Transcription

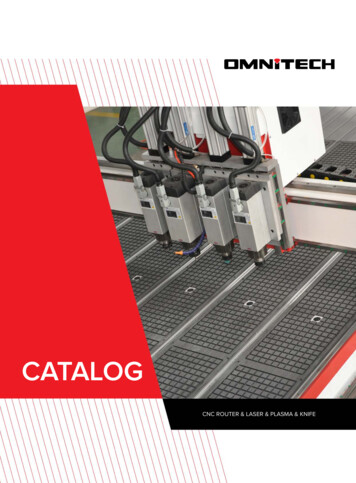

CATALOGCNC ROUTER & LASER & PLASMA & KNIFE

About UsOMNI is enterprise specializing in manufacturing, marketing and R&D of cnc router, laser and cnc plasma cutting machine. OMNIsupply machines to a wide variety of manufacturing sectors including aerospace, automotive, marine, recreational vehicles, 3D sculpture, concept models, pattern making, formed plastics and wood working, sign.Why choose OMNI? Improve Efficienty. Reduction in Labor Cost. Installation & Training Worldwide.Mission StatementDelivery : To distribute high value, quality and safety to our partners and customers;Economic: To operate company on a sustainable financial basis of profitable growth, increase and expand development for our partners and customers;Treatment: To respect, promote teamwork, encourage personal freedom and growth for employees.CertificatesE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineContents4&5 Axis CNC Router Gantry Moving 4Axis CNC Router Table Moving 4Axis 5 Axis CNC Router234ATC CNC Machining Center Series Linear Type ATC Machining Center Carrousel Type ATC Machining Center Moving Bridge ATC Machining Center567Basic Series Economical Model CNC Router High Precision CNC RouterCNC Knife Cutting Machine4 Axis Linkage CNC Router891011Multi-Head CNC Router Series Pneumatic Tool Change CNC Router Synchronized Multi-Head CNC Router A Model Synchronized Multi-Head CNC Router B Model121314EPS/Styrofoam CNC Router Series Economical EPS/Styrofoam CNC Router Industrial EPS/Styrofoam CNC Router1516CNC Stone RouterSign Making CNC RouterCNC Turner/Lather1718 12S CNC Router OMNI 1500A/OMNI1500B1920Custom Made CNC RouterAll-in-One Machine SeriesPlasma Cutting MachineFlame & Plasma Cutting Machine21222324Laser Machine Series Laser Die Cutting Machine Textile Cutting Laser Machine Marble Engraving Laser Machine Sign Making Laser Machine Metal & Nonmetal Laser Cutting Machine Fiber Laser Cutting MachineOptional AccessoriesAggregate Headhttp://www.omni-cnc.com/25262728293031321

Gantry Moving 4 AxisDesigned for European style furniture, (such as soffit, crown moulding, wall frame, stair jamb, column, balustrade), auto motive interior& exterior, mould, arts& crafts, chair, 3D work etc.Working Area(XY)1600*1800; 1500*3000 or othersWorking Area(Z)1000mm or othersPositioning Accuracy 0.02/300mmRepeatability 0.02/300mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceEthernet, USBOutput4.5kw (6HP), 18000RPMColletER32Table StructureMaterial Hold DownT slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Ballscrew on 3 axisMax. Traverse Speed45m/minSizeAccuracyControl PartSpindle Motor2Max power consumption4.2KW(without spindle)Power Source380V/3phase; 220V/3phaseCommand LanguageG and M codeSoftwareUG, AlphaCAM, Type3, UcancamE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineTable Moving 4 AxisITEMDESCRIPTIONX Y Z axis working area1300*2500*500mm, more sizeC Aixs -135 Table size1420*3040mmXYZ repositioning positioning accuracy 0.05mmTable surfaceVacuum combined with T-slotFrameSteel tube structureDrive system X-Y axisRack and pinionDrive system Z axisBall screwMax power consumption4.2KW(without spindle)Max working speed20000mm/minSpindle speed0-24000rpmWorking modeservoWorking voltageAC380V (220V) 3 phaseCommand languageG code, M codeInterfaceUSB, EthernetOperating systemSyntec/ SiemensSoftwareUG, Alpha Cam,Type3, Ucancamhttp://www.omni-cnc.com/3

5 Axis CNC Router4ITEMDESCRIPTIONX,Y,Z working area1220*2440*950mmTable size1320*2540mmSpindle10kw HSD spindle, 1000-24000rpm, liquid coolTool HolderHSK63FMotorYaskawa Servo motor and driverMoving modeTable movingC travelling 213 A travelling 135 Beam spacing(MM)4260Beam Height(MM)2150product fixed formT Slot TableTool magazineCarrousel tool magazine (8 positions)X, Y, Z Travelling Potioning Accuracy 0.03/300mmX, Y, Z Travelling Repositioning Accuracy 0.05mmControllerOSAI/ SiemensMax Rapid Travel Rate25,000mm/minMax working speed15,000mm/minZ Axis15,000mmm/minMachine size4260*2150*3300Total Power(kw)24KWMaximum lifting weights7.5TWorking voltageAC380V/50HzCommand languagesG code,M code, F/SOptionMasterCAM, Powermill, AlphaCAM etc 5 axis software packageE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineLinear Type ATC CNC RouterSizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm;1500*3000mm or moreWorking Area(Z)300mm or morePositioning Accuracy0.02mmRepeatability /- 0.05mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceUSB and EthernetOutput9kw , 24000RPMColletER32, Max 20mmTool ChangeAutomatic tool changerBT30 ISO30, 8 / 12 / 24 positionsTable StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 Axis, Rack & Pinion on XY, Ballscrew on ZMax. Traverse Speed45m/min380V/3phase; 220V/3phasePower SourceOptionalCommand LanguageVacuum pumpWatering or free-oil typeG and M codehttp://www.omni-cnc.com/5

Carrousel Type ATC CNC RouterSizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm;1500*3000mm or moreWorking Area(Z)300m or morePositioning Accuracy0.02mmRepeatability /- 0.05mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceUSB & EthernetOutput9kw (12HP), 24000RPMColletER32, Max 20mmTool ChangeAutomatic tool changerBT30 ISO30, 8 positionsTable StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 Axis, Rack & Pinion on XY, Ballscrew on ZMax. Traverse Speed45m/min380V/3phase; 220V/3phasePower SourceOptionalCommand Language6Vacuum pumpWatering or free-oil typeG and M codeE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineMoving Bridge CNC Machining CenterFurniture: ideally suitable for processing cabinet door, wooden door, solid wood furniture, panel wood furniture, windows, tables andchairs, etc. Well-suited for processing panel, insulating materials, plastic, epoxy resin, carbon mixed compound, etc. Decoration: acrylic, PVC, density board, artificial stone, organic glass, soft metals like aluminum and copper, Designed to meet diverse and complicated processing requirements, highly versatile with routing, drilling,cutting, side milling, sawing and other functions. Vacuum worktable fitted with aluminum alloy bars and suction cups is rigid yet flexible for various configurations. Cropping the fullsheet to your ideal size, routing, drilling, sawing, cutting, and milling—multiple functions, all in one.SizeAccuracyControl PartSpindle MotorWorking Area(XYZ)1300x3400x350mmTable Size1500*4000mmPositioning Accuracy0.05mmRepeatability /- 0.005mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceEthernet, USBOutput9kw (12HP), 24000RPMColletISO3014 vertical 3 horizontal 2 sawing units/ 9 vertical 3 horizon-Boring Unittal 2 sawing unitsTable StructureMaterial Hold DownVacuum pad clamping, moving beamTraverse SystemTraverse SystemRack and Pinion Drive, Hiwin Rail Linear Bearings on Y, HiwinRail Linear Bearings and Ball Screw on X and ZMax. Traverse SpeedOptionalCommand Language30m/min380V/3phase; 220V/3phasePower SourceVacuum pumpWatering or free-oil typeG and M codehttp://www.omni-cnc.com/7

Economical CNC RouterWorking Area(XY)1300*2500mm,1500*3000mm and moreWorking Area(Z)200mm or othersPositioning Accuracy0.03mmRepeatability /- 0.05mm3 Axis Control MotorStepper MotorControllerMACH3 DSP Remote Controller NC STUDIOInterfaceUSBOutput3kw,4.5kw,6kw / aircooling or watercoolingColletER20/ER25Table StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/minSizeAccuracyControl PartSpindle Motor380V/3phase; 220V/3phasePower SourceOptionalCommand Language8Vacuum pumpWatering or free-oil typeATCLinear Type or Carrousel Type ATCDust Collecting SystemDust collector Dust collector hoodG code & PLTE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineHigh Precision CNC RouterWorking Area(XY)1300*2500mm,1500*3000mm and moreWorking Area(Z)200mm or othersPositioning Accuracy0.03mmRepeatability /- 0.05mm3 Axis Control MotorAC Servo MotorControllerDSP remote controller/ NC studioInterfaceUSBOutput9KW HSD made in Italy, aircooling, 24000rpmColletISO30, BT30Table StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed45m/minSizeAccuracyControl PartSpindle Motor380V/3phase; 220V/3phasePower SourceOptionalCommand LanguageVacuum pumpWatering or free-oil typeATCLinear Type or Carrousel Type ATCDust Collecting SystemDust collector Dust collector hoodG code & PLThttp://www.omni-cnc.com/9

CNC Knife Cutting MachineTangential Knife system is designed to provide accurate cutting of heavier flexible and semi-rigid materials. The Tangential controlallows the machine to accurately cut square corners and maintain part accuracy.Application: Best solution of corrugated paper board, Corrugated Cardboard, fabric, rubber, snowboard and ski base materials, woodveneer for inlay/marquetry artwork, leather, carbon fiber pre-preg laminates for aerospace, military, and automotive components,cardboard for custom packaging,sea materials, films and much more.Besides tangential knife, omni also offer oscillating knife andcreasing knife.10ITEMDESCRIPTIONX,Y-Axis Travel1300*2500 ,1500*3000, 2000*3000mmZ-Axis Travel300mmSpindle Power9kw HSD Air-cooling Spindle, 24000rpmPositioning Accuracy0.02mmRepeatability /- 0.05mmMax. Rapid Travel Speed45m/minDrive System X, Y and Z axisRack and Pinion, Hiwin rail linear bearingDrive System Z axisLead Screw,Hiwin rail linear bearingStandard Work Surfacealuminium T-Plate Extrusion Combined Bakelite Vacuum TableWorking VoltageAC380V/50, 3PH ; 220V/60Hz,3PHCommand LanguageG Code&M CodeColletER32, Max 20mmTool ChangeBT30 ISO30, 8/12/24 PositionsE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting Machine4 Axis Linkage CNC RouterITEMDESCRIPTIONX,Y-Axis Travel1200mm*3000mmZ-Axis Travel300mmSpindle Power7.5KW air-cooling spindle, 24000rpmRemotion /- 0.05mmWorking Speed20m/minMax. Rapid Travel Speed40m/minDrive System X, Y and Z axisBallscrew on Z, Rack& Pinion on X,Y, Linear guide on three axis.MotorServoStandard Work SurfaceT slot tableWorking Voltage220V, 50Hz/380V,60Hz, 3phaseCommand LanguageG Code, PLTColletER32Rotary Device400mm *3000mmControllerDSP; SyntecInterfaceUSBhttp://www.omni-cnc.com/11

Pneumatic Tool Change CNC RouterSizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm,1500*3000mm and moreWorking Area(Z)200mm or othersPositioning Accuracy0.03mmRepeatability /- 0.05mm3 Axis Control MotorStepper MotorControllerDSP remote controller( NC studio l Mach3 )InterfaceUSBOutput3kw,watercooling, 24000rpm/4.5kw/6kw or othersColletER20/ER25Table StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/min380V/3phase; 220V/3phasePower SourceOptionalCommand Language12Vacuum pumpWatering or free-oil typeDust Collecting SystemDust collector Dust collector hoodG code & PLTE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineSynchronized Multi-Head CNC Router A ModelSizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm,1500*3000mm and moreWorking Area(Z)200mm or othersPositioning Accuracy0.03mmRepeatability /- 0.05mm3 Axis Control MotorStepper MotorControllerDSP remote controller( NC studio l Mach3 )InterfaceUSBOutput3kw,watercooling, 24000rpm/4.5kw/6kw or othersColletER20/ER25Table StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/min380V/3phase; 220V/3phasePower SourceOptionalCommand LanguageVacuum pumpWatering or free-oil typeDust Collecting SystemDust collector Dust collector hoodG code & PLThttp://www.omni-cnc.com/13

Synchronized Multi-Head CNC Router B ModelSizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm,1500*3000mm and moreWorking Area(Z)200mm or othersPositioning Accuracy0.03mmRepeatability /- 0.05mm3 Axis Control MotorStepper MotorControllerDSP remote controller( NC studio l Mach3 )InterfaceUSBOutput3kw,watercooling, 24000rpm/4.5kw/6kw or othersColletER20/ER25Table StructureMaterial Hold DownVacuum Combined T slotTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/min380V/3phase; 220V/3phasePower SourceOptionalCommand Language14Vacuum pumpWatering or free-oil typeDust Collecting SystemDust collector Dust collector hoodG code & PLTE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineEconomical EPS CNC Router1.Four-row imported ball bearing, widened linear lead rail, self-lubricating block, all these elements caused equal force at all directions while engraving, which ensures the accuracy and strength.2.OMNI CNC styrofoam cnc router Z axis can be heightened to 700mm-900mm, which is suitable for processing large-scale andsuper-thick material.3.Intelligent processing cross-border protection.4.Diversified control processing speed can be controlled separately, the speed of Idle running and roll setting, greatly improved thequality of processed products and processing efficiency.5.Die and mold industries:Sculpture various large non-metallic mold can be particularly suitable automotive foam mold, wooden ship model, wooden modelaviation, trains and other wooden mold.6.Syntec controller: PC Platform Control System; Auto File Saving Function While Power Off; Support MPG; Ethernet, USB Support.SizeAccuracyControl PartSpindle MotorTraverse SystemWorking Area(XY)1500*3000mm,2000*4000mm or moreWorking Area(Z)900mm or morePositioning Accuracy 0.09mmRepeatability /- 0.02mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceEthernet, CF card, USBOutput9kw (12HP), 24000RPMColletER32, Max 20mmTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/min380V/3phase; 220V/3phasePower SourceOptionalCommand LanguageVacuum pumpWatering or free-oil typeG and M codehttp://www.omni-cnc.com/15

Industrial EPS CNC Router1.Four-row imported ball bearing, widened linear lead rail, self-lubricating block, all these elements caused equal force at all directions while engraving, which ensures the accuracy and strength.2.OMNI CNC styrofoam cnc router Z axis can be heightened to 700mm-900mm, which is suitable for processing large-scale andsuper-thick material.3.Intelligent processing cross-border protection.4.Diversified control processing speed can be controlled separately, the speed of Idle running and roll setting, greatly improved thequality of processed products and processing efficiency.5.Die and mold industries:Sculpture various large non-metallic mold can be particularly suitable automotive foam mold, wooden ship model, wooden modelaviation, trains and other wooden mold.6.Syntec controller: PC Platform Control System; Auto File Saving Function While Power Off; Support MPG; Ethernet, USB Support.SizeAccuracyControl PartSpindle MotorTraverse SystemWorking Area(XY)2000*4000mm,2500*5000mm or moreWorking Area(Z)1000mm or morePositioning Accuracy 0.1mmRepeatability /- 0.05mm3 Axis Control MotorAC Servo MotorControllerSyntec PC platformInterfaceEthernet, USBOutput9kw (12HP), 24000RPMColletER32, Max 20mmTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed30m/min380V/3phase; 220V/3phasePower SourceOptionalCommand Language16Vacuum pumpWatering or free-oil typeG and M codeE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineCNC Stone RouterApplication Materials :Artificial stone, Marble, Granite, Ceramic Tile, Tombstone, milestone, Terrazzo, Limestone, Sandstone, Travertine, Quartzite, Slate,grindstone ,Jade, crystal, plexiglass, aluminum composite panel, aluminum block, copper, wood, MDF, hardwood, plywood and so on.Application Industries :Suitable for Curb & Paving Stone Forming industries, Stone processing factories, Tombstone processing industries, Advertisementindustries for Stone art craft works, Home & Outdoor Product making industries, Architectural decoration industries i.e.Technical Features :1.The machine adopted 4.5kw water cooling spindle for quickly stone processing or spindle for fast cutting aluminum sheet.2.Japan servo motor and driver ensure that with strong power for cutting and engraving various stone.3.Advanced 3D carve budget and stable broken line enables carving professional speed and precision. Advanced file pretreatmentfunction can correct the error in the files and compatible with the process codes of multiple national and international software.SizeAccuracyControl PartSpindle MotorWorking Area(XY)1300*2500mm or othersWorking Area(Z)320mm or othersPositioning Accuracy0.05mmRepeatability /- 0.05mm3 Axis Control MotorAC Servo Motor or Stepper MotorControllerNC studio /DSP Handle Controller/ SyntecInterfacePCIMC/USBOutput4.5 kw watercooling, 24000rpm or othersColletEr25Table StructureMaterial Hold DownClampTraverse SystemTraverse SystemLinear Guide on 3 axis, Rack and Pinion on Y, Ballscrew on ZMax. Traverse Speed32m/min380V/3phase; 220V/3phasePower SourceCommand LanguageMist Cooling SystemCooling Nozzle and PumpRotary attachmentAny size Rotary AttachmentG code & PLThttp://www.omni-cnc.com/17

Sign Making CNC RouterAny size of cnc router is acceptable for building. OMNI would suggest you suitable optional spare parts according to the material youprocess, such as rotary device for cylindrical material processing, coolant tray for metal and glass processing etc.These models are with ball screw driving on 3 axis, which could cause higher precision processing result. Machines are building withheavy duty and be used in the industries of woodworking, custom millwork, fixtures, channel letters, sign making, educational, modelmaking, prototyping, solid surface production, aerospace, foam packaging, plastic packaging equipment manufacturers, PCB fabricators, engraving, conveyor manufacturers, artistic carvings, name tags, puzzles etc.OR 1212OR 3030OR 1224OR 4040SizeMODELWorking Area(XY)mmOR 040400*400OR3030300*300Working Area(Z)mm100AccuracyPositioning Accuracy0.01Control Part3 Axis Control MotorStepperControllerNC studio /DSP remote controller/MACH3InterfacePCI/MC; USBOutput2.2KW/1.5KW0.8KWSpindle Motor50ColletER11 or ER16ER11Table StructureMaterial Hold DownT slotPVC tableTraverse SystemTraverse SystemRound Orbit and Ball screwMax. Traverse Speed6m/minPower SourceOptional220V(110V)/ single phaseDust collectordust collectorCommand LanguageG codeSoftwareType3/ Artcam18E-mail: sales@omni-cnc.comN/A

CNC Router & Laser Machine & CNC Plasma Cutting Machine12S CNC RouterOMNI cnc turner series allows machining of parts in the round. The rotary device (rotary attachment), or you may call it 4th axis indexer is like a smart lathe. It makes the rotation of the part the fourth axis of control. This means that you can profile objects in the wayyou might with a traditional lathe, but you can also do ornamental turning and free-form carving in the round. It mainly designed fordesigned mainly for staircase stuff, profile statue, furniture & cabinet feet, kitchen island legs, table legs, chair legs, newel posts, sofaleg, Buddha profile, corbel, modillion, baseball bat, crafts etc.ITEMDESCRIPTIONWorking Size1200mm*210mm -12 SpindlesMax. load of working bench1200KGWorking ModeServoMachine Dimension3360*2000*2200Spindle Power2.2kwSpindle Speed8000-24000rpmRepeated Positioning Precision0.05mmMax. Traveling Speed20m/minMax. Working Speed15m/minGross Weight2200KGVoltageAC380V/50HZ, AC220/60HZhttp://www.omni-cnc.com/19

OMNI 1500A/OMNI 1500BMost Advanced Material Loading Skill: When the workpieceto machine, machine’s 4 jaws could help to find the center.And it only takes 3 seconds for whole material loadingmaterial, with higher precision then auto loading. When youprocess larger diameter vase, you could use auto cutterand adjustable air-cylinder, this improve the workpiece surface finish and last the cutter life time. The center supporterfix workpiece center when it is under the condition of selfweight.1500AITEMDESCRIPTIONMax working dimensins20-300mmMachine toolsSpindle or Double machine toolsMax.lenght100mm-1500mmSpindle Max.speed700-2800r/minAir pressure0.6-0.8MpaIncomning total power5.5KWPower380V/3P/50HZMotor Torque of X, Z, Y axis4 Nm , 4 Nm , 17 NmWorking VoltageOMNI1500A with single tool 220V single phaseOMNI1500A with double tool 380V 3 phase, 220V 3 phase.1500BITEMDESCRIPTIONWorking SizeX:1500mm (2000mm is optional)Z: 150mm (200mm is optional)Working TableAluminium cast whollyX, Z AxisX rack and pinion, Z ball screwMoving Speed 88000mm/minWorking Speed 8000mm/minSpindle2.2kw (1.5 or 3kw is optional) 24000rpmMax Dia. Of Rotary Device200mmMax. Processing Material Size1500mmDriving ModeStepper drivingWorking Voltage220V, Single Phase, 50Hz ( 110V is optional)Code FormatG code20E-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineCustom Made CNC RouterOMNI undertakes ODM service and also could design the machine as customer’s requirement and application. OMNI has rich experience of machine design and building, could offer professional suggestion according to customer’s work demand.OMNI’s every custom-made product enjoys high comment from customers.You may process large diameter and long cylindrical stone with heavy duty, or large foam, or other large size mold etc.1. This cnc router’s rotary device is with double chuck at 400mm diameter, 3000mm length. Whole rotary device is with steel welded,motor we adopt big power servo motor. This rotary device configuration could meet your demand of processing heavy duty cylindrical material totally.2. CNC router is with 500mm Z axis travelling size, could procss large size mold, such as wood, foam, plastic material mold.3. 7KW HSD spindle, such big power spindle is good at of engraving, cutting and drilling on hard material.4. Servo system is with closed loop, ballscrew on x axis, both ensure the high precision of cnc router.5. Control system is with windows flatform, support USB port.OMNI design multi-function cnc router, which could process cylindrical material and flat material. We place the rotary device behindthe working table. And rotary device working dimension could up the whole machine working size. The working table is removable,when you process large diameter foam, taking away table could realize your demand.http://www.omni-cnc.com/21

All-in-One Machine Series1. Router-Laser Combined MachineThis machine is used in advertising industry mainly.Processing material usually are PVC, acrylic, wood,marble, MDF etc. Some job requires cnc router andlaser machine to process step by step, with thismachine, you could pay one machine price and getdouble value back.SizeWorking Area(XY)1300*2500mmWorking Area(Z)200mmAccuracyPositioning Accuracy0.05mmControl Part3 Axis Control MotorStepper/ServoControllerNC studio & Laser ControllerOutput3KWColletER20Spindle MotorLaser Power80W/100WTable StructureT slot or vacuum tableTraverse SystemTraverse SystemLinear guide on 3 axis, rack and pinion on x and y, ball screw on zMax. Traverse Speed20m/min380V, 50/60HZPower SourceOptionaldust collectorDust collectorCommand LanguageG codeSoftwareType3/ Artcam/ Corel Draw2. Router-Plasma Combined MachineThis machine allows you use it as cnc router andcnc plasma cutting machine. The working table ismovable, and with coolant tray for cooling metalpieces. And this machine also fits rotary device forcutting metal pipes.Working Area(XY)1300*2500mmWorking Area(Z)200mmAccuracyPositioning Accuracy0.05mmControl Part3 Axis Control MotorStepperControllerNC studio & Plasma controllerOutput3kwColletER20SizeSpindle Motor60A /100A/120A/200APlasma Power22Table StructureMaterial Hold DownT slot & Plasma TableTraverse SystemTraverse SystemLinear guide on 3 axis, rack and pinion on x and y, ball screw on zMax. Traverse Speed20m/minPower Source380V/220V 50/60HZCommand LanguageG codeSoftwareType3/ ArtcamE-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineCNC Plasma Cutting MachineOMNI plasma cutting machine could cut even, the shape of wave or other uneven shapes and steep pipe such cylindrical metal.Capacitance height controlThe advanced height linear calibration technology makes the cutting nozzle and cutting board be within 3 30mm in the automaticheight controlling in the capacitance mode;Simple and convenient linearization calibrationThe function of “One key for height calibration” guarantees that in any circumstances, the user only needs to press a key, he cancalibrate the absolute height measurement and achieve a linear height measurement.OMNI THC control system able to Perform corner speed control and height control, Breakpoint restoration, automatic power-back recovery and automatic breakpoint memory, Special short line machining feature based on smooth travel, extensively applicable to metal blanking as well as advertisement andironwork fabrication,advanced material inclined discharging design. All finished work pieces and fragments slide into tunnel for safeand convenient collection.SizeWorking Area(XY)1300*2500mm, 1500*3000mm or moreAccuracyPositioning Accuracy0.2mmRepeatability /- 0.3mm3 Axis Control MotorAC Servo Motor or Stepper MotorControllerStart Shaphon &Torch height controllerInterfaceUSBControl PartPlasma Power60A, 100A, 120A, 200A etcTable StructurePlasma tableTraverse SystemTraverse SystemLinear Guide& Rack&Pinion on XYMax. Traverse Speed30m/minPower Source380V/3phase; 220V/3phaseCommand LanguageG codehttp://www.omni-cnc.com/23

Flame & Plasma Cutting MachineThe gantry design for optimum performance in a wide range of processes including flame as well as for Plasma Cutting.OMNI provides choice and options that allow you to configure a gantry system with capacity and options you need for your applications.It combines powerful performance with multiple torch carriage flexibility to deliver high productivity of ultra accurate shapes such ascircles, rectangles, stars, hexagons or any shape your creativity can conquer.The Gas Control System is designed for efficient and safe gas control.The preheat control is provided as standard. Cutting flame vent-off valve is provided for safety.Plasma cutting possible .The machine is plasma ready. Various plasma equipment options are available for individual needs. Themachine can also be supplied with Arc Voltage Height Controller.ITEMDESCRIPTIONWorking Size1300*2500 or moreTraverse Speed8000mm/minControl SystemStarfireDrive SystemRack and PinionDrivesDual Drive Stepper or AC ServoMaterial Thickness of Flame5mm to 70mmMaterial Thickness Plasma0.5mm to 10mm (also 12mm, 15mm ,20mm)Plasma CompatibilityYesPower Input380V 50Hz or 220V 60Hz24E-mail: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineLaser Die Cutting Machine Adopt advanced DSP digital control system, international standard laser power supply, integrated framework style, high stability, high-speedusb2.0 interface output can support off-line working. Transmit files directly from Corel draw, AutoCAD, Photo Shop. Optimization of mechanical and electrical design, processing speedcan be up to 1000m/s, low noise. Big power and high stability laser tube, could work over 8000-10000hours, imported lens and mirror, long life-span, one step cutting canreach 30mm thickness on acrylic. Red Dot Pointer: Provides a visible means of determing engraving location. Air Assist: Remove heat and combustible gases from the cutting surface. Intuitive Control Panel: Speed, power, and more controls directly from the laser. Raster/Vector Color Mapping: Change your engraving speeds and power by using color settings. Waste Collecting Drawer Design, saving your time of cleaning laser machineSoftware we offerdSizeWorking Area(XY)1300*2500mm, 1600*2600mm or moreSpeedEngraving speed1-60000mm/minCutting speed1-10000mm/minResolution ratio 0.01mmLocation precision 0.01mmMax30mm AcrylicPrecisionCutting Thicknesswater-cooling chiller with air compressorWater cooling3 Axis Control MotorAC Stepper or Servo MotorControllerOMNI Laser ControllerInterfaceUSBLaser PowerOutput100W, 150W, 200WTable StructureMaterial Hold DownT blade and honeycombControl PartMin shaping textEnglish 1mm*1mmPower Source220V , 50Hz / 110V,60HzOptionalFume Extraction DeviceGraphic //www.omni-cnc.com/25

Textile Cutting Laser MachineThis laser machine is designed for the industry of textile, costume, leather for cutting, decoration etc.Moving table driven by big power motor to move cloth after cutting completed on working table. Fitting with the rolling shaft, you liftthe cloth to the shaft, then fix start part of cloth to working table, then could start cutting easily.SizeWorking Area(XY)1600*1000mm, 1300*2600mm and moreSpeedEngraving speed1-60000mm/minCutting speed1-10000mm/minResolution ratio 0.01mmLocation precision 0.01mmPrecisionwater-cooling chiller with air compressorWater coolingControl PartLaser Power263 Axis Control MotorStepper or AC Servo MotorControllerOMNI Laser ControllerInterfaceUSBOutput100W, 150W, 200WTable StructureTextile cutting suited tableMin shaping textEnglish 1mm*1mmPower Source220V , 50Hz / 110V,60HzGraphic l: sales@omni-cnc.com

CNC Router & Laser Machine & CNC Plasma Cutting MachineMarble Engraving Laser MachineThis laser machine is de

ATC CNC Machining Center Series Linear Type ATC Machining Center . OSAI/ Siemens 25,000mm/min 15,000mm/min 15,000mmm/min 4260*2150*3300 24KW 7.5T AC380V/50Hz . 3 Axis Control Motor Controller Interface Output Collet Material Hold Down Traverse System Max. Traverse Speed Vacuum pump