Transcription

Bruce Stewart – Field Heat Treatment Training Coordinator

INTRODUCTIONThe Quality Control Council of Canada is anorganization that represents Non Destructive TestingTechnicians and Field Heat Treatment Techniciansacross Canada.We have two permanent training facilities based inEdmonton AB with a total of three classrooms and oneshop area to accommodate practical training.The Field Heat Treatment Training Program has beenoperating since May 2009 and is recognized throughAlberta Apprenticeship and Industry Training (AIT)

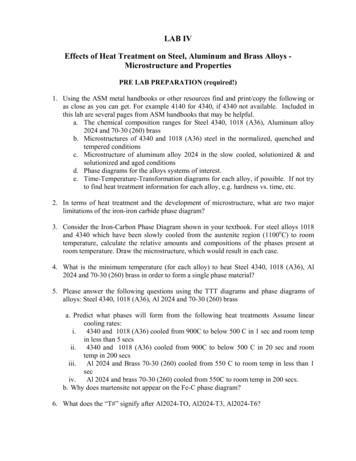

HEAT TREATMENT BASICSHeat treatment is used to avert or relieve the detrimentaleffects of high temperature and severe temperaturegradients inherent in welding, and to relieve residualstresses created by bending and forming (ASME).Field Heat Treatment consists of applying heat to weldedjoints and a limited volume of base metal adjacent to thejoints (referred as local heating), as opposed to heatingthe complete component in a furnace or oven.

HEAT TREATMENT BASICSThe four main heat treatment processes are:1. POST WELD HEAT TREATMENT (PWHT)2. PREHEATING3. BAKE OUT4. POST HEATINGPWHT is the main process we will be focusing on and isthe most commonly completed process in the FieldHeat Treatment OccupationPreheat will also be discussed

REASONS FOR PWHT The three primary benefits of PWHT are recognizedas: Relaxation of Residual Stresses Tempering Hydrogen Removal Consequential benefits such as: avoidance of hydrogeninduced cracking, dimensional stability, as well asimproved ductility, toughness and corrosion resistanceresult from the primary benefits.

HEAT TREATEMENT BASICS Electrical resistance is the most common field heattreatment method utilized for local heating of piping,tubing, pressure vessels and numerous otherstructures and components. In order to ensure Local PWHT is completed properlywe must first understand the importance of the: Soak Band Heated Band Gradient Control Band Control Zones vs. Monitor Zones

HEAT TREATMENT BASICS

HEAT TREATMENT BASICS ASME Codes dictate soak bands but have limited or noinformation regarding Heated Bands, GradientControl Bands or TC placement for ElectricalResistance Local Heating and reference the following: AWS D.10.10/D10.10M: 1999(R2009) – RecommendedPractices for Local Heating of Welds in Piping andTubing Welding Research Council Bulletin 452 –Recommended Practices for Local Heating of Welds inPressure Vessels

HEAT TREATMENT BASICS ASME is developing a standard (B 31P) that is solelyintended for Preheat and PWHT ASME also has a task group working on heat treatmentdata analysis regarding heated bands/control methods(verifying D10.10 recommendations) EPRI has conducted Thermal Modeling for RobustPost‐Weld heat treatment AWS developing a training program/certificationprocess for Field Heat Treatment Technicians

HEAT TREATMENT BASICSLocal circumferential band PWHT of a Butt Weld 12” NPS, 1 inch wallthickness Pipe in the horizontal position (AWS D10.10 HB1 calculations)

HEAT TREATMENT BASICSAWS D.10.10 controlled gradient temperature diagram

HEAT TREATEMENT BASICS

HEAT TREATMENT VERIFICATION The most common verification record for Field HeatTreatment is a controlled thermocouple strip chartthat may be accompanied with a drawing showingwork piece configuration along with TC placement. The chart verifies ramp rates, hold times andtemperature with these controlled thermocoupleswere met and very little other information Very few charts include monitor thermocouples thatwould verify axial temperature gradients, radialtemperature gradients or that “heat sinks” have beencontrolled

HEAT TREATMENT VERIFICATION It is extremely rare to hear of any inspector or QA/QCrepresentative physically inspecting a heat treatmentset up prior to, during or after heating Monitor thermocouples are rarely utilized or requiredwithin heat treatment procedures Knowledgeable Field Heat Treatment Technicians areamazed at these facts and realize that most charts usedas verification really tell the customer very little

CASE STUDY 12” NPS FLANGE Work piece is a standard 12” NPS schedule 80 P1 material2 controlling thermocouples (#’s 1&2) along with 6monitoring thermocouples (#’s 3‐8)1&2 Top and Bottom Centre on Weld Circumference3&4 either side on Weld Circumference5&6 Top and Bottom Centre of Heated Band7 – 2” from #1 onto Flange area of Soak Band8 – Inside bottom Centre of Weld Circumference

CASE STUDY 12” NPS FLANGE

CASE STUDY 12” NPS FLANGE

CASE STUDY 12” NPS FLANGE

CASE STUDY 12” NPS FLANGE

CASE STUDY 12” NPS FLANGE

CASE STUDY 12” NPS FLANGE

CONTROLLED THERMOCOUPLES

CONTROLLED AND MONITOR TC’SCentre of Heaters,Heated band hottest spot#1&2 Controls#3,4& 8 Monitors onWeld Area2” away from #1control TC onFlange Soak BandAreaTC #6 1300 FTC #5 1275 FTC#’S 1‐4, 8(1125F‐1160F)TC# 71000F

TEMPERATURE DIFFERENCES3½”2”TC #6TC #11300 F1150 FTC #71000 F

CASE STUDY CONCLUSIONS Controlled thermocouple charts are accepted as proofof proper heat treatment and may not always tell thewhole story To the untrained eye a heat treatment set up can looksufficient when it is actually unacceptable Uniform heating and temperature control of soakbands, heated bands, gradient control bands, throughthickness and axial temperature gradients are far moresignificant than a thermocouple verification chart.

PRE‐HEAT/INTERPASS HEATING

AWS D10.10 PREHEAT 12” NPS

TYPICAL FIELD PREHEAT SET UP

PROBLEMS

RESPONSIBILITIES? Heat Treatment Technician: Completed recognized formal training? Understanding Procedures? Utilizing proper set up configurations? Quality Assurance Department/Inspectors: Auditing Thermocouple placement, heated bandwidths, gradient control band widths? Were different thicknesses, materials or “heat sinks”controlled? What information are you getting from a chart?

OCCUPATION AWARENESS Field Heat Treatment Technician is a designatedoccupation in New Brunswick (1995) and Alberta(2008). The Quality Control Council of Canada is arecognized training provider for Field Heat TreatmentTechnicians through Alberta Apprenticeship andIndustry Training (AIT). Industrial Field Heat treatment is one of the most criticalaspects of achieving design intentions for weldedstructures and components. Despite numerous articles,case studies and journal references that prove the seriousnegative effects of improper Pre‐Heat and Post‐Weld HeatTreatment, the occupation remains underappreciated.

OCCUPATION AWARENESS A training program has been established for Field HeatTreatment Technicians based on the competencyprofile put together with Alberta Apprenticeship andIndustry Training (AIT). The technician is trained through a combination ofmentoring in the field / workplace along with formal,structured classroom instruction. AWS D10.10 is utilized as the governing document forspecialized Field Heat Treatment Technician training

HANDS ON TRAINING

30” OD WITH 16” OD ATTACHMENTAND RE‐PAD

LARGE CLOSING SEAM FIELD SET UPFOR PWHT

OCCUPATION AWARENESSLevel 1Level 2Level 31800 hrs &1800 hrs &1800 hrs &1 calendar year1 calendar year1 calendar year40 hrs formal training40 hrs formal training80 hrs formal trainingLevel 41800 hrs &1 calendar year80 hrs formal trainingWrite ProvincialOccupationalCertificate Exam

OCCUPATION AWARENESS

Occupational Awareness

CLOSING STATEMENTOnce we understand that proper Pre and Post Weld HeatTreatment are critical in achieving design intentions wemust then recognize and control any and allshortcomings.Owners, Contractors and Quality Assurancedepartments must ensure Heat Treatment applicationsare meeting requirements. This can only be achievedthrough a cohesive effort of all parties involved.

AWS D10.10 is utilized as the governing document for specialized Field Heat Treatment Technician training