Transcription

The mostcompact fiber lasermarking headLaser Marking SystemsVideojet 7340 & 7440 Fiber LasersFeaturing LightfootTM

Crisp, durable codesthat last the lifetimeof the product2

When manufacturingspace is limited,you need aninnovative lasermarking solution Introducing Lightfootthe world’s smallestlaser marking head!TMVideojet has redefined fiber lasertechnology with the Videojet 7340(20-Watt) and 7440 (30-Watt) fiberlaser marking systems, resettingthe standard for simplified laserintegration into packaging lines.,They are the first Videojet fiber lasersto feature our Lightfoot markinghead, making them the easiest, mostcompact fiber lasers to integrate,operate and service.The Lightfoot marking head is oneof a kind. The smallest in the industryboth in size and weight, it is IP69rated for use in washdown and harshenvironments.3

Evolved to fit themost restrictive spacesDeveloped to meet the needs of manufacturers whowork within small spaces, the Videojet 7340 and 7440fiber lasers feature the Lightfoot marking head, themost compact fiber laser marking head on the market.The 7340 and 7440 fiber lasers are an ideal solutionfor contract packagers and OEM manufacturers inthe Food, Beverage, and Consumer Packaged Goodsindustries who have space limitations, are looking forsimple integrations, or do frequent rapid changeovers.Simple integrationFaster installationSeamless operationAchieve easy integration and greaterBenefit from a versatile fiber laser solution thatControl the 7340 and 7440 fiber lasersversatility in tight spaces with a fiberis fast to set up, with virtually no consumables.through a range of familiar, easy-to-uselaser marking head that weighs less thanReduced mounting bracketry offers easyVideojet interfaces, ensuring seamless1kg / 2.2 lbs – the smallest and lightestadjustment of the fiber laser marking head,operation within your production line.fiber laser head on the market.aiding faster set-up and repositioning ofCompact in size, the 7340 and 7440 fiberthe laser head.Videojet Touch Control Software (TCS )offers remote control through eitherlaser marking head can be easily integratedFeaturing a pilot beam-based focal alignmentthe 10” tablet-like touchscreen or frominto production lines or complex machinery,installation process, the 7340 and 7440 offercompatible browser-based devices.allowing for an increased range of lasereasier, faster and more precise installation.installation opportunities.The advanced Videojet CLARiTY lasercontroller is an alternative user interface,featuring an intuitive touchscreen thatwill be familiar to users of other Videojetmarking and coding solutions.4

Actual size3/5/23205.0mm / 8.07 inchesMost compactfiber laserWeighing less than 1kg / 2.2 lbs,and similar in size to a VideojetContinuous Inkjet printhead3/5/23IP69 marking headBenefit from a hygienic, water and dusttight fiber laser marking head, protectedagainst close-range high-pressure,3/5/23high-temperature washdownsFast marking speeds3/5/23Up to 2,000 characters per second3/5/23Fast productchangeoversAchieve easy set-up and fast productchangeovers with the integrated pilotbeam3/5/23focus finder that can reflect thecode and actual size of the marking fieldEasy-to-useuser interfacesFamiliar touch-screen colouruser interface3/5/23Permanent, traceable,and readable codesCrisp, durable codes 3/5/23that lastthe lifetime of the productReduced mountingbracketryThe lightest marking head in the industry3/5/23 less mounting bracketry, aidingrequiresfast setup and repositioningVirtuallymaintenance-freeVery few wear partsSelect between3 or 10m umbilicalOffers flexibility of supply unit position5

The compact fiber laser that is easy to:IntegrateOptimised for washdown andharsh environmentsOption of 0 or 90 marking headDeveloped for manufacturers who require problem-free usageproduction machines even easier. The 7340 and 7440in washdown and/or harsh environments, the Lightfootfiber laser marking head is IP69 rated and will not requireThe 0 or 90 marking heads make integration into tightfiber laser head can be fit into tight mechanical spacesunlike any other laser marker.any additional housing or protective equipment.0 90 Available with optionalEtherNet / IP and PROFINET Umbilical lengthsEasily adapt your laser marking solution to fit your line withmarking head and supply unit to be close to eachoptional EtherNet / IP and PROFINET industrial protocols,allowing for greater control, communication and data collection.10mWhether the production line design allows theother or requires further distance, two umbilicallength options are available to ease integrationand deliver flexibility in positioning the laser.3m* Ethernet/IP is a trademark of ODVA. PROFINET is aregistered trademark of Profibus & Profinet International (PI).6

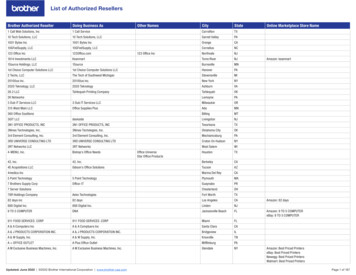

OperateFeatureTCS in browserIP65 designfor washdownAvailable with virtually any Videojet laser marking system, our range of lasercontrollers allows for simple operation and message creation, helping toensure seamless operation in production lines with a familiar look and feel.TCS on TU440Datamaster444Colour touchscreen4*Browser enableddevice interface4Simple messagecreationSmartGraph4Code AssurancePC softwareinterfaceCLARiTYTM444 **444Complexmessage creation4Variable datarequirementMultiple laserdevice control44 ***4Videojet TCS Videojet CLARiTYVideojet SmartGraphVideojet DatamasterOperators benefit from automatedmessage and simple code entry; anevent logging feature helps to tracksystem changes; and the enhanceduser access control minimises userinduced coding errors and downtime.* On tablet ** In browser on PC*** Each device controlled in anindividual browser window.Laser controller featuresbuilt-in Code Assurancesoftware to help minimisecoding and marking errorscaused by operator error.is a PC software forthe creation of moresophisticated andcomplex job creation,such as mark-on-the-flyapplications, alphanumericalcodes, serial numbers,barcodes, and 2D codes.is a tool to feed a largeamount of variable datato the laser, e.g. for alottery application.ServicePreventiveRemoteVideojet offers a range of fume extraction systems andVideojetConnectTM Remote Servicefilters to help keep your production area clean and maximiseallows you to monitor basic printer needs whileuptime. Fume extraction and filters are important elementsaway from the production line. In addition, you canof preventive maintenance, helping to remove the smokehave Videojet monitor critical alerts and proactivelyand particulate debris generated during the marking process.message you when potential downtime develops.7

Meeting yourstandards,whatever yourrequirementsFoils/filmsVideojet understands the difficulties of trying to fit a new laseronto a production line, resulting in manufacturers often havingWith the Videojet 7340 and 7440 marking head measuring justFood, Beverage and ConsumerPackaged Goods (CPG)Manufacturers41.3 mm in diameter, it is designed to fit anywhere on your line toVideojet understands the additional challenges of cleaningto trade-off optimal code quality, thus potentially increasingtheir scrap, just to make the printer fit.help ensure that you can achieve optimal focus and power density.These lasers have been specifically designed for regimes and processes that food, beverage, and CPGmanufacturers face on their production lines.To meet these needs, the IP69 rated marking head has beenengineered to operate under conditions where washdown isan essential part of the daily operational process. The hygienicdesign helps eliminate dust and water ingress, eliminatingthe need for the marking head to be removed from the lineduring washdown.With the 7340 and 7440 lasers, you can maintain an efficientcleaning operation and faster restart of the line knowing themarking head is protected for optimal productivity, withoutcompromising on code quality.Reduce your scrap andrework cost causedby coding errors byup to 33% using theintegrated pilot beamfocus finder.8Metal containersFood/beverage cansCupsBeverage caps

Plastic and metalParts-Marking ManufacturersVial capsFiber laser marking is an ideal solution for many parts-Pharmaceutical andCosmetics Manufacturersmarking manufacturers where complex, permanent codesThe Videojet 7340 and 7440 fiber laser marking systemsare required to be marked directly onto various part shapes,sizes, and substrates.can mark permanent codes at high production speeds onmultiple, high-density packaging substrates across a wideSpecifically engineered for marking on high-density plastics,aluminium, and stainless steel, the 7340 and 7440 fiberlasers provide you with permanent, traceable, and readablecodes.range of materials including metals, plastics, and foilswithout compromising on code quality, uptimeperformance, code length or content.When packaging types and materials vary fromThis is particularly important for the automotive andaerospace parts manufacturers who require DataMatrixcodes and / or human-readable information that needs tobe delivered in a durable format to last throughout thelifetime of the product.product to product and you need the flexibility to keep upwith regulations in your market, the 7340 and 7440 lasersare compact, flexible marking solutions. Increasing efficiencyand protecting your brand, these laser marking systemscan provide the ideal combination of marking speed andpermanent codes, to help ensure product security.Automotive plastic partsElectronic plastic partsBlister packsFoil packagingMetal partsStainless steel partsTubesPaper cartons9

Industry1Focus peace ofmind is built-instWith the integrated pilot beam focus finderFind your focus by simply turning it on!Developed with simple usability in mind, the Lightfoot markinghead features an integrated pilot beam focus finder.The pilot beam offers easier, faster and more precise focalalignment during the installation process or when needingfrequent line and /or product changeovers.3/5/23Integrated laser beamsas operators can easily see the pilot beam is in focus and the lasertriangulate to place theis ready to code with the highest quality, thanks to the built-indot inside the circle3/5/23There is no need for measurement tools or awkward adjustmentssystem using triangulation of two beams.No mechanicsor toolsFocus finderbuilt-inwhen focus is achievedClarity peaceof mindUptime AdvantageCode Assurance Achieve simple integration, reduced installation costs,and an increased freedom of positioning with anindustry-first, compact fiber laser marking head Control the laser through a range of familiar, easy-to-useVideojet user interfaces, reducing operator training needsand the risk of product rework and recalls Simplify laser head adjustment and positioningwith reduced laser head mounting bracketry Benefit from simple operation, message creation, andreduced operator errors with the Videojet Touch ControlSoftware (TCS ) or the Videojet CLARiTY laser controller Easily migrate to a laser marking solution, withthe added benefit of reduced consumables Reduce the need for additional housing or equipmentwith a water and dust tight IP69 laser marking head,facilitating worry-free usage in washdown andharsh environments10

Original Equipment ManufacturersA configured solutionfor your customers’applicationsVideojet understands that integration can be challenging in terms of spaceand the need for mounting accessories. The 7340 and 7440 lasers are compact,flexible and easy solutions and the compact accessories have been engineeredfor seamless integration and to meet the needs of your customers’ applications.Mechanical integrationConfigurabilityVideojet products move in a way that works for you.Videojet can configure our fiber lasers to fit within theTo help ensure optimal line and coding performance, theworkflow of your equipment. With its 0 and 90 marking7340 and 7440 fiber lasers offer the smallest laser headheads, 3 focal distances, 2 power levels and 2 umbilicaldimensions for simple integration into complex machinerylength options, these lasers can be installed in a variety ofand a wide range of bracketry to physically mount the laserpositions to fit in tight places, for example, within a cartoner.marker into your machine without disrupting its operation.Built-in ProductivitySimple Usability Mark up to 2,000 characters per second Achieve easy set-up and fast product changeovers with theintegrated pilot beam focus finder that can reflect the codeand actual size of the marking field Get closer to the product with the smallestfiber laser marking head on the market Benefit from easier, faster and precise focal distanceduring line or product changeover with pilotbeam-based focal alignment installation process Benefit from easy serviceability with the ability to quicklyremove or replace the fiber laser unit either on the productionline or within complex machinery F ocus more on production and less on user interaction andmaintenance with an easy-to-use laser solution that is intuitiveto the operator without the need for additional training11

Peace of mind comes as standardVideojet Technologies is a world-leader in the product identificationmarket, providing in-line printing, coding, and marking products,application specific fluids, and product LifeCycle AdvantageTM.Our goal is to partner with our customers in the consumerpackaged goods, pharmaceutical, and industrial goodsindustries to improve their productivity, to protect andgrow their brands, and to stay ahead of industry trendsand regulations. With our customer application experts andtechnology leadership in Continuous Inkjet (CIJ), ThermalInkjet (TIJ), Laser Marking, Thermal Transfer Overprinting(TTO), case coding and labelling, and wide array printing,Videojet has more than 400,000 printers installed worldwide.Our customers rely on Videojet products to print on overten billion products daily. Customer sales, application, serviceand training support is provided by direct operations withover 4,000 team members in 26 countries worldwide.In addition, Videojet’s distribution network includes morethan 400 distributors and OEMs, serving 135 countries.Global HeadquartersVideojet Sales & Service OfficesManufacturing & ProductDevelopmentCountries with VideojetSales & ServiceCountries with VideojetPartner Sales & ServiceCall us free on 91 75063 45599Email marketing.india@videojet.comvisit www.videojet.inVideojet Technologies (India) Pvt. Ltd.Unit No. S-220 A, 2nd Floor,Eastern Business District,L B S Marg, Bhandup West,Mumbai - 400078,Maharashtra, India 2021 Videojet Technologies Inc. All rights reserved.Videojet Technologies Inc.’s policy is one of continued product improvement.We reserve the right to alter design and/or specifications without notice.Part No. SL000680br-7340-7440-en-in-0721Patents pendingVISIBLE AND INVISIBLELASER RADIATIONAVOID EYE OR SKIN EXPOSURETO DIRECT OR SCATTERED RADIATIONMAX. AVERAGE POWER: 50 WMAX. PULSE ENERGY: 1.1 mJPULSE DURATION: 1 - 300 nsWAVELENGTH: λ 1040 - 1090 nmLASER CLASS 4(EN 60825-1:2014)e20 - 30 W

Videojet can configure our fiber lasers to fit within the workflow of your equipment. With its 0 and 90 marking heads, 3 focal distances, 2 power levels and 2 umbilical length options, these lasers can be installed in a variety of positions to fit in tight places, for example, within a cartoner. Original Equipment Manufacturers