Transcription

FISHING TOOL MANUALOil Field Services Division

Bill LinnFishing Tool Technical ServiceDownhole TrainerTraining CenterP.O. Box 9892013 Highway 135 N.Kilgore, Texas 75663903/984-5541 Direct903/984-2335 Fax903/983-6707 Mobile903/984-1608 Homebill.linn@weatherford.comECONOMICS – WHEN TO QUIT FISHING?D DVCsFdRd V CsFd RdMaximum Days To FishValue Of FishCost Of Side-TrackFishing Daily CostRig Daily CostSAMPLE:100,000 (V) 100,000 (Cs)10 days (D) 5,000 (Fd) 15,000 (Rd)

FISHING TOOL MANUAL TERMSAND CONDITIONS OF USEA.The materials contained in Weatherford’s Fishing Tool Manual are protected bycopyright, trademark and other forms of proprietary rights. Nothing containedherein shall be construed as conferring any license or right to use or practice anycopyright, trademark, patent or other forms of proprietary rights.B.This Fishing Tool Manual is not intended to address every issue that may arise inthe course of fishing operations or the planning of same. Each well and eachfishing job are unique and have numerous variables. Experience and otherspecialized training can complement the materials used in this Fishing ToolManual.C.Weatherford makes no representation as to the accuracy or completeness of thematerials in the Fishing Tool Manual. All materials are provided “AS IS”WITHOUT WARRANTY OF ANY KIND WHATSOEVER, EITHEREXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THEIMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR APARTICULAR PURPOSE OR NON-INFRINGEMENT. Weatherford expresslydisclaims all responsibility for the consequences, direct, indirect, consequential orotherwise, of any errors or omissions in the materials.15383 v1

Table of ContentsAlphabetical Listing of Tools . 7Cardinal Rules of Pipe Recovery. 9Mud Properties for Fishing. 10Cardinal Rules of Fishing . 11Field Use Formulas . 12Four Elements of Effective Jarring Operation. 13Stuck Pipe Situations. 14-20General Operational Comments on Fishing Tools. 22-24Cased Hole Fishing: Recommended Overshot/Washpipe/Cutter. 26Recommended Drill Pipe & Drill Collars for Open Hole & Cased Hole . 28Manual Stretch Calculations Based on Young’s Modulus. 30Buoyancy Factor . 31Demonstration of Buoyancy . 32String Shot Rod; Free Point Tool. 33Pipe Recovery Log. 34Pipe Recovery Log with Gamma Ray Log in Conjunction. 35Differential Temperature Log. 36Chemical Cutters. 37Freepoint Indicators . 38Baker Atlas Chemical Cutter . 39-40Pipe Recovery Systems: Selection Guide F/Wedge Type Chemical Cutter . 41Pipe Recovery Systems: Selection Guide F/Direct Action Chemical Cutter . 42Pipe Recovery Systems: Chemical Cutter Temperature and Pressure Ratings . 43Jet Cutters . 44-45Tools for Fishing Junk – Quiz . 155Tools for Fishing Junk – Answers . 156Fishing Wire-Line / Not Parted . 157Cable Guide Fishing Method. 158Fishing Wire-Line / Parted . 160US Service Locations & Telephone #’s. 161International Telephone #’s & Canadian Service Locations. 1625

6

Alphabetical Listing of ToolsBMBasketsFull Flow Type Reverse CirculationJunk BasketItco Type Bowen Junk BasketReverse Circulation Junk Basket105-10894-9799-103CCasing PatchesBowen Packer Type ExternalBowen Lead Seal Bowen Hydraulic ExternalBowen InternalExternal MechanicalHE “DH” WashoverMagnets – Fishing122-124113-116117-121125DDrill Collar WeightsOOvershotsSeries 10 & 20 Sucker RodSeries 70 Short CatchSeries 150 Releasing & CirculatingSeries 160 Side-DoorPPatchInternal - HomcoExternal - Bowen Packer TypeExternal - Bowen Lead vers - PackerJB BushingSimplex126127Rotary ShoesR.P.M. for Milling10923789JJarsAnadrill-Schlumberger TR,DC, FBJar Specifications87Bowen Jar Intensifier81Bowen Super Fishing Jar83Bowen Surface Bumper Jar151-153Bowen Type “Z”82HE Fishing Jar, TMC Jar84HE ACCM Accelerator85-86Wfd. Hydraulic Fishing Jar76Wfd. Hypulse Jar Slinger for use with Fishing Jars77Wfd. Dual-Acting Coiled Tubing Jar78Wfd. Hypulse Jar Slinger for use with Coiled Tubing Jars79Wfd. Lubricated Bumper Sub80JointsKnuckle JointUnlatching Joint91-93SSpearsAnchor WashpipeFull CircleItco Type Bowen Releasing141-14374-7566-73Surface Bumper Jar151-153UUnlatching Joint144-147WWashpipe SpearWashpipe SpecificationsWire-Line ord Fishing Tool ManualJanuary, 20037

8

Cardinal Rules of Pipe RecoveryPipe Recovery1. Free Point: Pipe is free or stuck. Always leave free pipe above the stuck point if youintend to fish this well. One or two joints above the stuck point is recommended.Always check torque and stretch.2. Chemical Cut: (Hypergolic) Must have liquid present. Does not work well in heavymuds ( 15 PPG). Bromide Triflouride freezes at 48 F and boils at 257 F. Very poortrack record in attempting to cut greater than 0.450” wall thickness.3. Jet Cut (Super Cutter): Cut in centralized area to avoid casing damage.4. Back-off: At second free connection above the stuck point.5. Severing Tool: Recommended for open hole use only. This tool will damageconcentric strings. GOEX recommends firing in the tool joint or coupling ifattempting to sever pipe not drill collars.6. Freepoint / Horizontal Wells: Torque including left hand torque and stretch readingsa must in order to insure back-off.Weatherford Fishing Tool ManualJanuary, 20039

Mud Properties for FishingWeight -Sufficient to maintain well control and control sloughing shales andwater flow. Fresh water weighs 8.3 ppg.Viscosity -Fresh water has a funnel viscosity of 26. In a drilling operation(10,000’ or less), the viscosity will probably run 32 to 36. Prior tologging, high viscosity sweeps are normally made with a viscosity inthe 70 range. In deeper wells or unconsolidated sand the viscosityshould be four times the weight.Velocity -Minimum velocity with drilling mud in open hole is 100 ft./min. by thedrill pipe. With clear completion fluids, minimum velocity is 150ft./min. In a milling operation, the velocity should be 200 ft./min ifpossible.Yield Point - A low yield will allow the mud to break down at the cutting structureand not lift the cutting. Drilling muds need a yield point of:10 - 15 to drill15 - 20 to washover30 to millA rule of thumb for yield point during drilling operations is that yieldpoint should match the mud weight.Water Loss - This is very important if wash-pipe is going to be placed in open hole.In hard rock formations a water loss below 10 is okay. Inunconsolidated sands as in Gulf Coast offshore, the water loss needs tobe below 5. Before placing wash pipe in the hole, lower the water lossbelow what it was when the drilling assembly became stuck. If youwere drilling with a 5 water loss and got stuck, lower it to a 3 beforerunning wash pipe.Weatherford Fishing Tool ManualJanuary, 200310

Cardinal Rules of Fishing1. Know your dimensions:A. O.D., I.D. length of the fishB. O.D., I.D. length of the fishing tool assemblyC. O.D., I.D. length of the work stringD. MOST IMPORTANT - Know where the top of the fish is2. Know all tensile & torsional strengths of everything you run in hole.3. Pulling out of hole: Never rotate the fish out of the hole.4. Trip time: Fast is not always the best.5. Never run anything in the hole that is not O.D. fishable unless you are aware of thatfact and make an informed decision that the reward is worth the risk. For example: anovershot is not O.D. fishable but we run them because it does not reduce the I.D. andwhen run with the bumper jar, it releases 99% of the time. This is an acceptable risk.6. Familiarize yourself with the Fish: Use composite catalog, technical manuals,manufacturer’s drawings to learn the critical points (depth to top of slips, packer elementand bottom slips) of removing, burning over or milling up a fish. If an exact copy of thefish, same type packer or stabilizer, etc., can be brought to the well site, it is much morevaluable than a drawing or dimensional data.Weatherford Fishing Tool ManualJanuary, 200311

Field Use FormulasManual Stretch -The overpull necessary to induce 3 ½” stretch per 1000 ft free pipe is:2208.5x Nominal Weight of the tube in lbs./ft.Hydraulic Force -D² x .7854 x pressureHydrostatic Pressure - .052 x weight x depthMax Pull on Pipe - O.D. 2 x .7854 AI.D. 2 x .7854 BA-B CC Net Wall AreaNet Wall Area x Minimum PSI Yield Max Pull on Pipe (J - 55 55,000)(N - 80 80,000)Hole Capacity -D² (In) 1029.4 Bbls/FtDisplacement -Steel Weights 65.63 Pound per GallonString Weight 65.63 Gallons DisplacementDivide Gallons Displacement by 42 Bbls/DisplacementTank Volume RectangleL(ft) x W(ft) x H(ft) Volume (bbls/ft)25.6Tank Volume CylinderD² (in) (Bbls/ft)1029.4Weatherford Fishing Tool ManualJanuary, 200312

Four Elements of Effective Jarring OperationIn any jarring operation, make sure you have met each of the four elements or youare not effectively jarring on the fish or stuck point. This addresses the up-jar only.1. Restricted Pull:A. Stuck SituationB. Restricted Pull Device i.e. Oil Jar2. Multiplier: Drill CollarsIf you do not run drill collars or Heviwate the multiplier is less than 1.3. Transition Area:A. Change in mass from drill collars to tubing or drill pipe also can be the transitionarea.B. Jar Accelerator/Intensifier is the perfect transition area.4. Stored Energy:A. Jar Accelerator/IntensifierB. Jarring work-stringWeatherford Fishing Tool ManualJanuary, 200313

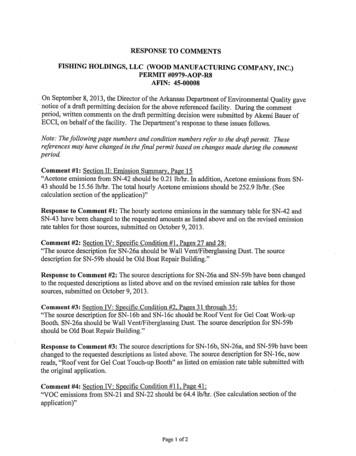

Differential StickingTop ViewPermeable ZoneStatic Filter CakePermeable orPorous FormationDrill CollarsHigher Pressure Formation thatmud has been weighted to controlWeatherford Fishing Tool ManualJanuary, 200314

Stuck Pipe Conditions“Identify the Problem”When pipe is stuck it is critical to correctly identify the problem-- Why is the pipe or B.H.A. stuck? Various types of sticking conditions are listed inthe following discussion.DIFFERENTIAL STICKING - This problem occurs world-wide. The B.H.A or drillstring becomes stuck due to the differential pressure across a zone. The B.H.A. ordrill-string is held in place against the bore hole by the hydraulic force of thehydrostatic weight of the drilling fluid.The most common cause of differential sticking is thick filter cake across a permeable zone.Preventive Action:1) Reduce wall contact w/ B.H.A. by using spiral drill collars and H.W.D.P.2) Keep string moving. Consider rotating drill-string while standing back pipe orpicking up a stand or making a connection.3) Maintain minimum mud weight.4) Daily short wiper trips.Indication of Differential Sticking:1) Typically occurs when pipe is not moving - especially while making a connection.2) Drill-string cannot be moved up, down or rotated.3) Circulation is not affected in any way.Recommended Procedure:1) Apply torque and jar down if drilling jars are in hole and working. If jars are not inhole or not working, apply torque and stack drill-string out. When not in jarringmode, apply torque and stack drill-string out.2) Spot a pipe releasing pill. Time is very critical. If the spotting agent is in place intwo hours or less, the chance of it working is enhanced. Local knowledge is veryimportant. What spotting agents work in your area and what is average time of release?3) Jarring option by itself is rarely successful because the hydraulic force holding the drillstring is commonly well over 1,000,000 pounds differential force.4) Wash-over Operation - Be very cautious. Use a short wash-pipe string. Go formaximum clearance between the bore-hole and wash-pipe O.D. Shoe designshould cut maximum clearance for the wash-pipe O.D. Be very cautious whenrunning a drill-collar spear, wash-over back-off connector, or internal screw-inassembly in combination with wash-pipe for washing over differential stuck pipe.Keep the wash-pipe m

Dual-Acting Coiled Tubing Jar 78 Wfd. Hypulse Jar Slinger for use with Coiled Tubing Jars 79 Wfd. Lubricated Bumper Sub 80 Joints Knuckle Joint 148-149 Unlatching Joint 144-147 M Magnets – Fishing 91-93 O Overshots Series 10 & 20 Sucker Rod 56-63 Series 70 Short Catch 64-65 Series 150 Releasing & Circulating 46-48 Series 160 Side-Door 159 P Patch Internal - Homco 129-130 External - Bowen .