Transcription

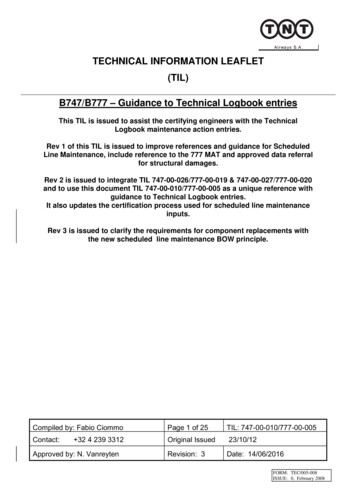

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)B747/B777 – Guidance to Technical Logbook entriesThis TIL is issued to assist the certifying engineers with the TechnicalLogbook maintenance action entries.Rev 1 of this TIL is issued to improve references and guidance for ScheduledLine Maintenance, include reference to the 777 MAT and approved data referralfor structural damages.Rev 2 is issued to integrate TIL 747-00-026/777-00-019 & 747-00-027/777-00-020and to use this document TIL 747-00-010/777-00-005 as a unique reference withguidance to Technical Logbook entries.It also updates the certification process used for scheduled line maintenanceinputs.Rev 3 is issued to clarify the requirements for component replacements withthe new scheduled line maintenance BOW principle.Compiled by: Fabio CiommoPage 1 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Introduction and History:Several Quality findings have already been made against logbook line maintenance entries on the B747 and B777fleet. Most findings are related to appropriate manual and/or related task missing, together with the correct manualrevision. Other findings have been made to incorrect ATA chapters and incomplete description of structural defectsand finally findings were raised due to incorrect accomplishment instructions references.Find hereafter an overview with some examples of correct logbook entry formulation for the most common raisedproblems for:1. Scheduled Line Maintenance:- Technical Order and Engineering Services Instruction- TNT Task Card (with Boeing Task Card Reference)- TNT Task Card (without Boeing Task Card Reference but with AMM reference)- TNT Task Card (without Boeing Task Card Reference and without with AMM reference)2. Unscheduled Maintenance:- Reference to AMM- Reference to FIM- Reference to SRM3. Where to find Document Revisions- me.tay.be- CD/DVD- Manuals4. Documentation of the use of Standard Parts, Raw Material and Consumable5. Incorrect Recording and Follow Up of Repetitive Maintenance out of ADD or DMI, especially with an intervalless then 48H (Daily Check).6. ADD/DMI record sheet time limit calculation7. Incomplete data in the ATL “Authority” field8. Confusion in definition of ADD and DMI9. No EASA Form 1 or Equivalent attached at Component ChangesCompiled by: Fabio CiommoPage 2 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)1. Scheduled Line MaintenanceScheduled Line Maintenance has to be accomplished via a Bill of Work, FORM TEC/04-009 and asdocumented in TPMThe process of certification of Scheduled Line Maintenance has changed since June 2016.Instead of a release to service in the Tech Log for each Maintenance Item per applicable Task Card, a singlerelease to service for the applicable Bill of Work in the Tech Log will be sufficient. Remember always to crossrefer to the CRS Tech Log on the BOW document for administrative follow up. .See an example of such certification:Make sure to enter the revision of the Task Card – deck /AMM/ . as applicable requested on the FormTEC/04-009.When a component replacement is done as a request of the BOW, this also needs to be identified anddocumented via the SRP as a separate entry.Compiled by: Fabio CiommoPage 3 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)2. Unscheduled Maintenance:Reference to Maintenance Manual:Refer to the applicable AMM task with the AMM revision used.Reference to Fault Isolation Manual and related Policy:Refer to the applicable FIM task. If not completely performed , refer to the parts accomplished. If the problem is notsolved, despatch per MEL as applicable when the problem is confirmed.Compiled by: Fabio CiommoPage 4 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Refer to the applicable FIM task. If not completely performed, refer to the parts accomplished. It the problem isintermittent and can not be repeated on ground, and if allowed per FIM, operations can be continued until fault reoccurrs.Refer to the applicable FIM task. If not completely performed, refer to the parts accomplished. It the problem cannot be confirmed, further operation is permitted if the system is confirmed operational per an operational test.Reference to Maintenance Access Terminal (MAT):Whenever the Maintenance Access Terminal is used to interrogate the aircraft on the status of a fault message, thefollowing methodology should be used. As per FIM, if the MAT shows ACTIVE for the maintenance message, the applicable FIM TroubleShooting procedure is to be followed. If the MAT shows LATCHED, do the applicable test per MAT to see if the fault gets unlatched. If the fault messages displays, there is an ACTIVE fault and the related FIM troubleshooting needs to be adhered to. ACTION TAKEN box to be completed as per aboveexamples. If the fault message does not show, the fault was intermittent. ACTION TAKEN shouldrefer to the Applicable MAT test and note the satisfactory result.Compiled by: Fabio CiommoPage 5 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Compiled by: Fabio CiommoPage 6 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Structural damage:When a structural damage is recorded, make sure to add the dimensions in the techlog, so there is a direct link tothe corrective maintenance action taken. Always note the Approval Reference Documents (AMM, SRM or CMM incertain nacelle cases, RDR, FROM81009, ) and make an entry on the D&B Chart.Compiled by: Fabio CiommoPage 7 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)3. Document revisions and where to find:The latest used document revisions at the time of task certification should be noted in the Technical Log asrequired per EASA AMC 145.A.55 (c) “Maintenance records” requirements:“Associated maintenance data is specific information such as repair and modification data. This does notnecessarily require the retention of all Aircraft Maintenance Manual, Component Maintenance Manual, IPC etcissued by the TC holder or STC holder. Maintenance records should refer to the revision status of the data used.”The revision status of the TNT Airways fleet documents can be found on following locations:Website “me.tay.be”:The revision of the document used on TNT Airways fleet can be found on the TNT Airways Technical websiteme.tay.be .As you can see here below, the document revision is illustrated at several places.1: if there is a unique document for the complete type fleet it will be reflected at the main folder2: if there are different documents applicable to part of the fleet, it will be reflected within a subfolders for thedocument type3: See also at every ATA chapter name in the applicable folderCompiled by: Fabio CiommoPage 8 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)CD / DVD:The revision of the manual can be found next to the manual number.Applicable Manuals :The revision of the applicable manual can off course also be found in the Manual itself, in the “FRONT MATTER”,next to the manual number.Compiled by: Fabio CiommoPage 9 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)4. Documentation of the use of Standard Parts, Raw Material and Consumables:It has been highlighted that the recording of the use of Standard Parts, Raw Material and Consumables wasnot well documented in the TNT Airways procedures, relating into ambiguity during Technical Logbook (ATL)entries.As such, it has been decided to update TPM 02-01-02 with following item:Reference to Standard Parts, Raw Material and ConsumablesStandard Parts shall only be fitted to the aircraft when accompanied by evidence of conformity traceable tothe applicable standard. Raw Material and Consumables shall only be used on aircraft when it meets therequired specification, has appropriate traceability and must be accompanied by documentation clearlyrelating to the particular material and containing conformity to specification statement plus manufacturing andsupplier source.Part number, certificate or batch number of such parts and material used shall always be mentioned in the“Action Taken” box. In case of multiple items have been used, a unique identified material list will be providedand referred to in the “Action Taken” box.Herewith an overview of the actions in the ATL required when installing parts:Type of InstalledPart/MaterialActionExampleComplete ATL Component Change SectionComponentsAdd a copy of the EASA “Form One” or other EquivalentDocumentStandard Part(or Services)Raw Material/ConsumableRecord Part Number and Certificate of ConformityNumber in the ATL Action Taken BoxAttachment 1Attachment 2Add a copy of the Certificate of ConformityRecord Part Number and Batch Number in the ATLAction Taken BoxAttachment 3Compiled by: Fabio CiommoPage 10 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)5. Incorrect Recording and Follow Up of Repetitive Maintenance out of ADD or DMI,especially with an interval less then 48H (Daily Check)See TPM 02-01-03 Deferred Defects Recording item 3.7:Compiled by: Fabio CiommoPage 11 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)When raising an ADD or a DMI with a repeat action, make sure the required repetitive inspection interval andrequirement is well documented on the ADD or DMI Record SheetWhen accomplishing the repeat inspection, ensure correct documentation of the applied procedure, albeit theapplicable MEL (M) action(example for correct application - see Attachment 4), an inspection per a certainSRM requirement (example for correct application see Attachment 5) , etc .Compiled by: Fabio CiommoPage 12 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)6. ADD/DMI record sheet time limit calculationThe following errors have been found :1) Time limit is left open;2) Time limit is set in number of days (mostly for D items where the time limit is 120 days);Note : if you do no have the tools necessary to calculate the date, please ask LMC to calculate thedate at the time you request the ADD number !)See extract of TPM 02-01-03Compiled by: Fabio CiommoPage 13 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)7. Incomplete data in the ATL “Authority” field :Forgetting Personnel Authorisation Number or Company Authorisation Number.Compiled by: Fabio CiommoPage 14 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)8. Confusion in definition of ADD and DMI :It was noticed that sometimes the use of ADD and DMI was mixed up when raising or extending a defect.See TPM 02-01-03 “Deferred Defects Recording” for definition of Acceptable Deferred Defects (ADD) DeferredMaintenance Items (DMI).ADD: Acceptable Deferred Defects are defects that are listed in the Minimum Equipment List. TheMinimum Equipment List is intended to authorise continuation of operations with inoperative items orequipment for a period of time until repairs can be accomplished.Typically named A12345.DMI: This type of Deferred Maintenance Items apply to those maintenance findings that are notcovered in the MEL and can be classified under one of the following categories:Items which have no affect on safety;Items which have no affect on normal Flight Crew operation;Items which are not a part of the certification basis for the aircraft;Items which are not part of the Emergency Equipment.Typically named D12345.Compiled by: Fabio CiommoPage 15 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)9. No EASA Form 1 or Equivalent attached at Component Changes :Several occasions were noted where the Forms provided to the technical services and related to the installedcomponent where not an EASA Form 1 or Equivalent.Typically, following policy applies:Full Regulation can be consulted in the PART 145 145.A.42 and related AMC.Compiled by: Fabio CiommoPage 16 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 1: Installing a ComponentCompiled by: Fabio CiommoPage 17 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Compiled by: Fabio CiommoPage 18 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 2a: Certificate of Conformity for certain ServicesCompiled by: Fabio CiommoPage 19 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Compiled by: Fabio CiommoPage 20 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 2b: Installing a Standard PartCompiled by: Fabio CiommoPage 21 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Compiled by: Fabio CiommoPage 22 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 3: Installing a Raw Material / ConsumableCompiled by: Fabio CiommoPage 23 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 4: Example of a Repetitive Inspection per MEL (M) action at pre flightCompiled by: Fabio CiommoPage 24 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

A i r wa ys S . A .TECHNICAL INFORMATION LEAFLET(TIL)Attachment 5: Example of a Repetitive Inspection per SRM at pre flightCompiled by: Fabio CiommoPage 25 of 25TIL: 747-00-010/777-00-005Contact:Original Issued23/10/12Revision: 3Date: 14/06/2016 32 4 239 3312Approved by: N. VanreytenFORM: TEC/005-008ISSUE: 0, February 2008

B747/B777 - Guidance to Technical Logbook entries This TIL is issued to assist the certifying engineers with the Technical Logbook maintenance action entries. Rev 1 of this TIL is issued to improve references and guidance for Scheduled Line Maintenance, include reference to the 777 MAT and approved data referral for structural damages.