Transcription

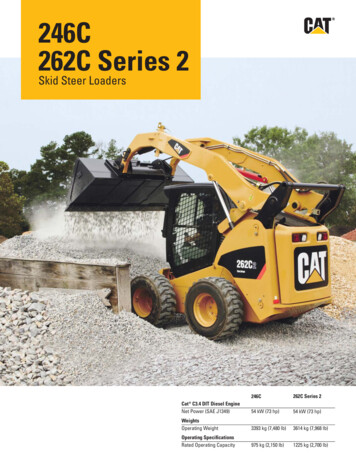

246C262CSeries2Skid Steer Loaders246C262C Series 2Cat C3.4 DIT Diesel EngineNet Power (SAE J1349)54 kW (73 hp)54 kW (73 hp)WeightsOperating Weight3393 kg (7,480 lb)3614 kg (7,968 lb)Operating SpecificationsRated Operating Capacity975 kg (2,150 lb)1225 kg (2,700 lb)

FeaturesSealed and Pressurized CabSealed and pressurized cab option providesa cleaner and quieter operating environment.Seat Mounted Adjustable ControlsErgonomic seat mounted adjustable controlsand available air ride seat can be adjustedto meet your personal preference.High Performance Power TrainIncreased horsepower and higher torquedeliver outstanding performance.High Flow XPS Hydraulic SystemHigh flow XPS hydraulic system availableon all models for applications demandingmaximum hydraulic work tool performance.More Work ToolsThe broad range of performance matchedCat Work Tools make the Cat Skid SteerLoader the most versatile machine onthe job site.ContentsOperator Station . . . . . . . . . . . . . . . . . . . . .3Power Train . . . . . . . . . . . . . . . . . . . . . . . . .4Lift Linkages. . . . . . . . . . . . . . . . . . . . . . . . .4Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . .5Work Tools . . . . . . . . . . . . . . . . . . . . . . . . . .6Serviceability . . . . . . . . . . . . . . . . . . . . . . . .7Customer Support. . . . . . . . . . . . . . . . . . . .7Specifications . . . . . . . . . . . . . . . . . . . . . . .8Standard and Optional Equipment. . . . .11Cat Skid Steer Loaders lead the industry in operatorcomfort, performance and versatility. Inside the spaciousoperator station, feel the superior comfort of a sealed andpressurized cab. Adjustable seat mounted controls and anavailable air ride seat keep you comfortable throughoutthe work day. Increased rated operating capacities,higher horsepower and improved drawbar performancehelp you get more done and increase your bottom line.

Operator StationSuperior comfort to keep you productive throughout the work day.Superior ComfortComfort and ease of operation have been designed into everyaspect of the operator station. The wide, spacious interior anduncluttered floor provide a comfortable work environment withexcellent head, shoulder and leg room to keep productivity highand help reduce fatigue.Sealed and Pressurized CabOperators spend long hours in the machine. The optional sealedand pressurized cab keeps dust out and clean air in for greateroperator comfort. Reduced sound levels within the cab alsohelp reduce fatigue.Seat Mounted Joystick ControlsErgonomic, seat mounted joystick controls enable a wide rangeof comfortable operating positions for operators of any size.The seat and controls are independently adjustable to meetthe specific needs of the operator.Advanced Machine Information and Control SystemThe optional Advanced Machine Information and Control System(AMICS) provides easy to read analog gauges for hydraulic oiland engine coolant temperature. The electronic display providesadditional operating information such as engine speed, job clockand diagnostic service codes. This display also provides the userinterface for the optional AccuGrade Grade Control System.The Selectable Work Speed Control, Selectable ImplementControl and Selectable Hystat Response Control modes allowthe operator to “dial in” his machine to maximize production.Additional Features for Maximum Comfort Air ride seat available for an unparalleled level of comfortin a skid steer loader. Easy to read instrument panels. Optional air conditioner and heater for greater comfortin extreme conditions. Optional Selectable Pattern Control which allows the operatorto select the control pattern they are most familiar with forgreater productivity.3

Power TrainAggressive performance with fuel efficiency.Cat EngineThe high performance power train provides high engine horsepower and torque.The machines feature the Cat C3.4 DIT engine – a rugged, reliable engine thatmeets U.S. EPA Tier 4 Interim/EU Stage IIIA emission requirements.Hand and Foot ThrottlesHand and foot throttles allow the operator to match engine speed to the task.The hand throttle is ideal for jobs requiring constant engine speed such as coldplaning, trenching or snow blowing. The foot throttle lets the operator vary enginespeed and minimize fuel consumption for other tasks such as load and carry, truckloading, grading and dozing.Electronic Torque ManagementThe Electronic Torque Management system maximizes power to the groundand prevents the engine from stalling in tough digging and dozing applications formaximum productivity. The system allows part throttle operation which providessmoother machine operation and reduces fuel consumption.Selectable Work Speed ControlThe optional Selectable Work Speed Control lets you select the ground speedthat is best suited for the application. This feature is useful in operations such astrenching and cold planing that require precise machine control at relatively slowand constant speeds.Selectable Hystat Response ControlThe optional Selectable Hystat Response Control lets the operator select one ofthree modes to match the machine’s drive response to the operator’s preference,skill level and application requirements.LiftLinkagesBuilt for tough workingconditions.Choice of Lift DesignsTwo types of lifting arrangements areavailable – vertical lift (path #1 above)and radial lift (path #2) – to meet yourspecific application needs.Vertical LiftThe 262C Series 2 features the verticallift design which provides extended reachand lift height for quick and easy truckloading and material placement. The liftheight is 3233 mm (127 in) on the262C Series 2.Radial LiftThe 246C, with its radial lift design,delivers excellent digging performanceand superior mid-lift reach.

HydraulicsExceptional lift, breakout and power to meet your needs.High Performance Hydraulic SystemMaximum power and reliability are built into the Cat Skid SteerLoader hydraulic system. In addition to providing power to thewheels, this system also powers the loader lift and tilt functions,powers the auxiliary circuit to drive work tools and drives theengine cooling fan. The hydraulic system features: Increased lift and tilt breakout forces allowing you to movemore material and get more done. Continuous demand fan for improved fuel efficiency, increasedhorsepower, reduced sound levels and improved cold weatherperformance. Cat ToughGuard hoses for increased reliability and durability. High capacity hydraulic tank and side-by-side cooling packagekeep components cool for maximum durability.Two Speed OptionTwo speed is available as an option to increase cycle timesand get the job done faster.High Flow XPSSelectable Implement ControlSpeed Sensitive Ride ControlHigh flow XPS hydraulic system isavailable on all models for greater machineversatility. Maximum performance canbe maintained regardless of the work toolspeed or conditions with this load sensing,pressure compensating system. Cat coolingsystems are sized to allow the operator tocontinuously power high flow work toolsin conditions that cause competitivemachines to overheat.The Selectable Implement Controloption with three levels of controlgives the operator the ability to adjustthe responsiveness and speed of the liftand tilt functions for more preciseimplement control.The optional Speed Sensitive RideControl system delivers a smoother rideon uneven terrain for superior comfort.It allows for both higher speed operationand better material retention for increasedproductivity. The system automaticallyturns off when digging or placing a loadfor maximum performance and control.5

Work ToolsDo more jobs with one machine using Cat Work Tools.The Right Tool for the JobDesigned and built for optimum performance anddurability, Cat Work Tools deliver high productivityin a variety of applications to maximize versatility: Augers Backhoes Blades (angle, dozer) Buckets (general purpose, high capacity, dirt,utility, light material, multi purpose, industrialgrapple, utility grapple) Brooms (angle, pickup, utility) Brushcutters Cold Planers Forks (pallet, industrial grapple, utilitygrapple, utility) Hydraulic Hammers Landscape Tillers Landscape Rakes Material Handling Arm Mulchers Power Box Rakes Shear Snow Blowers Stump Grinders Trenchers Vibratory Compactors Wheel SawsQuick CouplersWork tools can be changed quickly and easilywith the Cat Skid Steer Loader’s quick couplersystem. The standard quick coupler features manualengagement and disengagement of work tools usingtwo high leverage handles. The optional hydraulicquick coupler allows the operator to quickly changetools without leaving the cab.AccuGrade Grade Control System for SkidSteer, Multi Terrain and Compact Track LoadersCommon to AccuGrade systems for Track-TypeTractors and Motor Graders, this deeply integratedsolution automates the machine’s electrohydrauliccontrols to achieve a consistent grade across thework site, improve accuracy and increase productivity,ultimately lowering operating and material costs.6

ServiceabilitySimplified service and maintenance save you time and money.Easy ServiceConvenient service features make maintenance easy, reducingyour downtime: Rear door opens 90 degrees for easy access to both sidesof the engine. Cooling package tilts up to provide excellent access to theengine compartment. Cab tilts rearward for easy access to all hydraulic pumps,motors, valves, lines and hydraulic tank. Daily maintenance points are easily accessible. Wires are color coded and numbered for easy identification. S O SSM oil sampling valves are standard to allow regularmonitoring of the engine and hydraulic oil quality.Customer SupportUnmatched support makesthe difference.Superior Dealer ServiceYour Cat dealer is ready to assist you with your purchasedecision and everything after. Make detailed comparisons of the machines you areconsidering before you buy – with estimates of componentlife, preventative maintenance and the true cost of production. Customize the machine that is right for you using theBuild and Quote application on your dealer’s websiteor www.cat.com. Financing packages are flexible to meet your needs. Repair option programs guarantee the cost of repairsup front. Nearly all parts are available at the dealer parts counter. Operator training can improve your operator’s techniquesand boost your profits. Your Cat dealer can evaluate the cost involved in repairing,rebuilding and replacing your machine so you can makethe right choice.

246C and 262C Series 2 Skid Steer Loaders SpecificationsEngineEngine ModelOperating SpecificationsCat C3.4 DITNet Power (SAE J1349)CabRated Operating Capacity246C975 kg2,150 lb262C Series 21225 kg2,700 lbSAE J1040 MAY94,ISO 3471:1994FOPSSAE J1043 SEPT87,ISO 3449:1992Level IFOPS Level IISAE J231 JAN81,ISO 3449:1992Level II246C54 kW73 hp262C Series 254 kW73 hpRated Operating Capacitywith Optional Counterweight74 hp246C only – Internal 91 kgCounterweightincreases ROC by200 lb246C only – External 91 kgCounterweightincreases ROC by200 lb1336 kg2,945 lbTravel Speed12.5 km/h(Forward or Reverse)7.7 mph262C Series 21950 kg4,300 lb262C Series 22449 kg5,400 lbTravel Speed –19.3 km/h2-Speed Option(Forward or Reverse)12.0 mph246CService Refill CapacitiesGross Power (SAE J1995)246C262C Series 255 kW55 kW74 hpDisplacement3.3 L201 in3Stroke120 mm4.7 inBore94 mm3.7 inTipping LoadWeightsOperating Weight246C3393 kg7,480 lb262C Series 23614 kg7,968 lbBreakout Force, Tilt Cylinder246C3324 kg7,328 lb262C Series 23318 kg7,315 lbHydraulic SystemHydraulic FlowStandardLoader HydraulicPressure23 000 kPa 3,335 psiLoader HydraulicFlow84 L/min22 gal/minHydraulic Power31.9 kW42.8 hpHydraulic Flow8ROPSHigh Flow XPSMax. LoaderHydraulic Pressure28 000 kPa 4,061 psiMax. LoaderHydraulic Flow125 L/min 33 gal/minPower TrainChain box, each side10 L2.6 galCooling System14 L3.7 galEngine Crankcase10 L2.6 galFuel Tank98 L26 galHydraulic System57 L15 galHydraulic Tank42 L11 gal

Dimensions19135817156491814111671012123246C1 Wheelbase1240 mm48.8 in2 Length w/o Bucket2979 mm117.2 in3 Length w/Bucket on Ground3692 mm145.3 in4 Height to Top of Cab2104 mm82.8 in5 Max. Overall Height3998 mm157.4 in6 Bucket Pin Height at Max. Lift3122 mm122.9 in7 Bucket Pin Height at Carry Position200 mm7.8 in8 Reach at Max. Lift and Dump600 mm23.6 in9 Clearance at Max. Lift and Dump2425 mm95.4 in225 mm8.8 in10 Ground Clearance11 Departure Angle12 Bumper Overhang Behind Rear Axle26 1089 mm13 Maximum Dump Angle42.8 in40 14 Vehicle Width over Tires1676 mm66.0 in15 Turning Radius from Center – Machine Rear1730 mm68.1 in16 Turning Radius from Center – Coupler1386 mm54.6 in17 Turning Radius from Center – Bucket2167 mm85.3 in18 Max. Reach w/Arms Parallel to Ground1388 mm19 Rack Back Angle at Max. Height54.6 in85 9

246C and 262C Series 2 Skid Steer Loaders 12123262C Series 21 Wheelbase1240 mm48.8 in2 Length w/o Bucket2979 mm117.3 in3 Length w/Bucket on Ground3692 mm145.4 in4 Height to Top of Cab2104 mm82.8 in5 Max. Overall Height4075 mm160.4 in6 Bucket Pin Height at Max. Lift3233 mm127.3 in7 Bucket Pin Height at Carry Position200 mm7.8 in8 Reach at Max. Lift and Dump781 mm30.7 in9 Clearance at Max. Lift and Dump2450 mm96.4 in225 mm8.8 in10 Ground Clearance11 Departure Angle12 Bumper Overhang Behind Rear Axle26 1089 mm13 Maximum Dump Angle42.8 in50 14 Vehicle Width over Tires1676 mm66.0 in15 Turning Radius from Center – Machine Rear1730 mm68.1 in16 Turning Radius from Center – Coupler1386 mm54.6 in17 Turning Radius from Center – Bucket2167 mm85.3 in18 Max. Reach w/Arms Parallel to Ground1283 mm19 Rack Back Angle at Max. Height20 Bucket Pin Reach at Max. Lift1050.5 in85 373 mm14.7 in

246C and 262C Series 2 Standard EquipmentStandard equipment may vary. Consult your Cat dealer for details.ELECTRICAL12 volt Electrical System90 ampere AlternatorIgnition Key Start/Stop SwitchLights: Gauge backlighting, two rear taillights, two rear halogen working lights, twoadjustable front halogen lights, dome lightBackup AlarmHeavy Duty Battery, 880 CCAOPERATOR ENVIRONMENTGauges: Fuel level, hour meterOperator Warning System Indicators:Air filter restriction, alternator output,armrest raised/operator out of seat, enginecoolant temperature, engine oil pressure,glow plug activation, hydraulic filterrestriction, hydraulic oil temperature,parking brake engagedVinyl seat, mechanical suspensionFold-in Ergonomic Contoured ArmrestControl Interlock System, when operatorleaves seat or armrest raised: Hydraulicsystem disables, hydrostatic transmissiondisables, parking brake engagesROPS Cab, Open, Tilt UpFOPS, Level ITop and Rear WindowsHeadliner, DeluxeFloor MatInterior Rear View Mirror12 volt Electric SocketHornPOWER TRAINCat C3.4 DIT Diesel Engine (meets U.S.EPA Tier 4 Interim/EU Stage IIIA emissionstandards)Air Cleaner, Dual Element, Radial SealS O SSM Sampling Valve, Hydraulic OilFilters, Spin-on, HydraulicFilters, Bayonet-type, Fuel and WaterSeparatorTilt Up Radiator/Hydraulic Oil CoolerSpring Applied, Hydraulically Released,Parking BrakeHydrostatic TransmissionFour Wheel Chain DriveOTHEREngine Enclosure, LockableExtended Life Antifreeze, –37 C (–34 F)Machine Tie Down Points (4)Support, Lift ArmHydraulic Oil Level Sight GaugeRadiator Coolant Level Sight GaugeRadiator, Expansion BottleCat ToughGuard HoseAuxiliary, Hydraulics, Continuous FlowHeavy Duty, Flat Faced Quick DisconnectsSplit D-Ring to Route Work Tool HosesAlong Side of Left Lift ArmElectrical Outlet, BeaconBelly Pan CleanoutMANDATORY EQUIPMENTHydraulics, Standard or High Flow XPSQuick Coupler, Mechanical or HydraulicSeat Belt, 50 mm (2 in) or 75 mm (3 in)Comfort Package(must select one of the following): Open ROPS (C1): Suspension Seat(no heater or door) Enclosed ROPS with Heat (C2):Cup Holder, Radio Ready, Seat(choice of Suspension or Air Ride),Heater and Defroster, Side Windows,Door (either Glass or Polycarbonate) Enclosed ROPS with A/C (C3): Featuresof C2 Package plus Air ConditionerPerformance Package(must select one of the following): Performance Package 1: One Speed Performance Package 2: One Speed,Self Level Performance Package 3: Two Speed,Self Level Performance Package 4: Two Speed, SelfLevel, Ride Control, Advanced MachineInformation and Control System (AMICS)246C and 262C Series 2 Optional EquipmentOptional equipment may vary. Consult your Cat dealer for details.CounterweightBeacon, RotatingEngine Block Heater – 120VOil, Hydraulic, Cold OperationPaint, CustomAM/FM/Weather Band Radio with CD Playerand Auxiliary Input Jack11

246C and 262C Series 2 Skid Steer LoadersFor more complete information on Cat products, dealer services, and industry solutions,visit us on the web at www.cat.com 2012 Caterpillar Inc.All rights reservedMaterials and specifications are subject to change without notice. Featured machinesin photos may include additional equipment. See your Cat dealer for available options.CAT, CATERPILLAR, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”and the “Power Edge” trade dress, as well as corporate and product identity used herein,are trademarks of Caterpillar and may not be used without permission.AEHQ6577 (05-2012)Replaces AEHQ5968-01

Your Cat dealer can evaluate the cost involved in repairing, rebuilding and replacing your machine so you can make the right choice. 246C and 262C Series 2 Skid Steer Loaders Specifications. Engine Operating Specifi cations Cab . Engine Model Cat C3.4 DIT Rated Operating Capacity ROPS SAE J1040 MAY94,