Transcription

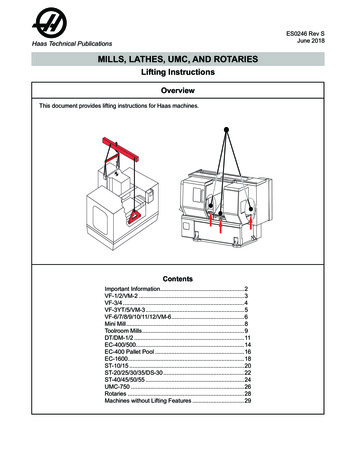

ES0246 Rev SJune 2018Haas Technical PublicationsMILLS, LATHES, UMC, AND ROTARIESLifting InstructionsOverviewThis document provides lifting instructions for Haas machines.ContentsImportant F-6/7/8/9/10/11/12/VM-6.6Mini Mill.8Toolroom Mills.9DT/DM-1/2.11EC-400/500.14EC-400 Pallet 2ST-40/45/50/55.24UMC-750.26Rotaries.28Machines without Lifting Features.29

Haas Technical PublicationsLifting InstructionsImportant InformationPlease read these instructions in their entirety before attempting to lift the machine.WARNINGIT IS IMPERATIVE THAT PREPARATION AND LIFTING OF THE MACHINE BEPERFORMED BY PROFESSIONAL RIGGERS. THESE INSTRUCTIONS ARE TO BE USEDAS A REFERENCE GUIDE ONLY.Specialized equipment is necessary to ensure that the machine is secure and level while being raised.IMPORTANT: VF-Series - The top column attachment points are the main lifting points and should remainvertically oriented to the floor throughout the entire lift.The front chains attached to the base are to help stabilize the machine and should not carry the mainload.When lifting the machine, slowly lift until all chains are taut, then lift the machine ensuring it remainsbalanced.Lifting brackets and hardware must be removed before machine operation, unless otherwise noted.Lifting kits are available for most machines. Kits include lifting brackets and mounting hardware. It is thecustomer's responsibility to supply all chains and spreader bars required to properly lift the machine. Contacta local Haas Factory Outlet (HFO) for more information.Store lifting brackets and hardware in a safe place. They must be used if the machine is to be moved. OnlyHaas supplied replacement hardware is authorized for use. If lifting hardware is lost or damaged, contactyour HFO.Refer to the lifting placard located on the rear of the machine for model specific lifting information.Notice: For lifting of machines not listed in this document, contact your local HFO for anolder version.ES0246 Rev SJune 2018Page 2 of 28

Haas Technical PublicationsLifting InstructionsVertical Machining CentersVF-1 / VF-2 Series / VM-2 Lift PlacardRefer to the lifting placard for small VMCs. Attach the lifting bracket and chains as shown. Ensure thatthe chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.Spreader bars are not provided by Haas Automation, Inc.ES0246 Rev SJune 2018Page 3 of 28

Haas Technical PublicationsLifting InstructionsVF-3 / VF-4 Lift PlacardRefer to the lifting placard for the VF-3 and VF-4. Attach chains to the lifting points as shown. Ensure thatthe chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.Spreader bars are not provided by Haas Automation, Inc.ES0246 Rev SJune 2018Page 4 of 28

Haas Technical PublicationsLifting InstructionsVF-3YT / VF-5 Series / VM-3 Lift PlacardRefer to the lifting placard for the VF-3YTs, VF-5s, and VM-3. Attach chains to the lifting points as shown.Ensure that the chains do not contact the sheet metal enclosure or electrical cables. Note the use ofspreader bars. Spreader bars are not provided by Haas Automation, Inc.ES0246 Rev SJune 2018Page 5 of 28

Haas Technical PublicationsLifting InstructionsLarge VMC Lift PlacardRefer to the lifting placard for large VMCs. Attach chains to the lifting points as shown. Ensure that thechains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars andspacers. Spreader bars and spacers are not provided by Haas Automation, Inc.ES0246 Rev SJune 2018Page 6 of 28

Haas Technical PublicationsLifting InstructionsVF-6 to 12 / VM-6 Lifting Hardware Details1. The front lifting brackets are located next tothe Y-axis waycover. The bracket will remainin place after lifting operation is complete.LiftingBracketES0246 Rev SJune 2018Page 7 of 28

Haas Technical PublicationsLifting InstructionsMini Mill Lift PlacardHaas Automation does not provide a lifting kit for the Mini Mill. The lifting features are built into the machine.It is the machine rigger’s responsibility to provide the means to lift and position the Mini Mill. The customermust supply all hardware required for lifting.Attach chains to the lifting points as shown. Ensure that the chains do not contact the sheet metal enclosureor electrical cables. Note the use of spreader bars. Spreader bars and spacers are not provided by HaasAutomation, Inc.ES0246 Rev SJune 2018Page 8 of 28

Haas Technical PublicationsLifting InstructionsToolroom Mills Lift PlacardHaas Automation does not provide a lifting kit for the Toolroom Mill. The lifting features are built into themachine. It is the machine rigger’s responsibility to provide the means to lift and position the Toolroom Mill.The customer must supply all hardware required for lifting. Attach chains to the lifting points as shown.Ensure that the chains do not contact the sheet metal enclosure or electrical cables.TM-1/1P and TM-2/2P: The front lifting points are 1/2"-13 tapped holes.Note: Swivel lifting hoists must be used when lifting this machine.ES0246 Rev SJune 2018Page 9 of 28

Haas Technical PublicationsLifting InstructionsToolroom Mills Lift PlacardHaas Automation does not provide a lifting kit for the Toolroom Mill. The lifting features are built into themachine. It is the machine rigger’s responsibility to provide the means to lift and position the Toolroom Mill.The customer must supply all hardware required for lifting. Attach chains to the lifting points as shown.Ensure that the chains do not contact the sheet metal enclosure or electrical cables.TM-3/3P: Remove the pendant arm shipping bracket before installing hardware. Move the pendant arm tothe operating position and secure in place to avoid damage from lifting chains. The front lifting points are 1/2"(13 mm) through holes which will accept 1/2" (13 mm) swivel lifting hoists, washers, and nuts.Note: Swivel lifting hoists must be used when lifting this machine.30"(762 mm)TM-3/3P57"(1450 mm)TM-3/3P97"(2460 mm)41" (1041mm)7000 lb(3200 kg)3Pø1/2" (13mm) Through Hole29-0962 Rev A 2014 Haas Automation, Inc.ES0246 Rev Sdiy.haascnc.comJune 2018Page 10 of 28

Haas Technical PublicationsLifting InstructionsDT/DM-1 Lift PlacardHaas Automation does not provide a lifting kit for the DT or DM machines The lifting features are built intothe machine. It is the machine rigger’s responsibility to provide the means to lift and position the DT/DMs.The customer must supply all hardware required for lifting.The front lifting hardware (eyebolts) should be forged steel and have 3/4"-10 UNC threads.Min. thread length of 1.0625" (26.988 mm). Working load capacity of 5100lbs (2320 kg).Two 3/4" (16mm) split lockwashers also needed.Refer to the lifting placard for the DT-1 and DM-1. Attach lifting chains and hooks to the lifting points asshown. Ensure that the chains do not contact the sheet metal enclosure or electrical cables.ES0246 Rev SJune 2018Page 11 of 28

Haas Technical PublicationsLifting InstructionsDT-1 & DT-2/DM-1 and DTM-2 Lifting Hardware Details1. Loosen, but do not remove, the top row ofscrews for the Y-axis way cover.Loosen2. Remove the two lower screws.Remove3. Remove the two bolts on the front sides of theY-axis way cover.RemoveES0246 Rev SJune 2018Page 12 of 28

Haas Technical PublicationsLifting Instructions4. Lift up the Y-axis way cover over the linearguides and push the cover toward the table.5. Install the eyebolts and necessary shackles.The front lifting hardware should be forged steeland have 3/4"-10 UNC threads.Min. thread length of 1.0625" (26.988 mm).Working load capacity of 5100lbs (2320 kg).Install two 3/4" (16mm) split lock washers.6. Remove the 3 roof panels shown for liftingstrap attachment access. Attach lifting strap asshown on lifting placard.ES0246 Rev SJune 2018Page 13 of 28

Haas Technical PublicationsLifting InstructionsHorizontal Machining CentersEC-400 / 500 Lift PlacardHaas Automation does not provide a lifting kit for the EC-400/500. The lifting features are built into themachine. It is the machine rigger’s responsibility to provide the means to lift and position the EC-400/500.The customer must supply all hardware required for lifting.The lifting hardware (eyebolts) should be forged steel and have 1"-8 UNC threads.Minimum thread length of 2.5" (64 mm). Minimum working load capacity of 9000lbs (4090 kg). Roundspacers required.Refer to the lifting placard for EC-400/500. Attach chains to the lifting points as shown. Ensure that thechains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.EC-400 / EC-500EC-400: 37" (94 cm)EC-500: 50" (126 cm)45 Min.EC-400 22000 lb(10000 kg)EC-500 31000 lb(14100 kg)EC-400: 50" (1260 mm)EC-500: 62" (1560 mm)4X LiftingEyebolt SpacerEC-400: 90" (2286 mm)EC-500: 101" (2565 mm)EC-400/EC-500:42" (1066 mm)29-0872 Rev B 2014 Haas Automation, Inc.ES0246 Rev SRefer to diy.haascnc.com for lifting detailsJune 2018Page 14 of 28

Haas Technical PublicationsLifting InstructionsEC-400 / 500 Lifting Hardware Details1. Remove the top front panels of the machine.2. Before lifting the machine, remove the holeplugs and install four 1"-8 forged steel shouldereyebolts, 1" steel washers, and spacers.Round spacer dimensions:2.00" (51mm) OD1.13" ID (29mm) ID0.75" (19mm) Thick3. Once the machine is in position, remove theeyebolts from the lifting holes and replace withbolts and washers.Top Front PanelsEC400ES0246 Rev SJune 2018EC400Page 15 of 28

Haas Technical PublicationsLifting InstructionsEC-400 Pallet Pool Lift PlacardHaas Automation does not provide a lifting kit for the EC-400 Pallet Pool. The lifting features are built into themachine. It is the machine rigger’s responsibility to provide the means to lift and position the EC-400 PalletPool.The customer must supply all hardware required for lifting.The lifting hardware should be forged steel and have 5/8-11 UNC threads.Min. thread length of 1.0625" (26.988 mm). Working load capacity of 5100lbs (2320 kg).Refer to the lifting placard for the EC-400 Pallet Pool. Attach chains to the lifting points as shown. Ensurethat the chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.Spreader bars are not provided by Haas Automation, Inc.EC-400 Pallet Pool20" (510 mm)EC-400PP 7500 lb(3450 kg)45 Min.29" (740 mm)29" (740 mm)313ES0246 Rev S142429-0873 Rev B 2014 Haas Automation, Inc.2Refer to diy.haascnc.com for lifting detailsJune 2018Page 16 of 28

Haas Technical PublicationsLifting InstructionsEC-400 Pallet Pool Lifting Hardware Details1. Before lifting the machine, install four (4) 5/8" x1-1/16" eyebolts and four (4) 5/8" flat washers.Note: The two left eyebolts are installed intoblocks bolted to the base plate.2. Once the machine is in position, remove theeyebolts from the lifting holes and replace withbolts and washers.ES0246 Rev SJune 2018Page 17 of 28

Haas Technical PublicationsLifting InstructionsEC-1600 / EC-1600ZT Lift PlacardRefer to the lifting placard for EC-1600. Attach chains to the lifting points as shown. Ensure that the chainsdo not contact the sheet metal enclosure or electrical cables. The lifting kit for the EC-1600 is available onloan from Haas Automation, Inc.ES0246 Rev SJune 2018Page 18 of 28

Haas Technical PublicationsLifting InstructionsEC-1600 / EC-1600ZT Lifting Hardware Details1. Wheels can be used to help position the liftingbeams beneath the EC-1600. The lifting kit(LK1600) is available from Haas Automation.2. Position the lifting beams under the machine sothat the EC-1600 is located in the lifting beamrecesses.00EC-16ES0246 Rev SJune 2018Page 19 of 28

Haas Technical PublicationsLifting InstructionsTurning CentersST-10/15 Series Lift PlacardRefer to the lifting placard for the ST-10 series lathes. Lifting hardware is not provided by Haas Automation.Attach chains and shackles as shown. Ensure that the chains do not contact the sheet metal enclosure orelectrical cables.!ST-10/1548" mm)19(1224"(609 mm)ST-10/15 6000 lb(all)(2750 kg)24"(609 mm)70"(1778 mm)90 90 55.3"(1404 mm)29-0876B Rev A 2016 Haas Automation, Inc.ES0246 Rev Sdiy.haascnc.comJune 2018Page 20 of 28

Haas Technical PublicationsLifting InstructionsST-20 / ST-25 / ST-30 / ST-35 / DS-30 Series Lift PlacardRefer to the lifting placard for the ST-20, ST-25, ST-30 and DS-30 series lathes. Attach chains to the liftingpoints as shown. Ensure that the chains do not contact the sheet metal enclosure or electrical cables.ES0246 Rev SJune 2018Page 21 of 28

Haas Technical PublicationsLifting InstructionsST-20 / ST-25 / ST-30 / ST35 / DS-30 Lifting Hardware Details1. To install the lift kit, remove the left side and twoback panels.2. Loop the front lifting strap around the rib of thebase casting as shown. Do not lift using thetailstock rails or the ribs between the rails.ES0246 Rev SJune 2018Page 22 of 28

Haas Technical PublicationsLifting InstructionsST-40 / ST-45 / ST-50 / ST-55 Series Lift PlacardRefer to the lifting placard for the ST-40/40L, ST-45/45L and ST-50/55 lathes. Attach chains to the liftingpoints as shown. The lifting points are cast into the machine, not in a lift kit. Ensure that the chains do notcontact the sheet metal enclosure or electrical cables. Note the use of spreader bars. Spreader bars are notprovided by Haas Automation, Inc.ES0246 Rev SJune 2018Page 23 of 28

Haas Technical PublicationsLifting InstructionsST-40 / ST-45 / ST-50/ ST-55 Lifting Hardware Details1. To access the lifting points, remove the topaccess panels.ES0246 Rev SJune 2018Page 24 of 28

Haas Technical PublicationsLifting InstructionsUMC-750/SS Lift PlacardRefer to the lifting placard for the UMC-750/SS. Attach chains to the lifting points as shown. Ensure that thechains do not contact the sheet metal enclosure or electrical cables.ES0246 Rev SJune 2018Page 25 of 28

Haas Technical PublicationsLifting InstructionsUMC-750/SS Lifting Hardware Details1. Remove the front lifting bracket beforeoperating the machine.ES0246 Rev SJune 2018Page 26 of 28

Haas Technical PublicationsLifting InstructionsRotariesLift the rotary table with the lift rings as shown to prevent damage to the gear set. Attach air supply to unitprior to lifting. All rotary tables (HRT's, TR's, TRT's and T5C's) use the 1/2-13 eyebolts for lifting. HaasAutomation, Inc. does not provide any lifting chains or straps for rotary products.T5C-3TR310TR160ES0246 Rev STR160YJune 2018TR210Page 27 of 28

Haas Technical PublicationsLifting InstructionsMachines without Lifting FeaturesThe following machines do not have a lifting features. Contact a qualified rigger to move the 0VS-3HS-3RHaas Bar 246 Rev SJune 2018Page 28 of 28

Refer to diy.haascnc.com for lifting details. ES0246 Rev S une 2018 Page 17 of 28 Haas Technical Publications Lifting Instructions EC-400 Pallet Pool Lifting Hardware Details 1. Before lifting the machine, install four (4) 5/8" x . Haas Technical Publications Lifting Instructions.