Transcription

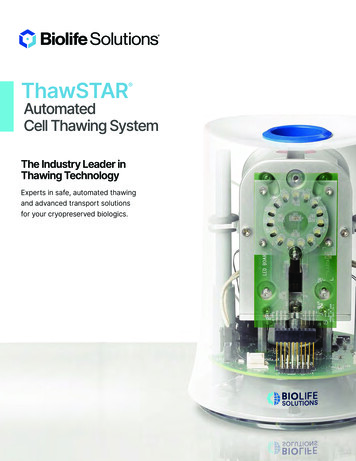

ThawSTAR AutomatedCell Thawing SystemThe Industry Leader inThawing TechnologyExperts in safe, automated thawingand advanced transport solutionsfor your cryopreserved biologics.

Customizable Thawing System for CryobagsThawSTAR CB is an automated thawing system designed to handle large volume 25-1000 mL cryobags. Operatedthrough a user-friendly software interface, the ThawSTAR CB System standardizes and streamlines cell thawing forconsistent and reproducible results. Consistent Thawing – Automated algorithm driven thawing withbiomaterial temperature sensing technology. Easy Operation – Intuitive software interface allows accesscontrol, enforcement of QC procedures, and optimized thawingalgorithms. Compatible with common cryobag form factors frommajor manufacturers. Biomaterial Safety – Single use Barrier Bag reduces the risk ofbiomaterial loss, and/or contamination; and positions cryobagfor optimal thaw performance. Precise and Reliable – Patent-pending heating technologyand real-time temperature-sensing analytics manage heatapplication for a reliable and documented thaw. An uneditablethaw archive is stored in internal memory.ThawSTAR CB: How it WorksPatented heating technology and sophisticated sensors detect bag temperature for a reliable and reproduciblethaw.The ThawSTAR CB Thawing System’s intuitive touchscreen interface allows users to select the size of their cryobagprior to insertion along with any desired modifications to the thawing parameters. To begin, insert the frozen cryobaginto a ThawSTAR CB Barrier Bag and seal to eliminate risk of contamination. The thaw process is signaled through thetouchscreen interface and the drawer of the instrument opens. The frozen cryobag is placed onto the drawer, aligningthe ThawSTAR CB Barrier Bag with the drawer guide pins to ensure correct positioning. The user will indicate the bagis in position, the drawer closes and the thawing procedure begins. The progress of the thaw is visible on the face ofthe touchscreen panel, and upon completion the drawer opens and the thawed cryobag is retrieved. Thawing data ispreserved in a memory file and can be downloaded to a USB memory drive for processing.Page 2ThawSTAR Automated Cell Thawing: Cryobags

SpecificationsThawSTAR CB SystemInstallationSelf-installed, out-of-the-box operationCapacityOne cryobagDimensions (H x W x D)19.5 x 38.5 x 45 cm (8 x 15 x 18 in)Weight11.3 kg (25 lb)Cryobag size25 mL - 1000 mLBag typeCompatible with all major manufacturers including OriGen Charter and Miltenyi Thawing temperatureDriven by protocol settings, ranging from 37 C - 50 CThawing time2-8 minutes (depending on fill volume)Input voltage100-120V, 200-240VPower requirementsMaximum 8AAccessoriesThawSTAR CB Barrier Bag (25, 50, 250, 500, 750, and 1000 mL)Ordering InformationThawSTAR Automated Cell Thawing SystemAST-90000ThawSTAR CB Automated Thawing System with 6 standard bag optionsAST-90001ThawSTAR CB Automated Thawing System with 6 standard bag options plus One Optimized Thawing AlgorithmAST-90025ThawSTAR CB Barrier Bags, 25 mL, 25 per packAST-90050ThawSTAR CB Barrier Bags, 50 mL, 25 per packAST-90250ThawSTAR CB Barrier Bags, 250 mL, 25 per packAST-90500ThawSTAR CB Barrier Bags, 500 mL, 25 per packAST-90750ThawSTAR CB Barrier Bags, 750 mL, 25 per packAST-91000ThawSTAR CB Barrier Bags, 1,000 mL, 25 per packAST-90011ThawSTAR CB Extended Limited Warranty (one year)AST-CUSTThawSTAR Algorithm Optimization (one protocol)AST-90013ThawSTAR CB Power CordsThawSTAR Automated Cell Thawing: Cryobags Page 3

Automated Thawing Systems for Cell Therapy VialsBioLife Solutions now offers three automated thawing systems for AT-Closed Vials : ThawSTAR AT2 for 2.0mL AT-Closed Vials, ThawSTAR AT6 for 6.0 mL AT-Closed Vials, and ThawSTAR AT10 for10 mL AT-Closed Vials. ThawSTAR AT-Closed Vial Thawing Systems replaceunstandardized manual methods such as water bath and handthawing and can be leveraged early in the R&D phase andscaled into commercial manufacturing and point of care. ContactBioLife Solutions regarding your vial size, vial load, initial vialtemperature and desired final thaw state to learn how quicklyand easily a dedicated thaw profile can be created for yourspecific application. BioLife Solutions will adjust the advancedthawing algorithm to provide a consistent and scaleable thawingoutcome for your cells that will service your specific cell therapyproduct through discovery, clinical trials, and point of care. ThawSTAR AT-Closed VialSystems Provide Reproducible Thawing ResultsEliminate human-dependent variability.ThawSTAR AT-Closed Vial System: Eliminates the contamination risk of water bath thawing procedures Simplifies training of the end-user Delivers consistent thawing performance and mitigates a variable process Provides specialized support for cells that have a rate-of-thaw to viability correlationThawSTAR AT Transporter: How it WorksThe transporter is comprised of an insulative foam base and lid, and an AT Core that accommodates 2.0 mL,6.0 mL and 10.0 mL AT-Closed Vials.ThawSTAR AT Transporter is a portable solution for handling and transporting frozen cell therapy vials from long-termstorage in vapor phase liquid nitrogen or in a -80 C freezer to downstream thawing with the ThawSTAR Automated CellThawing Instrument.Page 4ThawSTAR Automated Cell Thawing: AT-Closed Vial

SpecificationsThawSTAR AT2 InstrumentThawSTAR AT6 InstrumentDimensions (Diameter x Height)11.0 x 14.5 cm(5.7 x 4.3 in)CapacityOne 2.0 mLAT-Closed VialDimensions (Diameter x Height)11.0 x 14.5 cm(5.7 x 4.3 in)CapacityOne 6.0 mLAT-Closed Vial Fill volume0.5 - 2.0 mLFill volume2.0 - 5.0 mLThawing timeApproximately 3 - 5minutesThawing timeApproximately 3 - 6minutesComplianceCE mark (EMC and Safety), EN 60601-1-2, EN61010-1, RoHS, WEEEThawSTAR AT10 InstrumentThawSTAR AT TransporterDimensions (Diameter x Height)11.0 x 14.5 cm(5.7 x 4.3 in)CapacityOne 10.0 mLAT-Closed VialDimensions (L x W x H)20.0 x 16.0 x 16.0 cm(7.8 x 6.3 x 6.3 in)CapacitySix 2.0 mL, 6.0 mL or 10.0mL AT-Closed Vials Fill volume4.0 - 8.0 mLDry ice used 250 gThawing timeApproximately 3 - 6minutesHolding temperature -70 CComplianceCE mark (EMC and Safety), EN 60601-1-2, EN61010-1, RoHS, WEEEHolding time 1 hourOrdering InformationThawSTAR Automated Cell Thawing SystemAST-650ThawSTAR AT2 Automated Cell Thawing InstrumentAST-700ThawSTAR AT6 Automated Cell Thawing InstrumentAST-710ThawSTAR AT10 Automated Cell Thawing InstrumentAST-701ThawSTAR AT Transporter for six 2.0 mL 6.0 mL or 10.0 mL AT-Closed Vials ThawSTAR Automated Cell Thawing: AT-Closed Vial Page 5

Automated Thawing System for Cryogenic VialsThawSTAR Cell Thawing Instrument utilizes patent-pending STAR sensing technology to customize the thawfor each vial - whether obtained from liquid nitrogen or -80 C storage. ThawSTAR Automated Cell Thawing Instrument features intuitiveoperation, making integration and standardization easy. Simplyinsert a frozen cryogenic vial and retrieve it when the vial is gentlyraised at the end of the thaw cycle, (approximately 2.5 minutes).The small footprint and audio/visual feedback enable use in acell culture hood with the rest of the workflow. The ThawSTARInstrument reduces variability in cell preparations by criticalcontrol of vial thawing. This serves to remove operator error andday-to-day variations within a site as well as site-to-site variationacross multiple clinical centers in a single trial.ThawSTAR CFT Transporter: How it WorksComprised of an outer insulative foam lid and base, and an internal round CFT2 Core that accommodates up tofive 1.8 or 2.0 mL (CFT2), or five 1.5 mL (CFT1.5) cryogenic vials.Prior to using the ThawSTAR CFT Transporter, a thin layer of dry ice is added to thebottom of the base. The round CFT2 Core is placed over the dry ice and allowed toequilibrate to dry-ice temperature (approximately 20 minutes). Frozen vial is thenextracted from storage and quickly placed into the module. The lid is placed securely ontop of the base and all samples are maintained at dry ice temperature until transported tothe thawing location.Performance DataEx-Vivo B Cells: Post-thaw viability and consistency compared to water bathA total of 6 vials (2 each from 3 donors) containing ex vivostimulated B cells, were frozen in a -80 C freezer using aCoolCell cell freezing container and then stored in liquidnitrogen (LN2) for two weeks. One vial from each donorwas removed from LN2, placed into a ThawSTAR CFT2Transporter and thawed in a ThawSTAR CFT2 AutomatedCell Thawing Instrument. The other vial from each donorwas removed from LN2 and hand-carried to a waterbath. The vials transported and thawed in the ThawSTARTransport and Thawing System performed better in termsof cell viability and recovery.— Data generated by UCSF Diabetes Center and Transplant SurgeryPage 6ThawSTAR Automated Cell Thawing: Cryogenic Vials

SpecificationsThawSTAR CFT2 InstrumentThawSTAR CFT1.5 InstrumentDimensions (Diameter x Height)11.0 x 14.5 cm (5.7 in x 4.3 in)Dimensions (Diameter x Height)11.0 x 14.5 cm (5.7 in x 4.3 in)Capacity1.8 - 2.0 mL cryogenic vialCapacity1.5 mL cryogenic vialFill volume0.8 - 1.5 mLFill volume0.5 - 1.5 mLVial BrandCompatible with major vialmanufacturersVial BrandNalgene 5000-1020Thawing timeTypically less than3 minutesThawing timeTypically less than3 minutesThawSTAR CFT2 TransporterDimensions (Diameter x Height)11.4 x 15.0 cm (4.5 x 6.0 in)Dry ice used 1 50 gHolding temperature -70 CHolding time 1 hourThawSTAR CFT1.5 TransporterDimensions (Diameter x Height)11.4 x 15.0 cm (4.5 x 6.0 in)Dry ice used 1 50 gHolding temperature -70 CHolding time 1 hourIOPQ Packet for ThawSTAR CFT2 SystemQualification documentation and testing accessories based on GxP industry standardsand the GAMP 5 methodology. Contents include: Comprehensive documentation makes therapeutic cell thawing easy to authenticate Testing accessories included with Qualification Packet Step-by-Step IOPQ protocol and report templates for thawing in a controlled environmentOrdering InformationThawSTAR Automated Cell Thawing SystemAST-600ThawSTAR CFT2 Cell Transport and Thawing System, completeAST-601ThawSTAR CFT2 Automated Cell Thawing InstrumentAST-602ThawSTAR CFT2 Transporter for up to five 1.8 or 2.0 mL cryogenic vialsAST-614ThawSTAR CFT2 IOPQ Packet for ThawSTAR CFT2 SystemAST-603ThawSTAR CFT2 Confirmation VialsAST-630ThawSTAR CFT1.5 Cell Transport and Thawing System, completeAST-631ThawSTAR CFT1.5 Automated Cell Thawing InstrumentAST-632ThawSTAR CFT1.5 Transporter for up to five 1.5 mL cryogenic vialsAST-606ThawSTAR Instrument Power Supply and AdapterAST-611ThawSTAR Extended Limited Warranty(North America, includes Preventative Maintenance)AST-613ThawSTAR Extended Limited Warranty(International, includes Preventative Maintenance)The ThawSTAR System is for laboratory research use only. Any intended use for diagnostic purposes, direct transfusion, or in theproduction of therapeutic product(s) or vaccines(s) may require advance regulatory clearance which is the sole responsibility of theuser, as this is not a medical device that has undergone medical device registration, clearance, or approval by the U.S. Food and DrugAdministration (FDA), European Union, Health Canada, or the Australian Therapeutic Goods Administration.ThawSTAR Automated Cell Thawing: Cryogenic Vials Page 7

Low-Capacity Temperature Stability SystemBreakthrough portable solution for handling and transporting valuable frozen biological materials andtemperature-sensitive samples, or freezing samples at a collection siteThe closed-cell high-density polyethylene foamconstruction of the lid and base chamber is durable, nonabsorbent, and remains comfortable to the touch even whenloaded with dry ice and frozen materials. Magnetized lidensures safe transport of contents. The dry ice retainer orDIR and thermo-conductive shelf plate are constructed ofaluminum alloy anodized for durability.Delivers Reliable PerformanceBioT ULT Transporter maintains samples at -50 C for 24 hours and the BioT LN2 Transporter maintainscryogenic temperature at -150 C for approximately 2 hours. Ready to use in approximately 10 minutes Lightweight, easy to carry Intuitive assembly, durable Easy to clean and storeBioT ULT Transporter is comprised of three parts:magnetized lid, DIR dry ice retainer and base chamber.To begin, insert the DIR retainer, flanges down, into thebase chamber. Add pelletized dry ice into the cavitybetween the DIR retainer and the base chamber walls,filling to the top of the DIR retainer. A full load of dry ice isapproximately 13 lbs (5.8 kgs). The internal chamber willreach optimal working conditions ( -70 C to -50 C) withinapproximately 10 minutes and will be ready for use.Page 8BioT LN2 Transporter is comprised of five parts:magnetized lid, thermo-conductive basket, thermoconductive shelf plate, absorbent/baffle pad andbase chamber. To begin simply insert the thermoconductive basket into empty base chamber, followedby the absorbent/baffle pad. Place the thermoconductive shelf plate into the basket on top of theabsorbent/baffle pad. With the addition of LN2, ( 2.7L) the internal chamber will reach -150 C withinapproximately 10 minutes.BioT Transporter

Styrofoam Box and Dry Ice: 0.6 Inches Below -50 CA dry ice-filled Styrofoam box is currently thestandard method used for receiving, handling andtransporting valuable frozen samples. However,only a 0.6 inch (1.5 cm) high zone above the dryice stays below -50 C for 2 hours. Worse, at 2inches (5.0 cm) above the dry ice - the top of astandard 2-inch cryostorage box- the temperatureis above -20 C.BioT ULT Transporter: 8.0 Inches Below -50 CBioT ULT Transporter provides a stable ultra-lowtemperature ( -70 C to -50 C) work zone 8.0inches (20.3 cm) deep. Up to 8 standard 2-inchcryostorage boxes will remain safely below -50 Cfor over 8 hours with the lid open and over 24hours with the lid closed with one charge of dryice.SpecificationsBioT ULT TransporterBioT LN2 Transporter-70 C to -50 CLid off: over 8 hoursLid on: over 24 hours-180 C to -150 C at 6’’Lid off: 1 - 1.5 hoursLid on: 2 - 2.5 hoursDimensions (L x W x H)Internal working area: 29.0 x 16.2 x20.3 cm (11.4 x 6.4 x 8.0 in)External: 50.8 x 33.8 x 33 cm(20.0 x 13.3 x 13 in)Dimensions (L x W x H)Internal working area: 36.3 x 19.8 x17.8 cm (14.3 x 7.8 x 7.0 in)External: 50.8 x 33.8 x 33 cm(20.0 x 13.3 x 13 in)Amount of dry ice required5.4 kg (12.8 lb)Amount of LN2required 2.7 L to charge unitWeight empty3.6 kg (8.0 lb)Weight empty4.0 kg (8.8 lbs)Weight with dry ice9.0 kg (20.8 lb)Weight with LN26.2 kg (13.6 lbs)Working depth -50 Cup to 20 cm (8.0 in) from chamberfloorWorking depth -150 Cup to 15.2 cm (6 inches) from floorplateCapacity8 standard 2-inch cryostorage boxes18, 250 mL cassettesCapacity 6 standard 2-inch cryostorageboxes 24, 250 mL cassettesOrdering InformationBioT ULT TransporterAST-500DBioT ULT Transporter, magnetized lid, DIR dry ice retainer and base chamberAST-500LBioT LN2 Transporter, magnetized lid, thermo-conductive basket, thermo-conductive shelf plate and absorbent padand base chamberAST-501DBioT DIR Retainer, thermo-conductive dry ice retainerAST-501LBioT LN2 Basket, thermo-conductive basket, thermo-conductive shelf plate and absorbent padBioT Transporter Page 9

Ultra-Low, High-Capacity Mobile Temperature Stability SystemBioT ULT Workstation is a breakthrough solution for handling and transporting valuabletemperature-sensitive biomaterials, or freezing samples at collection site.The dry ice-based BioT ULT Workstation provides a secureultra-low temperature (ULT) -75 to -50 C work area forprocessing or transporting critical frozen samples. Thepatent-pending DIR cooling insert technology ensures thatsamples are completely immersed in temperatures below-50 C during the operating period. Requiring minimal dry ice,the chamber equilibrates to -50 C within 30 minutes andcontinues to cool for over 15 hours with the lid open with asingle charge of dry ice.Maintains -75 to -50 C for 15 hoursULT handling and transport for a variety of applications Cherry-picking, sorting or other short term handling of criticalsamples outside a -80 C freezer Controlled-temperature transfer of frozen samples within andbetween facilities Transfer of temperature-sensitive materials to long-term storagetanks or automated biobank facilities Preparing, labeling or packaging of frozen samples for shipmentPerformance DataBioT ULT Workstation: 10.0 inches below -50 CBioT ULT Workstation equilibrates to -50 C in less than30 minutes and entire chamber maintains temperaturestability for over 15 hours. Temperature measured at 0inches (blue), 4 inches (red), 7 inches (green), 10 inches(lavender).Page 10BioT ULT Workstation

SpecificationsBioT ULT WorkstationInternal Dimensions (L x W x H)105.4 x 33.0 x 35.5 cm / 41.5 x 13.0 x 14.0 inExternal Dimensions (L x W x H)152.4 x 71.1 x 44.5 cm / 60.0 x 28.0 x 17.5 inHours of -50 C coolingLid open: over 15 hoursAmount of dry ice required41 kg (90 lb)Working depth -50 Cup to 25.4 cm (10 in)Ordering InformationBioT ULT WorkstationAST-508BioT ULT Workstation, dry ice based freezing Includes: container base, lid and cart. Temperature monitoring and alarm system available upon request.BioT ULT Workstation Page 11

info@biolifesolutions.com biolifesolutions.com 2021. BioLife Solutions. All rights reserved. Patents pending. BioLife Solutions, ThawSTAR,BioT, STAR designations are trademarks owned by BioLife Solutions.BR-AST-210118R01.

dard bag options plus One Optimized Thawing Algorithm AST-90025 ThawSTAR CB Barrier Bags, 25 mL, 25 per pack: AST-90050. ThawSTAR CB Barrier Bags, 50 mL, 25 per pack: AST-90250. ThawSTAR CB Barrier Bags, 250 mL, 25 per pack: AST-90500. ThawSTAR CB Barrier Bags, 500 mL, 25 per pack: AST-90750. ThawSTAR CB Barrier Bags, 750 mL, 25 per pack: AST-91000