Transcription

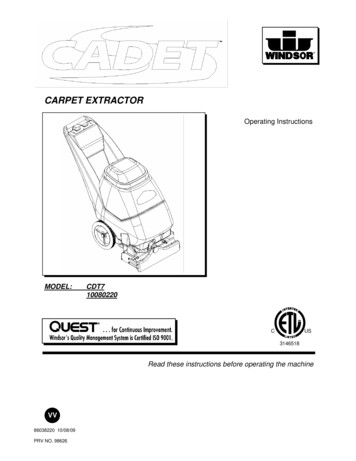

CARPET EXTRACTOROperating InstructionsMODEL:CDT710080220CUS3146518Read these instructions before operating the machineVV86038220 10/08/09PRV NO. 98626

MACHINE DATA LOG/OVERVIEWMODELDATE OF PURCHASESERIAL NUMBERSALES REPRESENTATIVE #DEALER NAMEOPERATIONS GUIDE NUMBERPUBLISHEDYOUR DEALERName:Address:For the name and address of your dealer contact: Windsor IndustriesPhone Number:1CADET 86038220 03/16/07

TABLE OF CONTENTSMachine Data Log/Overview.1Table of Contents.2HOW TO USE THIS MANUALHow to use this Manual.1-1SAFETYImportant Safety Instructions .2-1Hazard Intensity Level .2-2Grounding Instructions.2-3OPERATIONSTechnical Specifications. .3-1Controls/Component Location .3-2Filling Operation.3-5Operations. .3-6Cleaning Procedure. .3-8Accessory Tool Usage. . 3-10MAINTENANCEService Schedule . 4-1Periodic Maintenance. .4-2Daily/ Regular Maintenance.4-2Vacuum Motor Replacement .4-3Belt Replacement.4-4Solution Pump Replacement . 4-5Wiring Diagram. .4-6Troubleshooting Chart .4-7GROUP PARTS LISTFrame Assembly. . 5-1Brush Assembly. . 5-3Pump Assembly(prior to SN). . 5-5Pump Assembly . 5-7Vacuum Shoe Assembly. 5-9Control Panel Assembly. 5-11Solution Tank Assembly. . 5-13Recovery Tank Assembly. . 5-15Suggested Spare Parts/Notes . 5-17CADET 86038220 03/16/072

HOW TO USE THIS MANUALThis manual contains the following sections:-HOW TO USE THIS MANUALSAFETYOPERATIONSMAINTENANCEPARTS LISTThe HOW TO USE THIS MANUAL section will tellyou how to find important information for orderingcorrect repair parts.Parts may be ordered from authorized dealers.When placing an order for parts, the machine modeland machine serial number are important. Refer tothe MACHINE DATA box which is filled out duringthe installation of your machine. The MACHINEDATA box is located on the inside of the front coverof this manual.The SAFETY section contains important informationregarding hazard or unsafe practices of themachine. Levels of hazards is identified that couldresult in product or personal injury, or severe injuryresulting in death.The OPERATIONS section is to familiarize theoperator with the operation and function of themachine.The MAINTENANCE section contains preventivemaintenance to keep the machine and itscomponents in good working condition. They arelisted in this general order:-PeriodicDaily/RegularTroubleshootingThe PARTS LIST section contains assembled partsillustrations and corresponding parts list. The partslists include a number of columns of information:MODELDATE OF PURCHASESERIAL NUMBER-SALES REPRESENTATIVE #-DEALER NAMEOPERATIONS GUIDE NUMBER-PUBLISHEDThe model and serial number of your machine is onthe bottom back-end of the machine.--REF – column refers to the referencenumber on the parts illustration.PART NO. – column lists the partnumber for the part.PRV NO. - reference number.QTY – column lists the quantity of thepart used in that area of the machine.DESCRIPTION – column is a briefdescription of the part.SERIAL NO. FROM – column indicatesthe first machine the part number isapplicable to. When the machine designhas changed, this column will indicateserial number of applicable machine.The main illustration shows the mostcurrent design of the machine. Theboxed illustrations show older designs.If column has an asterisk (*), callmanufacturer for serial number.NOTES – column for information notnoted by the other columns.NOTE: If a service or option kit is installed on yourmachine, be sure to keep the KIT INSTRUCTIONSwhich came with the kit. It contains replacementparts numbers needed for ordering future parts.NOTE: The number on the lower left corner of thefront cover is the part number for this manual.1-1CADET 86038220 03/16/07

SAFETY INSTRUCTIONSIMPORTANT SAFETY INSTRUCTIONSWhen using an electrical appliance, basic precautionmust always be followed, including the following:READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.This machine is for commercial use.! WARNING:To reduce the risk of fire, electric shock, or injury:Connect to a properly grounded outlet. See Grounding Instructions.Do not leave the machine unattended. Unplug machine from outlet when not in use and before maintenance orservice.Use only indoors. Do not use outdoors or expose to rain.Do not allow machine to be used as a toy. Close attention is necessary when used by or near children.Use only as described in this manual. Use only manufacturer’s recommended components and attachments.Do not use damaged electrical cord or plug. Follow all instructions in this manual concerning grounding themachine. If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped intowater, return it to an authorized service center.Do not pull or carry machine by electrical cord, use as a handle, close a door on cord, or pull cord around sharpedges or corners.Do not run machine over cord. Keep cord away from heated surfaces.Do not unplug machine by pulling on cord. To unplug, grasp the electrical plug, not the electrical cord.Do not handle the electrical plug or machine with wet hands.Do not operate the machine with any openings blocked. Keep openings free of debris that may reduce airflow.This machine is intended for cleaning carpet only.Do not vacuum anything that is burning or smoking, such as cigarettes, matches, or hot ashes.This machine is not suitable for picking up health endangering dust.Turn off all controls before unplugging.Machine can cause a fire when operating near flammable vapors or materials. Do not operate this machine nearflammable fluids, dust or vapors.This machine is suitable for commercial use, for example in hotels, schools, hospitals, factories, shopsand offices for more than normal housekeeping purposes.Maintenance and repairs must be done by qualified personnel.If foam or liquid comes out of machine, switch off immediately.SAVE THESE INSTRUCTIONSCADET 86038220 03/16/072-1

HAZARD INTENSITY LEVELThe following symbols are used throughout this guide as indicated in their descriptions:HAZARD INTENSITY LEVELThere are three levels of hazard intensity identified by signal words -WARNING and CAUTION and FORSAFETY. The level of hazard intensity is determined by the following definitions:! WARNINGWARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.! CAUTIONCAUTION - Hazards or unsafe practices which could result in minor personal injury or product or propertydamage.FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.Report machine damage or faulty operation immediately. Do not use the machine if it is not in properoperating condition. Following is information that signals some potentially dangerous conditions to theoperator or the equipment. Read this information carefully. Know when these conditions can exist. Locateall safety devices on the machine. Please take the necessary steps to train the machine operatingpersonnel.FOR SAFETY:DO NOT OPERATE MACHINE:Unless Trained and Authorized.Unless Operation Guide is Read and understood.In Flammable or Explosive areas.In areas with possible falling objects.WHEN SERVICING MACHINE:Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on themachine. Use manufacturer approved replacement parts.CADET 86038220 03/16/072-2

GROUNDING INSTRUCTIONSTHIS PRODUCT IS FOR COMMERCIAL USE ONLY.PROPER GROUNDINGGrounding PinELECTRICAL:In the USA this machine operates on a standard 15amp 115V, 60 hz, A.C. power circuit . The amp,hertz, and voltage are listed on the data label foundon each machine. Using voltages above or belowthose indicated on the data label will cause seriousdamage to the motors.GroundedOutletFig. AMetal ScrewAdaptorGrounded Outlet BoxFig. BTab For Grounding ScrewAdaptorFig. CGROUNDING INSTRUCTIONS:This appliance must be grounded.If it shouldmalfunction or break down, grounding provides a pathof least resistance for electric current to reduce therisk of electric shock. This appliance is equipped witha cord having an equipment-grounding conductor andgrounding plug. The plug must be inserted into anappropriate outlet that is properly installed andgrounded in accordance with all local codes andordinances.This appliance is for use on a nominal 115-volt circuit,and has a grounded plug that looks like the plug in“Fig. A”. A temporary adaptor that looks like theadaptor in “Fig . C” may be used to connect this plugto a 2-pole receptacle as shown in “Fig. B”, if aproperly grounded outlet is not available.Thetemporary adaptor should be used only until aproperly grounded outlet (Fig. A) can be installed by aqualified electrician. The green colored rigid ear, lug,or the like extending from the adaptor must beconnected to a permanent ground such as a properlygrounded outlet box cover. Whenever the adaptor isused, it must be held in place by a metal screw.NOTE: In Canada, the use of a temporary adaptor is notpermitted by the Canadian Electrical Code! WARNING:Improper connection of the equipment-groundingconductor can result in a risk of electric shock. Checkwith a qualified electrician or service person if you arein doubt as to whetherthe outlet is properlygrounded. Do not modify the plug provided with theappliance - if it will not fit the outlet, have a properoutlet installed by a qualified electrician.CADET 86038220 03/16/072-3

TECHNICAL SPECIFICATIONSPOWER TYPEGENERAL DIMENSIONS/WEIGHTELECTRICAL: 115 V, 15 A, 60 HZVacuum shoe: 17” (43.18 cm) castaluminum with spring loaded downpressureELECTRIC VACUUM MOTOR: (1) –3 stage, 1 hp, 99cfm (2.80 cubic meters/min.) Waterlift –117” (297cm)BRUSH: (1) 15” (38.1 cm.)WHEELS: (2) 10” dia. (25 cm) wheelsby 2”SOLUTION PUMP: Diaphragm style, internal bypassWEIGHT: 92lbs. (42kg)SOLUTION CAPACITY: 7 gallons (26.5ltr)LENGTH: 41” (104 cm)RECOVERY CAPACITY: 7 gallons (26.5ltr)HEIGHT: 34” (86.36 cm)BRUSH SPEED: 1000 rpmWIDTH: 17.5” (44.45 cm)SOLUTION SPRAY: 2 quick changejets.POWER CABLE: 50’ (12.7 m) )3-1CADET 86038220 03/16/07

CONTROLS/COMPONENT LOCATIONS1. Main Handle. Used to pull and maneuvermachine.2. Electrical Cord.33. Pump Switch. Turns on pump and enablesspray.54. Brush/Spray switch. Turns on brush motorand activates electro-valve to dispense solutionto floor through jets. Intermittent, off, andcontinuous settings.5. Vacuum Motor Switch. Turns on vacuummotor6. Brush Motor Circuit Breaker. 6 amp. Breakerprotecting brush motor.417. Vacuum Motor Circuit Breaker. 15 amp.Breaker protecting vacuum motor.8. Recovery Dump Hose. Facilitates drainingdirty cleaning solution.769. Solution Dump Hose. Facilitates drainingexcess cleaning solution from solution tank.289CADET 86038220 03/16/073-2

CONTROLS/COMPONENT LOCATIONS1. Solution Accessory Tool Hookup. Used forvarious auxiliary cleaning tools.102. Vacuum Hose Door. Used to connect variousauxiliary 1 ½ inch cleaning tool vacuum hoses.3. Brush Height Adjustment. Used to regulatebrush height from storage position to variouscarpet heights.14. Recovery Tank. Used to collect dirty cleaningsolution.5. Solution Tank. Used to hold cleaning solution.96. Recovery Tank Dome.237. Vacuum Shoe.8. Brush Housing.9. Front Lifting Handle.10. Cleaning Solution Filter.645783-3CADET 86038220 03/16/07

CONTROLS/COMPONENT LOCATIONS1. Solution Intake Cover.2. Vacuum Intake Cover.3. Float Shut-Off.4. Clean-Out Opening.5. Pour Spout.6. Lift Handle.6124653CADET 86038220 03/16/073-4

FILLING OPERATIONSSTEP1RECOVERY TANKRemove recoverytankSOLUTIONTANKSTEP2FILL LINEAdd water7 gal.(26.5 ltr.)140 F (60 C)STEP3FILLING THE CADETNOTE: Use clean bucket of water to fill solution tank7 – 14oz.(207ml – 414ml)Add cleaningchemicalDo not put defoamer, solvents, spotter orprespray chemicals in the solution tank.Do not allow water to spill into vacuum motor inlet.Dry spillage from top of solution tank beforereplacing recovery tank.CHEMICALSSuitable 5Non-Compatible ChemicalsAldehydesAromatic HydrocarbonsSP ButylsCarbon TetrachlorideClorox*Chlorinated BleachesChlorinated HydrocarbonsLysol*Methyl Ethel Ketone (MEK)Perchorethylene T 86038220 03/16/07Replace recoverytank

OPERATIONSSTEP1Remove electrical cord and literature fromrecovery tank. Fill solution tank (see fillingoperations, page3-5).STEP2Plug cord into grounded outlet.Note: Be sure dome is seated on recoverytank, and float shut-off is installed correctly.STEP3Adjust brush to proper setting.Note: For good operation the brush mustskim the carpet. If circuit breaker trips raisebrush to prevent damage to motor or carpet.STEP4Turn on both Vacuum and Pump motorswitches (“ON” ADET 86038220 03/16/073-6

OPERATIONSTip machine back by main handle to moveto starting point.STEP5Lower machine to floor.STEP6Select intermittent or continuous switchsetting to turn on brush and start solutionspray.The intermittent setting requires theoperator to hold the switch in the “on”position with the thumb, and is typicallyused in small areas where short cleaningpasses are made.The continuous setting allows the operatorto set the switch in the “on” position withone touch, and is typically used in largeareas where long cleaning passes aremade.3-7STEPINTERMITTENT7CONTINUOUSCADET 86038220 03/16/07

CLEANING PROCEDURE1ft.(30cm)STEP1Start at wall closest to power outlet. Pullstraight back without pushing down onhandle.STEP2Release intermittent setting or turn offcontinuous setting on brush/spray switchapproximately 1 foot before endingcleaning pass.STEP3Push down on handle to raise vacuumshoe and brush before moving to the nextcleaning pass. Overlap brush contactarea approximately 1inch.OFF1in.(25mm)SOLUTIONINTAKE COVERDuring operation, observe the following: TheSTEP Cadet is equipped with clear internal covers to4facilitate operator viewing of dirty solution andvacuum air flow.During operation, observe the vacuum intakecover. Large amounts of water or foam enteringthe vacuum system can damage the vacuummotor. If you notice either condition, shut downthe machine immediately. Empty recoverytank and/or add defoamer to recovery tank.VACUUMINTAKE COVERCADET 86038220 03/16/073-8

CLEANING PROCEDUREUse right side of machine for cleaningagainst walls.STEP5After cleaning, turn off all controls, returnbrush to storage position and carefullyunplug machine.STEP6OFFOFFOFFTo speed drying, use a Windblower fan.STEP7Empty recovery tank by releasing dumphose. Use a hose with cold water to cleanout the recovery tank. Also drain solutiontank after each use.STEP8RECOVERYDRAINSOLUTIONDRAIN3-9CADET 86038220 03/16/07

ACCESSORY TOOL USAGESTEP1Use only one of the following acceptableaccessory tools.HT – 86000610 PRV NO. 89227DDH – 86000060 PRV NO. 89226DH – 86031540 PRV NO. 39504Pull back collar and insert over machinemounted fitting, then release collar to lockinto place.STEP2STEPPUMPVACUUMON3Lift door on front of vacuum shoe and insert1 ½ inch hose cuff into hole.Turn on Pump and Vacuum Switch. Note:Be sure intermittent/continuous switch is incenter (off) position and brush is in storageposition.ONOFFSTEP4Squeeze handle on accessory tool to begincleaning.CADET 86038220 03/16/073-10

MAINTENANCESERVICE SCHEDULEMAINTENANCECheck machine for cord damageCheck recovery dome and gasket fordamage and cleanlinessCheck brush – should be clean with nolint or strings attachedInspect vac shoe for blockage; removefibers with coat hanger, etc.Check hoses for wear, blockages, ordamageCheck handles, switches, and knobsfor damageCheck vac motor intake filter and cleanRun one gallon of water throughsystemClean out recovery tank and checkfloat valve to make sure it moves freelyClean out solution tank and removeand clean vacuum intake screenClean outside of all tanks and check fordamageRun vac motor for at least one minuteto allow motor to dryStore with dome off tank to allow thetank to dryCheck all bearings for noiseCheck all gaskets for wear and leakageCheck vacuum intake screen fordamage; replace if necessaryCheck pump pressure; observe spraypattern and check with gauge ifnecessaryCheck and clean solution screenCheck belts for wear and replace asnecessaryCheck brush for wear; ensure bristlesare not damagedCheck cables for frayingCheck the spray bar (manifold) fordamage; replace if broken or bentCheck condition of vac shoe and framefor damageCheck overall performance of machineCheck vac motor carbon ****CADET 86038220 03/16/07*

MAINTENANCEPERIODIC MAINTENANCETwice a month, flush a white vinegar solution (Onequart vinegar to two gallons of water) or antibrowning solution (mixed as directed) through theextractor. This will prevent build-up of alkalineresidue in the system. If spray jets become clogged,remove the spray tips, wash them thoroughly, andblow-dry.NOTE: Do not use pins, wire, etc. to clean nozzlesas this could destroy spray pattern.Periodically inspect all hoses, electrical cables andconnections on your machine. Frayed or crackedhoses should be repaired or replaced to eliminatevacuum or solution pressure loss. If the cableinsulation is broken or frayed, repair or replace itimmediately. Don’t take chances with electrical fireor shock.7. Remove lint and dirt build-up from brush andhousing.NOTE: Brush removal.A. To remove brush, grab and pull brush outfrom end opposite drive belt (operator’sright). Remove other end from brush driver.B. To install brush, line up slots in brush corewith pin in driver on drive belt side(operator’s left) and push brush onto driver.Then snap bearing end (opposite end) ofbrush into retaining clip.8. Check cooling air screen (located on framebehind left wheel) for lint or debris.9. Check float and shut-off screen and clean asnecessary.NOTE: Always store machine with brush in “Store”position.DAILY / REGULAR MAINTENANCEBefore making any adjustments or repairs to themachine, disconnect the power cord from electricalsource.1. Empty unused cleaning solution from thesolution tank.2. Inspect and clean filter screen in solution tank.3. Flush pumping system with 4 or 7 liters of clean,hot water.4. After each use, rinse tank with fresh water.Periodically inspect the recovery tank anddecontaminate if necessary, using a HospitalGrade Virucide or a 1-10 bleach to watersolution. Waste water should be disposed ofproperly.5. Check for and remove any lint or debris aroundvac shoe.6. Check spray jets for full spray pattern.CADET 86038220 03/16/074-2

MAINTENANCEONLY QUALIFIEDMAINTENANCEPERSONNEL ARE TOPERFORM THE FOLLOWING REPAIRS.! WARNING:VACUUM MOTOR REPLACEMENTVacuum Motor Carbon Brushes Replacement (Ametek)1. Turn off all switches and unplug machine.End Cap2. Remove recovery tank.3. Remove the (2) screws that fasten the solution tank tothe frame, and tilt tank back to expose the inside of theframe.CarbonBrushesWARNING: The greenground wire must beattached for safe operation.See wiring diagram.4. Locate the vacuum motor wires and disconnect at theconnector. Close the solution tank.5. Remove the (6) screws holding the vacuum motor cover(p/n 27809) to the solution tank.6. Remove the vacuum motor.Note: When replacing carbon brushes loosen wire terminalBEFORE removing screws on bracket.WireTerminal7. Reverse process to install vacuum motor.Vacuum Motor Carbon Brushes Replacement (Windsor)End CapCarbonBrushesNote:Placestop ingroove.WARNING: The greenground wire must beattached for safe operation.See wiring diagram.If armature commutator is grooved, extremely pitted or notconcentric, the motor will need to be replaced or sent to aqualified service center.Important:These brushes wear quicker as the length shortens due toincreased heat. Spring inside brush housing will damagemotor if brushes are allowed to wear away completely.If armature commutator is grooved, extremely pitted or notconcentric, the motor will need to be replaced or sent to aqualified service center.Wire TerminalImportant:These brushes wear quicker as the length shortens due toincreased heat. Spring inside brush housing will damagemotor if brushes are allowed to wear away completely.3 [9.5mm]83/8 (9.5mm)Periodically check the length of the carbon brushes. Replaceboth carbon brushes when either is less than 3/8" (9.5mm)long.4-3Periodically check the length of the carbon brushes. Replaceboth carbon brushes when either is less than 3/8" (9.5mm)long.CADET 86038220 03/16/07

MAINTENANCEONLY QUALIFIEDMAINTENANCEPERSONNEL ARETO PERFORM THE FOLLOWING REPAIRS.! WARNING:BELT REPLACEMENT1. Turn off all switches and unplug machine.2. Remove recovery tank and brush.3. Remove the (2) screws that fasten the solutiontank to the frame, and tilt tank back to exposethe inside of the frame.4. Loosen the (4) screws that hold the brush motorin place and slide motor forward to releasetension in belt.5. Remove the (2) screws that fasten the vacuumshoe links (p/n 05016) to the brush housing.6. Remove the (3) screws that fasten the side plate(p/n 62759) to the brush housing to remove belt.NOTE: All components associated with drivingthe brush will come out with the side plate.7. Reverse process to install belt.86249420PRV NO. 6275986227350PRV NO. 05016CADET 86038220 03/16/074-4

MAINTENANCE! WARNING:ONLY QUALIFIED MAINTENANCE PERSONNEL ARE TO PERFORMTHE FOLLOWING REPAIRS.SOLUTION PUMP REPLACEMENT1. Turn off all switches and unplug the machine.2. Remove recovery tank.3. Remove the (2) screws that fasten the solution tank to the frame, and tilt tank back to expose theinside of the frame.4. Remove solution hoses from fittings in pump.5. Remove the (2) screws that fasten the pump to the frame.6. Reverse process to install pump.4-5CADET 86038220 09/27/07

WIRING DIAGRAM86268450PRV NO. 8833286268830PRV NO. 8863686266890PRV NO. 8865586004480PRV NO. 41353CADET 86038220 03/16/074-6

TROUBLESHOOTING CHARTPROBLEMNo Power, NothingRunsVacuum Motor Will NotRunVacuum Motor RunsButSuction Is PoorPoor Or No Water Flow(Carpet Is Streaky)CAUSEPlug in cord.Reset breaker.Call for service.Call for service.Reset breaker.Call for service.Call for service.Call for service.Remove debris from vac shoe.Dome gasket defective or missing.Vacuum hose cracked or hose cuff loose.Recovery tank full / float ball stuck in theup position.Main pump switch off.Replace as necessary.Replace or repair as necessary.Turn off vac motor. Drain and rinserecovery tank.Turn on.Jets clogged or missing.Clean using a vinegar /water solution orreplace.Drain solution tank and clean solutionfilter.Call for service.Turn on brush switch.Reset circuit breaker.Replace as necessary.Call for service.Solution filter clogged.Brush Does Not Spin4-7SOLUTIONIs the cord plugged in.Circuit breaker tripped in building.Faulty switch.Faulty power cord or pigtail.Vacuum circuit breaker tripped.Faulty main vacuum switch.Loose wiring.Faulty vac motor.Debris lodged in vac shoe.Faulty solenoid.Brush switch off.Brush circuit breaker tripped.Brush belt broken.Faulty brush motor.CADET 86038220 03/16/07

MAINTENANCETHIS PAGE INTENTIONALLY LEFT BLANK.CADET 86038220 03/16/074-8

FRAME ASSEMBLY307191815SEE SOLUTION 4424CADET 86038220 03/16/07

FRAME 25262728293031323334PART 0PART 22212110”11122113FRAME, CLP FAMILYHOSE ASM, 1.5 BLK VAC X 15.5HUBCAP, 5/8” SHAFTHARNESS, MAIN, CDTHINGE, TANK TO FRAMEMOTOR ASM, BRUSH CLP FAMILYNUT, 10-32 HEX NYLOCKNUT, 1/4-20 HEX NYLOCK SSFOAM TAPE, 1/8 THK X 3/4 1SDAPLATE, BRUSH MTR CLAMPPULLEY, 1.4 OD, 6GR, MICRO-VPLUG, HOLE, .375” BLKPLUG, 9/16 OD BLK NYLONSCR, 1/4-20 X 1/2 PPHMS SSSCR, 10-32 X 3/4 PPHMSWASHER, 1/4 ID X 5/8 OD SSWASHER, 1/4 LOCK EXT STAR SSWASHER, #10 X 9/16 ODSET SCR, 10-32 X 1/4 KCPSTRAIN RELIEF, 90 DEGREEWHEEL, 1-15/16 X 10” HOOSIERAXLE, 5/8 X 17.06LHEAT SHRINK, 3/4 ID UL/CSASEAL, FRAME/TANKCLAMP, 7/16 DIA NYLON ULCLAMP, 2.0” WORM GEARSCR, 1/4-20 X ½ HHCS PLTDSCR, 1/4-20 X 1 PPHMS SSPIN, ROLL 1/8” X 1.0”LSCR, 1/4-20 X 1.25 PPHMS SSNUT, 1/4-20 HEX W/ STAR WASHERCADET 86038220 03/16/07SERIAL NO.FROMNOTES:1000466105-2

BRUSH 44536403733474126321728 3534321134227611914172320302529254639255-3CADET 86038220 03/16/07

BRUSH ASSEMBLYREFPART NO.PRV 1111221111121REFAXLE, ROLLERADAPTER, BRUSH BRG.BEARING, 1.125ODX.500IDX.375BELT, 180J6 MICRO-VBRUSH, 15L X 3.38ODBRKT, BRUSH PULLEYBRKT, BRUSH HEIGHTFRAME, CLP FAMILYGUARD, THREADHOUSING, BRUSH 15"LABEL, BRUSH HEIGHTLINKAGE, ASM, BRUSH HEIGHTLINKAGE ASM, ROLLER SUPPORTLINK, ROLLER, FRONTLEVER, HEIGHT ADJUSTMENTNUT, 10-32 HEX NYLOCKNUT, 3/8 DIA CAP, TYPE PUSH PLTPLATE, BRUSH HOUSING RHPLATE, BRUSH HOUSING LHPLATE, AXLE RETAINERPULLEY, 2.2 OD, 6GR, MICRO-VPIN, ROLL 1/4 X 1.25LROLLER, 1.9 DIA X 10.5 LGSCR, 10-32 X 5/8 PFHMSSCR, 10-32 X 1/2 PPHMS SS DLSCR, 10-32 X 1/2 FHMS SSSCR, 10-32 X 3/8 FHMS SSSCR, #10-24 X 1/2 SHCSWASHER, #10 LOCK EXT STAR SSWASHER, #10 X 9/16 ODSCR, 1/4-20 X.5/8 THMS PLTD NPBRUSH, 15 L X 3.35 OD G2RING, TOLERANCE 7/8CLIP, BEARINGDRIVER, BRUSHSHLDR BOLT, 3/8 OD X 3/8 L SS NPRING, 1/2 EXT. SNAPPIN, CLEVIS 1/4 X 1/2 PLTDCOTTER, 1/4" RINGSPACER, .81ID X 1.06OD, ALUMPULLEY ASM, BRUSHDRIVER ASM, BRUSHBRUSH ASM, 15 INADAPTER, BRUSH BRG. DIE CASTBEARING, R6 3/8 IDBRUSH BEARING ASM.KIT, BRNG/ADPTR EXTRCTRCADET 86038220 03/16/07SERIAL 56310000905635-4

PUMP ASSEMBLYPRIOR TO SERIAL NO. 100016666314320134101692816212318 11219152011177252628C6(SEE SOLUTION 5TANK)265-52427CADET 86038220 03/16/07

PUMP ASSEMBLYREFPART NO.PRV G, 1/4 ANCHOR W/1" HEXCONNECTOR, 1/8FPT X 1/4 TUBEQCELBOW, SWIVEL, 1/4MPTX1/4TUBEELBOW, SWIVEL,1/4MPTX3/8TUBEQCJET BODY, MINI PROMAX BODYJET, MINI PROMAX 9504NUT, 10-32 HEX NYLOCKPUMP ASM, 115V 73 PSI W/CONNPLUG, 9/16 OD BLK NYLONSCR, 10-32 X 1.0 PPHMSSCR, 1/4-20 X 5/8 HHCS SSFITTING,1/4 TUBE,"Y", QCTEE, 1/4 MPT X 3/8 TUBE, QCVALVE ASM,SOLENOID CLP FAMILYWASHER, 1/4"IDX1.0OD. FLAT SSWASHER, #10 X 9/16 ODWASHER, 7/16 X 3/4 X .19RUBBERNIPPLE, 1/4 CLOSENIPPLE, 1/4 FPT QDELBOW, 1/4 MPT X 3/8 TUBE, QCSCR, 10-32 X 3/8 PPHMS SSOPENWIRE, 22" GRN/18 76011 X 76011HOSE, 3/8 URETHANE X 29"HOSE, 3/8 NYLON X 6"HOSE, 1/4 URETHANE X 6"SCREEN, INTAKEHOSE, 3/8 ID NYL11 YLW X 29”CADET 86038220 03/16/07SERIAL NO.FROMNOTES:100002906510000466105-6

PUMP ASSEMBLYFROM SERIAL NO: 8292928C(SEE SOLUTIONTANK)265-72427CADET 86038220 03/16/0765

PUMP ASSEMBLYREFPART NO.PRV IONSERIAL NO.FROMNOTES:COUPLING, 1/4 ANCHOR W/1" HEXCONNECTOR, 1/8FPT X 1/4 TUBEQCELBOW, SWIVEL, 1/4MPTX1/4TUBEELBOW, SWIVEL, 3/8MPTX3/8TUBEQCJET BODY, MINI PROMAX BODYJET, MINI PROMAX 9504NUT, 10-32 HEX NYLOCKPUMP ASM, 120V SHURFLOPLUG, 9/16 OD BLK NYLONSCR, 10-32 X 1.25 PPHMS SSSCR, 1/4-20 X 5/8 HHCS SSFITTING,1/4 TUBE,"Y", QCTEE, 3/8 MPT X 3/8 TUBE, QCVALVE ASM, 120V CLP FAMILYWASHER, 1/4"IDX1.0OD. FLAT SSWASHER

carpet heights. 4. Recovery Tank. Used to collect dirty cleaning solution. 5. Solution Tank. Used to hold cleaning solution. 6. Recovery Tank Dome. 7. Vacuum Shoe. 8. Brush Housing. 9. Front Lifting Handle. 10. Cleaning Solution Filter. 6 4 5 7 8 CADET 86038220 03/16/07 3-3