Transcription

Product OverviewMore than just pumps Drum and container pumps Eccentric worm-drive pumps Motors Centrifugal immersion pumps Air-operated diaphragm pumps Flow meters Mixers Accessories Filling units Drum emptying systems Customized all-in solutions Custom made design1

About FLUXFLUX pump technology – the right solution even for demanding fluidsMore than just pumpsOne Brand. One Promise.The FLUX name has been synonymouswith pump technology for more than60 years. It was the invention of theelectric drum pump that sparked it alloff. In the meantime of course thetechnology has become more sophisticated. FLUX company innovationshave markedly improved working routines for filling and transferring fluids.It is often said that medium-sizedcompanies are the engines ofprogress. We would be pleased ifour family business were able tosubstantiate this claim.When you choose FLUX you are making a good decision for the long term.With our products we want to assistyou to save time and money and bythe way ‒ spare your nerves as well.We are therefore delighted when youdiscuss your requirements with us.Pumping, emptying, mixing, filling and metering ‒ when liquids are set in motionthe requirements are very diverse. In any event the process must run smoothly.This is what the FLUX brand name stands for. It is recognised across the globeas a byword for quality, for safety and for solutions which are able to fulfil everysingle demand on a long-term basis.Smooth-running processes ‒ FLUX not only guarantees this for liquids which arerelatively easy to pump but also when the pumping medium is viscous or doesn'tflow at all, when it is aggressive or used in processes which are common in thehygiene sector or sectors where there is an explosion hazard. To ensure that thetasks are solved in the best possible way for the customer FLUX has a huge rangeof expertise to offer. In other words, a lot more than just pumps. From a technicalpoint of view this means a comprehensive product system of pumps, motors, flowmeters, accessories and a whole lot more. From the project point of view, "Morethan just pumps", means accompanying our customers from the first telephonecall through to the end solution ‒ and if required beyond that.This is how FLUX keeps processes moving. Long-term. Simple, complex orcustom-made inclusive design assignments: FLUX is prepared for any request andin particular for the fact that our customers need more than just pumps.Best wishes,Klaus Hahn,CEO FLUX-GERÄTE GMBHMILESTONES OF PUMP TECHNOLOGY:1950The first electric drum pump in the world was christened FLUX21955Foundation of the present day FLUX-GERÄTE GMBH1953First explosion protected drum pump1997First explosion protected collector motor constructed

QualityFrom the inventors of the electricdrum pump.Customer focusIndividual solutions for yourrequirements.SafetyGood to know: It's a FLUX product. Reliability. In concrete terms: Everyminute of downtime is a minute toomuch. FLUX strives to preventdowntimes in the best way possible. Long service life. High-qualitytechnology is one of the mostimportant prerequisites for longterm trouble-free processes. Made in Germany. FLUX has itscentral production location inMaulbronn, Baden-Württemberg. A wards. Such as the iF ProductDesign award which FLUX brandproducts have won several timesunderline the unique claim of theFLUX brand. Extensive range of products.FLUX offers an extensive range ofproducts based on individual components, pre-configured sets andsystem solutions. Individual solutions. For specificrequirements FLUX designs andimplements special adaptations,custom-made products and complexsolutions in-house. Technology partners. FLUXconsultants are the competentcontact for the customer – on thetelephone or with the customer onsite. On-call delivery All popularproducts are available from thelarge warehouse at the headquartersin Maulbronn. Local warehouses indifferent countries supplementcapacities where it is economicalto do so. After-sales support. FLUX guarantees a repair service and supply ofreplacement parts for a period ofup to 20 years following date ofpurchase. Demanding media. FLUX technologycovers an enormous spectrum ofdiffering media. It goes without saying that FLUX provides maximumsafety and reliability for demandingmedia as well. Special solutions for individualindustries. Different industries.Different challenges. Whether foodindustry, pharmaceuticals industry,hygienic or explosion-hazardsectors: The focus always is onproduct and user safety. Handling. Risks which could otherwise occur in operation have alreadybeen taken into consideration byFLUX in the design phase. Theresult: Products which are able tohandle complex tasks but which canstill be operated with a few simplemovements.2003First brushless drum pump motorand build conform to ATEX Directive 94/9/EC2014First brushless battery motor to drive pumps worldwide2010Further development of the VISCOFLUX drum emptying systems3

entechnik:emie:Lebensmittel:Pharmazie:The right solution for every industryPetrochemie:Chemie:With its application-based products FLUX has the right solution for every sector of industry. Use our icons as a guide to helpyou to find the products which aresuitablefor Lackindustrie:your Industrie:und Lackindustrie:Petrochemie:und Lackindustrie:Oberflächentechnik: Farben-Farben-ChemicalIndustrySurface technologyPaints and sWater treatmentAgricultureKosmetik:Lebensmittel: Lebensmittel:Petrochemie: hnik:Farben- und Lackindustrie:Landwirtschaft:Certified safety for the most widest range of industries and countries: FLUX products have been developed and certifiedfor use around the world; they comply with the highest demands and safety standards. With FLUX you are always on thesafe side everywhere.All FLUX products conform to pertinent fundamental health& safety regulations of the EC Machinery DirectivePetrochemie:Chemie:Chemie:Industrie:und Lackindustrie:2006/42/ECand are therefore CE certified. In addition, FarbenFLUX productsbear the Eurasian EAC mark issued byLandwirtschaft:Kosmetik:the customs union of Russia/Belarus/Kazakhstan.Furthermore, selected FLUX products are available with the following certificates:Petrochemie: en- und LackindustrFor use in the pharmaceutical, foods andcosmetics sectorthere are pumps with 3A certification, FLUX FOODpumps conform to EG 1935/2004 and are suitablefor contact with food or products available whichconform to FDA CFR 21.Industrie:Industrie:Farben- und Lackindustrie: Kosmetik:Farben- und Lackindustrie:Landwirtschaft:Dependent on version FLUX motors are availablewith VDE GS, UL or also CSA test certificationare available.For use in explosion-hazardous areas FLUX productswith explosion protection are available which are builtand certified to conform to ATEX Directive smetik:

Table of contentsOverviewSummary of FLUX pump series06Drum and container pumps (series F 300 / F 400)08JUNIORFLUX/COMBIFLUX (series F 300)09Drum and container pumps (series F 400)10Eccentric worm-drive pumps (series F 500)12Suitable motors for FLUX pumps series F 300, F 400 and F 50014Centrifugal immersion pumps (series F 600 / F 700)16Air-operated diaphragm pumps (series FDM / RFM)18Flow meters (FMC / FMO / FMT)20Mixers22Additional products and accessories23Filling units24Drum emptying systems - VISCOFLUX family25Customized all-in solutions26Custom made design275

Summary of FLUX pump seriesHelps you to identify the best pump for your requirements quicklyFLUX Pump SeriesDrum pumps series F 300JUNIORFLUX/COMBIFLUXDrum and container pumps Eccentric worm-driveseries F 400pumps series F 500Page 9Pages 10 - 11Pages 12 - 13Typical areas of application Mobile filling of liquid mediain small quantitiesMobile filling of liquid media(incl. pre-defined quantities)and/or mixingMobile and stationaryfilling of low through highviscosity media incl.shear-sensitive media(incl. pre-defined quantities)Container/applicationSmall containers, 200 l drums 1 000 l IBCs 200 l drums 1 000 l IBCstanks 1 000 l 200 l drums 1 000 l IBCstanks 1 000 las process pumpFlow rate max.*60 l/min240 l/min50 l/minHead max.*8.5 mWs30 mWs80 mWsViscosity max.*250 mPas1 200 mPas80 000 mPas Brushless battery motor Mixing pump 99.98 % drum emptying Easily stripped down pump Also as application-based Flow metering via pulseAvailable certificatesSpecial featuresgenerator possible forversion with bearing flangepump setsDrive optionsElectricElectric or pneumaticOptional mains connection orstorage battery* dependent on pump model, medium and motor6Electric or pneumatic

Drum emptying systemsVISCOFLUXCentrifugal immersionpumps series F 600and F 700Air-operated diaphragmpumps series FDM and RFMPage 25Pages 16 - 17Pages 18 - 19Mobile and stationaryfilling of high-viscosity mediaand media just capable offlowing through to media notcapable of flowing (incl.pre-defined quantities)Stationary and mobile usableprocess pumps for fillingand circulating liquid mediain bulk quantitiesProcess pumps for liquid(incl. abrasive) to highviscosity media ‒ for low tohigh flow volumes and highpressure build-up 200 l drums with Ø560 mm, 571 mm,conical drums 1 000 l IBCstanks 1 000 las process pump 1 000 l IBCstanks 1 000 las process pumpMax. 50 l/min depending onviscosity and flow properties74 m³/h1 000 l/min80 mWs35 mWs200 mWsPasty2 500 mPasJust capable of flowing Also for conical drums Also for seaworthy E.g. can be used for Stroke counter can beAdBlue tank systems container drums Flow metering via bearingflange with pulse generatorwhere required Integration in processesvia control unit possible Pump available with left/right operationElectric or pneumaticintegrated Filter press high-pressurepump Cycle control can beintegrated Version with flap valve forsemi-solids of max. 50 mmElectricPneumatic7

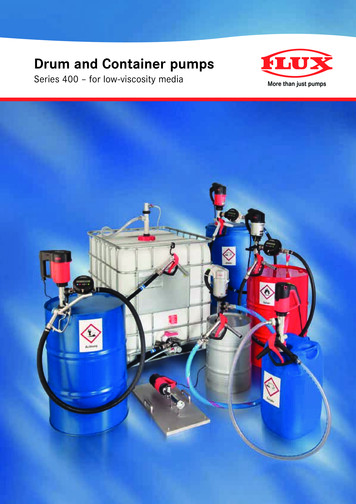

k:Drum and container pumpsFor pumping low viscosity fluids out of various ndustrie: ntechnik:Farbenund Lackindustrie:Lebensmittel:Pharmazie: n- und Chemie: ft:Pharmazie:Industrie: chnik:Oberflächentechnik:Farben- und Lackindustrie:FLUX drum and container pumps are suitable forpumping various low-viscosity and also especiallyaggressive and highly-flammable fluids. The axialPetrochemie:und Lackindustrie: Landwirtschaft:Kosmetik:Chemie:Chemie: Farbenimpellerpumps provide a pulsation-free pumpingaction. Constructed on the modular design, differentpumps are able to be driven by the same motor. As aresult oftheir low weight the pumps can be easilyIndustrie:Farben- und Lackindustrie:Farbenund ried from container to container. The easy handlingof motor and pump keeps changeover times short.Various pumps with and without mechanical seal are availableLandwirtschaft:Industrie:Farben- und Lackindustrie:Industrie: Kosmetik:Farbenund Lackindustrie:as well Kosmetik:as versions for higher pumping heads and mixingpumps. FLUX drum and container pumps are available inversions with explosion protection, with 3A certification aswell as FLUX FOOD pumps (Directive (EC) 1935/2004 :FDA CFR 21 compliant). Moreover especially pre-configuredpump sets for typical applications are available.Technical dataF 300F 400For containerSmall contain- Hobbocks,ers, Hobbocks, 200 l drums, 200 l drums, IBCs, tanksIBCsFlow rate max.60 l/min*240 l/min*Head max.8.5 mWs*30 mWs*Viscosity max.250 mPas*1 200 mPas*Motor driveElectricElectric/pneumaticBattery motor FBM-B 3100 — the solution where cables areproblematic or not desired.Ancillary products and accessoriesA wide range of ancillary products and accessoriesis available for many different FLUX drum andcontainer pump applications such as e.g. Fume gland F low meters Hoses F illing units Hand nozzles and other outlet fittingsFLUX FOOD for application in the food industry.* dependent on pump model, medium and motor8

JUNIORFLUX/COMBIFLUXFor filling small quantitiesThe small drum pumps JUNIORFLUX and COMBIFLUX are particularly suitable for filling comparatively smallquantities from containers such as cans up to 200 litre drums. The small diameter of the outer tube makes itpossible to pump out of tight openings.JUNIORFLUXFor filling small quantities; with fixed commutator motorAdvantages/characteristics: Motor and pump with fixed connection Available with choice of two types of seal Low overall weight - minimal amount of exertionnecessary when changing drums Can pump out of narrow-necked containersExamples of media: Acids and lyes Fertiliser solutions Pesticides Cleaning agents Demineralized Water (purified water)Technical dataFlow rate max.57 l/min*Head max.8.5 mWs*Viscosity max.250 mPas*Pump materialOuter tubePolypropylene,Polyvinylidine fluoride, Stainless steelImmersion length mm(standard)500/700/1 000COMBIFLUXFor filling small quantities; with removable motorAdvantages/characteristics: Motor easy to remove Connection of motor to pump via quick-action coupling Driven by a brushless battery motor or electricalcommutator motor with mains connection Sealless design Low overall weight minimal - amount of exertionnecessary when changing drumsExamples of media: Acids and lyes Fertiliser solutions Pesticides Cleaning agents Demineralized Water (purified water)Technical dataFlow rate max.60 l/min*Head max.8.5 mWs*Viscosity max.250 mPas*Pump materialOuter tubePolypropylene,Polyvinylidine fluoride, Stainless steelImmersion length mm(standard)500/700/1 000/1 200* dependent on pump model, medium and motor9

Drum and container pumpsFor pumping low viscosity fluids out of various containersFLUX drum and container pumps are always a "double act" comprising motor and pump. Both components can varyquite flexible. For example different pumps are able to be driven with the same motor. Ideal for reliable pumping ofvarious low-viscosity liquids - incl. especially aggressive and highly flammable ones. As a result of their low weightthe pumps can be easily carried from container to container. The easy handling of motor and pump keeps changeovertimes short.F 430With mechanical sealAdvantages/characteristics: No carrying-over of the medium - one pump can be usedfor different media Easily dismantled for fast cleaning Immersion depth to 3 000 mm possible FOOD version available Stainless steel and Hastelloy C versions can be used inhazardous areas Available as version for dry running installation Steel core in the inner tube (PP and PVDF) providesgreatest stability and prevents longitudinal changes athigh and low temperaturesTechnical dataFlow rate max.240 l/min*Head max.30 mWs*Viscosity max.1 200 mPas*Pump materialOuter tubePolypropylene,Polyvinylidine fluoride,Stainless steel, Aluminium, Hastelloy CImmersion length mm(standard)700/1 000/1 200Examples of media: Suitable for almost all low-viscosity fluids incl.FOOD mediaF 424Sealless designAdvantages/characteristics: L ow-maintenance ‒ due to sealless design B uilt to last S tainless steel version for use in hazardous areas N on-sensitive to dry running N o contamination from lubricants or wear of sealmaterials possibleExamples of media: S uitable for almost all low-viscosity media10* dependent on pump model, medium and motorTechnical dataFlow rate max.240 l/min*Head max.30 mWs*Viscosity max.1 200 mPas*Pump materialOuter tubePolypropylene, Polyvinylidine fluoride,Stainless steelImmersion length mm(standard)700/1 000/1 200

F 427Can be taken apart completelyAdvantages/characteristics: E asy and fast disassembly for cleaning or sterilisation C an be completely stripped down to individual partswithout using tools M inimal dead spots A lso available as FOOD and 3A certified versionExamples of media: S uitable for almost all applications; also for products inthe pharmaceutical, FOOD and cosmetics industriesTechnical dataFlow rate max.240 l/min*Head max.13 mWs*Viscosity max.1 000 mPas*Pump materialOuter tubeStainless steelImmersion length mm(standard)700/1 000/1 200F 425For 99.98 % drum emptyingAdvantages/characteristics: L ess than 0.05 l residual amount left in 200 l drum F lowback stop valve prevents back flow of the mediuminto the emptied drum W ith optimal use of the product reduced drum cleaningor waste disposal costs S tainless steel version can be used in hazardous areas H ighest stability provided by steel core in inner tube;no longitudinal changes at high and low temperaturesExamples of media: V aluable, high-quality liquids e.g. cosmetics additives Toxic, dangerous and environmentally damaging substancesTechnical dataFlow rate max.130 l/min*Head max.13 mWs*Viscosity max.1 200 mPas*Pump materialOuter tubePolypropylene,Stainless steelImmersion length mm(standard)700/1 000/1 200F 426For mixing and/or pumpingAdvantages/characteristics: F or pumping and/or mixing inhomogeneous media S witch lever for easy changing between mixing/pumpingand pumping ‒ during running operation, too E asily disassembled for fast cleaning S tainless steel version can be used in hazardous areas S teel core in the inner tube prevents longitudinal changesat high or low temperaturesExamples of media: P aints, lacquers, 2-phase mixtures, emulsions* dependent on pump model, medium and motorTechnical dataFlow rate max.240 l/min*Head max.13 mWs*Viscosity max.1 200 mPas*Pump materialOuter tubePolypropylene,Stainless steelImmersion length mm(standard)1 000/1 20011

fbereitungPharmazie:Oberflächentechnik:Eccentric worm-drive pumpsFor pumping low to high-viscosity n- und Lackindustrie:Petrochemie: :Lackindustrie:Lebensmittel:Farbenund :Pharmazie:Farben- und Chemie: Kosmetik:schaft:Industrie: ie:Farben- und :Chemie:Industrie:Landwirtschaft:Farben- und haft:Kosmetik:Kosmetik:Technical dataMotor connectionContainer/applicationgear (GS)flange (S) 200 litre drums, IBCs, tanksand as process pumpFlow rate max.50 l/min*Head max.80 mWs*Viscosity max.Motor drive types30 000 mPas*(GS6 80 000 80 000 mPas*mPas*)Electric, pneumaticF 550 TR in action in the industrial sector – pumping viscoussoftener.* dependent on pump model, medium and motor12Oberflächentechnik:Farben- und Lackindustrie:Landwirtschaft:Farben- und gFLUX eccentric worm-drive pumps are suitable forpumping thin to high-viscosity fluids. The displacementpumps work with low turbulence at a constantpressure and provide for a gentle and pulsation-freeoperation. Whereas the series F 550 pumps are usedin the industrial sector the series F 560 is especiallyconfiguredfor the pharmaceuticals, food and cosmeticsFarben- und Lackindustrie:industries. All pumps can be used mobile and stationary, are made of only a few components and easy todisassemble.Kosmetik: is a choice of versions for immersing in the materialThereand for installing outside the container; versions with explosion protection, 3A certification and FLUX FOOD pumps(Directive (EC) 1935/2004 and FDA CFR 21 compliant). Forconnection of the motor there is a choice between bearingflange (S) and gear (GS). For pumping especially highviscosity media there are drum emptying systems witheccentric worm-drive pumps available (see page 25).Additional advantages/characteristics F 560Hygienic pump for use inpharmaceuticals, food and cosmetics industries Minimal dead spots Pump/shaft/worm easy to disassemble Available with inliner suction protection –also suitable for containers with inliners FOOD version for contact with foodstuffs accordingto directives EC 1935/2004 and FDA CFR 21 3A certified versions availableF 560 GS in operation in the hygiene sector - pumping rawmaterial for a cream into a mixing vat.

GS/GS6Eccentric worm-drive pumpsF 550/ F 560 with gear C onnection of motor to pump fast and simple withunion nut F or fluids of up to 30 000 mPas (80 000 mPaswith GS6) G ear ratio 1:15.9 (GS) or 1:6.75 (GS6) F or use with electrical commutator motors andcompressed air motors (drum pump version) L ight for mobile use A vailable with 3A certification E xplosion-protection version available A vailable as FLUX FOOD pumpSEccentric worm-drive pumpsF 550/ F 560 with bearing flange C onnection of motor via bearing flange For fluids up to 80 000 mPas F or use with three-phase motors, gear motors andcompressed air motors E xact metering via impulse generator possible F or long running periods E xtremely quiet L ong service life F or stationary use A vailable with 3A certification With explosion protection certification, where required A vailable as FLUX FOOD pumpTREccentric worm-drive pumpsF 550/F 560 for dry installation F or containers which are not accessible from above L iquid must be free flowing F or increasing pressure in process lines C an be mounted on trolley or panel F or mobile or stationary use Connection of motor via bearing flange Versions with anti-clockwise/clockwise running Pumps for use in hazardous areas available Also available as FOOD version13

Suitable motorsFor the FLUX pumps of the series F 300, F 400 and F 500For pump seriesF 300F 400 and F 500 GSBattery(brushless)TypeMotor typeCommutatorFBM-B 3100FEM 3070FEM 4070F 457F 458F 460 Ex

Suitable motors for FLUX pumps series F 300, F 400 and F 500 14 Centrifugal immersion pumps (series F 600 / F 700) 16 Air-operated diaphragm pumps (series FDM / RFM) 18 Flow meters (FMC / FMO / FMT) 20 Mixers 22 Additional products and accessories 23 Filling units 24 Drum emptying systems - VISCOFLUX family 25 .