tipsFaults and wearOverload, poor fuel, wrong choice of spark plug, and stop-and-gotraffic conditions are just a few of the factors that can lead tospark plug faults. Here is a short checklist to help you identifythe fault:SymptomCauseSpark erosion, corrosionPossible consequencesThermal overloadWrong or poor fuelIncorrect thermal valueMelted electrodesIncandescent ignitionMisfiring(due to larger electrode gap)Incandescent ignitionResidues in combustion chamberFaulty valvesPlugs with incorrect thermal valueFuel with insufficient octane countPiston damageValve damageSpark plug damageKnockingFuel with insufficient octane countWrong ignition timingExcessive compressionUncontrolled rise in pressureand temperature can lead to pistonand spark plug damageMisfiringFaulty, old, leaking spark plugconnectorSpark-over to insulator;Damage of the catalytic converterSpark plug installationAs spark plugs are designed for specific engines, the correct plugmust always be used. Plugs with the incorrect thermal rating,electrode gap or thread length can lead to reduced engine performance or even damage the engine and/or catalytic converter.Installing and removing them carefully is also imperative.nnnnnWhen removing them, make sure that no dirt gets into thecombustion chamber. First loosen the plug by a few turns,then clean the plug shaft using compressed air or a brush,before screwing the plug out completely.Apply a thin film of BERU special grease to the spark pluginsulator.ZKF01 - 0 890 300 029 with 10g contentsZKF02 - 0 890 300 045 with 50g contents.When installing plugs, make sure that the plug thread andcylinder head bore are clean. With BERU spark plugs, a nickelcoating on the plug body avoids the need for lubrication.Be sure to use the correct tightening torque (see table).Warning: If you drop a spark plug, do not use it. Eveninvisible damage can lead to misfiring and may even damagethe catalytic converter.Check spark plug connectors for wear. If you see signs ofembrittlement or hairline cracks, replace the connectors.

11Workshop tipsIMPORTANT : WHEN INSTALLING PLUGS, IT IS ESSENTIALTO USE THE CORRECT TIGHTENING TORQUE.If extreme burn-off or melting occurs on the center electrode,despite using the specified tightening torque, the cause is almostcertainly due to an uncontrolled combustion process (e.g. incandescent ignition or high-speed knocking). Possible causes: wrongheat rating , discharge valve clearance too small, wrong ignitiontiming , unsuitable fuel quality, deposits in the combustion chamber, or too lean a fuel mix.Torque in Nm, thread must not be greasedFlat seat plugs:Plug threadCylinder headCast ironM 10x1M 12x1,25M 14x1,25M 18x1,510–1515–2520–3530–45NmNmNmNmLight alloy10–1515–2520–3020–35Conical seat plugs:M 14x1,25 15–25 Nm 10–20 NmM 18x1,5 15–30 Nm 15–23 NmBERU assembly aidsFor easy and reliable spark plug replacement without jamming thewrench or cracking the insulator, we recommend the use of specialtools.BERU SPARK PLUG ASSEMBLY AID ZMH001The mechanic’s extended armTHE PROBLEM In the engine compartment, space is painfullytight. When screwing the spark plug in or out, the mechanic caninjure or burn his hand on the engine – or drop and damage thespark plug.THE SOLUTION The BERU spark plug assembly aid, made ofrubber, acts as the “mechanic’s extended arm”: it holds the sparkplug securely, so that it can be screwed in and out carefullyafter loosening or before tightening.BERU SPARK PLUG ASSEMBLY AID ZMH002Reliable spark plug replacement without tiltingTHE PROBLEM The relatively large opening in the spark plugshaft means that when fitting or removing spark plugs using anextension, there is a risk of tilting the wrench, causing the sparkplug insulator to crack. The consequence: misfiring due to sparksjumping across the cracked insulator can destroy the catalyticconverter.THE SOLUTION Simply insert the BERU assembly tool, suitable foralmost all vehicle models, into the 3/8” spark plug extension andpush it into the spark plug shaft. The wrench will now remainparallel to the shaft and cannot be tilted.BERU SPECIAL GREASE ZKF001/ZKF002To prevent the spark plug connector from fusing to the spark plugneck and damaging the sealing lips, we recommend greasing thespark plug insulator with BERU special grease. This also increasesresistance to spark-over.123NmNmNmNmArticle NameBERUshort codeBERUorder numberSpark plugassembly aidZMH0010 890 000 001Article NameBERUshort codeBERUorder numberSpark plugassembly aidZMH0020 890 000 002Article NameBERUshort codeBERUorder numberBERU Special grease, ZKF001Tube 10 g0 890 300 029BERU Special grease, ZKF002Tube 50 g0 890 300 0451 Signs of high voltage spark-overs2, 3 BERU Spark Plug Connector Grease:When smeared into the connectorbefore screwing in the spark plug,the greease protects fromembrittlement , and consequentlyfrom high voltage spark-overs(ZKF001 0 890 300 029 / 10 gZKF002 0 890 300 045 / 50 g)

12FutureThe future of the spark plugIn the development of modern petrol engines, the technologytrends are going towards modified combustion processes andhigh-charged, smaller engine units (downsizing). BERU engineersare developing the optimal spark plugs for this purpose in closeco-ordination with the international automobile manufacturers.Less fuel consumption, lower emissions, more driving enjoyment:these simple watchwords summarize the current technical trendsin the development of spark ignition engines.Total and partial variability in the valve drive through phasersor valve stroke control, as well as direct injection with wall, airor jet-driven injection represent the current start of the art. Thenewest generations of injection systems with piezo-controlledinjectors extends the range for de-throttled, lean engine operation, and should thus ensure the required reductions in petrolconsumption and emissions.In close co-operation with international automotivemanufacturers BERU engineers are developinginnovative spark plug concepts for modern sparkignition engines.This all results in new demands on the spark plugs:nnnnsmaller construction dimensionsspecifically positioned body electrodes (earth electrodes)more accurate spark positions, andhigher dielectric and mechanical strength in spark plug ceramics.High demands placed on the new generations of spark plugsWith the new direct injection systems, there is less room availablefort he spark plug within the cylinder head in spark ignitionengines. This is turn makes it necessary to have a lengthenedfitting thread and/or a modified spark plug geometry. M12spark plugs are being increasingly used, although in comparisonto the traditional M14 spark plugs, they must manage to workwith a reduced ceramic wall thickness. Demands in the oppositedirection – smaller wall thicknesses on the insulator and increasedvoltage requirements – make it necessary to achieve new developments in materials, geometry and processes.Improvement of ceramics propertiesAs an insulator material for passenger car spark plugs, analuminium oxide based ceramic has proved dependable, sincethis material fulfils the electrical and mechanical requirementsregarding dielectric strength, even at temperatures of up to1,000 C. The main factor that determines the properties ofthe present ceramics is residual porosity. In order to obtain aconsiderable reduction in this, and consequently to improve evenfurther the dielectric strength and the mechanical strength ofthe spark plugs, the development engineers for the BERU have,amongst other things, undertaken modifications to the ceramicadditives.

13FutureNew Spark plug geometries for even longer lifeThe automotive manufacturers currently require a target operating life for spark plugs of 60,000to 120,000 kilometres. Simultaneously, the increase in the requirement for electric potential dueto wear on the spark plug spark gap must be kept as low as possible. This means that it is necessaryto develop novel electrode geometries, materials and processes. For spark plugs with nickelalloy-based electrodes, the wear mechanism is determined to a large extent by oxidation. Thisresults in a requirement for nickel alloys that have a stable, durable oxide layer. In the case ofspark plugs with electrodes coated with oxidation-stabilized precious metals, e.g. platinum oriridium, it must above all be ensured that there is a permanent attachment of the precious metalonto the nickel-based spark plug electrodes.New high-voltage connector forincreased flashover resistanceDownsizing is a key technology for reducing fuel consumption and emissions. This new technologyconfronts the ignition systems designer with new challenges, because downsized engines have lessinstallation space available and work at higher combustion chamber pressures and higher ignitionvoltages, which drastically increases the danger of high voltage flashovers at the spark plug.In order to provide increased flashover resistance, BERU has developed a new high-voltageconnector, which – for the same spark plug dimensions – offers a greater insulating surface,thanks to an 8.5mm longer insulator neck, thus increasing the flashover resistance by up to9000 volts. It is not only the added insulation surface that provides more protection againstinsulation breakdown and flashovers, but a new type of contact method. Instead of an externalcontact point (as in SAE or M4) contact occurs on the inside via a pressure spring. This novel,conically converging pressure spring connector is designed in such a way that the front end issecurely enclosed by the bowl-shaped recess of the ignition

n Air spark distance/variable spark distance: spark distances, that can pass via air and the insulator. By combining the mutually independent air spark and variable spark distances, electrode burn-off can be reduced, leading to a significantly increased service life for spark plugs. The spark plug must be screwed into the cylinder head so that it