Transcription

Every year your industry grows more competitive. Products are manufactured faster,cheaper, better. Demands are greater, and your customers’ requirements are continuallychanging. What doesn't change is your need for a reliable, competent source forthreaded inserts and precision machined products. At Tri-Star Industries, we want to bethat source, and we will work hard to earn and maintain your confidence in us.What is important to you is important to us. At Tri-Star Industries, our top priority isTotal Customer Satisfaction. Our program emphasizes: Quality – We are registered to ISO 9001, and Statistical Process Control is anintegral part of our manufacturing process. On-time Delivery – Most orders for stock items ship the same day. We areproud that, year after year, we average greater than 98.5% on-time delivery. Competitive Pricing – Our experienced personnel, the most advanced equipmentand highly efficient production methods, combined with blanket order programs,cumulative pricing plans and low minimums, ensure the best price possible forevery order. Customer Service – Our conscientious staff is committed to providing a prompt,courteous response to every customer request. In addition, Tri-Star’s extensivedatabase is used by every department, assuring that all certification, packagingand labeling requirements are met. Application Engineering – With our expertise in design engineering, plastics andthe manufacturing process, we are unsurpassed in the design of cost-effectivealternatives for special applications.We invite you to rely on Tri-Star Industries for the threaded inserts and precisionmachined products that will help you stay competitive and profitable. We wantyour business. From design to delivery, we will focus on your total satisfaction.Let us prove it to you.Sincerely,Andrew NowakowskiPresident

What are inserts ?Inserts are used to strengthen plastic partsin which screws are to be installed andremoved more than once. Most are made ofbrass, which provides long thread life as wellas a solid, secure fastening base. Ours arealso available in aluminum, stainless steeland free-machining steel by special order.Inserts are commonly used to reinforce twotypes of plastic: Thermoplastic or ThermosetPlastic. Thermoplastics are like wax. Atusable temperatures they are solid, but atelevated temperatures they get soft andmelt. In contrast, thermoset plastics havea molecularly cross-linked structure which ispermanently “set” into shape during themanufacturing process.Thermoplastic compounds are generallymore resilient than thermosets and respondwell to the ultrasonic or thermal installation ofinserts. Thermoset compounds, however, areoften brittle and less resilient than thermoplastics. They respond better to molding orpost-molding cold insertion.Our inserts come in a variety of styles andsizes to meet a variety of applications. Theyare manufactured to the following threadspecifications: UNC-2B and UNF-2B for inchthreads and ISO-6H for metric threads.Installation methodsInsert Molding: Molding an insert into anassembly increases the total molding timebecause extra time is needed to load theinsert. Molded-in inserts may also cause sinkmarks. They are widely used with thermoset(non-meltable) plastics.Post-molded: Post-molded inserts eliminatethe downtime associated with molding athread or an insert into a plastic part, such asdie damage caused by improper placement.Advantages include faster assembly,reduced open press time and no sink marks.Ultrasonic: The most common method forinstalling inserts into thermoplastic materials,it provides fast, positive anchoring. An insertis placed in a molded or drilled hole whichguides it and provides resistance. Anultrasonic horn contacts the insert anddelivers ultrasonic vibrations which travelthrough the insert during the “weld cycle.”Frictional heat is immediately developedwhich melts the plastic as the horn drives theinsert into position. After the vibrationscease, the equipment applies clamp pressureuntil the plastic cools, preventing back-out.Thermal: During thermal/heat insertion, theinsert is placed into a molded or drilled hole.Pressure is applied with a heated probe thatcontacts the top surface and minor threaddiameter of the insert. Localized meltingtakes place, and plastic flows in and aroundthe knurls and serrations. When the properdepth is reached, the probe is removed andthe plastic re-solidifies, locking the insert inplace. Upon removal of the probe, a minimalamount of withdrawal (back-out) of the insertmay occur. Thermal/heat insertion provides agood alternative to the ultrasonic method, butit is a slower process. Some benefits include: Multiple inserts can be installedsimultaneously, even on different levels Quiet when compared to ultrasonic Thermal equipment is less expensive thanultrasonic equipment Excellent for larger insertsCold Insertion: Some inserts can simply bepressed in after molding. However, pressinginserts into cold plastic may create unwantedstress. Larger boss (or wall thicknesses) arerequired to prevent stress fracture. Pull,torque and jack-out strengths are significantlylower compared to thermal or ultrasonicinstallation.Variables to considerLubricants, Fillers or Glass in the Plastic:If the plastic’s filler or glass content exceeds40%, assembly or performance problemsmay result.Molded Versus Drilled Holes: Molded holesprovide better performance than drilled holesbecause a strong skin of denser material isformed around them during molding. This isparticularly true with structural foam plasticswhich are porous under the skin.Plating and Color-coding: We offer a fullrange of plating and/or color-coding services.The most common metal finishes includenickel, tin and zinc. Inserts of similar sizeand configuration are often color-coded toprevent inadvertent mixing (inch threads vs.metric threads).3

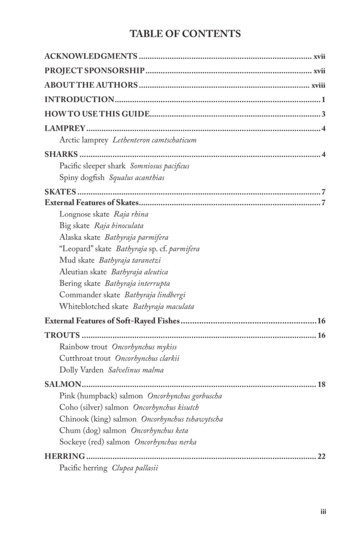

Pg.No.67H Series Tapered Inserts – The leading insert for ultrasonic or thermal installation intothermoplastic or structural foam. A row of unique “knuckle knurls” reduces residual stressand increases strength. The tapered design reduces installation time, making alignmentfaster and more accurate.89C Series Chevron Inserts – Designed for straight holes using ultrasonic or thermal processes.This series features two opposing bands of sharp diagonal knurls of different diameters formaximum gripping power. A lead-in pilot diameter assures true perpendicular alignment.10HC Series Headed Chevron Inserts – The HC Series features a flange for a greaterload-bearing surface in weaker plastics. The flange provides a large contact area forelectrical connections. Used in reverse-entry applications, the HC Series offers exceptionalpull-out strengths.11S Series Symmetrical Inserts – For fast, high-volume applications, symmetrical inserts installwithout orientation using ultrasonic or thermal equipment. They are designed for straight holesand are ideal for thin-wall applications because little stress is applied to the walls of the part.12P & HP Series Press-in Inserts – Straight-hole inserts install easily in hard or thermosetplastics without heat or special equipment. Three bands of helical knurls anchor the insertfirmly into place and provide excellent torque-out resistance.E & HE Series Expansion Inserts – Designed to provide strong, usable threads in thermosetand other hard plastics. The inserts are pressed into the plastic and expand when theassembly screw is installed. The sharp diamond knurls secure them into the plastic. Insertsare available with or without a flange.13SH & SC Series Threaded Studs – Available in H or C Series body designs. Studs arecommonly used to fulfill specific design functions, to save money in production costs, tofunction as electrical contacts or to replace self-tapping or removable screws. Thread lengthsare variable to meet your specific requirements. Special studs without threads can be usedas axles, pivots, pins, locating points or solder terminals.1415MB Series Mold-in Blind Inserts & RM Series Rotational Mold-in Blind Inserts – Designedfor mold-in applications. The inserts feature a blind thread (closed bottom) that prevents plasticfrom entering the bottom of the insert. The hex design of the rotational molded insert providesgreater holding power in softer materials.16KS Series Knurled Spacers, Threaded – Designed for a wide variety of applications, theseinserts are commonly used for stacking printed circuit boards or when a threaded spacer isrequired. They can also be molded into a plastic component.CL Series Compression Limiters – Unthreaded spacers (bushings) used to strengthenplastics during compression loads. These types of loads are generated when fasteningbolts and screws during assembly. Compression limiters can be designed for anyinstallation method.16Specials & Custom Designed Parts – Our design engineers will be happy to adaptan existing insert or custom design one specifically for your application. And you’ll besurprised how quickly we get back to you.174

When designing a mating component clearancehole, it is very important that the insert, not theplastic, carries the load. The hole in the matingcomponent should be larger than the outsidethread diameter of the screw and smaller thanthe insert diameter. This prevents the insert fromjacking out (Figure 1). When the matingcomponent hole is larger than the insertdiameter, a jack-out condition exists (Figure 2).Figure 1CorrectBoss diameter / wall thicknessThe performance value of an insert isproportional to the wall thickness (bossdiameter) surrounding it. When an increase inwall thickness does not produce an increase inperformance, optimum thickness has beenreached. Optimum thickness, on average, is twotimes the hole diameter. If a boss is too large, asharp drop in performance may result becausethe hole may become oversized as the moldedplastic shrinks. When the hole diameter is largerthan recommended, less material is displacedand the insert does not become fullyencapsulated in the plastic part – resulting inlower performance values.Hole specificationsHole depth is the key to achieving a flushinstallation and preventing excess plastic fromforming on the threads at the bottom of theinsert. Countersinks should not be molded into ahole where an insert is to be installed.All of our inserts have a pilot or “lead-in”diameter that assures proper alignment of theinsert during installation, as well as acounterbore or countersink at each end of theinsert for easy installation of the mating screw.Figure 2IncorrectShould alterations in hole sizes be necessary,please contact our Engineering Department fortechnical assistance.Remember, there are two types of molded holesreferred to in this catalog.The “straight hole” has a maximum of a 1 taperor 1/2 per side. The “tapered hole” has anapproximate 8 included angle.1 Design considerations Hole sizes are not core pin sizes. Core pins should be designed to allow for theshrinking of plastic.Min. BossMin. Depth Insert Length .030" For solid (blind) inserts and threaded studs, werecommend adding a small vent at the bottomof the hole to allow trapped air and othergasses to escape.Radius8 Min. Boss Expect your inserts to seat flush with or .005”above the plastic surface.Min. Depth Insert Length .030"Radius5

Superior in design and performanceH Series Tapered Inserts outperform all competitive inserts for ultrasonic andthermal applications. Our customers confirm it.We’ve eliminated the outward stress that occurs with other insert designs duringthe installation process. Our proprietary “knuckle knurl” ensures a more uniformflow of material into the diagonal knurls and undercuts, ensuring a complete fill,reducing installation time and increasing holding strengths.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.H SeriesLongLONG8 SHORTDEMin. BossDAMin. Depth Insert Length .030"BH 6-328-32PartNumber080 x 115HMETRICThreadSizeM1.6 x 0.35080 x 188H256 x 115HPartNumberBCDEF .004[long] .004[short] .004 .004 .002-.000 2.159.153.318M16 x 115HM16 x 188HM2.0 x 0.4A.188M20 x 115H.115Min.Boss256 x 188HM20 x 188H440 x 135HM25 x 135H440 x 219HM2.5 x 0.45 M25 x 219H.219.146.172.159.141.318440 x 285HM25 x .185.412.230.250.234.226.468540 x 150HM3.0 x 0.5540 x 250H632 x 150HM35 x 250H832 x 185HM40 x 185H832 x 375HM4.0 x 0.7.150.250M35 x 150H632 x 250H832 x 312H.135M30 x 150HM30 x 250HM3.5 x 0.6.188.150.250.185M40 x 312H.312.213.250.234.208.468M40 x 375H.375.213.250.234.208.468continued on next page6Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com

INCHThreadSize10-24METRICABCDEF .004[long] .004[short] .004 .004 .002-.000 .002-.0001024 x 150H.150.267.297.277.267.5541024 x rtNumberThreadSizePartNumber.3751024 x 375H10-321032 x 150H.150.267.297.277.267.5541032 x 40.5231.080.493.563.540.4881.080.3751032 x 375HM5.0 x 50 x 265HM50 x 438H.265.438.3002520 x 300H.5002520 x 500H2528 x 300HM6.0 x 1.02528 x 500HM60 x 300HM60 x 500H.300.500.3353118 x 335H.5623118 x 562H3124 x 335HM8.0 x 1.253124 x 562HM80 x 335HM80 x 562H.335.562.3753816 x 375H.6253816 x 625H3824 x 375H3824 x 625HM10.0 x 1.5M100 x 375HM100 x 625H.375.625Stainless Steel Inserts – Class 3A/4H screw must pass with finger torque, standard class go gage may stop onlast thread. Part numbers for Stainless Steel Inserts are the same as listed in the chart, but ending with -SS.Thread sizes of 0-80, 2-56, M1.6 and M2.0 in H Series Inserts have a single diamond knurl.Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com7

Most popular, most overall length choicesSome thermoplastics, like polycarbonates and structural foams, are brittle –especially in thin-wall applications. Our chevron inserts add considerable strength.Two opposing bands of sharp diagonal knurls provide high tensile pull-outload carrying capability. Little or no stress is applied to the walls of the molded holes.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.1 HAMin. BossMin. Depth Insert Length .030"BRadiusCINCHThreadSize2-56METRICBCHole HMin.BossPartNumberThreadSizePartNumber .004 .004 .004 .003 –.000256 x 100CM2.0 x 0.4M20 x 100C.143.100.123.126.252256 x 125CM2.0 x 0.4M20 x 125C.143.125.123.126.252256 x 157CM2.0 x 0.4M20 x 157C.143.157.123.126.252M2.5 x 0.45M25 x 135C.186.135.154.157.314M3.0 x 0.5M30 x 135C.186.135.154.157.314M2.5 x 0.45M25 x .157C.186.157.154.157.314M3.0 x 0.5M30 x 157C.186.157.154.157.314M2.5 x 0.45M25 x 170C.186.170.154.157.314M3.0 x 0.5M30 x 170C.186.170.154.157.314M3.0 x 0.5M30 x 197C.186.197.154.157.314M2.5 x 0.45M25 x 226C.186.226.154.157.314M3.0 x 0.5M30 x 226C.186.226.154.157.314.218.125.185.188.376440 x 135C440 x 157C4-40440 x 170C440 x 226C632 x 125C632 x 150C6-32AM3.0 x 0.5M30 x 150C.218.150.185.188.376M3.5 x 0.6M35 x 150C.218.150.185.188.376.218.226.185.188.376632 x 226C632 x 250C632 x 281CM3.0 x 0.5M30 x 250C.218.250.185.188.376M3.5 x 0.6M35 x 250C.218.250.185.188.376M3.5 x 0.6M35 x 281C.218.281.185.188.376continued on next page8Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com

INCHThreadSizeMETRICABCHole HPartNumber .004 .004 .004 .003 –.000M40 x 185C.249.185.218.221.442M40 x 250C.249.250.218.221.442832 x 321CM40 x 321C.249.321.218.221.4421024 x 185CM50 x 185C.280.185.249.252.5041024 x 225CM50 x 225C.280.225.249.252.504M50 x 250C.280.250.249.252.5041024 x 310CM50 x 310C.280.310.249.252.5041024 x 375CM50 x 375C.280.375.249.252.5041032 x 185C.280.185.249.252.5041032 x 225C.280.225.249.252.5041032 x 250C.280.250.249.252.5041032 x 310C.280.310.249.252.5041032 x 375C.280.375.249.252.504PartNumberThreadSize832 x 185C8-3210-2410-321/4-201/4-285/16-18832 x 250C1024 x 250CM5.0 x 0.82520 x 226CM60 x 226C.342.226.312.315.6302520 x 250CM60 x 250C.342.250.312.315.630M60 x 312C.342.312.312.315.6302520 x 375CM60 x 375C.342.375.312.315.6302520 x 500CM60 x 500C.342.500.312.315.6302528 x 226C.342.226.312.315.6302528 x 250C.342.250.312.315.6302528 x 312C.342.312.312.315.6302528 x 375C.342.375.312.315.6302528 x 500C.342.500.312.315.630M80 x 250C.406.250.374.377.754M80 x 500C.406.500.374.377.7543124 x 250C.406.250.374.377.7543124 x 00.465.468.936.659.625.623.6271.2542520 x 312C3118 x 250C3118 x 500C5/16-24M4.0 x 0.7Min.Boss3/8-163816 x 500C3/8-243824 x 500C1/2-135013 x 625C1/2-205020 x 625CM6.0 x 1.0M8.0 x 1.25M10.0 x 1.5M100 x 500CStainless Steel Inserts – Class 3A/4H screw must pass with finger torque, standard class go gage may stop onlast thread. Part numbers for Stainless Steel Inserts are the same as listed in the chart, but ending with -SS.Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com9

Straight hole flanged / headedHC SeriesInsertsoffer thebenefits as the C Seriesplus a flanged head.HC Seriesinsertsoffersamethe sameRecommendedhole sizesThis insertoffersa largefor electrical connections and greater pullbenefitsas CSeriescontactplus a areaflangedSee the chart below. Hole sizes are notout strengthsfor reverseentrycontactapplications.head. Theyoffer a largeareanecessarily core pin sizes. The corefor electrical connection and greaterRecommendedHole SizeSee chartfor installation pinsholeshouldsize. be designed to allow forpull-out strengthsfor –reverseentryshrinkageof the plastic. For nGuidelines.applications.release of core pins a 1 overall taper isAacceptable. The depth of the hole1 Dshould be the length of the insert plusHMin. toBoss.030” minimumcontain any flash thatMin. Depth might be displaced.RadiusInsert Length .030"BCINCHMETRICAD .004 .004FlangeThickness.188.157.123.018.126.252M2.5 x 0.45 HM25 x 226C.218.226.154.021.157.314M3.0 x 0.5HM30 x rtNumber .0042-56H256 x 157CM2.0 x 0.4HM20 x 157C4-40H440 x 226CBHole HCThreadSizeMin. .003 –.000 BossHM35 x 180C.250.180.185.027.188.376H632 x 281CHM35 x 281C.250.281.185.027.188.376H832 x 185CHM40 x 185C.281.185.218.033.221.442HM40 x 250C.281.250.218.033.221.442H832 x 321CHM40 x 321C.281.321.218.033.221.442H1024 x 225CHM50 x 225C.312.225.249.040.252.504HM50 x 250C.312.250.249.040.252.504HM50 x 375C.312.375.249.040.252.504H1032 x 225C.312.225.249.040.252.504H1032 x 250C.312.250.249.040.252.504H1032 x 375C.312.375.249.040.252.504HM60 x 300C.375.300.312.050.315.630HM60 x 500C.375.500.312.050.315.630H2528 x 300C.375.300.312.050.315.630H2528 x 500C.375.500.312.050.315.6305/16-18H3118 x 500C.437.500.374.050.377.7545/16-24H3124 x 500C.437.500.374.050.377.7543/8-16H3816 x 500C.550.500.465.065.468.9363/8-24H3824 x 500C.550.500.465.065.468.9366-328-3210-24H632 x 180CH832 x 250CH1024 x 250CM3.5 x 0.6M4.0 x 0.7M5.0 x 0.8H1024 x 375C10-321/4-20H2520 x 300CH2520 x 500C1/4-28M6.0 x 1.0M8.0 x 1.25 HM80 x 500CM10.0 x 1.5 HM100 x 500CStainless Steel Inserts – Class 3A/4H screw must pass with finger torque, standard class gogage may stop on last thread. Part numbers for Stainless Steel Inserts are the same as listedin the chart, but ending with -SS.10Tri-StarIndustries 800-882-8980 email:email: sales@tristar-inserts.comsales@tristar-inserts.com www.tristar-inserts.comTri-StarIndustries 800-882-8980 www.tristar-inserts.com

The natural choice for high-volume automatic feedingSay goodbye to expensive part orientation feeding mechanisms. Our symmetricalinserts can be installed either end first for faster installation and lower costs.By decreasing outward hoop stress, symmetrical inserts decrease cycletimes. Their proportionally engineered design ensures that the displacedmaterial is encapsulated by knurls and undercuts. They are designed forstraight hole applications.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.A1 HMin. BossMin. Depth Insert Length .030"BRadiusCINCHThreadSize2-56METRICABCHole HPartNumber256 x 115SThreadSizePartNumber .004 .004 .004 .003 –.000M2.0 x 0.4M20 x 115S.123.115.138.126.252256 x 157SM2.0 x 0.4M20 x 157S.123.157.138.126.252M2.5 x 0.45M25 x 226S.154.226.175.157.314M3.0 x 0.5M30 x 226S.154.226.175.157.314Min.Boss4-40440 x 226S6-32632 x 281SM3.5 x 0.6M35 x 281S.185.281.206.188.3768-32832 x 321SM4.0 x 0.7M40 x 321S.218.321.239.221.44210-241024 x 375S.375.270.252.5041032 x 375SM50 x 375S.24910-32M5.0 x 0.8.249.375.270.252.5041/4-202520 x 500S.500.333.315.6302528 x 500SM60 x 500S.3121/4-28M6.0 x 1.0.312.500.333.315.6305/16-183118 x 500S.500.393.377.7543124 x 500SM80 x 500S.3745/16-24M8.0 x 1.25.374.500.393.377.7543/8-163816 x 500S.500.484.468.9363824 x 500SM100 x 500S.4653/8-24M10 x 1.5.465.500.484.468.936Stainless Steel Inserts – Class 3A/4H screw must pass with finger torque, standard class go gage may stop onlast thread. Part numbers for Stainless Steel Inserts are the same as listed in the chart, but ending with -SS.Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com11

P & HP Series inserts provide adequate holding strengths without the use ofultrasonic or heat equipment. These inserts are most commonly used in thermosetor other hard plastics. The pilot end provides for fast alignment. The insert is placedin a hole, pressure is applied and the three bands of helical knurls dig down deepand lock the insert in place.HP SeriesP SeriesBMin. BossMin. Depth Insert Length .030"LP SeriesA1 HARadiusLP Series InsertsINCHHP SeriesRecommended HoleSize – See chart forinstallation hole size.Additional informationcan be found on page5, Design Guidelines.METRICALHole HThreadSizePartNumberThreadSizePartNumber .004 .004 .003 –.000Min.Boss2-56256 x 157PM2.0 x 0.4M20 x 157P.134.157.121.2424-40440 x 208PM3.0 x 0.5M30 x 208P.165.208.150.3006-32632 x 247PM3.5 x 0.6M35 x 247P.197.247.182.3648-32832 x 292PM4.0 x 0.7M40 x 292P.228.292.213.42610-241024 x 328P1032 x 328PM5.0 x 0.8M50 x 328P.25910-321/4-202520 x 364P1/4-282528 x 364PM6.0 x 1.0M60 x 364P5/16-183118 x 364P5/16-243124 x 364PM8.0 x 1.25M80 x 22.364.307.614.383.364.368.736.383.364.368.736HP Series InsertsINCHABLHole HThreadSizePartNumberThreadSizePartNumber .004 .004 .004 .003 –.000Min.Boss2-56H256 x 157PM2.0 x 0.4HM20 x 157P.189.024.157.121.2424-40H440 x 208PM3.0 x 0.5HM30 x 208P.220.024.208.150.3006-32H632 x 247PM3.5 x 0.6HM35 x 247P.250.029.247.182.3648-32H832 x 292PM4.0 x 0.7HM40 x 292P.283.032.292.213.426HM50 x 207P.313.043.207.244.488HM50 x 328P.313.040.328.244.488H1032 x 207P.313.043.207.244.488H1032 x .73610-2410-3212METRICH1024 x 207PH1024 x 328P1/4-20H2520 x 364P1/4-28H2528 x 364P5/16-18H3118 x 364P5/16-24H3124 x 364PM5.0 x 0.8M6.0 x 1.0HM60 x 364PM8.0 x 1.25HM80 x 364PTri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com

The E & HE Series Expansion inserts are designed to provide strong reusable threadsin thermoset and other hard plastics. Inserts are pressed into the plastic and expandwhen the assembly screw is tightened. The sharp diamond knurling provides resistanceto tensile and torque loads. The mating screw should be designed for full threadengagement. This will allow the insert to fully expand. For best results, the bossdiameters should be approximately 2-1/2 times the recommended hole size. In “throughhole” applications, the HE Series flange adds greater strength for tensile pull loads.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.E SeriesDBAABCE SeriesHE SeriesE Series InsertsHE SeriesINCHMETRICA .005B .005Hole Size .003 6256 x 157EM2.0 x 0.4M20 x 157E.136.157.1264-40440 x 188EM3.0 x 0.5M30 x 188E.165.189.1576-32632 x 250EM3.5 x 0.6M35 x 250E.197.252.1858-32832 x 312EM4.0 x 0.7M40 x 312E.230.315.21710-241024 x 375EM5.0 x 0.8M50 x 375E.260.374.24810-321032 x 375E.260.374.2481/4-202520 x 500EM6.0 x 1.0M60 x 500E.327.500.3115/16-183118 x 500EM8.0 x 1.25M80 x 500E.390.500.374HE Series InsertsINCHMETRICA .005B .005C .005D .005Hole Size .003 6H256 x 157EM2.0 x 0.4HM20 x 157E.189.136.024.157.1264-40H440 x 188EM3.0 x 0.5HM30 x 188E.220.165.024.189.1576-32H632 x 250EM3.5 x 0.6HM35 x 250E.252.197.031.252.1858-32H832 x 312EM4.0 x 0.7HM40 x 312E.283.230.031.315.21710-24H1024 x 375EM5.0 x 0.8HM50 x 375E.315.260.039.374.24810-32H1032 x 375E.315.260.039.374.2481/4-20H2520 x 500EM6.0 x 1.0HM60 x 500E.374.327.051.500.3115/16-18H3118 x 500E M8.0 x 1.25HM80 x 500E.433.390.051.500.374Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com13

The body of this threaded stud is specifically modeled after our H Series Insert.Its key feature is the tapered design, which allows for easy insertion into taperedmolded or drilled holes. They may be installed using the thermal or ultrasonicmethod or can be molded in place.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.8 GEMin. BossARadiusMin. Depth Insert Length .030"BFCINCHMETRICHole FABPartNumberSM20 x .004 .004S256 xThreadSizeM2.0 x 0.4.141.188.112.123.107.2464-40S440 xM2.5 x 0.45SM25 x.172.219.146.159.141.318M3.0 x 0.56-32SM30 x.219S632 x.250.190.206.185ThreadSize2-56PartNumber8-32S832 x10-24S1024 x10-32S1032 x1/4-20S2520 x1/4-28S2528 x5/16-18S3118 x5/16-24S3124 x3/8-16S3816 x3/8-24S3824 xM3.5 x 0.6M4.0 x 0.7M5.0 x 0.8M6.0 x 1.0SM35 xSM40 xSM50 xSM60 xM8.0 x 1.25SM80 xM10 x 1.5SM100 500.562CHole EG .004 .002 –.000 .002 –.000 0.4881.080* When ordering, customer needs to specify the "G" dimension to form the part number.Example: 8-32 with a thread length 1/2" (.500”) S832 x 500HPart numbers for Stainless Steel Inserts are the same as listed in the chart, but ending with -SS.14Tri-StarTri-Star IndustriesIndustries 800-882-8980800-882-8980 email:email: sales@tristar-inserts.comsales@tristar-inserts.com www.tristar-inserts.comwww.tristar-inserts.com

The body of this threaded stud is modeled after our C Series Insert. Its keyfeature is the opposing diagonal knurls, which will provide exceptional rotationaland tensile resistance. The SC Series is designed for straight molded or drilledholes. They may be installed using the thermal or ultrasonic method or can bemolded in place.Recommended Hole Size – See chart for installation hole size.Additional information can be found on page 5, Design Guidelines.1 GHAMin. BossMin. Depth Insert Length ThreadSizePartNumber .004 .004 .004Hole H Min.G .010 .003 –.000 BossS256 xM2.0 x 0.4SM20 x.143.157.123.126.2524-40S440 xM2.5 x 0.45SM25 x.186.226.154.157.314M3.0 x 0.5SM30 x.186.226.154S.157.3146-32S632 xM3.5 x 0.6SM35 x.218.281.185P.188.3768-32S832 xM4.0 x 0.7SM40 x.249.321.218E.221.44210-24S1024 x.280.375.249.504SM50 xC.252M5.0 x 32S1032 x1/4-20S2520 x1/4-28S2528 x5/16-18S3118 x5/16-24S3124 x3/8-16S3816 x3/8-24S3824 xM6.0 x 1.0SM60 xM8.0 x 1.25SM80 xM10.0 x 1.5SM100 x* When ordering, customer needs to specify the "G" dimension to form the part number.Example: 8-32 with a thread length 1/2" (.500”) S832 x 500CPart numbers for Stainless Steel Inserts are the same as listed in the chart, but ending with -SS.Tri-Star Industries 800-882-8980 email: sales@tristar-inserts.com www.tristar-inserts.com15

MB Series Mold-in Blind Inserts*This threaded insert is designed to be molded into the plasticcomponent during the molding cycle. Typically, the insert isplaced on a core pin in the mold during the molding cycle. Theinsert is designed with aggressive knurling and undercuts toresist rotational and tensile pull loads. The part has a closedbottom (blind thread) to eliminate plastic flow into the threads.Although our catalog insert is brass, this product can also bemanufactured in stainless steel, steel and aluminum. See ourwebsite for stock sizes or contact our Engineering Department.MB Series* The manufacturing process may leave a small cut-off nib on the closed end.Refer to our website for common sizes.RM Series Rotational Mold-in Blind Inserts*Designed primarily for rotational molding, the hex andundercut features provide high resistance to torque andtensile pull loads. The part has a closed bottom (blind thread) toeliminate plastic flow into the threads. Various sizes and lengthscan be manufactured to your specifications. See our website forstock sizes or contact our Engineering Department.RM Series* The manufacturing process may leave a small cut-off nib on the closed end.Currently available on custom basis only.KS Series

Tri-Star Industries 800-882-8980 email:sales@tristar-inserts.com www.tristar-inserts.com 6 E 8 Min. Boss Radius C A Min. Depth Insert Length .030" F D B C D LONG SHORT Thread Size 0-80 2-56 4-40 5-40 6-32 8-32 Part Number