Transcription

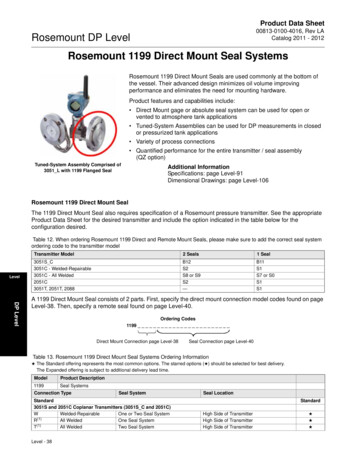

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelRosemount 1199 Direct Mount Seal SystemsRosemount 1199 Direct Mount Seals are used commonly at the bottom ofthe vessel. Their advanced design minimizes oil volume improvingperformance and eliminates the need for mounting hardware.Product features and capabilities include: Direct Mount gage or absolute seal system can be used for open orvented to atmosphere tank applications Tuned-System Assemblies can be used for DP measurements in closedor pressurized tank applications Variety of process connections Quantified performance for the entire transmitter / seal assembly(QZ option)Tuned-System Assembly Comprised of3051 L with 1199 Flanged SealAdditional InformationSpecifications: page Level-91Dimensional Drawings: page Level-106Rosemount 1199 Direct Mount SealThe 1199 Direct Mount Seal also requires specification of a Rosemount pressure transmitter. See the appropriateProduct Data Sheet for the desired transmitter and include the option indicated in the table below for theconfiguration desired.Table 12. When ordering Rosemount 1199 Direct and Remote Mount Seals, please make sure to add the correct seal systemordering code to the transmitter modelLevelTransmitter Model2 Seals1 Seal3051S C3051C - Welded-Repairable3051C - All Welded2051C3051T, 2051T, 2088B12S2S8 or S9S2—B11S1S7 or S0S1S1DP LevelA 1199 Direct Mount Seal consists of 2 parts. First, specify the direct mount connection model codes found on pageLevel-38. Then, specify a remote seal found on page Level-40.Ordering Codes1199Direct Mount Connection page Level-38Seal Connection page Level-40Table 13. Rosemount 1199 Direct Mount Seal Systems Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.ModelProduct Description1199Seal SystemsConnection TypeSeal SystemStandard3051S and 2051C Coplanar Transmitters (3051S C and 2051C)WWelded-RepairableOne or Two Seal SystemR(1)All WeldedOne Seal SystemT(1)All WeldedTwo Seal SystemLevel - 38Seal LocationStandardHigh Side of TransmitterHigh Side of TransmitterHigh Side of Transmitter

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 13. Rosemount 1199 Direct Mount Seal Systems Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.All In-Line Transmitters (3051S T, 3051T, 2051T, 2088)WAll WeldedOne or Two Seal SystemHigh Side of Transmitter3051C Coplanar Transmitters (3051C)WDetermined byOne or Two Seal SystemHigh Side of TransmitterTransmitter CodeSeal Fill FluidSpecificTemperature Limits(2)GravityNo Extension 2-in. (50 mm)4-in. (100 mm)Thermal Optimizerat 77 FExtensionExtension(25 C)StandardASyltherm XLT 0.85-102 to 293 F -102 to 293 F102 to 293 F102 to 293 F(-75 to 145 C)(-75 to 145 C)(-75 to 145 C)CSilicone 7041.0732 to 401 F32 to 464 F32 to 500 F32 to 599 F(0 to 205 C)(3) (0 to 240 C)(3)(0 to 260 C)(3)(0 to 315 C)DSilicone 2000.93-49 to 401 F-49 to 401 F-49 to 401 F-49 to 401 F(-45 to 205 C) (-45 to 205 C)(-45 to 205 C)(-45 to 205 C)HInert1.85-49 to 320 F-49 to 320 F-49 to 320 F-49 to 320 F(Halocarbon)(-45 to 160 C) (-45 to 160 C)(-45 to 160 C)(-45 to 160 C)G(4)(5)Glycerine1.135 to 203 F5 to 203 F5 to 203 F5 to 203 Fand Water(-15 to 95 C)(-15 to 95 C)(-15 to 95 C)(-15 to 95 C)N(4)Neobee M-20 0.925 to 401 F(3)5 to 437 F5 to 437 F5 to 437 F(-15 to 205 C) (-15 to 225 C)(-15 to 225 C)(-15 to 225 C)P(4)(5)Propylene1.025 to 203 F5 to 203 F5 to 203 F5 to 203 FGlycol and(-15 to 95 C)(-15 to 95 C)(-15 to 95 C)(-15 to 95 C)Water Standard Seal Connection TypeStandardAStandard Direct MountDirect Mount Connection TypeSeal SystemConnection TypeStandardStandardLevelAll Coplanar Transmitters (3051S C, 3051C and 2051C)94Direct Mount, No Extension93Direct Mount, No Extension96Direct Mount, No Extension97Direct Mount, No ExtensionB4Direct Mount, 2 in. (50 mm) ExtensionB3Direct Mount, 2 in. (50 mm) ExtensionB6Direct Mount, 2 in. (50 mm) ExtensionB7Direct Mount, 2 in. (50 mm) ExtensionD4Direct Mount, 4 in. (100 mm) ExtensionD3Direct Mount, 4 in. (100 mm) ExtensionD6Direct Mount, 4 in. (100 mm) ExtensionD7Direct Mount, 4 in. (100 mm) ExtensionAll In-Line Transmitters (3051S T, 3051T, 2051T, 2088)95Direct Mount, No ExtensionD5Thermal OptimizerTuned-System Assembly, two sealsOne Seal SystemTuned-System Assembly, two sealsOne Seal SystemTuned-System Assembly, two sealsOne Seal SystemTuned-System Assembly, two sealsOne Seal SystemTuned-System Assembly, two sealsOne Seal SystemTuned-System Assembly, two sealsOne Seal SystemWelded-RepairableWelded-RepairableAll WeldedAll WeldedWelded-RepairableWelded-RepairableAll WeldedAll WeldedWelded-RepairableWelded-RepairableAll WeldedAll Welded One Seal SystemOne Seal SystemAll WeldedAll Welded (1) All welded system connection types require either a 316L SST or Alloy C-276 isolating diaphragm in the pressure transmitter model codes.(2) At ambient pressure of 14.7 psia (1 bar-a) and ambient temperature of 70 F and must be further derated if ambient, temperature exceeds 70 F (21 C).(3) Maximum process temperature is limited by heat transfer to the transmitter.(4) This is a food grade fill fluid.(5) Not suitable for vacuum applications.Level - 39DP LevelExtension Length

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelContinue specifying a completed model number by choosing a remote seal type below: The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time. Transmitter Availability— UnavailableCoplanarExtensionsFlanged Seal AssembliesInline 0 in. 2-in.4-in.Process ConnectionsStandardpageLevel-49FFW Flush Flanged Seal (1) 2-in. / DN 50 / 50A3-in. / DN 80 / 80A4-in. / DN 100 / 100ApageLevel-52RFW Flanged Seal — 1/2-in.pageLevel-55EFW Extended Flanged Seal (1) pageLevel-59FCW Flush Flanged Seal – Ring Type Joint(RTJ) Gasket Surface (1)pageLevel-61RCW Ring Type Joint (RTJ) Flanged Seal pageLevel-63FUW and FVW Flush Flanged Type Seals Standard / DN 15/4-in.1-in. / DN 25 / 25A11/2-in. / DN 40 / 40A 1 1/2-in. / DN 40 / 40A2-in. / DN 50 / 50A3-in. / Headbox/ DN 80 / 80A4-in. / Headbox/ DN 100 / 100A 2-in.3-in.— ½-in.¾-in.1-in.1 ½-in. DN 50DN 803ExpandedLevelDP LevelCoplanarExtensionsThreaded Seal AssembliesInline 0 in. 2-in.4-in.Process ConnectionsStandardpageLevel-64RTW Threaded Seal — ¼ –18 NPT3/8 –18 NPT½ –14 NPT¾ –14 NPT1 – 11.5 NPT1 ¼ –11.5 NPT1 ½ –11.5 NPTG1/2 A DIN 16288R1/2 per ISO 7/1pageLevel-67HTS Male Threaded Seal G1G1 ½G21-11.5 NPT1 ½ -11.5 NPT2-11.5 NPTExpandedLevel - 40Standard

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP Level The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.CoplanarExtensionsHygienic Seal AssembliesInline 0 in. 2-in.4-in.Process ConnectionsStandardpageLevel-68SCW Hygienic Tri-Clover Style Tri-ClampSeal 1 ½-in.2-in.2 ½-in.3-in.4-in.pageLevel-69SSW Hygienic Tank Spud Seal 2-in. Extension6-in. ExtensionpageLevel-70STW Hygienic Thin Wall Tank Spud Seal — 0.8 in ExtensionpageLevel-71EES Hygienic Flanged Tank SpudExtended Seal DN 50DN 80pageLevel-72VCS Tri-clamp In-Line Seal ———1-in.1 ½-in.2-in.3-in.4-in.pageLevel-73SVS Varivent Compatible HygienicConnection Seal Tuchenhagen Varivent CompatiblepageLevel-74SHP Hygienic Cherry-Burrell “I” Line Seal ———2-in.3-in.pageLevel-75SLS Dairy Process Connection - FemaleThread Seal per DIN 11851 ———DN 40DN 50Standard ExpandedDP LevelLevelCoplanarExtensionsSpecialty Seal AssembliesInline 0 in. 2-in.4-in.Process ConnectionsExpandedpageLevel-76WSP Saddle Seal — 2-in.3-in.4-in. or LargerLevel - 41

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP Level The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.pageLevel-77UCP Male Threaded Pipe Mount Seals andPMW Paper Mill Sleeve Seals ——1 ½-in. with ThreadedKnurled Nut1-in. with Cap ScrewRetainerpageLevel-78CTW Chemical Tee Seal — Retro-fitpageLevel-79TFS Wafer Style In-Line Seal ———pageLevel-80WFW Flow-Thru Flanged Seal — 1-in. / DN 251 ½-in. / DN 402-in. / DN 503-in. / DN 804-in. / DN 1001-in.2-in.3-in.(1) Available with ANSI Class 300 or EN 1092-1 PN 40 or JIS B2238 20K or lower flange ratings.LevelDP LevelLevel - 42

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelRosemount 1199 Remote Mount Seal SystemsRosemount 1199 Remote Mount Seals are used commonly at the top of thevessel when a DP measurement is required. They are available in threedifferent diameters to optimize time response and reduce temperatureeffects.Product features and capabilities include: Remote Mount Seals can be used for high temperature applications Remote Mount Seals are used on the low pressure side of the transmitterfor Tuned-System Assemblies that can be used for DP measurements inclosed or pressurized tank applications Variety of process connectionsTuned-System AssemblyComprised of 3051 L with1199 Flanged Seal Quantified performance for the entire transmitter / seal assembly (QZoption)Additional InformationSpecifications: page Level-81Certifications: page Level-93Dimensional Drawings: page Level-106Rosemount 1199 Remote Mount SealThe 1199 Remote Mount Seal also requires specification of a Rosemount pressure transmitter. See the appropriateProduct Data Sheet for the desired transmitter and include the option indicated in the table below for theconfiguration desired.Table 14. When ordering Rosemount 1199 Direct and Remote Mount Seals, please make sure to add the correct seal systemordering code to the transmitter model2 Seals1 SealB12S2S8 or S9S2—B11S1S7 or S0S1S1LevelA 1199 Remote Mount Seal consists of 2 parts. First, specify the capillary model codes found on page Level-44.Then, specify a remote seal found on page Level-45.Ordering Codes1199Remote Mount Connection page Level-44Seal Connection page Level-45Level - 43DP LevelTransmitter Model3051S C3051C - Welded-Repairable3051C - All Welded2051C3051T, 2051T, 2088

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelCapillary/Fill FluidNOTE:Use Table 15 for Capillary Type Connections. Use Table 13 for Direct Mount Type Connections.Table 15. Rosemount 1199 Remote Mount Seal Systems Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.ModelProduct Description1199Seal SystemConnection TypeSeal SystemStandard3051S and 2051 Coplanar Transmitters (3051S C and 2051C)WWelded-RepairableOne or Two Seal SystemMWelded-RepairableOne or Two Seal SystemDWelded-RepairableTwo Seal SystemR(1)All WeldedOne Seal SystemT(1)All WeldedTwo Seal SystemS(1)All WeldedTwo Seal SystemAll In-Line Transmitters (3051S T, 3051T, 2051T, 2088)WAll WeldedOne or Two Seal System3051 Coplanar Transmitters (3051C)WDetermined by Transmitter Code One or Two Seal SystemMDetermined by Transmitter Code One or Two Seal SystemDDetermined by Transmitter Code Two Seal SystemLevelSeal LocationStandardHigh Side of TransmitterLow Side of TransmitterBalanced System - Same Seal on Low and HighSideHigh Side of TransmitterHigh Side of TransmitterLow Side of Transmitter High Side of Transmitter High Side of TransmitterLow Side of TransmitterBalanced System - Same Seal on Low and HighSide DP LevelSeal Fill FluidSpecific Gravity at77 F (25 C)Temperature Limits(2)StandardA(3)Syltherm XLTCSilicone 704DSilicone 200HInert (Halocarbon)G(4)(5) Glycerin and WaterN(4)Neobee M-20P(4)(5)Propylene Glycol and Water0.851.070.931.851.130.921.02–102 to 293 F (–75 to 145 C)32 to 599 F (0 to 315 C)–49 to 401 F (–45 to 205 C)–49 to 320 F (–45 to 160 C)5 to 203 F (–15 to 95 C)5 to 437 F (–15 to 225 C)5 to 203 F (–15 to 95 ) Standard Seal Connection Type / Capillary ID, DescriptionStandardB0.03-in. (0.711 mm) IDC0.04-in. (1.092 mm) IDD0.075-in. (1.905 mm) IDE0.03-in. (0.711 mm) ID, PVC CoatedF0.04-in. (1.092 mm) ID, PVC CoatedG0.075-in. (1.905 mm) ID, PVC CoatedH0.03-in. (0.711 mm) ID, 4-in. Support TubeJ0.04-in. (1.092 mm) ID, 4-in. Support TubeK0.075-in. (1.905 mm) ID, 4-in. Support TubeM(6)0.03-in. (0.711 mm) ID, PVC Coated, 4-in. Support Tube with Closed EndN(6)0.04-in. (1.092 mm) ID, PVC Coated, 4-in. Support Tube with Closed EndP(6)0.075-in. (1.905 mm) ID, PVC Coated, 4-in. Support Tube with Closed EndStandard Capillary Length / Direct MountStandard011 ft (0.3 m)055 ft (1.5 m)Level - 44Standard

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 15. Rosemount 1199 Remote Mount Seal Systems Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time. 1010 ft (3.0 m)1515 ft (4.5 m)2020 ft (6.1 m)511.6 ft (0.5 m)523.3 ft (1.0 m)534.9 ft (1.5 m)546.6 ft (2.0 m)558.2 ft (2.5 m)569.8 ft (3.0 m)5711.5 ft (3.5 m)5813.1 ft (4.0 m)5916.4 ft (5.0 m)6019.7 ft (6.0 m)Expanded2525 ft (7.6 m)3030 ft (9.1 m)3535 ft (10.7 m)4040 ft (12.2 m)4545 ft (13.7 m)5050 ft (15.2 m)6123 ft (7.0 m)6226.2 ft (8.0 m)6329.5 ft (9.0 m)6432.8 ft (10.0 m)6536.1 ft (11.0 m)6639.4 ft (12.0 m)6742.6 ft (13.0 m)6845.9 ft (14.0 m)6949.2 ft (15.0 m)(1) All welded system connection types require either a 316L SST or Alloy C-276 isolating diaphragm in the pressure transmitter model codes.(2) At ambient pressure of 14.7 psia (1 bar-a) and ambient temperature of 70 F and must be further derated if ambient, temperature exceeds 70 F (21 C).Level(3) Temperature limits are reduced in vacuum service and may be limited by seal selection.DP Level(4) This is a food grade fill fluid.(5) Not suitable for vacuum applications.(6) Compression fitting does not provide a hermetic seal.Continue specifying a completed model number by choosing a remote seal type below: The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.Flanged Seal AssembliesProcess ConnectionsStandardpageLevel-49FFW Flush Flanged Seal2-in. / DN 50 / 50A3-in. / DN 80 / 80A4-in. / DN 100 / 100ApageLevel-52RFW Flanged Seal1/2-in./ DN 15/4-in.1-in. / DN 25 / 25A11/2-in. / DN 40 / 40A3Standard Level - 45

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP Level The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.1 1/2-in. / DN 40 / 40A2-in. / DN 50 / 50A3-in. / Headbox/ DN 80 / 80A4-in. / Headbox/ DN 100 / 100A2-in. / DN503-in. / DN 80pageLevel-55EFW Extended Flanged SealpageLevel-57PFW Pancake SealpageLevel-59FCW Flush Flanged Seal – Ring Type Joint (RTJ) Gasket Surface2-in.3-in.pageLevel-61RCW Ring Type Joint (RTJ) Flanged Seal½-in.¾-in.1-in.1 ½-in.pageLevel-63FUW and FVW Flush Flanged Type SealsDN 50DN 80 ExpandedThreaded Seal AssembliesProcess ConnectionsStandardpageLevel-64RTW Threaded Seal¼ –18 NPT3/8 –18 NPT½ –14 NPT¾ –14 NPT1 – 11.5 NPT1 ¼ –11.5 NPT1 ½ –11.5 NPTG1/2 A DIN 16288R1/2 per ISO 7/1pageLevel-67HTS Male Threaded SealG1G1 ½G21-11.5 NPT1 ½ -11.5 NPT2-11.5 NPTLevelStandard DP LevelExpandedHygienic Seal AssembliesProcess ConnectionsStandardpageLevel-68Level - 46SCW Hygienic Tri-Clover Style Tri-Clamp Seal1 ½-in.2-in.2 ½-in.3-in.4-in.Standard

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP Level The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.pageLevel-69SSW Hygienic Tank Spud Seal2-in. Extension6-in. ExtensionpageLevel-70STW Hygienic Thin Wall Tank Spud Seal0.8 in ExtensionpageLevel-71EES Hygienic Flanged Tank Spud Extended SealDN 50DN 80pageLevel-72VCS Tri-clamp In-Line Seal1-in.1 ½-in.2-in.3-in.4-in.pageLevel-73SVS Varivent Compatible Hygienic Connection SealTuchenhagen VariventCompatiblepageLevel-74SHP Hygienic Cherry-Burrell “I” Line Seal2-in.3-in.pageLevel-75SLS Dairy Process Connection - Female Thread Seal per DIN 11851DN 40DN 50 ExpandedProcess ConnectionsDP LevelSpecialty Seal AssembliesLevelExpandedpageLevel-76WSP Saddle Seal2-in.3-in.4-in. or LargerpageLevel-77UCP Male Threaded Pipe Mount Seals and PMW Paper Mill SleeveSeals1 ½-in. with ThreadedKnurled Nut1-in. with Cap ScrewRetainerLevel - 47

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP Level The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.LevelDP LevelLevel - 48pageLevel-78CTW Chemical Tee SealRetro-fitpageLevel-79TFS Wafer Style In-Line Seal1-in. / DN 251 ½-in. / DN 402-in. / DN 503-in. / DN 804-in. / DN 100pageLevel-80WFW Flow-Thru Flanged Seal1-in.2-in.3-in.

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelFlanged Seal AssembliesFFW FLUSH FLANGED SEALTable 16. FFW Flush Flanged Seal – Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.CodeStandardADExpandedJIndustry StandardsANSI/ASME B16.5 (American National Standards Institute/American Society of Mechanical Engineers)EN 1092-1 (European Standard)Standard JIS B2238 (Japanese Industrial Standard)Process Connection StyleStandardFFWStandard Flush Flanged SealProcess Connection SizeStandardG7J9ANSI/ASME B16.5EN 1092-1JIS B22382-in.3-in.—4-in.DN 50—DN 80DN 10050 A80 A—100 AANSI/ASME B16.5EN 1092-1JIS B2238Class 150Class 300Class 600————PN 4010K20K40K——Class 900Class 1500Class 2500———PN 10 / 16 (DN 100 only)———PN 63PN 100PN 160———————Diaphragm and WettedUpper HousingFlange316L SST316L SSTAlloy C-276, seam weldedAlloy C-276, seam weldedTantalum, seam weldedTantalum, seam weldedTantalum, brazedTantalum, brazed316L SST316L SST316L SST316L SST316L SST316L SST316L SST316L SSTCS316 SSTCS316 SSTCS316 SSTCS316 SSTStandard Flange / Pressure RatingStandard Diaphragm and Wetted, Upper Housing, Flange 3(1)(2)(3)(4)D3(1)(2)(3)(4)LevelDP LevelStandard124GExpandedE567HJKStandard Level - 49

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 16. FFW Flush Flanged Seal – Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.ExpandedMB(1)(2)KB(1)(2)DJDFDVRH(2) (5)DH(6)DEDPWW(2)(7)DZ(6)D4D5Alloy C-276, solid faceplateAlloy C-276, solid faceplateAlloy B304L SSTAlloy 400Titanium Grade 4Titanium Grade 4Alloy 600Nickel 201316Ti SST (WNr 1.4571)Zirconium 702Alloy C-22Duplex 2507 SSTAlloy C-276 / 316L SSTAlloy C-276 / 316L SST316L SST316L SST316L SSTTitanium GR.4316L SST316L SST316L SST316Ti SST (WNr 1.4571)316L SST316L SST316L SSTCS316 SST316 SST316 SST316 SST316 SST316 SST316 SST316 SST316Ti SST (WNr 1.4571)316 SST316 SST316 SSTFlushing Connection Ring Material (Lower Housing)(8)Standard0ABExpanded2H6VNone316L SSTAlloy C-276Standard Duplex 2205 SSTTitanium Grade 4Nickel 201Alloy 400Flushing Connection Options, Quantity (Size)LevelStandard01379None1 (1/4-18 NPT)2 (1/4-18 NPT)1 (1/2-14 NPT)2 (1/2-14 NPT)Standard Options (Include with selected model number)DP LevelGasket MaterialStandardJExpandedNKPTFE gasket (for use with flushing connection ring)Standard Grafoil gasket (for use with flushing connection ring)Barium Sulfate filled PTFE gasket (for use with flushing connection ring)Flushing Plug, Vent/Drain ValveStandardDGHAlloy C-276 plug(s) for flushing connection(s)316 SST plug(s) for flushing connection(s)316 SST vent/drain for flushing connection(s)Diaphragm ThicknessExpandedC70.006-in. (150 µm) available with 316L SST, Alloy C-276, and Duplex 2507 SST for abrasive applications0.002-in. (50 µm) available with 316L SST and Alloy C-276Mounting FlangeExpanded4(9)Level - 50Flat face, flush flangedStandard

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 16. FFW Flush Flanged Seal – Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.Code ConformanceStandardT(10)Wetted Materials Compliance to NACE MRO175/ISO 15156, MRO103Standard Gasket Surface FinishExpanded1Gasket Surface Ra 125 Max.Cold Temp ApplicationStandardBExtra Fill For Cold Temp ApplicationStandard Diaphragm CoatingExpandedU(11)V(12)0.001-in. (25 µm) gold plated DiaphragmPTFE coated diaphragm for nonstick purposes onlyCapillary ChangeExpanded2Radial capillary connectionAlternate DesignStandardE(12)One Piece DesignTypical Model Number: 1199 W DC 1 0 A FFW 7 1 DA 0 0Standard (1) Only available with two piece design.(2) For use with spiral wound metallic gaskets.(3) Not available with option code C.(4) Only available in Process Connection Size code G, 7, and J.(5) Not available with welded capillary connections or direct mount.(6) Operating temperature limited to 302 F (150 C).(7) Only available with one-piece design, option code E.Level(8) Supplied standard with ThermoTork TN9000.(10) Materials of Construction comply with metallurgical requirements highlighted within NACE MR0175/ISO 15156 for sour oil field production environments.Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refiningenvironments.(11) Only available on 316LSS, Alloy 400 and Alloy C-276.(12) Not available with transmitter option code Q8, for Material Traceability per EN 10204 3.1 of the transmitter / seal assembly.Level - 51DP Level(9) The mounting flange and upper housing are a single item for the one-piece design. Only available with diaphragm and wetted part material codes DA, DB,DJ, DF, DV, DH, DE, DP, WW, DZ, D4, DC, and D5.

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelRFW FLANGED SEALTable 17. RFW Flanged Seal Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.CodeIndustry StandardStandardAANSI/ASME B16.5 (American National Standards Institute/American Society of Mechanical Engineers)DEN 1092-1 (European Standard)ExpandedJJIS B2238 (Japanese Industrial Standard)Standard Process Connection StyleStandardRFWStandard Flanged SealProcess Connection SizeStandard24DFExpanded1ABCStandardANSI/ASME B16.5EN 1092-1JIS B22381-in.11/2-in.————DN 25DN 4025A40A——1—DN 10DN 15DN 20—10A15A20AANSI/ASME B16.5EN 1092-1JIS B2238Class 150Class 300Class 600————PN 4010K20K40K—Class 900Class 1500Class 2500——————PN 63PN 100PN 160——————DiaphragmUpper HousingFlange316L SST316L SSTAlloy C-276Alloy C-276TantalumTantalum316L SST316L SST316L SST316L SST316L SST316L SSTCS316 SSTCS316 SSTCS316 SST304L SSTAlloy BAlloy 600316L SST316L SST316L SST316 SST316 SST316 SST/2-in.3/4-in.—— Flange/Pressure RatingLevelDP LevelStandard124GExpanded567HJKStandard Diaphragm, Upper Housing, Flange MaterialStandardCADACBDBCCDCExpandedDFDJDELevel - 52Standard

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 17. RFW Flanged Seal Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.DVDPDKRH(1)DHD4D5DZAlloy 400Nickel 201Alloy 20Titanium Grade 4Titanium Grade 4Alloy C-22Duplex 2507 SSTZirconium 702316L SST316L SST316L SSTTitanium Grade 4316L SST316L SST316L SST316L SST316 SST316 SST316 SST316 SST316 SST316 SST316 SST316 SSTFlushing Connection Ring Material (Lower Housing)(2)StandardABDExpanded2FHVC316L SSTAlloy C-276Plated CSStandard Duplex 2205304L SSTTitanium Grade 4Alloy 400Tantalum lined 316L SST (no flushing connection allowed)Flushing Connection Options, Quantity SizeStandard513Expanded79None1 (1/4-18 NPT)2 (1/4-18 NPT)Standard 1 (1/2-14 NPT)2 (1/2-14 NPT)Options (Include with selected model number)Gasket MaterialPTFE gasketStandard Grafoil gasketBarium Sulfate filled PTFE gasketEthylene Propylene gasketFlushing Plug, Vent/Drain ValveStandardDGHAlloy C-276 plug(s) for flushing connection(s)316 SST plug(s) for flushing connection(s)316 SST vent/drain for flushing connection(s)Standard Diaphragm ThicknessExpandedC0.006-in. (150 µm) available with 316L SST, Alloy C-276, and Duplex 2507 SST for abrasive applicationsBolt MaterialExpanded3304 SST Bolts (Only available for Stud Bolt Design)Code ConformanceStandardT(3)Wetted Materials Compliance to NACE MRO175/ISO 15156, MRO103LevelDP LevelStandardJExpandedNKRStandard Gasket Surface FinishExpanded1Gasket Surface Ra 125 Max.Level - 53

Product Data SheetRosemount DP Level00813-0100-4016, Rev LACatalog 2011 - 2012Table 17. RFW Flanged Seal Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.Cold Temperature ApplicationStandardBExtra Fill For Cold Temp ApplicationStandard Diaphragm CoatingExpandedU(4)0.001-in. (25 µm) Gold plated diaphragmV(5)PTFE coated diaphragm for nonstick purposes onlyLarge Diaphragm SizeExpanded94.1-in. (104 mm) Diaphragm DiameterTypical Model Number: 1199 W DC 1 0 A RFW 2 1 DA A 5(1) Not available with welded capillary connections or direct mount.(2) Supplied with C4401 Aramid fiber gasket.(3) Materials of Construction comply with metallurgical requirements highlighted within NACE MR0175/ISO 15156 for sour oil field production environments.Environmental limits apply to certain materials. Consult latest standard for details. Selected materials also conform to NACE MR0103 for sour refiningenvironments.(4) Only available on 316LSS, Alloy 400 and Alloy C-276.(5) Not available with transmitter option code Q8, for Material Traceability per EN 10204 3.1 of the transmitter / seal assembly.LevelDP LevelLevel - 54

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelEFW EXTENDED FLANGED SEALTable 18. EFW Extended Flanged Seal Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time. CodeIndustry Standard Available— UnavailableStandardAANSI/ASME B16.5 (American National Standards Institute/American Society of Mechanical Engineers)DEN 1092-1 (European Standard)ExpandedJJIS B2238 (Japanese Industrial Standards)Standard Process Connection StyleStandardEFWExtended Flanged SealStandard Process Connection SizeStandard79Expanded4GHKANSI/ASME B16.5EN 1092-1JIS B2238Extension Diameters3-in.4-in.DN 80DN 10080A100A2.58-in. (66 mm)3.50-in. (89 mm)11/2-in.2-in.3-in. (Headbox)4-in. (Headbox)DN 40DN 50DN 80 (Headbox)DN 100 (Headbox)40A50A—1.45-in. (37 mm)1.90-in. (49 mm)2.875-in. (74 mm)3.780-in. (97 mm)ANSI/ASME B16.5EN 1092-1JIS B2238Class 150Class 300Class 600————PN 4010K20K40K——Class 900Class 1500Class 2500———PN 10/16 (DN 100 only)———PN 63PN 100PN 160———————Standard Flange/Pressure RatingDiaphragm, Extension and Gasket Surface, Upper Housing, Flange mExtension/Gasket SurfaceUpperHousingMountingFlange316L SST316L SSTAlloy C-276Alloy C-276316L SST316L SSTAlloy C-276Alloy C-276316L SST316L SST316L SST316L SSTAlloy C-276TantalumTantalum316L SST316L SSTTantalum Lined316L SST316L SST316L SSTStandard LevelDP LevelStandard124GExpandedE567HJKAvailable with ProcessConnection Code794GHK316 SSTCS316 SSTCS 316 SST316 SST316 SST — —————— Standard Level - 55

Product Data Sheet00813-0100-4016, Rev LACatalog 2011 - 2012Rosemount DP LevelTable 18. EFW Extended Flanged Seal Ordering Information The Standard offering represents the most common options. The starred options ( ) should be selected for best delivery.The Expanded offering is subject to additional delivery lead time.D5D9Duplex 2507 SST Duplex 2205 SSTDuplex 2507 SST 316L SST316L SST316L SST316 SST316 SST Extension LengthStandard246Expanded813579ANSI/ASME B16.5EN 1092-1 / JIS B22382-in.4-in.6-in.50 mm100 mm150 mm8-in.1-in.3-in.5-in.7-in.9-in.200 mm25 mm75 mm125 mm175 mm225 mmStandard Fractional Extension LengthANSI/ASME B16.5Standard00-in.EN 1092-1 / JIS B22380 mmStandard Options (Include with selected model number)Diaphragm ThicknessExpandedC0.006-in. (150 µm) available with 316L SST, Alloy C-276, and Duplex 2507 SST for abrasive applicationsCode ConformanceStandardT(1)Wetted Materials Compliance to NACE MRO175/ISO 15156, MRO103Standard Gasket Surface FinishLevelExpanded1Gasket Surface Ra 125 Max.Cold Temperature ApplicationDP LevelSta

A 1199 Remote Mount Seal consists of 2 parts. First, specify the capillary model codes found on page Level-44. Then, specify a remote seal found on page Level-45. Table 14. When ordering Rosemount 1199 Direct and Remote Mount Seals, please make sure to add the correct seal system ordering code to the transmitter model Transmitter Model 2 Seals .