Transcription

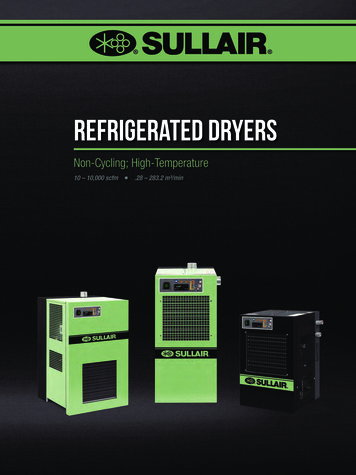

Refrigerated DryersNon-Cycling; High-Temperature10 – 10,000 scfm .28 – 283.2 m³/min

The Importance of Clean,Dry Compressed AirWater jeopardizes everything you want your compressed air system to do. Failure to remove this water ruinsproduct and fouls process. That’s why it is vital to have a reliable air treatment system in place to help protectyour equipment and your operations.Sullair Refrigerated Air Dryers reliably remove harmful moisture and contaminants from compressed air,helping protect your compressed air system, machinery and downstream tools.How?1. Saturated compressed air enters the system andis precooled in the air/air heat exchanger.Humid compressed air2. Then, precooled air moves downstream throughthe air/refrigerant heat exchanger. The heatexchanger’s vertical profile design reducescondensed moisture by nearly 99% usinggravitational force.3. To reliably prevent separated droplets from reentering the airstream, condensate collects ina large reservoir with subsequent recirculationwhere flow velocity is significantly reduced.Dry compressed airCooling4. Accumulated condensate is then discharged fromthe dryer via drain.The dried, cold process air passes back through theheat exchanger to be reheated — reducing relative airhumidity and recovering up to 60% cooling capacity.Non-CyclingNon-Cycling dryers are ideal for running at fullload because they maintain a constant energyconsumption no matter the flow and air demand.Sullair non-cycling dryers use a hot gas bypass tomaintain a stable dew point in varying operatingconditions and control the amount of refrigerantcirculating through the dryer.2Condensate

RefrigerateddryersThe next generation of Sullair Refrigerated Air Dryers focuses onefficient design, energy-saving technology and stable dew pointin all operating conditions.Sullair Refrigerated Air Dryers are built for durableperformance, optimum reliability and feature:n Uniqueheat exchanger designed for minimum pressure dropand gravitational self-cleaningn Hot gas bypass designed for stable dew point in all operating conditionsn Integrated SULLIMAXTM drain for reliable condensate dischargeand maximum energy savings*n Energy-saving technologyn Oversized condensersn Smaller high-performance compressorsn Easy-open panels providing simplified access for routine maintenance and serviceSullair Refrigerated Air Dryers are availablein the following configurations:nnnSR — Sullair Refrigerated Dryer — 10 to 480 scfmSR — Sullair Refrigerated Dryer — 20 to 10,000 scfmSRHT — Sullair Refrigerated High Temperature Dryer — 20 to 350 scfm* Optional on SR models3

SR SeriesSULLAIR REFRIGERATED DRYERS10 – 480 scfmVertical profile heat exchangern Minimum pressure dropn Gravitational self-cleaningn Hot gas bypass designed for stable dew pointin varying operating conditionsn Compact designn Timer solenoid drainn Easy-open panels for simplified servicenSR SeriesSULLAIR REFRIGERATED DRYERS20 – 10,000 scfmVertical profile heat exchangern Minimum pressure dropn Gravitational self-cleaningn Hot gas bypass designed for stable dew pointin all operating conditionsn Easy-open panels for simplified servicennnnHigh-efficiency performanceOversized condensersIntegrated SULLIMAX drainSullair Refrigerated Dryers come with a 2-year bumper-to-bumper and 5-year heat exchanger warranty.4

SRHT seriesSULLAIR REFRIGERATED HIGH TEMPERATURE DRYERS20 – 350 scfmMaximum operating temperature up to 210 Fn Vertical profile aluminum heat exchangern Minimum pressure dropn Gravitational self-cleaningn Hot gas bypass designed for stable dew pointin all operating conditionsn Integrated SULLIMAX drain*n Integrated pre-filtern Large cross section of flow channels forlow velocities and reduced power inputn Easy-open panels for simplified servicen* SRHT 20–40 offer timer solenoid drain optionFlow Rates scfmMax Inlet Air Temperature FMax Inlet Operating Pressure psigStandard Outlet Pressure Dew Point FISO 8573-1:2010 Air Quality ClassStandard Condensate DrainOptionsSR SERIESSR SERIESSRHT10 – 48020 – 10,00020 – 350130160210SR 10 – 50: 232SR 20 – 50: 232SR 75 – 480: 200SR 75 – 10,000: 20037 – 4137 – 3845 – 50Class 4 – 5Class 4 – 5Class 5 – 6Timer SolenoidSULLIMAX SULLIMAX SULLIMAX Condensate DrainPC Connection Kit**Timer Solenoid Condensate Drain200** Available on SR models 600 scfm and upSullair Refrigerated Dryers come with a 2-year bumper-to-bumper and 5-year heat exchanger warranty.5

AboutSullairFor more than 50 years, Sullair has been on the leading edge of compressedair solutions. We were one of the first to execute rotary screw technology in our aircompressors, and our machines are famous all over the world for their legendarydurability. As the industry moves forward, Sullair will always be at the forefront withquality people, innovative solutions, and air compressors that are built to last.Sullair was founded in Michigan City, Indiana in 1965, and has since expanded with a broadinternational network to serve customers in every corner of the globe. Sullair has offices inChicago and manufacturing facilities in the United States and China — all ISO 9001 certifiedto ensure the highest quality standards in manufacturing. In addition, Sullair Suzhou andShenzhen facilities are ISO 14001 and OHSAS 18001 certified.Sulliar is A Hitachi Group CompanyRELIABILITY.DURABILITY.PERFORMANCE.These are the pillars that drive the qualityof Sullair compressed air solutions. It’s apromise we keep with every machinewe make.RELIABILITYCustomers who work with Sullair have found that the intangibles make all the difference— things like trust, confidence, and peace of mind. They go to work every day having fullfaith in their equipment, as well as the knowledge that dedicated distributors and Sullairpersonnel have their back every step of the way.DURABILITYBulletproof. Built to last. However you spin it, Sullair compressed air solutions are init for the long haul, driven by innovative designs pioneering the air treatment industry.And ready to stand the test of time.PERFORMANCESullair is constantly innovating to improve our compressed air solutions. For ourcompressed air treatment line, this means more energy efficiency. With air treatmentbeing a vital part of your entire compressed air system, Sullair is committed to helpingyou protect your equipment and manage your operating expenses.6

SRseriesSULLAIR Refrigerated DryersFREQUENCY: 60 HzModel #FLOW RATE(scfm)CONNECTIONSIZE (NPT)PRESSUREDROP (psid)Power Consumption— Load (kW)Height(in)Width(in)Depth(in) 8 Weight(lbs)SR 101031.50.1917121446SR 15153 8 20.217121449SR 20201/2 0.60.2119152055SR 35351/2 1.30.2919152062SR 50501/2 2.20.319152071SR 75751 2.60.4529141775SR 10010011/4 2.20.729141886SR 12512511/4 3.50.9729141888SR 15015011/4 4.9129141890SR 17517511/2 2.81.05352223119SR 22022011/2 3.60.91352223123SR 3003002 21.15382225207SR 3753752 2.92.07382225212SR 48048021/2 2.22.25442629317Capacity correction factors for differing Operating pressureOperating Pressure psigCorrection .231.27Capacity correction factors for differing ambient air temperaturesAmbient Air Temperature F8090100110115Correction Factor1.11.0710.830.7Capacity correction factors for differing inlet air temperaturesInlet Air Temperature FCorrection FactorRequired pre-filtration μmRecommended post-filtration μmStandard Opertating VoltageSR 10–150SR 175–480Standard outlet pressure dew point FISO 8573-1:2010 Air Quality Class Maxinlet air temperature FMin/max ambient temperature FMax inlet pressure psigSR 10–50SR H230V/1PH37–45Class 4–5130 F34 F/115 F232200 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATREFSPECNC201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC.

SR seriesSULLAIR Refrigerated DryersFREQUENCY: 60 HzFLOW RATE(scfm)CONNECTIONSIZE (NPT)PRESSUREDROP (psid)Power Consumption— Load (kW)Height(in)Width(in)Depth(in)Weight(lbs)SR 20201/2 0.40.2629141762SR 30301/2 10.2729141764SR 50501/2 2.20.392914177579Model #SR 75751 2.20.48291417SR 10010011/4 20.5832191882SR 12512511/4 2.61321918101SR 15015011/4 3.31.05321918110352223121SR 20020011/2 1.7115 V - 1.10230 V - 1.10460 V - 1.22SR 25025011/2 3.6230 V - 1.39460 V - 1.38352223139SR 3003002 1.5230 V - 1.64460 V - 1.41382225203SR 3503502 1.9230 V - 2.19460 V - 1.8382225207SR 40040021/2 1230V - 2.48460 V - 2.7442629331SR 50050021/2"1.52.97442629355SR 6006003 2.22.65583139529SR 8008003 2.93.25583139534SR 100010003 2.84.6583139608SR 125012503 3.65.6583139686SR 150015004 2.86.46945471021SR 175017504 1.97.56945471186SR 200020004 2.68.66945471190SR 250025004 3.69.86945471349SR 300030006 2.812.27151691830SR 400040008 2.815.77455872330SR 500050008 4.123.57455872650SR 600060008 3.223.79661854040SR 7500SR 8000SR 10,00075008 4.526.69661854430800010,00010 10 2.83.83540.79696616110710752805990 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATREFSPECNC201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC.

SR seriesSULLAIR Refrigerated DryersFREQUENCY: 60 HzCapacity correction factors for differing Operating pressureOperating Pressure psigCorrection .231.27Capacity correction factors for differing ambient air temperaturesAmbient Air Temperature F8090100105110115120Correction Factor1.11.0910.940.870.780.69Capacity correction factors for differing inlet air temperaturesInlet Air Temperature FCorrection 0.450.4Required pre-filtration μmRecommended post-filtration μmSR 600–10,000Standard Operating Voltage10.01UL/CSA control panelSR 20–200SR 125–400SR 600–10,000Optional Operating VoltageStandard outlet pressure dew point FISO 8573-1 2010 Air Quality ClassMax inlet air temperature FMin/max ambient temperature FMax inlet pressure psigSR 20–50SR 75–500MODBUS ready 232200* 600–10,000 scfm units only 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATREFSPECNC201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC.

SRHTseriesSULLAIR Refrigerated HIGH TEMPERATURE DryersFREQUENCY: 60 HzModel #FLOW RATE(scfm)CONNECTIONSIZE (NPT)PRESSUREDROP (psid)Power Consumption— Load (kW)Height(in)Width(in)Depth(in)Weight(lbs)SRHT 20201/2 1.50.2125171682SRHT 30301/2 2.80.2825171688SRHT 40401/2 2.90.3125171690SRHT 50501/2 4.10.4625171693SRHT 75751 3.80.77451618112SRHT 10010011/4 30.88522020134SRHT 15015011/4 51.1522020146SRHT 20020011/2 3.31.55552223165SRHT 25025011/2 5.11.82552223185SRHT 3003002 4.12.6592831291SRHT 3503502 4.52.7592831304* At 45 F Outlet PDPCapacity correction factors for differing Operating pressureOperating Pressure psigCorrection .231.27Capacity correction factors for differing ambient air temperaturesAmbient Air Temperature FCorrection Capacity correction factors for differing inlet air temperaturesInlet Air Temperature F140160170180195210Correction Factor1.261.131.0710.90.81Integrated aftercoolerPre-filter includedStandard Operating VoltageSRHT 20–150SRHT 200–350Recommended post-filtration μmStandard outlet pressure dew point FISO 8573-1:2010 Air Quality ClassMax inlet air temperature FMin/max ambient temperature FMax inlet pressure psig115V/1PH230V/1PH0.0145–50Class 6210 F34 F/ 120 F200 2019 Sullair, LLC. All rights reserved. Specifications including appearance subject to change without notice. SAPATREFSPECNC201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC.

For more information, contact your local authorized Sullair distributor.Sullair Non-CyclingRefrigerated Dryersscfm10,000SR Series20–10,0001000800600400200SR Series10–480SRHT Series20–3500 2019 Sullair, LLC. All rights reserved. Specifications subject to change without notice. SAPATREFNC201901-1The Sullair symbol and Sullair wordmark are registered trademarks of Sullair, LLC. SULLIMAX is a trademark of Sullair, LLC.

Smaller high-performance compressors Easy-open panels providing simplified access for routine maintenance and service. Sullair Refrigerated Air Dryers are available . in the following configurations: SR — Sullair Refrigerated Dryer — 10 to 480 scfm SR — Sullair Refrigerated Dryer — 20 to 10,000 scfm