Transcription

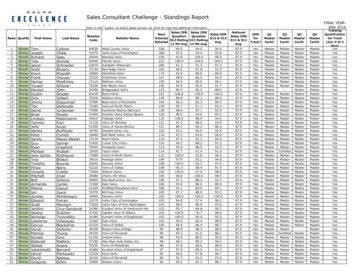

Technical Manual

AEROSOLSEquipment & Implement EnamelsEngine EnamelsHi Temp PaintSandable PrimersProfessional SeriesSelf Etching Primer122222SPECIAL COATINGS & SEAM SEALERSRubberized UndercoatingRocker GuardRocker Panel ProtectorSeam & Joint SealerUrethane Sealer & Adhesive33333MISCELLANEOUSDouble Sided Urethane TapeCut-Off WheelsJet Strip Paint StripperRazor BladesShop WipesUrethane AcceleratorWeather Strip AdhesiveUltimate Hand Cleaner44444445Mixing CupsClean SheetsPaint SticksPaint StrainersCream HardenerSpreaders556666MASKING & PREP PRODUCTSMasking PaperPlastic SheetingHi Density Plastic SheetingSeat Covers7788Floor MatsWheel Maskers88BODY FILLERSLightweight Body FillerPremium Lightweight Body FillerFiberglass Reinforced Body Filler2K Glazing & Finishing Putty9101112Fiberglass ResinFiberglass ClothFiberglass Mat131414SOLVENTS, THINNERS & REDUCERSLacquer ThinnerEnamel ReducerUrethane ReducerSpray Gun CleanerVM&P Naphtha151515151515Basecoat ReducersWax & Grease RemoverAnti Static Wax & Grease RemoverAdhesive Remover16171717CATALYSTSWet Look Enamel HardenerSynthetic Enamel Hardener181818PRIMER & SEALERSSuper Etch Precoat PrimerEtch Fill Self Etching PrimerEpoxy PrimerFast Prime1920212223Urethane PrimerHi Prime Lacquer PrimerBarrier Coat Waterborne PrimerAcrylic SealerShadeSystem 2K Sealer2425262728CLEAR COATSProduction ClearQuick Spot Clear293031Urethane ClearHi Solids3233BUFFING & POLISHING PADSCompounding PadsPolishing PadsDouble Sided PadsTie On Bonnets35353535Foam Buffing PadsVented Foam PadsCool Curve Foam Pads6” Foam PadsMini 3” Pads3434343434DETAIL ITEMSWash MittScrub SpongeWax ApplicatorCheese ClothChamois (synthetic)353535353535Flexible PrimerBlack Trim PaintBlack Bumper PaintCut In Clear2222

Equipment & Implement 12647164026400Black GlossWhite GlossSilver AluminumNew Caterpillar YellowOld Caterpillar Yellow (light)Harvester RedJohn Deere YellowJohn Deere GreenFord BlueFord GrayAllis Chalmers OrangeSchool Bus YellowLow Gloss BlackMassey Ferguson RedRed PrimerGray PrimerSubstrates Fully cured finishes - Sand with 240 - 320 grit paper Steel - Sand with 80 - 180 grit & prime with Equipment & Implement PrimerMixing Reduction is not required. If reduction is preferred, reduce with VM&P Naphtha (for spray applications) or Mineral Spirits (for brushing or rolling applications) at a 16:1 ratio.Set Up TechTip/Needle:Spot Air Pressure:Overall Air Pressure:Coverage1.4mm to 1.6mm35 - 45 psi / HVLP 5 to 10 psi at cap45 - 55 psi / HVLP 5 to 10 psi at cap500 sq ft /gallon @ 1 milApplicationProduct can be rolled, brushed, airless or compressed air sprayed. Apply 2 - 3 coats until sufficient coverage or hiding is achieved. Allow each coat to become hand slick before additional coats are applied.DryingDries to the touch in 4 to 6 hours.Pot Life: Indefinite if sealedPhysical DataVOC RTSHumidity ResistanceSalt Spray Test 3.5 lb./gallonVery goodVery goodMaster TipsDo not apply in direct, hot sunlight. Surface & air temperature should be between 40-90 F duringapplication and dry time. Catalyzation is not recommended.Page 1

ALL PURPOSE ENAMELSAB600Gloss BlackAB605Flat BlackAB670Gloss WhiteAB642Bright RedAB680Chrome AluminumENGINE ENAMELSAB613Universal BlackAB601Ford BlueAB606Ford Dark BlueAB607Chevy OrangeAB609GM BlueAB625Ford/Universal RedHI-TEMP PAINTSAB602BlackAB604WhiteSANDABLE PRIMERSAB694Red OxideAB699GrayAB698BlackNet Weight12 oz12 oz12 oz12 oz12 oz11 oz11 oz11 oz11 oz11 oz11 oz11 oz11 oz12 oz12 oz12 ozProfessional Series998894139143908391039648Self Etching PrimerFlexible PrimerSatin Black Trim PaintFlexible Bumper Black GlossFlexible Bumper Original BlackCut-In Clear12 oz12 oz11 oz12 oz12 oz11 ozPage 2

Rubberized Undercoating - Non-paintableAn asphaltic, non-paintable, rubber and wax coating which contains no asbestos fiber and isfast drying. Perfect for undercarriage protection, sound deadening, and wheel well coating.Helps prevent rust. Very flexible and will not crack or peel. Black color.Part #7668DescriptionRubberized UndercoatSize15.45 oz/439 grRocker Panel Guard - PaintableAn economical gravel guard that offers a tough and flexible paintable coating. The coating’s rubberizedbase remains pliable to absorb impacts and resists chipping. Use on rocker panels, gravel shields, innerpanel sound deadening, trunk panels, chassis, wheel wells, etc. Seals out moisture to protect from theformation of rust and corrosion. Chip resistant and will not pinhole. Do not apply sealer over this product. Black color.DescriptionSizePart #7658Rocker Panel Guard - Black14 oz/396 grRocker Panel Protector - PaintableA premium fast drying permanent textured coating designed for protecting rocker panelsand valance panels from stone chips and other road abrasion and weathering. Perfect forrocker panels, gravel shields, fender wells, trunk panels, inner panel protection, etc. It’ssuper strong adhesion and durability offers a coating that will not flake or chip off, remainsflexible and will not crack. Do not apply sealer over this product. Available in 850 ml“schutz” style cans in black or beige.DescriptionSizePart #7652Rocker Panel Protector-Black28.7 fl oz/850ml7653Rocker Panel Protector-Beige28.7 fl oz/850mlSeam & Joint SealersA very flexible seam sealer for all types of auto body sealing. Excellent tooling time afterapplication without the use of solvent. Tooling with solvent will offer an extra slick appearance. Paintable in 30 to 60 minutes after application. Skin time is approximately 10 minutes.Sets to a firm abrasion resistant seal that’s tough with excellent flexibility. No cracking orpeeling. Great for use on cowl seams, floor seams, door skins, wheel house seams, trunkseams, etc.Part #760576077612DescriptionSeam & Joint Sealer-BeigeSeam & Joint Sealer-BlackSeam & Joint Sealer-ClearSize10 oz/300ml10 oz/300ml10 oz/300mlUrethane Sealant & AdhesiveA one component polyurethane adhesive & sealant for areas that are subjected to mechanicalstress, shock, vibrations, and sudden impacts. The moisture cure, non sag system curesthrough atmospheric moisture to a rubber like adhesive and sealant. The flexibility of the product will not crack. Paintable in 30 minutes. Product also offers filing and patching propertiesthat can be sanded. Excellent adhesion to aluminum bare metal primed and painted, FRP, SMC,and RIM. Excellent weather resistance. Great for bonding roof panels, floor panels, interior andexterior body side moulding and trim.Part #7627DescriptionUrethane Sealant Adhesive-BlackSize10.5 oz/310mlPage 3

Urethane AcceleratorReduces dust/tack free and tape times. Autobody Master urethane accelerator can be added tourethane coatings such as primers, color coats, and clears when improved curing times aredesired. Compatible with all major paint urethane systems. Very concentrated, recommended 1/2ounce per sprayable quart. Great for cool shop conditions.DescriptionSizePart #8220Urethane AcceleratorPintJet Strip Paint StripperFast and efficient removal of the toughest automotive & industrial finishes. Fast acting andeffective on conventional and two component primer and paint systems. Jet Strip can beused on metal or masonry. Loosened finish can be flushed off with water or solvent, orremoved by scrapping. Non-Flammable for your safety.DescriptionSizePart #7713Jet Strip Paint StripperGallonWeather Strip AdhesiveBonds all types of rubber and vinyl to doors and trunks. Waterproof,flexible and dries fast. Color: AmberDescriptionSizePart #7001Weather Strip Adhesive135 mlDouble Sided TapePremium double sided high density urethane foam tape coated with high temperature and UV resistance acrylic adhesive on both sides. This tape is excellent for bonding heavy moldings and trimwith it’s superior holding power.DescriptionSizePart #AV7682DDouble Sided Urethane Tape1/2” x 60’AV7683DDouble Sided Urethane Tape7/8” x 60’7684Double Sided Urethane Tape1/2” x 15’7685Double Sided Urethane Tape7/8” x 15’Cut Off WheelsAbrasive reinforced wheels. Cuts all ferrous materials with ease.Disks measure 3” x 1/16” x 3/8”.DescriptionSizePart #1150Cut Off Wheels 50/box3”x1/16”x3/8Razor BladesPremium quality #9 Steel back razor blades. Packaged 100 per safety dispenser.DescriptionSizePart #1100#9 Razor Blades 100/box#9Shop WipesBarrel type roll 2 ply soft and absorbent towels. Over 1000’ per roll. ShopWipes come in an easy tote-a-long box so you can move the towels to the job. Absorbstwice as much solvent than a cotton shop rag. Roll can be removed from box and willfit most stationary dispensers.DescriptionSizePart #1800Shop Wipes 1000/rollPage 4

Ultimate Hand CleanerSpecially formulated hand cleaner that offers the ULTIMATE in cleaning and conditioning power. Easilyremoves and powers away urethane adhesives, sealers, and paints. Also loaded with skin conditionersthat offers antibacterial properties to help heal injured hands and keep hands healthy.DescriptionSizePart #602Hand Cleaner2oz608Hand Cleaner8oz616Hand Cleaner16oz620Hand CleanerGallonMixing CupsEconomical disposable mixing cups featuring the most popular mixing ratios. Cupmeasures 32 fluid oz. of product and offers a convenient lid for temporary storageof product.DescriptionSizeUnits/CasePart #1010Mixing Cups32oz1001011LidsFits 32oz100Clean SheetsNon porous sheets for mixing body fillers and putties. Sheets will notabsorb resins like cardboard. Disposable tear off sheets gives you a cleanmixing surface every time.DescriptionSizePart #CS100ABM Clean Sheets 100/mix pallet12” x 12”Page 5

Paint SticksPart #520DescriptionPaint Sticks approx. 500/boxPaint StrainersMedium nylon meshPart #1000DescriptionPaint Strainers 1000/boxCream HardenersIndividual cream hardeners for all body fillersPart #431443154319432043244325DescriptionWhite Cream HardenerWhite Cream HardenerBlue Cream HardenerBlue Cream HardenerRed Cream HardenerRed Cream HardenerSize1 oz2.75 oz1 oz2.75 oz1 oz2.75 ozSpreadersIndividual spreaders.Part #12011204120512061209121212131215DescriptionBlue Glazing SpreaderYellow SpreaderYellow SpreaderYellow SpreaderBody Filler KnifeBody Filler Mixing BoardBlack Squeegee/SpreaderBlack Squeegee/SpreaderSize2”4”5”6”3”5”Page 6

Green Machine Glazed Masking Paper:Machined glazed for greater hold-out. Unique fiber design makes it ideal for use with alltypes of finishes, especially lacquers, enamels, urethane, polyester and epoxy coatings.Perfect for tough automotive, and industrial application. Excellent conformability.Part #121836Description12” Green18” Green36” GreenSize12”18”36”Purple Machine Glazed Masking Paper:Machined glazed for excellent hold-out. Unique fiber design makes itperfect for use of all automotive finishes where surface paint and solvent hold-out is needed. Excellent conformability.Part #112118136Description12” Purple18” Purple36” PurpleSize12”18”36”Plastic Sheeting:Extremely low static. Good stretch and tear strength. Quickly maskoff vehicles, cutting away repair area for the fastest masking jobavailable. EZ Dispenser box keeps plastic clean and simple to dispense.Part #400DescriptionEconomy PlasticSize12’ x 400’Page 7

Premium Plastic Sheeting:High density plastic sheeting that offers high tear and puncturestrength. Specially treated so paint clings to surface and doesn’t flakeoff. EZ Dispenser keeps plastic clean and simple to dispense, evenwithout a masking machine. PAINTABLE!Part #403403-16DescriptionHi Density PlasticExtra Wide Hi Density PlasticSize12’ x 400’16’ x 350’Seat Covers:Plastic seat covers to protect customer’s interior seats. Slip and grip plastic keeps seatcover in place. 125/boxPart #407DescriptionSlip & Grip Seat CoversSizeFits MostFloor Mats:Plastic floor mats to protect customer’s interior floors. Slip and grip plastic keeps mats inplace. 250/box.Part #409DescriptionSlip & Grip Floor MatsSize16”x21”Wheel Maskers:Canvas wheel maskers for overspray protection of automotive tires. #2000fits up to most 15” tires, #2017 fits larger SUV and Truck tiresPart #20002017DescriptionBlue Wheel MaskersBlue Wheel MaskersSizeUp to 15”Up to 17”Page 8

Lightweight Body FillerAn economical Lightweight Body Filler offering smooth and creamy texture that spreads easily for excellent feather edging. Adheres to galvanized, aluminum and bare steel. Sands easily and won’t load up sandpaper. Great for a general use body filler.Part #44014404DescriptionLightweight Body FillerLightweight Body FillerSizeGallonQuartSubstrates & PrepClean surface removing dirt, wax, grease & oil.Grind away any corrosion or rust using 36 or 40 grit grinding disc.Rough sand substrate no finer than 80 grit paper.Mixing50:1 50 Parts Lightweight Body Filler1 Part RED OR BLUE Cream HardenerAs a general rule, scoop appropriate amount of body filler for a single application on a non poroussurface. Drawing a straight line across the widest points of body filler “puddle” will provide the 50:1mix ratio needed for proper catalyzation.Do not whip air into mixture, stir in circular motion.ApplicationApply thin layer using firm pressure to ensure proper adhesion. Apply additional layers building slightly higher and larger to allow for sanding.Repeat process as necessary.DryingGel TimeSand TimeRecoatApproximately 4 to 7 minutesApproximately 15 minutesAllow 1 hour cure time before coating with primer or sealer.Master TipsDo not return unused catalyzed portion to filler can. Allow for extended flash off time if wax & greaseremover used on filler.Page 9

Premium Lightweight Body FillerTruly a premium body filler that’s tack free, self etching, and stain resistant. Formulated with finest resins available to offer superior spreading andsanding properties. Self etching body filler adheres to steel, aluminum,zinc, and galvanized metals.Part #4450DescriptionPremium Body FillerSizeGallonSubstrates & PrepClean surface removing dirt, wax, grease & oil.Grind away any corrosion or rust using 36 or 40 grit grinding disc.Rough sand substrate no finer than 80 grit paper.Mixing50:1 50 Parts Body Filler1 Part BLUE Cream HardenerAs a general rule, scoop appropriate amount of body filler for a single application on a non porous surface.Drawing a straight line across the widest points of body filler “puddle” will provide the 50:1 mix rationeeded for proper catalyzation.Do not whip air into mixture, stir in circular motion.ApplicationApply thin layer using firm pressure to ensure proper adhesion. Apply additional layers building slightlyhigher and larger to allow for sanding.Repeat process as necessary.DryingGel TimeSand TimeRecoatApproximately 4 to 7 minutesApproximately 15 minutesAllow 1 hour cure time before coating with primer or sealer.Master TipsDo not return unused catalyzed portion to filler can. Allow for extended flash off time if wax & greaseremover used on filler.Page 10

Fiberglass Reinforced Body FillerHigh strength body filler that offers superior adhesion to steel, zinc, andgalvanized metals. Corrosion resistant, waterproof, and rust proof.Strength comes from short strands of fiberglass fibers. A final coat ofglazing or finishing putty is recommended.Part #4600DescriptionFiberglass Body FillerSizeGallonSubstrates & PrepClean surface removing dirt, wax, grease & oil.Grind away any corrosion or rust using 36 or 40 grit grinding disc.Rough sand substrate no finer than 80 grit paper.Mixing50:1 50 Parts Body Filler1 Part BLUE Cream HardenerAs a general rule, scoop appropriate amount of body filler for a single application on a non porous surface. Drawing a straight line across the widest points of body filler “puddle” will provide the 50:1 mixratio needed for proper catalyzation.Do not whip air into mixture, stir in circular motion.ApplicationApply thin layer using firm pressure to ensure proper adhesion. Apply additional layers building slightlyhigher and larger to allow for sanding.Repeat process as necessary.DryingGel TimeSand TimeRecoatApproximately 4 to 7 minutesApproximately 15 minutesAllow 1 hour cure time before coating with primer or sealer.Master TipsDo not return unused catalyzed portion to filler can. Allow for extended flash off time if wax & greaseremover used on filler.Page 11

2K Glazing PuttyA two part glazing and finishing putty offeringsuper smooth texture, fast dry, and no shrinkage. Excellent adhesion properties allows you toapply directly to metal, body filler, fiberglass andcured topcoats to fill minor imperfection.Part #4724Description2K Glazing PuttySize24 oz TubeSubstrates & PrepClean surface removing dirt, wax, grease & oil.Grind away any corrosion or rust using 36 or 40 grit grinding disc.Rough sand substrate no finer than 80 grit paper.Mixing50:1 50 Parts Glazing Putty1 Part BLUE Cream HardenerAs a general rule, scoop appropriate amount of body filler for a single application on a non porous surface. Drawing a straight line across the widest points of body filler “puddle” will provide the 50:1 mixratio needed for proper catalyzation.Do not whip air into mixture, stir in circular motion.ApplicationApply thin layer using firm pressure to ensure proper adhesion. Apply additional layers building slightlyhigher and larger to allow for sanding.Repeat process as necessary.DryingGel TimeSand TimeRecoatApproximately 2 to 3 minutesApproximately 15 minutesAllow 1 hour cure time before coating with primer or sealer.Master TipsDo not return unused catalyzed portion to filler can. Allow for extended flash off time if wax & greaseremover used on filler.Page 12

Fiberglass ResinAutobody Master Fiberglass Resin offers finishing grade resinunlike many other brands that offer laminating grades. Used inconjunction with fiberglass cloth, mat, and tape. Fiberglass Resinoffers excellent rebuilding properties to torn or rotted fiberglass &metal.Part #41004104DescriptionFiberglass ResinFiberglass ResinSizeGallonQuartSubstrates & PrepMetal, fiberglass, & woodSurface must be clean and dry. Strip any existing paint or varnish. Rough sand or sand blast metalsurfaces.1tooz Mixingof fiberglass resin12 drops 112ouncedrops of liquid hardenerApplicationFiberglass and metal - Apply tack coat to substrate. When coat becomes tacky, apply fiberglass fabric, starting at one end and unrolling fabric working out bubbles and wrinkles. Apply catalyzed resinusing a brush, roller, squeegee or spreader. Completely saturate fabric and work out any bubbles orwrinkles. If additional layers are needed, apply fabric before previous layer has cured to avoid sanding between layers.Soft Woods - If resin soaks in, continue to apply layers until a tacky coat can be achieved, then applycloth or mat.DryingGel TimeSand Time10-15 minutes30 minutesMaster TipsDo not apply in direct sunlight. Sunlight can breakdown resin properties during application and causeimproper cure and adhesion. In warmer temperatures, 90 F and above, use 50% less hardener toallow for longer working time. In colder temperatures, 65 F and below, use up to 100% more hardener. Do not apply at temperatures below 60 degrees. Always begin and end project with a wet coat ofresin.Page 13

FIBERGLASS CLOTH & MAT CLOTH: Interwoven cloth material that offers high patching strengthto repairs of fiberglass, metal, and plastic. Must be used with fiberglass, polyester, or epoxy resins. Wets fast, lays down smooth andeasily drapes to conform to contours and shapes. Excellent highstrength backing patch over holes, punctures, and breaks. MAT: Fiberglass mat material reinforced with long, fiberglassstrands. Used to reinforce fiberglass, polyester, and epoxy resinswhere bulk and waterproofing is required. Use for the repair of holesand badly damaged areas in fiberglass, metals, and plastics. Easy tohandle on flat or curved surfaces. May be used with or tape to buildlayers of laminateFiberglass ClothPart #41104111DescriptionFiberglass ClothFiberglass ClothSize1yd x 38”3yd x 38”Fiberglass MatPart #41154116DescriptionFiberglass MatFiberglass MatSize1yd x 38”3yd x 38”Substrates & PrepSurface must be dry, clean, and free from paint, varnish, dirt and other foreign mater.Rough sand or sand blast to ensure proper adhesion.ApplicationFirst apply wet coat of catalyzed resin with roller or brush. When resin becomes tacky, apply fiberglasscloth. Working from one end, unroll fabric, stretching and working out air bubbles. Once cloth is appliedroll out remaining bubbles with resin roller. Apply second coat of resin with roller or brush Apply secondlayer of fabric to build up surface. If resin cures between layers, surface must be sanded for properadhesion between coats.Master TipsDo not apply in direct sunlight. Sunlight can breakdown resin properties during application and causeimproper cure and adhesion. Do not apply at temperatures below 60 degrees. Always begin and endproject with a wet coat of resin.Page 14

Lacquer Thinner - General Purpose GradeFormulated from high quality solvents to offer a high solvency general purpose lacquer thinner.DescriptionSizesPart #5700General Purpose Lacquer Thinner1,5,16 & 55Lacquer Thinner - Color GradeSpecial blend of high quality solvents for thinning lacquer color coats or lacquer primer surfacers.DescriptionSizesPart #5770Fast Color Grade Lac. Thinner1,5,16 & 555780Medium Color Grade Lac. Thinner5790Slow Color Grade Lac. ThinnerEnamel ReducerExcellent for acrylic enamel paints & primers. Compatible with all major paint manufacturers.DescriptionSizesPart #5855Fast Enamel Reducer1,5, & 555875Medium Enamel Reducer5890Slow Enamel ReducerPremium Urethane ReducerPremium urethane grade solvents for reducing urethane, epoxy, primers and clear coats.DescriptionSizesPart #8860Fast Urethane Reducer1 Gallon8870Medium Urethane Reducer8885Slow Urethane ReducerPaint PrepSolvent based. Excellent cleaner prior to priming, painting, pin stripping, or attaching graphics andemblems. Removes wax, oil, grease, and other surface contaminates.DescriptionSizePart #5900-1Wax & Grease Remover1 & 5 GallonAnti Static Wax & Grease RemoverWater based. Removes wax, oil, grease, and other surface contaminates. Also works great as a guncleaner for water based products. Excellent final cleaner prior to paint application.DescriptionSizePart #5910Wax & Grease RemoverGallonSpray Gun Cleaning SolventFormulated for fast and efficient cleaning of spray guns. Removes old hard dry finishes and can beused over and over many times.DescriptionSizePart #5914-1Spray Gun Cleaning SolventGallon5914-5Spray Gun Cleaning Solvent5-GallonVM&P NaphthaFast evaporating solvent primarily used to thin exterior and interior oil paints, varnishes and syntheticenamels for spray application.DescriptionSizePart #5960-1VM&P NaphthaGallon5960-4VM&P NaphthaQuartPage 15

Basecoat Reducers P, D, SSpecialized solvent formulations of basecoat reducers to be used as excellent alternative basecoat reducers tothe three most popular basecoat / clearcoat systems on the market.Basecoat Reducer P is formulated to be used as an alternative reactive reducer utilized in PPG's DBUBasecoats. Basecoat Reducer D is formulated to be used as an alternative basecoat reducer utilized inDuPont's Chromabase Basecoats. Basecoat Reducer S is formulated to be used as an alternative basecoatstabilizer utilized in Sherwin Williams’ Ultra 7000 Basecoats.Part escriptionBasecoat Reducer P - FastBasecoat Reducer P - MediumBasecoat Reducer P - FastBasecoat Reducer P - MediumBasecoat Reducer D - FastBasecoat Reducer D - MediumBasecoat Reducer D - FastBasecoat Reducer D - MediumBasecoat Reducer S - SpotBasecoat Reducer S - OverallBasecoat Reducer S - SpotBasecoat Reducer S - QuartGallonGallonQuartQuartMixing - SHAKE WELL BEFORE USE!Basecoat Reducer P:1 part DBU Color, 1 1/2 to 2 parts Basecoat Reducer P - BCPBasecoat Reducer D:1 Part DuPont Chromabase, 1 Part Basecoat Reducer D - BCDBasecoat Reducer S:1 part SW Ultra 7000, 1 Part Basecoat Reducer S - BCSDryingP4 hoursDN/ASN/AFlash10 to 15 Min.5-10 Min.Hand SlickRecoat30-60 Min.15-30 Min.20-40 Min.GelClear WindowP: If Basecoat dries more than 24 hours, scuff sand and reapply color.D: If Basecoat dries more than 24 hours, scuff sand and reapply color.S: If Basecoat dries more than 7 days, basecoat must be REMOVED.Master TipsSHAKE WELL BEFORE USE! Do not use Basecoat Reducers to clean equipment or melt in overspray.Reducer P must be used within 5 days after opened. All basecoat reducers should be tightly sealed during storage.VOC RTSP: 6.6 D 6.4 S 6.6Page 16

Paint PrepSolvent based. Excellent cleaner prior to priming, painting, pin stripping, orattaching graphics and emblems. Removes wax, oil, grease, and other surfacecontaminates.Part #5900-15900-5DescriptionWax & Grease RemoverWax & Grease RemoverSizeGallon5 GallonGenerously apply wax and grease remover to substrate either with acloth soaked in wax and grease remover or by spray applicator.Wipe surface with a clean dry cloth before the wax and grease removerhas flashed off the substrate.Anti StaticWax & Grease RemoverWater based. Use on plastics to avoid flash fire from static spark. Removes static frompre-paint surface thus reducing dirt, dust and lint. Excellent final cleaner and wipe downsolution prior to priming, painting or pin stripping. Removes wax, oil, grease, and othersurface contaminates. Also works great as a gun cleaner for water based products.Part #5910DescriptionWax & Grease RemoverSizeGallonGenerously apply wax and grease remover to substrate either with a cloth soakedin wax and grease remover or by spray applicator.Wipe surface with a clean wet cloth before the wax and grease remover hasflashed off the substrate. Finish drying surface with clean dry cloth. Try to avoidexcessive wiping.Master TipUse Anti Static Wax & Grease Remover when degreasing on or around body fillers or putties.Because fillers and putties can “hold” solvents when wiped with solvent based degreasers, a“ring” can appear if all of the solvent had not released prior to topcoating. Anti Static is waterbased and will not cause the “ring” caused by trapped solvent when using a solvent baseddegreaser around fillers or putties.General Purpose Adhesive RemoverRemoves adhesives, silicone, wax, grease, oil, tar, rubber cement and other contaminants froma variety of surfaces. Leaves no oily film and dries fast. Nozzle top included for easy dispensingPart #5984DescriptionGeneral Purpose Adhesive RemoverPage 17Size1 Quart

Wet LookHigh solids catalyst to enhance acrylic enamel gloss and durability. Wet Look offers a superhigh gloss finish that’s more durable and chemical resistant than conventional enamel finishes.Add to conventional acrylic enamel paints for higher gloss and increased durability.Part #81058108DescriptionAcrylic Enamel HardenerAcrylic Enamel HardenerSize1/4 PintPintSubstrates & PrepSurface must be primed and or sealed and ready for paint.Always clean surface with wax & grease remover prior to painting.MixingTypically 8:4:1 (8 Parts Acrylic Enamel Color : 4 Part Enamel Reducer : 1 Part Wet Look Hardener)Note: Follow paint manufacturers reduction ratio. Some paints come partially reduced from manufacturer.DryingFlash TimeDust FreeTack FreeSand/RecoatPot Life10-15 minutes10 minutes1 hourOvernight to 48 hoursTypically 4 - 6 hoursMaster TipsDue to large variance in reducer temperature ranges, above figures are typical of performance when proper temperature reducer is used. Always add catalyst slowly to reduced paint. Adding catalyst to quickly orto unreduced paint can cause the paint to shock.SyntheticHigh solids catalyst to enhance synthetic enamel gloss and durability. Produces a finish that’smore durable and chemical resistant than conventional synthetic enamel finishes.Part #8132DescriptionSynthetic HardenerSizePintSubstrates & PrepSurface must be primed and or sealed and ready for paint.Always clean surface with wax & grease remover prior to painting.MixingTypically 8:4:1 (8 Parts Synthetic Enamel Color : 4 Part Synthetic Reducer : 1 Synthetic Hardener)Note: Follow paint manufacturers reduction ratio. Some paints come partially reduced from manufacturer.DryingFlash TimeDust FreeTack FreeSand/RecoatPot Life10-15 minutes10 minutes1 hourOvernight to 48 hoursTypically 4 - 6 hoursMaster TipsDue to large variance in reducer temperature ranges, above figures are typical of performance when proper temperature reducer is used. Always add catalyst slowly to reduced paint. Adding catalyst to quickly orto unreduced paint can cause the paint to shock.Page 18

Super EtchSuper Etch is a precoat primer that offers the ultimate in adhesion to bare steel, aluminum,galvanized and zinc coated substrates. Formulated to be used as a pretreatment coating,Super Etch bites into the substrate and promotes the adhesion of additional primers andsealers. Color: Transparent Olive Green. Mix Ratio 1:1Etch FillEtch Fill provides the convenience of a self etching corrosion resistant precoat primer withmoderate filling properties. Etch Fill offers excellent adhesion to bare steel, aluminum, galvanized and zinc coated substrates. Etch Fill etches into the substrate and fills minor imperfections. Etch Fill can be topcoated with additional primers, sealers or topcoat directly withcolor. Color: Mauve/Rose. Mix Ratio 1:1Epoxy PrimerEpoxy Primer offers good corrosion resistance, excellent adhesion, and excellent color holdout. Epoxy Primer can also be used as a sealer when reduced with a urethane gradereducer. Lead, chromate and isocyanate free. Color: Green/Gray, Black and White. MixRatio4:1Fast PrimeFast Prime is an extremely versatile, high build primer surfacer that’s ready to sand in 45minutes. Fast Prime offers excellent corrosion resistance and adhesion to bare metal. UseFast Prime as the primer of choice when you’re looking for a production oriented primersurfacer. Color: Gray. Mix Ratio 4:1Urethane PrimerUrethane Pri

Shop Wipes 4 Urethane Accelerator 4 Weather Strip Adhesive 4 Ultimate Hand Cleaner 5 . 6461G 6461 John Deere Yellow 6443G 6443 John Deere Green 6435G 6435 Ford Blue . Barrel type roll 2 ply soft and absorbent towels. Over 1000' per roll. Shop Wipes come in an easy tote-a-long box so you can move the towels to the job. Absorbs