Transcription

XT H SERIESIndustrial X-rayand CTAdvanced IndustrialX -ray and CT

Insight into the insideA wide range of applicationsAnywhere the internal structure matters, X-ray andCT technology serves as an efficient tool to provide valuableinformation. Detailed capture and measurement of internalfeatures is often vital for quality control, failure analysis andmaterial research across various industries. Connector wiringFault detection and failure analysisAssembly inspection of complex mechanismsDimensional measurement of internal componentsPart-to-CAD comparisonAdvanced material researchAnalysis of the biological structuresDigital archiving of modelsAUTOMOTIVETurbocharger cast housingJet engine turbine blade Electrical connectorsInjection nozzlesSensors (e.g. Lambda sensor)LED light pipesSmall high-pressure die cast partsDPF (Diesel Particulate Filters)AEROSPACE Wax turbine bladesCast turbine bladesCrack analysis in componentsWeld analysisPLASTIC INJECTION MOLDINGBatteryGet the inside picture of complexindustrial parts, by looking into theinternal structure. Use CT capabilityto qualify and quantify any inner orouter dimension in a smooth, fast,non-destructive process.3D printed impellerIndustrial X-ray and CT systems bring high accuracy andthe ability to measure internal and external dimensionssimultaneously without destroying the part. Furthermore,they provide additional insight through the fourth dimensionof material density and structure, rapidly making X-raytechnology a must-have tool in the production toolbox.A LEGACY OF MORE THAN 30 YEARS INX-RAY AND CTWith an experience of more than 30 years,Nikon Metrology has an extensive installation base ofthousands of X-ray and CT inspection systems worldwide.CT specialists in Tring, UK, design, develop andmanufacture complete systems, incorporating proprietarymicrofocus X-ray sources, high-precision 5-axis fullyprogrammable manipulators and fast acquisition andreconstruction software. Complex plastic components (e.g. fan) Soft, translucent materials where tactile or optical is nooption Ultrasonic welding of plastic partsPHARMACEUTICAL/MEDICALSectioned light bulbPlastic connector Medicine dispensersSmall medical devices (instruments, stents, pacemaker, etc)Small plastic or composite partsBone structuresImplants (dental, hip, knee, skull)RESEARCH Material verification and analysis (e.g. structure, porosity,defects) Paleontology (e.g. bones, skulls, fossils) Geology and soil science Archeology Renewable energy (batteries, solar cells, etc.)Medical injectorFemur bone

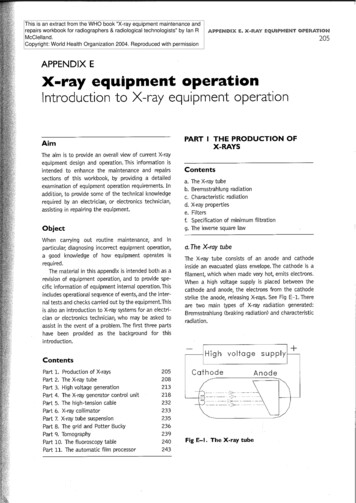

X-ray sourcesXT H 225IN-HOUSE DESIGN AND BUILDDetailed capture and measurementof internal component andassembly features is often vitalfor quality control, failure analysisand material research. The entrylevel versatile XT H 225 systemoffer a microfocus X-ray source, aninspection volume to accomodatesmall to medium sized parts andhigh image resolution. Ready forultrafast CT reconstruction, theXT H 225 covers a wide rangeof applications, including theinspection of plastic parts, smallcastings and complex mechanismsas well as researching materials andnatural specimens.Nikon Metrology X-ray sources are at the heart of our technologyand have been designed and manufactured in-house from 1987 tothis day; offering over 30 years of knowledge. Being at the heart ofthe image, control over the X-ray source technology allows NikonMetrology to quickly move with the market and develop completeand innovative solutions to the application demand. All sources areopen-tube giving a low cost of ownership and range from low (180)to medium (225) to high (450) kV, all with micron resolution.One X-ray tube, five target modules,limitless applications180 kV TRANSMISSION TARGET-Liquid-cooled Transmission TargetSub-micron feature recognitionHigh resolution up to 180 kVPerfect for high resolution CT of small samples225 kV REFLECTION TARGET-Liquid-cooled Reflection TargetSpot size down to 3 micronHigh resolution up to 225 kVOutstanding image quality and high resolution acrossa broad sample range225 kV ROTATING.TARGET 2.0The World’s only 450 kVmicrofocus source-Liquid-cooled Rotating Reflection Target3x higher resolution for the same power as static target3x higher power for the same resolution as static targetResulting in significantly faster scan timesNo cool-down periods; continuous operation upto a stunning 450 Watts powerEASY OPERATIONFLEXIBILITY IN CTLOW COST OF OWNERSHIPUsers are operational with thesystem within a few days of training.A CT wizard guides operatorsthrough the data acquisition process.Customizable macros automate themeasurement workflow, and tightintegration with industry-standardpost-processing applications streamlinethe decision making process.Specific applications require moredetailed images or higher accuracy.The XT H 225 can be configuredwith different flat panels or sourceconfiguration (reflection/ transmissiontarget) to adapt resolution to thespecimen’s needs: full part in coarseresolution and high resolution in adesired region of interest. A small spotsize and a high-resolution flat panelcreate sharp images.Regardless of the target of choice, theXT H 225 system uses an open-tubeX-ray source that guarantees a lowercost-of-ownership. The open X-raytube allows for local maintenance ofinternal tube components rather thanwhole tube replacements. TheXT H 225 system is self-containedand quick to install. No special floortreatments are required.320 kV SOURCE450 kV REFLECTION TARGET- Unique 450kV microfocus source with25 micron accuracy and repeatability- Rotating Target source option for 5x fasterscanning- Liquid-cooled advanced technology for450 Watt continuous power- Orders of magnitude higher resolutionthan minifocus sources at same energy- Industry leading performance with fasterscan times and higher accuracy-Liquid-cooled Reflection TargetUnique 320 kV high-power microfocus sourcePenetrates dense samples while maintaining high resolutionIdeal for rock cores, castings and dense objectsMULTI-METAL TARGET-Industry unique multi-metal targetOptimise the X-ray profile generatedChange metals without breaking vacuumUnrivalled flexibility for complex applicationsVersatility to enhance image contrast, perfect for materialsresearch and moreWITH ALL NIKON METROLOGY CTSYSTEMS YOU CAN- Verify complex internal structures- Isolate and inspect included components- Measure internal dimensions without sectioningthe sample- Automatically detect and measure internalvoids/volumes- Reveal internal and external surfaces with ease- Reduce total inspection time- Reduce number of iterations to fine-tune(pre-) production parameters

XT H 225 ST 2xXT H 320The XT H 225 ST 2x system isideally suited to a wide rangeof materials and sample sizes.The system can be configuredwith a range of industry-leadingflat panel detectors, up to2,880 x 2,880, 150 µm pixels, tobest suit the user application.The XT H 320 is a large cabinetsystem for the X-ray CT scanningand metrology of large components.The system consists of a 320 kVmicrofocus source delivering up to320 W of power.A high resolution flat panel is usedto collect high quality images of thesample. The system is controlled byInspect-X software which makes thecollection of CT data and setting upof measurements simple and easy.The system can output volume datato industry standard volume viewingsoftware.Tools for increasing scan speed,prolonging system uptime andmaintaining measurement accuracy,when combined with the interchangeableX-ray targets and motorized FID, provide aflexible tool for Quality Control laboratories,Production facilities, Research and Developmentdepartments and academia.AVAILABILITY ANDPRODUCTIVITYAuto.Filament Control intelligentlycontrols the X-ray source to double thelifetime of the filament, without long-lifefilaments that would reduce the highresolution micro-focus nature of thesource. Less frequent changing of thefilament means the system is availablemore of the time.When a short turnaround is required,Half.Turn CT allows faster CT scans byonly rotating the sample just over180 degrees. Novel centre of rotationand new reconstruction algorithms allowautomated scans which retain the qualityof a longer 360 degree CT scan.TRACEABLE ACCURACYUNRIVALLED FLEXIBILITYAutomated calibration of any CTscan position is possible withLocal.Calibration; leading toimproved measurement accuracy formetrology applications.With four X-ray target heads,unique flexibility is achieved from asingle source. Targets are easily userexchanged, to allow optimisationof the source for the sample beingscanned.As the CT scan position is calibratedwith reference to a known artefact,measurements can be made witha high level of confidence withtraceable procedures.POWERFUL 320 kV MICROFOCUSMost system suppliers only offer microfocus sources up to225 kV, while more powerful sources in their offerings areminifocus. With larger samples, one often needs morepenetration power and therefore Nikon Metrology offers aunique 320 kV microfocus X-ray source. As the X-ray spot sizeof these sources is orders of magnitude smaller compared tominifocus sources, end users benefit from superior resolution,accuracy and a wider array of measurable parts.With a motorised FID (Focal spot toImager Distance) adjustment, theuser does not have to increase eitherX-ray power or detector exposureto compensate for the fall in X-rayintensity between the source andflat panel detector. A faster scantime or a higher signal to noise ratiois possible when a shorter FID isselected.MCT225: ABSOLUTE ACCURACY FOR METROLOGY CTFEATURESDimensional inspection using industrial CT has many advantages as all internaldimensions are measured without destroying the part. Metrology CT ispossible by - either calibrating scans by performing time consuming referencemeasurements - or by using a metrology grade system.- Temperature controlledenclosure- Liquid cooled X-ray source- Finite element Analysis (FeA)optimized manipulator- High precision linear guideways- High resolution optical encodersThe MCT225 is pre-calibrated using accuracy standards by VDI/VDE 2630guidelines for Computed Tomography in dimensional measurement. Several keymetrology features provide enable an impressive absolute accuracy specificationof 9 L/50 µm combined with a long term stability.Extended information andspecifications can be found in theMCT225 brochure or datasheet.ALL ANALYSIS IN ONE GODimensioning / GD&TCAD comparisonVoid analysis

XT H 450High voltage microfocus CTThe XT H 450 system offers the necessarysource power to penetrate through highdensity parts and generate a scatter-freeCT volume with micron accuracy. At thecore of this powerful equipment is a 450kV microfocus source, providing superiorresolution and accuracy up to 450 Wpower whilst offering sufficient X-raypower to penetrate dense specimens.The system is available with a flat panel(for 3D cone-beam CT) or a proprietaryCurved Linear Diode Array (CLDA) (for2D fan-beam CT) that optimizes thecollection of the X-rays without capturingthe undesired scattered X-rays.LARGE CAPACITY MANIPULATORSamples weights up to 100 kgPROTECTIVE ENCLOSURENo risk of radiation exposureFLAT PANEL & CLDAChoice of flat panel or CLDA, or both,to suit the application450 kV MICROFOCUSThe proprietary 450 kV source is the world’s only microfocus X-ray source at this energy, enablingthe XT H 450 system to deliver 25 micron repeatability and accuracy. As this microfocus spotsize is considerably smaller than existing mini-focus sources, the level of detail that it captures isbeyond comparison. With the rotating target the level of detail possible with 450 kV can nowbe collected up to 5x faster, or with higher accuracy in a similar scan duration, compared to thedefault 450 kV source.DUAL MONITORSFull screen imageand software controlsUNIQUE CLDA TECHNOLOGYWhen X-rays hit an object, they are absorbed but also scattered, an undesired phenomenon thatincreases as the density of the object increases. Scatter coming from all points of the part reducesimage contrast sensitivity, as is visible on flat panel images. Nikon Metrology has developed aproprietary CLDA that optimizes the collection of the X-rays travelling through the part, withoutcapturing the undesired scattered X-rays. By avoiding image pollution and associated contrastreduction, the CLDA realizes stunning image sharpness and contrast. The linear array of diodesis curved to further enhance image quality by keeping the X-ray path length to diode receptorsconstant compared to straight arrays. This allows longer crystals to be used to enhance the X-raysensitivity and hence boost the signal-to-noise ratio and reduce the scan time.LOW COST OF OWNERSHIPServiceable open-tube sourceNIKON METROLOGY 450 kVWorld’s only 450 kV microfocus X-raysource, available in static or rotating targetCASTING INSPECTIONTURBINE BLADE INSPECTIONCT VERSATILITY WITH CONFIGURABLE SYSTEMSMicrofocus sources at this energyare needed to run highly accurateinspection of dense industrial objects,such as large castings. The XT H450 3D is a system designed to giveindustry leading performance inthe scanning of large objects wherescattering is not a limiting factor, e.g.large low density castings. For higher density castingswhich exhibit scatter, the XT H 450 can build a 3Dvolume by combining CLDA 2D CT slices.A 450 kV source in combination with aCLDA is ideal for radiographic and CTinspection as well as metrology of smallto medium metal alloy turbine blades.Such an X-ray system offers sufficientsource power to penetrate through thepart and generate a scatter-free CT volume. In a productionenvironment, the system runs automatic data acquisition,high-speed CT reconstruction and inspection, generating pass/fail status for each inspected part. Blade manufacturers can rundetailed CT metrology inspection of turbine blades (e.g. wallthickness) to optimize the fuel economy of jet engines.When there is no standard X-ray and CT system available that suitsyour organization’s specific requirements, Nikon Metrology canprovide a configurable CT system that can be built into (existing)cabinets or walk-in rooms. These modular systems support multiplesources, multiple detectors, specific manipulators and can becustom-configured to fit a variety of applications.LARGE ACCESS DOORWalk-in cabinet accessible vialarge pneumatic controlled door

Intelligent softwareIntuitive and user-friendly software is essential to simplifythe process of CT scanning complex samples for accurateinspection. Developed in-house, Inspect-X is designed tostreamline the process of acquiring and reconstructingCT data, for both advanced and beginner users. Thefocus of Inspect-X is on intelligence, offering users onlythe information they need at any moment, thereforesimplifying the task at hand.ASTM E2737Evaluate and track the performance of thedetector with ASTM E2737. Dedicatedsoftware performs all necessary functions,including artefact manipulation, imagecollection and data analysis, creating a detailedreport automatically and rapidly with uniqueperformance tracking and trend analysis.Nikon CT AutomationA major step closer tozero-defect productionCT WIZARDIntuitive guide through the stepsto acquiring CT data.FULLY PROGRAMMABLE SOFTWAREInspect-X is unique in the X-ray CT market,offering unparalleled control through the use ofits programmable interface. The possibilities areinfinite, allowing custom experimentation, forexample time-lapse CT or complete integrationof the system within your production line.BATCH INSPECTION IS STANDARD WITHINSPECT-X SOFTWAREBatch inspection allows automation of multiple scanswith manual part handling.FAST RECONSTRUCTIONIndustry leading reconstruction,developed and controlled in-house.SEMI-AUTOMATED IS POSSIBLE WITHIPC PROGRAMMINGSemi-automated inspection allows automation of alltasks with multiple part loading.FLEXIBLE SOLUTIONSInspect-X has multiple scanning techniquesto meet the most demanding of applications.From conventional circular CT scanning toX.Tend, which extends the vertical scan heightof the X-ray system and Limited Angle, amethod for improving the resolution of smallerregions of interest on a sample.IN-LINE AUTOMATION WITH ROBOTINTEGRATIONIn-line automation allows full integration to yourproduction line.SIMPLE INTERFACEWith a large radiograph image and clearicons, the simple user interface reducesthe operators learning curve.ONE TOUCHAfter selecting the part type from the scan library,only one button has to be pressed to start the scan,reconstruct the data, perform the analysis and output aresults file.

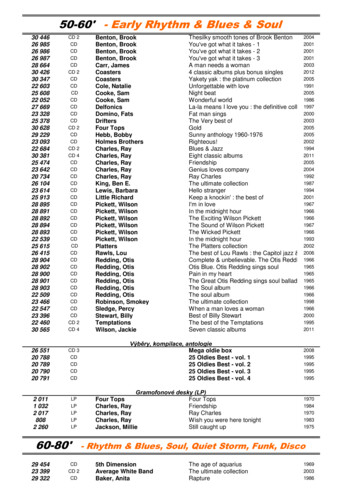

X-ray SourceXT H 225XT H 225 ST 2xTypeMCT 225XT H 320XT H 450Reflection TargetRotating Target 2.0Multimetal TargetReflection TargetRotating Target320 kV450 kV450 W450 WOpen Tube MicrofocusTarget OptionsReflection TargetReflection TargetTransmission Target Transmission TargetMultimetal TargetMultimetal TargetRotating Target 2.0Max. EnergyReflection Target225 kVMax. Power225 W450 WMin. Focal Spot225 W1 µm3 µm80 µmSystemMax. CT Swept Diameter280 mm265 mm250 mm300 mm468 mmMax. FID970 mm nominal1,110 mm nominal1,175 mm1,025 mm1,200 mmFID TypeMoveableMotorised moveableFixed15 kg50 kg100 kgMax. Sample Weight100 kgDetectorMax. Pixel Matrix2,880 x 2,8802,048 x 2,048150 µm200 µmMin. Pixel SizeMax. Frame Rate30 fpsType7.5 fps30 fps30 fpsASTM E2597 Flat PanelCLDACabinetLength1,830 mm2,414 mm2,695 mm3,613 mmWidth875 mm1,275 mm1,828 mm1,828 mmHeight1,987 mm2,202 mm2,249 mm2,249 mmWeight2,400 kg4,200 kg8,500 kg14,000 kgNIKON METROLOGY NVNIKON CORPORATIONGeldenaaksebaan 329B-3001 Leuven, BelgiumTel: 32 16 74 01 00 Fax: 32 16 74 01 03Sales.NM@nikon.comShinagawa Intercity Tower C, 2-15-3, Konan,Minato-ku, Tokyo 108-6290 JapanTel: 81 3 6433 3701 Fax: trology/NIKON METROLOGY EUROPE NVTel: 32 16 74 01 01Sales.Europe.NM@nikon.comNIKON METROLOGY, INC.Tel: 1 810 2204360Sales.NM-US@nikon.comNIKON METROLOGY GMBHTel: 49 6023 91733-0Sales.Germany.NM@nikon.comNIKON METROLOGY UK LTD.Tel: 44 1332 811349Sales.UK.NM@nikon.comNIKON METROLOGY SARLTel: 33 1 60 86 09 76Sales.France.NM@nikon.comNIKON MÉXICO - METROLOGYTel: 52 (442) 688 5067Sales.NM-MX@nikon.comMore offices and resellers at www.nikonmetrology.comNIKON INSTRUMENTS (SHANGHAI) CO. LTD.Tel: 86 21 6841 2050 (Shanghai branch)Tel: 86 10 5831 2028 (Beijing branch)Tel: 86 20 3882 0551 (Guangzhou branch)NIKON SINGAPORE PTE. LTD.Tel: 65 6559 3651NIKON INSTRUMENTS KOREA CO. LTD.Tel: 82 2 2186 8400NIKON SALES (THAILAND) CO., LTD.Tel: 66-2633-5100NIKON INDIA PRIVATE LIMITEDTel: 91-124-4688500ISO 14001 Certifiedfor NIKON CORPORATIONISO 9001 Certifiedfor NIKON CORPORATIONIndustrial Metrology Business UnitXTH SERIES EN 0321 – Copyright Nikon Metrology NV 2021. All rights reserved. The materials presented here are summary in nature, subject to change, and intended for general information only.Specifications

With a motorised FID (Focal spot to Imager Distance) adjustment, the user does not have to increase either X-ray power or detector exposure to compensate for the fall in X-ray intensity between the source and flat panel detector. A faster scan time or a higher signal to noise ratio is possible when a shorter FID is selected. POWERFUL 320 kV .

![[AWS Black Belt Online Seminar] AWS X-Ray](/img/17/20200526-blackbelt-x-ray.jpg)