Transcription

AdhesiveTechnologiesLabels PackagingTechnical GuideEurope2020

Adhesives inspiredby innovationNo one does innovation like Avery Dennison.For more than 85 years we’ve been developingnew adhesives to meet the changing needs of thelabelling and packaging industry. We’re the only labelproducer making proprietary adhesives, and we’releading the development of sustainable, innovativeand compliant solutions across all sectors.With over 400 adhesive scientists working in sevenR&D centers globally, we solve the challengesfaced by our global customers in real time, offeringbespoke adhesive performance to every cornerof the world. Today, you’ll find Avery Dennisonadhesives everywhere you look.Material science is at our core. The world didn’thave self-adhesive labels until we invented them.And we’ve been advancing quality and innovationin material science ever since.Past, presentand future1935: the first self-adhesive1990s: our deep-freeze adhesivesToday: we’re focused on increasing ourenabled labelling in sub-zeroportfolio with sustainable adhesives thatlabels were developed by ourtemperatures. Adhesives forsupport circularity, as well as specializedrough, low-energy surfaces, suchfunctional adhesives that enable labelling onfounder Stan Avery.as tyres, were another of ourchallenging surfaces including automotivepioneering inventions.and low-temperature cryogenic applications.1970s: all-temperature2010s: Avery Dennison furtheremulsion acrylic broughtinvests in sustainable solutionsa wide range of adhesiveincluding CleanFlake adhesivepossibilities to the market.technology, which enables therecycling of PET packaging.2000s: sustainability becomes akey focus for Avery Dennison andthe entire label and packaging1960s: we invented thefirst range of solventrubber-based adhesives.industry. We developed a wash-offadhesive to enable reuse for thereturnable beverage market.1LPM/EU/2020/June

Which adhesiveis right for chemicalcomposition:We make use of three adhesive coatingtechnologies: emulsion, hotmelt, and solvent.Within each coating technology, we work withadhesive chemical compositions that aremeticulously engineered to meet your applicationand performance demands. We have more than160 specifically-tailored adhesive variants tochoose from in Europe bberAcrylicRubberHybridSiliconeThree coating technologies allow us to engineer adhesives that offer a wide range offunctionality within each type of chemical composition.Our main adhesives are acrylic- and rubber-based, but we also develop hybrid andsilicone adhesives for challenging applications specific to automotive. We are able tomodify the adhesive composition so that the finished label behaves as you need it to.Emulsion AcrylicSuitable for high-speed conversion,emulsion acrylic adhesive is anexcellent choice for food contact.We also have low-migration adhesivesfor pharmaceutical applications.Emulsion RubberEmulsion rubber adhesives are oftenmade from natural rubber thus requiringadditives to stabilize their performance.In many cases this limits food approvalcompliance. Stability to UV light andageing performance have to be evaluateddepending on application requirements.Hotmelt UV-AcrylicThese long-life adhesives suitapplications for secure industrial,outdoor, and chemical containers.Hotmelt UV-acrylic adhesive hasexceptional chemical resistance, andis heat resistant. It offers excellentperformance across every metric.Continued on next page -- 2LPM/EU/2020/June

Hotmelt RubberWith powerful adhesion and tack onthe broadest range of surfaces, hotmeltrubber adhesive is a high-performingoption for everything from cardboardto reusable coffee cups. It offers thebest low-temperature performanceand exceptional chemical resistance.It also adheres well on rough orcontaminated surfaces.Solvent AcrylicHigh adhesion on a wide variety ofsubstrates is one of the benefitsof solvent acrylic adhesives. Theseadhesives offer exceptional water, heat,and chemical resistance, and are thepreferred option for goods undergoingpasteurization or sterilization. They aresuperb for reclosure labels and tamperevident applications.Solvent HybridThese are the best performers onchallenging, textured or contaminatedsurfaces – designed for harshenvironments where exceptional adhesion,chemical and heat resistance are needed.Solvent hybrids combine the best ofacrylic and rubber adhesives, with superiorperformance and good conversion.Solvent SiliconeThe adhesive of choice for difficultapplications. Solvent silicone adhesivesstick to silicone surfaces such as airbagsin the automotive safety sector. They’revery good performers on flexiblesubstrates, like hoses and rubber pipes,and they answer the current marketneed for applications involving mouldedproducts contaminated by release agents.Solvent RubberPowerful solvent rubber adhesivesrange from ultra-permanent to cleanlyremovable. They have high chemicaland water resistance and are suitablefor challenging surfaces.Benefit ubberSolventAcrylicSolventRubberExcellent tack and adhesionAdhesion to a wide range of surfacesConversion (eg. die cutting, bleed)Low temperature performanceChemical resistanceFood and other approvalsn/aCostReclosuresS692NS7000S2000NGExample MR980RS517NR100S451S277Excellent3LPM/EU/2020/June

How to choose theright adhesiveWe have an adhesive for every application.Our emulsion, hotmelt, and solvent-basedadhesives can be engineered to meet yourapplication requirements.Choosing the right adhesive begins withconsidering industry compliance regulations,functionality of the label or packaging, andpreferably packaging design for recyclability.ComplianceRegulations designed to protect thehealth and well-being of the public arecritical in key industries such as foodand medicine. We work closely withcustomers, end-users and industryassociations to develop adhesives thatare compliant with both current andfuture regulations in the markets whereproducts are sold.FunctionalityAn adhesive is only complete when itsfunctionality matches application needs.For instance, it may need to deliver cleanremovability, or convenience in retail/home environments, or water-whiteningresistance in wine and spirits applications(to retain a luxury look). In someapplications, adhesive functionality mustprotect the integrity of the packaging,acting as a security solution by showingif the packaging has been tamperedwith. Other examples include a widevariety of resealable adhesives, givingthe best reclosure label performance onflexible product packaging. This includespersonal or household care wet wipes,where our reclosure labels keep oxygenout of the pack but retain moisture, andalso food packaging where the labelprevents spillages and keeps contentsin the pack.SustainabilitySustainability is a focus not only forbrand owners but across the wholeindustry. It’s our mission to lead theshift towards a circular economy,by developing sustainable labellingsolutions. We are continuing to developan adhesives portfolio that meetsrecycling guidelines and standards evenbetter than before.Choices range from adhesives thatremove cleanly from packaging in therecycling process, through to an adhesivethat is permanent and doesn’t remove atall (enabling reuse of durable, reusablepackaging). We are also continuing ourdevelopment work around compostablelabel solutions. No matter what your goalsare, we will find an adhesive solution thatenables your sustainability vision.4LPM/EU/2020/June

How to choose theright adhesiveApplicationWhen we design an adhesive we start with the application in mind. With dedicatedteams for different applications we follow closely the needs and requirements foradhesives, for instance in pharma or durable applications. These insights help us topropose adhesives when the application field is known.FacestockAdhesive choice is often also influenced by the label facestock. Our adhesives aretailored to the facestock material. We have a wide range of ready-made adhesives,for labelling materials that range from sustainably-sourced or recycled-contentpaper and film facestocks through to highly durable long-lasting filmic nentRemovableWash-offDurablesMainly paperfacestock1234567Adhesivechemistry:4567Mainly es, beers& spiritsPharmaPetrochemical & industrialApplication surfaceNot all application surfaces are the same, even if they look similar to the naked eye.Surface polarity influences the level of anchorage between the adhesive and theapplication surface.Polar surfaces such as PET and glass have a High Surface Energy (HSE), so are easierto stick to. Apolar surfaces such as PVC and HDPE have Low Surface Energy (LSE), soadhesives don’t stick as easily and are more challenging. We offer an adhesive portfoliodesigned to match the polarity profile of every surface type, and our team of adhesiveexperts is always on hand to help you find the right match for your own application.EasySmoothChallengingSlightly rough PolarGloss (glass,PET, metal,stainless steel) PolarMatt (glass, metal,stainless steel,PET) ApolarGloss plastics(PP, PE) ApolarMatt plastics (PVC,crates, HDPE, PP)Rough Coated cards, nonsilicone varnished Uncoated cards,textile, matt varnished,cardboard Planed wood,fiberboard, chemicaldrum (PE)Heavy rough orcontaminated Tyres, wood,carpets, concrete,stone, palletsExtremely difficult Silicone rubber, hotmetal, airbags Dusty and oilcontaminatedsurfaces5LPM/EU/2020/June

TemperatureApplication temperature and service temperature both need to be consideredto ensure that labels adhere during application, and also that they remain in placethroughout the product life cycle.Most of our adhesives are designed for ambient conditions, with a minimumapplication temperature of 5 C. Once in service, our regular adhesives can surviveservice temperatures between -40 C to 80 C. Note that label printers and brandowners can greatly extend that application range by using pressure-sensitive labeladhesives that go beyond the scope of regular service temperatures:Cold chain for cryogenicsS8093 for extreme heatOur cold chain adhesive is the firstof its kind, withstanding a servicetemperature as low as -196 C. It copeswith temperatures that are crucial forcutting-edge medical applications suchas vaccines, stem cells, clinical trials,and bio-banking.Our specially-engineered adhesives cancope with extreme heat. S8093 adhesiveresists short-term temperatures up to 220 C, making it an excellent choicefor the metal industry.Effect of application temperature on tackTackHow to choose theright adhesive-30-20-1001020Application temperature ( c)Room temperatureChilled foodsDeep freezeEvery adhesive has its own optimum application temperature window. A removableadhesive at room temperature is actually permanent at low temperature!6LPM/EU/2020/June

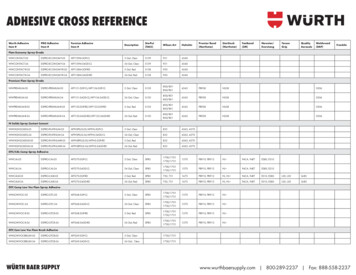

Cold temperature selection guideAdhesive behaviour during labelling, as affected by temperature:ApplicationAdhesiveCoating Technology4 CGeneralS2550Emulsion acrylicS2045NRubber-based hotmeltS2060NRubber-based hotmeltS2800Emulsion acrylicS2065NRubber-based hotmeltC2040Emulsion acrylicC2075NRubber-based hotmeltS2800Emulsion acrylicS2045NRubber-based hotmeltC2075NRubber-based hotmeltWine, spirits & beverageS2047NRubber-based hotmeltPetrochemical & industrialD170NRubber-based hotmeltS2085Rubber-based hotmeltS2045NPRubber-based hotmeltS2060NPRubber-based hotmeltC2020PEmulsion acrylicS451Rubber-based solventF1Rubber-based hotmeltTS8000Rubber-based hotmeltTS79Rubber-based hotmelt(in combination with paper labels)General(in combination with film labels)Pharma*Very rough surface labelling-5 C-10 C-15 C-20 CKey:AcceptableBest at these specific minimum application temperatures *Pharma cryogenic adhesives are designed for labelling at room temperature, with subsequent storage at -196 C isclaimer: Testing was conducted using an HDPE surface, according to FTM9. The ratings ( ) provide a directionalDindication of adhesive performance and should not be interpreted as a product footprint data. We recommendtesting a complete label construction for your specific application upfront, to ensure the desired level of adhesionduring labelling.7LPM/EU/2020/June

Core Adhesive PortfolioGeneral applications – Paper & VIHigher end( C)Direct foodcontactFatty cAdhesive with high initial tack, excellent adhesionand good low temperature performance on a widevariety of substrates.5-2080 EmulsionPermanentTrueCutTMS2550acrylicAdhesive with an increased initial tack, excellentadhesion and good low temperature performanceon a wide variety of substrates.0-2080 EmulsionPermanentTrueCutTMS2046acrylicAdhesive with a very high initial tack, excellentadhesion and good low temperature performanceon a wide variety of substrates.3-2080 S2000NEmulsionPermanentacrylicAdhesive with high initial tack, excellent adhesionand good low temperature performance on a widevariety of surfaces.0-2080 S2025NAdhesive with excellent tack and adhesion on awide variety of surfaces, including apolar, slightlyrough and curved. This adhesive is designedspecifically for application at room temperatureonto cardboard surfaces.5-4070 HotmeltPermanentA high-tack adhesive for smooth to slightlyrubberrough surfaces and good performance at lowertemperatures.0-4070 S2065N-5-570 HotmeltPermanentAdhesive with excellent tack and adhesion onrubbersmooth and slightly rough polar and apolar surfacesincluding cardboard. Very good performance atlower temperatures.0-4070 S445N-5-4070 EmulsionRemovableGood tack and adhesion, as well as clean removacrylicability across a broad spectrum of applications.Offered in combination with film and paper facestock.-15-3080 S2012HTEmulsionPermanentacrylicAdhesive with good tack and adhesion performanceon a wide range of surfaces, even at lowtemperatures. Very low bleeding characteristicsfor optimal use in hot laser and copier machines.0-2080 S2012HTCEmulsionPermanentacrylicAdhesive with high initial tack and adhesion on awide range of surfaces including cardboard.Very low bleeding characteristics for optimal usein hot laser and copier machines.0-2080 LR2NGood tack and adhesion in combination with cleanremovability across a broad spectrum ofapplications. The adhesive is designed for optimaluse in laserprinters and copier machines.-15-3080 EmulsionPermanentHigh adhesion in both ambient and heavily chilledacrylicconditions, suitable for direct food applications.Excellent application performance on a wide rangeof surfaces.-15-50120 C2040-15-5080 ptionS2045NHotmeltPermanentrubberAdhesive with excellent wettability and adhesionto polar and apolar surfaces. Designed for automaticlabel dispensing, in particular for air blowing dispensing systems at cool temperatures down to 0 C.S2060NHotmeltPermanentrubberHighly aggressive adhesive suitable for use ondifficult and rough surfaces, such as rubber goods,fibre drums and plastic containers, excellentperformance at low lsionPermanentacrylicGood adhesion at low temperatures and freezerconditions, good tack and adhesion to a wide varietyof surfaces such as cardboard, plastic films, HDPE,PP and PET.Minimumapplicationtemp. ( C)Lower end( C)Service temp.Food approvalContinued on next page -- 8LPM/EU/2020/June

General applications – Paper & VI (continued)Service temp.FoodapprovalLower end( C)Higher end( C)Direct foodcontactHotmeltDeep freezeGood tack and adhesion across a broad spectrumrubberof applications at low temperatures and freezerconditions.-25-5070 WX6030EmulsionWash-offacrylicPermanent wash-off adhesive used in combinationwith paper facestock.Typically used in applicationslike work in process and Ship & Track, e.g. labellingof plastic crates.5-2080 S2660Adhesive with high initial tack, good adhesion onpolar and apolar surfaces and good mandrelperformance. Recommended for difficult labelshapes and high speed C2075NEmulsionPermanentacrylicGeneral applications – FilmDirect foodcontactFatty foodcontact5-2080 EmulsionPermanentA clear general purpose adhesive for smooth toClearCutTMS7000acrylicslightly rough surfaces enabling high speedconverting and dispensing with thin filmic facestocks.5-2080 S4000NAn ultra-clear adhesive for smooth polar surfaces,excellent wet-out with PET liners (no-label look).10-20100 A high-tack adhesive with excellent adhesion andwet-out performance even for rough surfaces suchas HDPE and for applying large labels.0-2080 HotmeltPermanentA high-tack adhesive for smooth to slightly roughrubbersurfaces and good performance at lowertemperatures.0-4070 ecycling)5-2060 HotmeltDeep freezeGood tack and adhesion across a broad spectrumrubberof applications at low temperatures and freezerconditions.-25-5070 S2800-15-50120 ylicDescriptionA clear general purpose adhesive for smooth toslight rough surfaces.S2045NA clear adhesive enabling PET bottle recycling.Adhesive is deactivated during the PET recyclingprocess, allowing the facestock, ink and adhesiveto cleanly separate from the PET flakes.C2075NEmulsionPermanentacrylicHigh adhesion in both ambient and heavilychilled conditions, suitable for direct foodapplications. Excellent application performanceon a wide range of surfaces.Minimumapplicationtemp. ( C)Higher end( C)Food approvalLower end( C)Service temp.Fatty foodcontactMinimumapplicationtemp. ( C) 9LPM/EU/2020/June

SolventPermanentAn ultra clear adhesive, high adhesion on glassacrylicbottles, withstand temperature extremes(pasteurization) and offers excellentwater-whitening resistance.10-40115S7400EmulsionPermanentacrylicA clear adhesive for prime beer label applications,enabling high speed converting and dispensing withthin filmic acrylicAn ultra permanent clear adhesive for labelling ofreturnable bottles or water-gallons that withstandsup to 30 product life-cycles, including the hightemperature caustic baths in the washing process.5-2090EmulsionWash-offAdhesive for returnable glass bottles, facilitatingacryliceasy label removal in conventional bottle washer.Features excellent wet-out, clarity andwater-whitening resistance.5-2070W7600Adhesive for returnable glass bottles, facilitatingeasy label removal in conventional bottle washer.5-2060 A clear adhesive for labelling of one-way glassbottles, facilitating clean separation of selfadhesive label from glass particles (cullet) enablingclean glass recycling process.5-2060 nWash-offacrylicGRX1EmulsionWash-offacrylicWine & spirits Direct foodcontactFatty foodcontactS2030EmulsionPermanentacrylicAdhesive for difficult label shapes and high speedconversion, excellent die-cutting and strippingproperties and very good mandrel performance.5-2080 S2047NRubberPermanenthotmeltAdhesive with high tack and adhesion on difficultbottle surfaces, good performance at lower temperatures and an excellent ice bucket resistance.5-3070 WLAEmulsionWash-offacrylicAdhesive for labelling of returnable wine and spiritsglass bottles, allows paper labels to be easilywashed off in a hot alkaline nent wash-off adhesive, available incombination with decorative paper facestocksfor wine bottle labelling. Wash-off temperature –min. 21 C, optimal at 60 C. No additives needed.5-2080S700SolventPermanentacrylicHigh-tack adhesive with good adhesion on a varietyof surfaces, including apolar and rough, suitable forsmall diameter labels.5-4090Z1010Adhesive using the Aqua OpaqueTM technologyreducing the loss of opacity in wet conditions.Provides excellent diecutting and strippingproperties and enables high speed manentacrylicDescriptionMinimumapplicationtemp. ( C)Higher end( C)Food approvalLower end( C)Service temp.Fatty foodcontactHigher end( C)Direct foodcontactFood approvalLower end( C)Minimumapplicationtemp. ( C)Beer & beverageService temp. 10LPM/EU/2020/June

EmulsionPermanentacrylicSX6030Certified compostable adhesive, good initial tackand adhesion on a wide variety of surfaces.5-2080 Adhesive supporting compostability, featuringgood initial tack and adhesion on a wide variety ofsurfaces. Certified OK Compost in combinationswith specific facestocks.5-1550 Adhesive for security labelling, e.g. traditional anddry VOID labels, box-tear. Very high adhesion andtack, especially on rough surfaces, good chemical,heat and humidity resistance.SolventPermanentAdhesive for use in security seal applications incosmetics, electronics and pharmaceutical industry.acrylicHigh adhesion and tack on variety of surfaces, goodchemical, heat and UV resistance.Higher end( C)S700Technology5-40905-4090 Food approvalLower end( C)AdhesiveMinimumapplicationtemp. ( C)Service temp.Fatty foodcontactEmulsionPermanentacrylicDirect foodcontactS9500DescriptionDirect foodcontactTypeHigher end( C)TechnologyMinimumapplicationtemp. ( C)AdhesiveFood approvalLower end( C)Service temp.Fatty foodcontactCompostable 11LPM/EU/2020/June

Reclosure & removablesLower end( C)Higher end( C)MR980RSolventReclosureacrylicAdhesive with the highest resistance to solventsused in more demanding household wet wipesapp lications. Exhibits excellent clarity, UVresistance, clean removability and a smooth peelfrom PET, PE and PP sive with very good moisture and solventresistance for personal care, cosmetics & baby wetwipes reclosure applications. Exhibits excellentclarity and UV resistance, clean removability anda smooth peel from PET, PE and PP surfaces.5-2080 R1490MAdhesive with moisture and solvent resistance forpersonal care, cosmetics & baby wet wipes reclosureapplications. Adhesive exhibiting excellent UVresistance, clean removability and a smooth peelfrom PE and PP surfaces.5-2080 HotmeltReclosureSemi-permanent adhesive for cosmetic wipesUV acrylicapplications featuring excellent clarity, durability,chemical and UV resistance. Suitable for low-surfaceenergy surfaces like PE, PP.5-2080 R5050-15-2570 EmulsionRemovableA clear, UV resistant adhesive featuring high ageingacrylicstability for removable labels, e.g. for industrial andcosmetics applications. Offered in combination withfilm facestock.0-40100 C3NFEmulsionRemovableacrylicAdhesive featuring high ageing stability forremovable labels and a very good performance onsmooth & flat surfaces such as uncoated (window)glass. Offered in combination with film facestock.0-40100 UR400SolventUltrarubberRemovableAdhesive with ultra-low peel, ideal for book labelsand large, short-term labels where highest level ofremovability/easy peel is required. Offered incombination with paper facestock.5-2080UR500Adhesive suitable for ultra-removable labelsespecially if there is a requirement for automaticdispensing onto a product. Offered in combinationwith paper facestock.-20-4080R100SolventRemovableA superior, smooth peel removable adhesive forrubberpaper labels, suitable for many surfaces such asPET, PP, greeting cards, stainless steel and glass.Good initial tack and superb low temperatureperformance.-20-4080 R5000NEmulsionRemovableGood tack and adhesion, as well as cleanacrylicremovability across a broad spectrum of applications. Offered in combination with film andpaper facestock.-15-3080 R5000N HTEmulsionRemovableacrylicHigh tack and adhesion in combination withexcellent and clean removability from mostsurfaces; polymeric (e.g. PET, PP, ABS), card andfibre board, aluminium, stainless steel or glass.-15-3080 R5100A semi-permanent adhesive, widely used forrepositionability purpose, e.g. on wine bottles.Offered in combination with paper facestock.-20-4070 iptionR3200NEmulsionReclosureacrylicAdhesive with superior and clean removability forreclosure lablling solutions for food packaging incl.applications involving direct labeling of moist andfatty foodstuffs and deep freeze emovablerubberFatty foodcontactMinimumapplicationtemp. ( C)Direct foodcontactServicetemp.Food approval 12LPM/EU/2020/June

Automotive, electronics & industrialS277SolventPermanentrubberHighly aggressive permanent adhesive withexcellent tack and adhesion to a wide variety ofsurfaces including rough and apolar, e.g. freshlymoulded HDPE bottles.5-2080S445NHotmeltPermanentrubberHighly aggressive adhesive suitable for use ondifficult and rough surfaces, such as rubber goods,fibre drums and plastic containers, excellentperformance at low temperature.-5-4070 S477EmulsionPermanentacrylicClear adhesive for oil can applications, featuringexcellent initial tack, adhesion, wet-out performanceeven on apolar surfaces such as HDPE. Improvedtemperature water, solvent and chemical resistance.0-2080 S8002EmulsionPermanentacrylicAdhesive with high adhesion to a wide range of polarand apolar surfaces, good initial tack and chemicalresistance. S8002 is suitable for labelling electronichome appliances and curved surfaces.5-40150S8020EmulsionPermanentacrylicClear adhesive with good adhesion performanceon polar and apolar surfaces, excellent temperatureand UV esive for labelling of durable goods, good heatand UV resistance and good adhesion on polarsmooth surfaces like metal, ABS, Polystyrene,Polycarbonate and Nylon.5-40150AL170SolventPermanentacrylicStrong adhesive for polar surfaces (metals) with veryhigh ageing stability and excellent chemicals andheat resistance. Adhesive for cable labels or overlaminating purposes in automotive industry.0-40150S8015SolventPermanentacrylicHigh strength adhesive, high initial tack, adhesionand shear and high chemical and temperatureresistance. Offers strong permanent bonding todifficult surfaces, such as apolar plastics andcoatings used in automotive industry7-40150S8030All-round performing high strenght adhesive, goodadhesion to polar and apolar surfaces, long termdurability and good chemical resistance.7-40150HotmeltPermanentHigh-tack adhesive for apolar and rough surfaces,UV Acrylicsuperior cohesion and good chemical andtemperature hesive(RHA)Universal Rubber Hybridised Adhesive (RHA) withhigh adhesion on wide variety of surfaces includingtextured and apolar. Features high chemical andtemperature hesive(RHA)Rubber Hybridised Adhesive (RHA) with extremelyhigh adhesion on wide variety of surfaces includingtextured and apolar. Features high chemical andtemperature resistance.5-40150S8092SiliconePermanentSilicone adhesive suitable for applications onsurfaces contaminaded by silicone. Widely used inautomotive safety systems (airbags, hoses, mouldedparts icBondStructual bond adhesive, remains removable until itis pressed and heat activated to reach structuralbond on various surfaces.10-4080S3100Adhesive with very high tack and adhesion to a widevariety of surfaces including apolar.5-20120HotmeltPermanentUV acrylicFatty foodcontactHigher end( C)Direct foodcontactLower end( C)Minimumapplicationtemp. ( C)Service temp.Food approval 13LPM/EU/2020/June

TyresTS8000HotmeltPermanentrubberAdhesive with superb anchorage to curved andextremely irregular surface of tyres, not affected bycontaminants such as mould release agents orcomponents migrating from the rubber. Offered incombination with film facestock.0-2070TS79HotmeltPermanentrubberAdhesive with superb anchorage to curved andextremely irregular surface of tyres, not affectedby contaminants such as mould release agents orcomponents migrating from the rubber. Offered incombination with paper ve with superb anchorage to curved andextremely irregular surface of tyres, not affectedby contaminants such as mould release agents orcomponents migrating from the rubber. Offered incombination with paper VI facestock.0-2070F1HotmeltPermanentrubberAdhesive for difficult rough, uneven and absorbingsurfaces, e.g. tyres, wooden crates, jute sacks. F1 isan extremely soft adhesive with a tendency to flow.0-4050TS8018Adhesive developed for the tyre manufacturingprocess, to be used in the vulcanization process ona variety of green tyres, providing extremely highfinal adhesion trubberDescriptionPharmaceuticalFatty foodcontactHigher end( C)Direct foodcontactLower end( C)Minimumapplicationtemp. ( C)Servicetemp.Food approvalHigher end( C)Direct foodcontactFatty k and good adhesion on glass, PE, PP andcardboard. Developed for applications on cylindricalcontainers, e.g. pill bottles. Adhesive suitable forautoclave, gamma and ETO sterilisation.0-2080 S692NPEmulsionPermanentacrylic/low migrationA clear adhesive with lowest risk for migration,excellent UV resistance, good adhesion on polar andapolar surfaces. Adhesive for applications on smallcylindrical containers, curved surfaces and suitablefor use in labels to applied on high speed productionlines. Can be sterilised in autoclave, gamma and ETO.5-2080 S4000N LUMEmulsionPermanentacrylicAn ultra-clear, luminescent adhesive for use withclear filmic face and liner materials (no-label look),enabling the detection of mising label

Every adhesive has its own optimum application temperature window. A removable adhesive at room temperature is actually permanent at low temperature! S8093 for extreme heat Our specially-engineered adhesives can cope with extreme heat. S8093 adhesive resists short-term temperatures up to 220 C, making it an excellent choice for the metal .