Transcription

SINCE 1842COMPACT TRACK LOADERSB Series

2

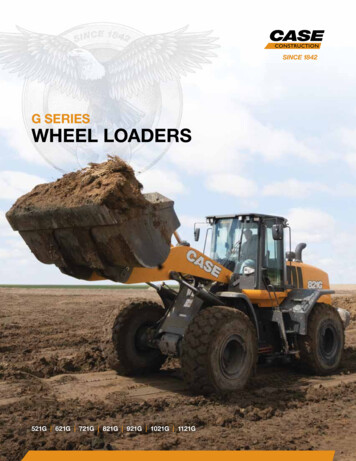

TAKE CONTROL.GET MORE DONE.All-new CASE B Series compact track loaders (CTL)offer a completely re-imagined operator interface andenvironment designed to simplify operation and putmore power and control into the hands of the operator.Match that with productivity-enhancing horsepowerand torque, numerous hydraulic options and extremeattachment versatility, industry-leading visibility, and liftgeometries and size classes to meet every demand.The CASE B Series CTLs are the efficient, productivityenhancing earthmoving solution your fleet demands.TR270BTR310B Powerful breakout forces for groundwork Industry-leading visibility for greater awareness Spacious, easy-to-enter cabTR340B Dial in and save machine settings that can easilybe recalled based on application or operatorpreference Maintenance-free Tier 4 Final emissions solutions Extreme attachment compatibilityTV370B W e've retained the strength and styling of the framefrom the previous series, and have re-engineeredmany of the critical inner workings of the machine tostand up to the hard work and extreme environmentsyou face every day.TV450B3

INDUSTRY-LEADING VISIBILITYThe all-new B Series backup camera enhances what is already theindustry’s best visibility, with excellent forward sightlines, low entrythreshold, skylight, cab-wide rearview mirror, large rear window and360 lighting that gives operators excellent views to the bucket orattachment, over the tracks and around the machine — day or night.4

SIMPLIFIED OPERATION.MORE CONTROL.CASE CTLs have never been easier or more intuitive to operate. The all-new8-inch LCD multi-function display puts critical machine information at theoperator’s fingertips. It also helps making and storing settings easier than anyprevious CASE CTL, and the all-new backup camera significantly improvesjobsite awareness. New joysticks, simple electro-hydraulic controls andeasier start-up and throttle controls* all improve the operator experience. Simple start-up procedure E asy switching betweenoperating patterns (ISO and H) I ndustry-exclusive split screenbackup camera/data display E xcellent controllability withelectro-hydraulic controls More comfortable joysticks Creep Speed enhancesattachment operation*CHECK OUT A 360-DEGREE VIEW OF OUR CAB AT CASECE.COM/BSERIES5

TIER 4 DONE RIGHT,MADE EASY.One solution does not fit all. CASE carefully considered eachmachine’s application, life expectancy, maintenance needsand operators. That’s why every CASE compact track loaderfeatures a proven Tier 4 Final solution tailored to that model.The result? Compliance without compromise or complexity.CASE Tier 4 Final-certified equipment is easier to maintain and,unlike competitive models, won't require you to master additionalmaintenance procedures. In fact, most CASE machines havemaintenance-free emission solutions, so you can stay focusedon your work—and not maintaining your machine.CASE Tier 4 Final Solutions in Simple LanguageCEGRSCRWhat it means: Cooled Exhaust GasRecirculation. For Tier 4 Final, it workswith a combination of the after-treatmenttechnologies listed here.What it means: Selective CatalyticReduction. It’s a simple after-treatmentsolution that combines DEF (DieselExhaust Fluid) with exhaust to convertemissions into nitrogen and water.DEF is a non-toxic liquid that reactswith engine exhaust in the presenceof a catalyst to perform the emissionsconversion.What it means to you: As an in-enginesystem, CEGR requires no operatormaintenance or management. CEGRis included in all CASE compact trackloader models.DOCWhat it means: Diesel OxidationCatalyst. The DOC oxidizes themachine’s exhaust to create heat andmanage emissions.What it means to you: DOC is amaintenance-free solution—no fluids toadd and no filter to replace.6What it means to you: Because SCRis an after-treatment system, it lowersexhaust temperatures and does notrequire unproductive fuel use associatedwith burning off particulate matter—great for larger engines. This offers asignificant reduction in fuel use and hasno DPF to replace. Keeping it runningis simple — just refill DEF as needed.Fuel savings, lower maintenance costand greater productivity will help lowertotal operating costs for the life of themachine.

TR270BTR310BTR340BTV370BTV450BGross HP 7474907490Maintenance-FreeEmissions Systems33Diesel ExhaustFluid333No DPF t o Replace33333Increased Fuel Tier 4 FinalSolution7

LOW GROUND PRESSUREWhen protecting the terrain is important, CASE compacttrack loaders boast a light footprint with ground pressureas low as 4.2 psi (29 kPa).8

LOW GROUND PRESSURE.HIGH PRODUCTIVITY.MORE SPACE,MORE COMFORTAt nearly three-feet wide, CASE compacttrack loaders have one of the roomiestROPS/FOPS-certified cabs in theindustry. New controls and environmentaldesigns provide even more legroom.And enclosed cabs are fully sealedand pressurized to reduce noise anddust. Options include Bluetooth radio,climate controls and a heated seat.DOZER-STYLEUNDERCARRIAGEThe dozer-style undercarriage and tracksare engineered to hold better on slopes andtake command of muddy or sandy terrain.The rigid-track frame has fewer movingparts for greater durability and easiermaintenance than suspension-track systems.LOADER STOPS IMPROVEGRADING, STRENGTHCASE compact track loaders feature aloader frame support that transfers theload to the chassis of the machine whengrading instead of putting that stress onthe loader arms. This improves gradingperformance and reduces lifetime stress/strain on the unit for long-term reliability.ECONOMY MODE &ENGINE PROTECTIONSet shutdown timers to limit idling, engagethe ignition timeout feature to limit batterydrain, and leverage the engine protectioncapabilities to shut down the machineand protect the engine from conditionsthat may cause greater downtime.CREEP SPEEDOPTIMIZES ATTACHMENTSSet machine travel at a consistent speedand independently operate the throttlepower to the attachment for optimalperformance not tied to machine speedin applications such as cold planing,sweeping and snow blowing.ELECTRO-HYDRAULICCONTROLSDial the machine in to meet the demandsof each application with all-newelectro-hydraulic controls availablethrough the 8-inch LCD multi-functiondisplay. Adjust general machineresponsiveness to high, medium or low;or dive deeper to individually adjust tilt,lift and drive speed, as well as loaderarm and control aggressiveness.9

QUICK, TOOL-FREE SWITCHINGSwitch loader attachments without the added hassleof getting out of your cab. Standard Connect UnderPressure (CUP) manifolds facilitate fast, easy and toolfree connecting and disconnecting of hydraulic linesby releasing pressure into the standard case drain.RENTALSimple is powerful. CASE compact track loadersfeature simple controls, easy setting adjustments,and auxiliary hydraulics and a universal couplerthat make each model ideal for rental operationswith a broad range of attachments.10

MAXIMIZE YOURBUSINESS OUTPUT.AUXILIARY HYDRAULICPACKAGES AVAILABLECASE compact track loaders are compatible with more than 250 buckets, forks,brooms, augers, rakes, grapples, hydraulic hammers, snow accessories, balespears and other CASE attachments, including CASE skid steer and compactwheel loader attachments.StandardAll models come standard with a universal coupler that will work with numerousattachment manufacturers, meaning you can do more with a single machine togive your business even greater versatility. Consult your dealer for details.High-FlowLaser Grading BoxMulcherRotary CutterConcrete ClawEnhanced High-FlowHydraulic BreakerSide Discharge Bucket4-in-1 BucketTree PullerSecondary AuxiliaryScrap GrappleRoot RakeDozer BladePickup BroomFront Electric/Multi-FunctionCold PlanerRock SawAugerTrencherVibratory RollerBale HandlerPallet ForksArctic SectionalSno-Pusher SEE OUR FULL LINE AT CASECE.COM/ATTACHMENTSINTEGRATED HYDRAULICQUICK COUPLERQuickly switch attachmentsfrom the comfort of the cab.11

MATCH THE LIFTTO THE TASK.The CASE B Series includes both radial-lift and vertical-lift models. The benefitsdepend on your application. That's why CASE offers both lift patterns in varioussizes to make sure you have the right machine for the job.VERTICAL LIFTVertical-lift machines areengineered for lift-and-carry andtruck-loading jobs. The geometryof the dual arm allows the loadto rise directly up, providingmaximum reach at full height.Vertical-lift machines are ideal forreaching over the side of and intothe middle of high-side trucks.RADIAL LIFTRadial-lift machines are engineeredfor digging, prying and pushing. Theangle of the arm ties directly intothe chassis for superior strengthwhen digging and pushing. It alsoprovides maximum reach at theoperator’s head height, making itperfect for loading and unloadingpallets from trucks.12

AGRICULTUREMove more bales. Check off more chores. Witha full range of sizes, increased reach and over250 attachments, CASE compact track loadershelp producers and ranchers lift, load, carry andmove more, all year long.13

LANDSCAPINGWhether pallet loading, earthmoving or haulingmaterials, CASE compact track loaders combinepower, universal attachment versatility and yearround cab comfort options—all in a lineup withlow ground pressure that won't damage lawns.14

RESIDENTIAL CONSTRUCTIONWorking around homes and other contractors?User-friendly electro-hydraulic controls adjustsensitivity for precise maneuvering. Industryleading visibility, including the all-new backupcamera, provides clearer sight lines to all areasaround the machine. It all results in simpler, moreproductive operation.15

MAINTENANCEMADE EASY.NO TOOLS NECESSARYCASE compact track loaders continue the hallmark of simpleserviceability with features like tool-free access to the oil cooler,radiator and other routine maintenance points.LOW MAINTENANCEService is simple. Regular check points are grouped into a singlearea under the engine compartment cover, easily accessiblethrough the heavy-duty rear door. The entire cab tilts forward injust a few easy steps to access the entire drivetrain compartmentfor easy service and inspection.EASE OF TROUBLESHOOTINGShort descriptions tied to fault codes simplifycommunication and troubleshooting with yourCASE dealer.1Easy access to everything1 Easy-tilt cab access to powertrain2 Hydraulic pressure release valve3Battery4Engine oil filter5DEF tank*6Hydraulic fill7Master disconnect switch8Air filter9Hydraulic filter10Engine oil fill11Hydraulic site gauge 12 Fuel filter with WIF sensor 13 Heavy-duty rear door34*DEF Diesel Exhaust FluidOnly available on 90 hp machines.216

567891012111317

SUPPORT COMESSTANDARD.BASE & EXTENDED LIMITED WARRANTY COVERAGE: *1-YEAR/UNLIMITED-HOUR FULL-COVERAGE BASE LIMITED WARRANTY2-YEAR/2,000-HOUR FULL-COVERAGE BASE LIMITED WARRANTY2-YEAR/2,000-HOUR EXTENDED LIMITED ENGINE WARRANTYDiscuss the extended engine warranty coverage details with your dealer.UPTIME SOLUTIONSYour CASE dealer can provide solutions to meet all your needs and keepyou productive.STRONGER PRODUCT SUPPORT SOLUTIONSYour CASE dealer knows how you can best maximize yourequipment investment and uptime—with genuine CASE parts,expert service and a complete range of product support solutionsincluding CASE remanufactured and all-makes parts. CASEsupports better parts availability and faster deliveries throughnine parts distribution centers in North America and a forecastingsystem to ensure that the right parts will be there when youneed them. And only CASE dealers have exclusive access to theElectronic Service Tool (EST) that quickly pinpoints machine issues.Just ask your dealer for details.CMYKCNH IndustrialAftermarket Solutions0. 90. 100. 23AW CNHI Aftermarket Solutions CMYK.aiAC05 04 2019CMYK0. 0. 0. 100FLEXIBLE FINANCIAL OPTIONSSpecialized finance programs and flexible leasing packages put youin the driver’s seat of industry-leading CASE equipment while nononsense warranties and comprehensive protection plans ensure thatyour equipment is protected. As the only finance company dedicatedto CASE, we offer strong products and services designed around yourunique needs and are the only ones supported by the helpful serviceprofessionals at your CASE dealer.18*Please see your CASE dealer for limitations, exclusions and confirmation of policies in effect.

19

GET PRECISECASE CTLs are compatible with precisionconstruction solutions, such as the CASE lasergrading box, to help you do the job faster andmore accurately.20

STANDARD ANDOPTIONAL FEATURESStandardOPERATOR n Cab (No Heat or HVAC)AspiratorEnclosed Cab with Heaterand ACBlock Heater, 120VEnclosed Cab with HVAC,Demolition DoorHYDRAULICSOperator Security CodesStandard AuxiliaryHydraulics8-inch LCD Multi-FunctionDisplayHigh-Flow AuxiliaryHydraulicsMachine Settings UserAccess LevelsEnhanced High-FlowAuxiliary HydraulicsCreep SpeedSecondary AuxiliaryHydraulicsEconomy ModesManual CouplerIgnition TimeoutHydraulic CouplerEngine Protection SettingsFront on Seat, VinylOptionalNot Ride Control Air Ride Suspension/Heated SeatOne-Way Self LevelThree-Point Seat Belt, 2 inSingle-Point Lift HookThree-Point Seat Belt, 3 inFour-Point Lift HookTwo-Speed ControlsCylinder GuardHand ControlsExtra CounterweightHand and Foot ControlsElectro-Hydraulic ControlsCASE SiteWatch TelematicsFOPS Level 2 ModificationRearview s, 12.6 in (320 mm)Tracks, 15.7 in (400 mm)Tracks 17.7 in (450 mm)Undercarriage Hose CoversHeavy-Duty Rear DoorBeacon LightHeavy-Duty Front LightsSide LampFour-Corner LED StrobeSpecial PaintDebris Seal Package21

SPECIFICATIONSAND 450BLift ineFPT F5H FL463A*G001FPT F5H FL463A*G001FPT F5B FL413 D*C001FPT F5H FL463A*G001FPT F5B FL413 D*C001Gross Horsepower — hp(kW)74 (55)74 (55)90 (67)74 (55)90 (67)Net Horsepower — hp (kW)68 (51)68 (51)84 (63)68 (51)84 (63)Peak Torque — lb ft (Nm)232 (314)232 (314)282 (383)232 (314)282 (383)Displacement/Cylinders — in³ (L)207 (3.4) / 4207 (3.4) / 4207 (3.4) / 4207 (3.4) / 4207 (3.4) / 4Emissions Certification*SolutionsTier 4 Final Certified(CEGR, DOC)Tier 4 Final Certified(CEGR, DOC)Tier 4 Final Certified(CEGR, SCR)Tier 4 Final Certified(CEGR, DOC)Tier 4 Final Certified(CEGR, SCR)Rated Operating Capacity(ROC) 35% — lb (kg)1,890 (860)2,170 (984)2,380 (1 079)2,590 (1 178)3,150 (1 432)Rated Operating Capacity(ROC) 50% — lb (kg)2,700 (1 225)3,100 (1 406)3,400 (1 542)3,700 (1 682)4,500 (2 045)Tipping Load — lb (kg)5,400 (2 449)6,200 (2 810)6,800 (3 084)7,400 (3364)9,000 (4 091)Bucket BreakoutForce — lb (kN)7,270 (32.3)8,680 (38.6)8,700 (38.7)8,776 (39.0)9,188 (41.8)Standard AuxiliaryHydraulics — gpm (L/min)24.2 (91.5)24.2 (91.5)24.2 (91.5)24.2 (91.5)24.2 (91.5)High-Flow AuxiliaryHydraulics — gpm (L/min)32.4 (122.6)32.4 (122.6)37.6 (142.5)37.6 (142.5)39.5 (149)Operating Weight — lb (kg)8,270 (3 750)8,880 (4 027)10,000 (4 536)9,630 (4 370)10,610 (4 823)DIMENSIONSTR270BTR310BTR340BTV370BTV450BHeight to Bucket Hinge Pin125.1 in (3.18 m)125.1 in (3.18 m)126.7 in (3.22 m)131.6 in (3.34 m)131.6 in (3.34 m)Dump Height with Foundry/Excavating Bucket100.6 in (2.56 m)100.6 in (2.56 m)102.2 in (2.59 m)105.1 in (2.67 m)104.1 in (2.65 m)Height to Top of ROPS78.7 in (2.00 m)78.7 in (2.00 m)80.4 in (2.04 m)80.4 in (2.04 m)80.4 in (2.04 m)Overall Length with Foundry/Excavating Bucket129.1 in (3.28 m)129.1 in (3.28 m)142.6 in (3.62 m)141.9 in (3.60 m)144.4 in (3.67 m)Track Width12.6 in (320 mm)15.75 in (400 mm)17.7 in (450 mm)17.7 in (450 mm)17.7 in (450 mm)* Note:CEGR Cooled Exhaust Gas Recirculation DOC Diesel Oxidation CatalystSCR Selective Catalytic Reduction22

BUILDING CONSTRUCTIONCASE saves you time and helps reach maximumproductivity through features like maintenancefree Tier 4 Final solutions, easy pattern selectionand stored operator profiles that help you focusmore on work and less on setting or servicing theequipment.23

SINCE 1842BUILDING ASTRONG CASE.Since 1842, we at CASE Construction Equipment have lived by anunwavering commitment to build practical, intuitive solutions thatdeliver both efficiency and productivity. We continually strive to makeit easier for our customers to implement emerging technologies andnew compliance mandates.Today, our global scale combined with our local expertise enables usto keep customers’ real-world challenges at the center of our productdevelopment. This focus has led to numerous innovations like RideControl , electro-hydraulic controls, blade shake, PowerLift , overcenter boom design and the peace of mind that only CASE ProCareprovides.Every CASE machine is backed by more than 300 North Americandealer locations, thousands of OEM, remanufactured and all-makesparts, and flexible financing and insurance options that provide thekind of reliable, steadfast support you expect from a professionalpartner.We are passionate about improving the lives of others, whetherinvesting in our veterans or raising awareness about local infrastructureinitiatives through Dire States. Our goal is to build both strongermachines — and stronger communities.At the end of the day, we do what’s right by our customers and ourcommunities so that they can count on CASE.CaseCE.com/CTL 2020 CNH Industrial America LLC. All rights reserved. CASE,CNH Industrial Capital and CNH Industrial Trademarks are registeredin the United States and many other countries, owned by or licensedto CNH Industrial N.V., its subsidiaries or affiliates. Printed in U.S.A.Contains 10%.post-consumer fiber.Form No. CCE202010CTLReplaces Form No. CCE202008CTLIMPORTANT: CASE Construction Equipment Inc. reserves the rightto change these specifications without notice and without incurringany obligation relating to such change. Availability of some modelsand equipment builds vary according to the country in which theequipment is used. The illustrations and text may include optionalequipment and accessories and may not include all standardequipment. Your CASE dealer/distributor will be able to give youdetails of the products and their specifications available in your area.CASE Construction Equipment is biodiesel-friendly.NOTE: All engines meet current EPA emissionsregulations. All specifications are stated inaccordance with SAE Standards or RecommendedPractices, where applicable.Always read the Operator’s Manual before operatingequipment. Inspect equipment before using it, andbe sure it is operating properly. Follow the productsafety signs and use any safety features provided.

QUICK, TOOL-FREE SWITCHING Switch loader attachments without the added hassle of getting out of your cab. Standard Connect Under Pressure (CUP) manifolds facilitate fast, easy and tool-free connecting and disconnecting of hydraulic lines by releasing pressure into the standard case drain. RENTAL Simple is powerful. CASE compact track loaders