Transcription

ASSET INTEGRITY INTELLIGENCETHE PIPING INTEGRITY MANAGEMENT CHALLENGELAZA KRSTIN, Principal Consultant at ABBFERNANDO VICENTE, Asset Integrity & Reliability Management Consultant at ABBVOLUME 23, ISSUE 2MARCH APRIL 2017

THE PIPING INTEGRITY MANAGEMENTCHALLENGEBY: LAZA KRSTIN, Principal Consultant at ABBFERNANDO VICENTE, Asset Integrity & Reliability Management Consultant at ABBINTRODUCTIONThe mechanical integrity of process piping is critical to effectively manage process safety, environmental hazards, and business risks in the oil & gas, chemical, petrochemical and powerindustries. Operating companies seek to achieve cost-effectiverisk management and stay in compliance with state and federalregulations. So, how does one determine the optimum levels ofinspection and maintenance for piping? The scale and complexity of the facility (thousands of feet of process piping in a typical refinery), significant costs related to inspection (insulationremoval, provision of access,) variety of inspection techniques,and other factors present significant challenges in establishing amechanical integrity strategy for piping. D oes the inspector know the key hazards and vulnerabilities/deterioration mechanisms for piping, and understand therisks to the business? Management: “We have a Risk-Based Inspection system” Reality: In the authors’ experience with clients around theworld, Risk-Based Inspection (RBI) approaches often do notadequately identify the specific vulnerabilities of piping, ortranslate these into effective inspection plans. Management: “Our inspection regime complies withAPI 570” Reality: This mention of API 570 (American PetroleumInstitute) usually means the site has a statistical approachThese challenges are compounded by piping and process complexbased on Thickness Measurement Locations (TML), in theities, misunderstandings and underestimating the importance ofbelief that corrosion is uniform, so its condition can be deterpiping. The reality is that many asset integrity management promined by thickness measurements at defined locations.grams focus on pressure vessels, heat exchangers, and fired heaters without considering the piping systems as an important asset. Let’s look more closely at some typical myths.A process piping system failure or leakage could have a signifi- Myth No.1: Pressure vessels are more important for plantcant impact on the business due to interruptions in production, orsafety than piping.a catastrophic effect if an explosion or fire occurs or a hazardous Reality: Contrary to what many plant personnel might think,fluid is released.piping is more likely to fail than a pressure vessel. IncidentThis article highlights some of the myths, the challenges, and thedata from a variety of sources shows that approximately 40%good practices related to piping integrity management activitiesof major plant losses are due to piping—the largest singlein order to help inspection and maintenance managers make thecause. For example, the UK’s Health and Safety Executiveright decisions to develop cost-effective piping inspection plansReport RR672 "Offshore Hydrocarbon Release 2001-2008"without compromising the asset’s reliability or performance.revealed that piping is the most common equipment typeto experience releases, together with associated equipmentPART 1 – THE CHALLENGEsuch as flanges and valves.The following statements from site management illustrate thenature of the “piping integrity management challenge”:The myth may arise from the situation in most countries wherelegislation focuses on pressure vessels rather than piping.Management: “We meet all our legal obligations” Myth No.2: The requirements for managing piping areReality:specified in legislation. So compliance with regulations The primary purpose of legislation is to protect workers,is sufficient to assure the integrity of piping.the public and the environment. Legislation does not cover Reality: Legislation in many countries does not cover piping,the risks to the business from an incident.or only covers certain categories of piping. For example, the In most countries, legislation does not adequately coverEuropean Pressure Equipment Directive applies only to thepiping (if at all).design and construction of new piping and does not applyto piping equal to or less than NPS 1 (Nominal Pipe Size Management: “Inspection is done by the official thirdin inches). In some other regions, “larger bore” piping hasparty inspector; we get a certificate for continuedmore focus than “small bore” piping (based on stored energyoperation from him”considerations). This can lead to an impression that small-boreReality:piping is not important. However, most mechanical engineersknow that many leaks involve small-bore piping because of How much piping is actually inspected?the range of loads to which it can be subjected, its inherent2Inspectioneering JournalMARCH APRIL 2017

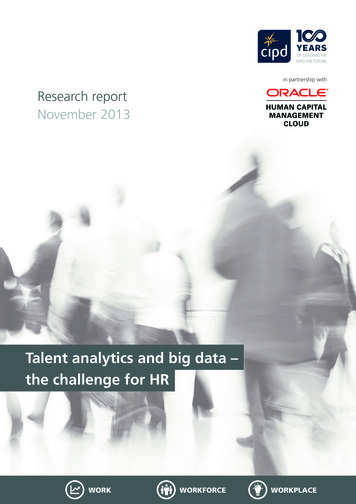

vulnerability to failure (corrosion, vibration/fatigue, mechanical damage, etc.), and the sheer amount of small-bore pipingin a typical facility. It is worth noting that for most processplants (even large-scale refineries) the average pipe size (basedoverall length) is between NPS 2 to NPS 4. There are manythousands of feet of piping in a typical process plant, andmuch of it is not readily accessible for inspection.shutdowns and overhauls. A Bolted Flange Joint Assemblyis a complex mechanical device; therefore, a Joint IntegrityProgram (JIP) should be an integral part of every piping integrity management plan including quality of materials selected,well-trained competent technicians and effective management controls. The American Society of Mechanical Engineer’sASME PCC-1 “Guidelines for Pressure Boundary Bolted FlangeJoint Assembly” gives guidance for the training and qualification of bolted joint assembly personnel, and may be used todevelop joint assembly procedures for a broad range of sizesand services as well. ailures of small bore piping may be regarded as “minor incidents,”Fbut these can be early warnings of major weaknesses in management systems and plant practices. And each incident representsa potential disruption to production and places plant personnelunder increased risk.The Business PerspectiveAs organizations are coming under increasing pressure to deliver Myth No.3: Piping integrity is the responsibility of themore for less, the challenge for the inspection and maintenance“Inspection Team.”managers is to develop a cost-effective piping inspection plan. Reality: Piping integrity is everyone’s responsibility. ManyFrom the asset management point of view, “cost-effective” usupiping incidents are caused by operational excursions outside ally represents the lowest combined business impact of costs,of the design limits or ineffective management of change,risks and performance, or the maximization of net value, over thenot simply “deterioration” or “ineffective maintenance.”piping life cycle (design, construction and installation, commisImplementing an effective operational integrity programsioning, operation, maintenance and decommissioning).(e.g., Integrity Operating Windows) helps focus the inspectionplan (scheme of examination) on the key vulnerabilities andlocations where potential problems may occur. Myth No.4: Piping supports are not included inthe inspection plan; they are not part of thepressure envelope. Reality: The integrity of a piping system is not only dependent on the soundness of the “pressure envelope” but also onthe pipe supports. A proper support system is required to takethe weight of the pipe (including its contents, fittings, valves,etc.), to control movement of the piping, and protect sensitiveequipment, through all its operational modes.Figure 1. Optimum value achieved by optimizing total cost/risk/performanceimpact. Source “Asset Management – an anatomy” Institute ofAsset Management.I f supports are not properly designed, installed and maintained,excessive stress can be created in the piping system, and excessive loads can be transmitted to support structures and connected The challenge for managers is to answer the following questions:equipment. This may exhibit as pipe deformation, leaking joints, D o you understand the complexities and vulnerabilitiesdamage to connected equipment, and failure at welds and otherassociated with your piping systems (corrosion, creep, stress“high stress” points. If the excessive stress coincides with detecorrosion cracking, fatigue, etc.) and how these will changerioration mechanisms (e.g., internal and external corrosion andover time?stress corrosion cracking), premature pipe failure may occur. H ow much piping should you inspect and how often?Experience across the process industries indicates that corrosionAll of it, or some of it? How do you decide what and howunder pipe supports is a major area of concern for plant mainteoften to inspect?nance engineers and inspectors. API RP 574 (supplements the API570 piping inspection code), provides guidance how to inspect F or corrosion under insulation, should you remove 100% ofpiping supports.the piping insulation to fulfil the inspection plan? Myth No.5: Flanges are not an integrity issue - the maintenance team go round and tighten flanged joints withmanual torque wrenches. C an you demonstrate the business consequences on yourpiping systems when faced with management demands toreduce capital investment or maintenance budgets? Reality: Incident reports indicate that flanged joints areinvolved in a large proportion of piping failures. In addition,a number of operating companies cite a significant number of leaks from flanged joints during start-up following C an you easily identify which inspection could be deferredwhen there is funding or cash flow constraints? D o you have the appropriate data and information to supportyour piping integrity management decision-making?MARCH APRIL 2017Inspectioneering Journal3

Do you know if your people have the right competencesand capabilities to manage your piping integrity management plan?To answer these questions properly, organizations should developand implement a sound piping integrity management plan.PART 2 – IMPROVEMENT USING GOODPRACTICESvariables in order to achieve the desired results (i.e., productwithin specification, safe operation, reliability, etc.). These limits are generally called operating limits or operating envelopes.It is important that operating boundaries are established,and documented, including allowable excursions duringstart-up and shut-down of facilities. It is equally importantthat systems are in place to communicate when piping hasbeen operated outside of the agreed limits, so that appropriateaction can be taken.In Part 1, we looked at the challenges faced by operating companies to cost-effectively manage the integrity of their pip A good practice for piping is the establishment, implemening systems. The scale and complexity of piping systems in atation, and maintenance of integrity operating windowstypical process plant presents technical, organizational, and(IOWs). IOWs are a specific subset of these key operatingpractical challenges. Legislation in most countries does notlimits that focus on maintaining the integrity or reliabilityprovide much help:of process equipment. Typically, IOWs address issues that The primary purpose of legislation is to protect workers, theinvolve process variables that, when not adequately monitoredpublic, and the environment.or controlled, can impact the likelihood and rates of deterioration, which may result in a loss of containment. IOWs are It tends to ignore piping - this is interpreted to mean thatthe link between operation and inspection, and help to detectpiping is less of a concern (and requires less attention) thanand communicate changes in the process that can threatenpressure vessels.the integrity and reliability of pressure systems. Excursions Legislation does not address risks to the business in general—outside of IOWs should be communicated to relevant personloss of inventory, loss of business, damage to reputation.nel who can assess the implications for piping integrity. Manycompanies have set up automatic notification via dashboardsConsequently, operating companies should do more than theor emails so that all the relevant information can be presentedlegislation requires—they should manage the wider businessfor assessment as quickly as possible. API RP 584 providesrisks. The “better companies” do!guidance how to implement IOWs.Applying industry practices is required throughout the entire lifeInspection and Maintenancecycle of the piping. The life cycle will include the following stages: Inspection, maintenance, and repair of piping systems can be1. Design, construction and installation (early failure stage)difficult due to piping configuration and geographical layout.The piping inspection plan could consume a large portion of2. Commissioning, operation and maintenancethe maintenance budget if it is not designed, planned, and(in-service stage)implemented properly. Generally, process plants (depending3. Decommissioning (wear-out stage)of the plant size) can have between 1,000-5,000 piping systems.For that reason, inspection resources for piping should beDesign, Construction and Installationappropriately focused using systematic, consistent techniques,Piping systems need to be designed, manufactured, fabricated,such as RBI and/or criticality analysis, to identify which sysinstalled, inspected, and tested in compliance with their specificatem to inspect and what inspection methods to employ. Thetions. However, experience shows that specific areas of weaknessinspection plan should identify what, where, when, and howexist during this early stage. For example, it is not uncommonpiping should be inspected.for the piping to be incorrectly installed (e.g., pipe is over-stressedduring assembling process, wrong welding procedures, bad prac- API 570 “Piping

API RP 574 (supplements the API 570 piping inspection code), provides guidance how to inspect piping supports. Myth No.5: Flanges are not an integrity issue - the main-tenance team go round and tighten flanged joints with manual torque wrenches. Reality: Incident reports indicate that flanged joints are involved in a large proportion of piping failures. In addition, a number of operating .