Transcription

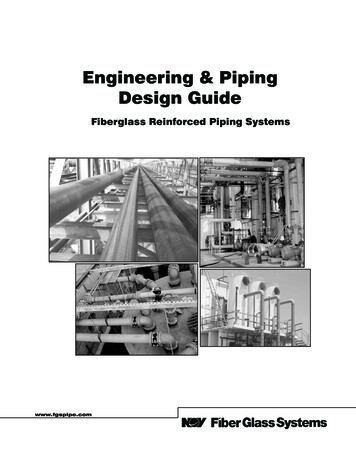

Britt Engineering Associates, Inc. Birmingham, ALLDesign Guide: Supporting FRP Piping SystemsBy: Frank Britt PEThis paper presents a method of analysis andillustrations of typical supports that weredeveloped specifically for FiberglassReinforced Plastic (FRP) Pipe. Britt EngineeringAssociates manufacturers a complete family ofpipe and duct supports. These designs includefeatures resulting from suggestions by designengineers and construction people who havedetermined how improvements would makethe design and installation easier and faster.This family of designs is 30 years old and yetcontinues to grow and improve because welisten to the people who use them.In the late 60's and early 70's, FRP materialswere being developed that would propel themarket of FRP pipe to new heights. FRP wasbeing specified in new applications where onlyspecialty alloys had been used and, as theapplications expanded, FRP was becoming thecomplete problem solver. Resin manufacturerswere developing new Polyester and VinylEsters. Fabricators were developingmanufacturing methods that improved qualityand reduced costs. In 1974 reports indicatedthat corrosion applications of FRP were to bethe growth industry of the future, but aboutthat same time some users were finding thatfrequent piping failures were causing concern.One of the major manufacturers of resinsdetermined that most of the piping failurescould be eliminated through the use of propersupports, guides, and anchors. The technicalinformation presented in this catalog is theresult of the cooperative effort of thismanufacturer and an engineering firm thatresulted in the installation of a completelysuccessful system that used FRP almostexclusively. These principles of pipe designalong with the supports in this catalog havebeen used in thousands of piping systems withcomplete success.When deviations to catalog standards arerequired, Britt Engineering Associates isprepared to provide design assistance and isequipped to furnish any specials that might berequired. Britt Engineering Associates iscontinually cooperating with engineers,designers, and construction personnel in thespecification of hangers and supports, and willassist in the interpretation of applicable pipingcodes. All supports are manufactured in the USusing domestic materials only.Britt Engineering Associates supports arealmost always made to order since the outsidediameter of FRP pipe varies depending on themanufacturer, wall thickness, and corrosionliner thickness. Being custom made it isimportant to order the supports as early in theschedule as possible. The company will workclosely with your engineering and purchasingdepartment to insure the best possible fit up ofsupport to the pipe and that schedules are met.The supports illustrated in this paper areintended for installation and service asdesigned and specified herein. Exceedingsupport spans, hanging one pipe beneathanother, lack of component support andattempting to modify supports are someexamples of misapplication. If there is aquestion about application, call BrittEngineering Associates. Our supports are

Britt Engineering Associates, Inc.Birmingham, ALmanufactured to comply with strict standardsand care must be exercised to prevent misuse.How do I start? Review piping specifications.Review piping drawings.Review structural drawingsReview valve and fitting specifications.Locate possible hanger locations.Analyze thermal movement, stress, and flexibility of the piping system.Calculate hanger loads.Select hanger types.Check hanger clearance around existing piping and equipmentThe following notes concerning the designand installation of FRP pipe and supportsare provided as a help to the designer orengineer. These design notes are intended toserve as a guide to the proper use of thesupports described in this catalog, and whileit is impossible to cover every pipingcondition, experience indicates thatapproximately 95% of the supportrequirements can be met through the use ofthese standard designs. If the designer isfaced with special conditions where aspecial design might be required he shouldcontact Britt Engineering Associates forassistance.The principles of design and analysis forFRP pipe differ considerably from theprinciples of design for the metallic pipe.The analysis of steel pipe normally beginswith maximum flexibility, and the finalsupport-guide-anchor design ends whenallowables are achieved. When dealing withFRP pipe, the analysis normally begins with1-27-2018Page 2 of 16a fully anchored system and the finalsupport-guide-anchor configuration isestablished when the minimum stresscondition is reached (based on the availablestructural steel).The fully anchored FRP piping system isoften referred to as an anchor to anchorsystem. This simply means that an anchor isplaced at each end of a straight run ofpiping. The pipe is restrained by theanchors from growing thermally and isguided to prevent buckling. Thisarrangement is never considered with ametallic pipe, but the low compressivemodulus of FRP allows anchoring. Theanchor loads are normally less than 1/60ththat of steel but must be considered in thestructural design of the support system,especially in large diameter pipe.Many vendor catalogs include tables that thedesigner can use to determine support,guides and hanger spacings. The spacingsBritt Engineering Associates, Inc.

Britt Engineering Associates, Inc.Birmingham, ALare usually based on a specific gravity of1.2, a liquid temperature of 160 or 180degrees F, and a limited deflection of 1/2".This information is useful for estimating butin most instances the spacings are not basedon total pipe stress. Very seldom is pressurestress considered in the derivation of thesetables. In FRP piping systems it is veryimportant that the total stress is consideredwhen selecting support spans. By using theequations presented in the technical sectionof this catalog the designer can accuratelydefine support and guide spacings and beassured that the pipe is designed to operatewithin the specified allowable stress.The use of the procedures outlined in theTechnical Section of this catalog willGreatly improve the reliability and servicelife of any FRP piping system. The sameprocedures will work equally well with ductsystems. As these procedures were beingdeveloped, it became evident that there wereno commercially available standard supportsfor FRP piping. Many different designswere illustrated in many of the catalogs, buta review of the designs indicated thatadditional work would be needed to makethem work. Britt Engineering Associatesdeveloped a family of special FRP pipesupport designs that was based on themaximum loads that might be expected inFRP piping. This family of supports hasbeen used in almost every environment andin almost every condition found in processindustries. Over the past 18 years, newdesigns have been added to expand theapplications, and the size range was1-27-2018Page 3 of 16extended to pipe diameters of 108" and120".When specifying the supports shown in thiscatalog the designer will recognize the easeof application and will become familiar withthe unique features that are important to thedesign of an FRP system. The long supportwith a full bonded liner eliminates failuresdue to local stresses. The low profile of allBritt Engineering Associates supports keepsthe pipe close to the structural steel thusreducing the size and amount of auxiliarysteel. Selecting standards greatly reducesdesign time and the standardization ofsupports reduces manufacturing costs.Interchangeability and standardizationreduces or eliminates all field reworkthereby reducing construction costs. Eachsupport is clearly marked for easyidentification.As a word of caution, the designer isreminded to call Britt EngineeringAssociates when the need for sizes and loadsexceed the support tables in this catalog.While Britt Engineering Associates hasother standards that have been developed forspecial applications, the use of thesesupports must be checked against actualconditions.Duct systems can be supported using thesame basic designs shown in this catalog;however, since duct systems very seldomhave fluid loads, the supports can be muchlighter. All installation dimensions remainthe same.Britt Engineering Associates, Inc.

Britt Engineering Associates, Inc.Birmingham, ALThe designer should review the followingdesign considerations to insure that allsupports are correctly used. If there are anydeviations from these standard practices anddesigns, the designer should contact BrittEngineering Associates.1. FITUP of SUPPORT - The designermust specify the maximum OD of the FRPpipe to insure proper support fit. Pipespecifications normally require the pipemanufacturer to maintain a tolerance 1/8" 0.0" on the OD and the manufacturer isrequired to state the maximum OD in hisquotation. The support will bemanufactured to fit within 1/16" of themaximum OD.2. LOCATION of SUPPORTS - Whensupporting pipe inside of a building, thebuilding steel will provide the easiestsupport points. If the support spacing isbased on the spacing of the structural steeland is found to exceed the calculatedsupport spacing, use a slightly (1/16")thicker pipe wall and re-run spacingcalculations. Continue adding wallthickness until the required span is reachedor until added wall thickness starts todecrease span capability. If the pipe doesnot span, then intermediate supports,requiring the addition of auxiliary steel, arerequired. Of course, a comparison of theincreased pipe cost vs. the cost of auxiliarysteel will allow the designer to decidewhether a heavier pipe will offeradvantages.3. LOCATION of GUIDES - Guidesserves as supports and also provides lateral1-27-2018Page 4 of 16restraint to prevent buckling of the pipewhen the pipe expands due to elevatedtemperatures. Smaller piping will requiremore frequent guiding, and in some cases,the use of guides may be required at everysupport point. Larger piping may requireevery other support point to be a guide.Calculations should be made to determineexact requirements.5. FIXING of ANCHORS - FRP anchorsare designed to grip the pipe lightly and arenever to be allowed to clamp the pipe withany excessive force. The anchor is fixed tothe pipe by applying shear collars, or FRPbands to the pipe on either side of theanchor. Except for very unusual cases thecollars are applied in the field after theanchor has been installed. The collars arebuilt up of layer's of 1-1/2 oz. mat to athickness that allows the anchor to bearagainst the collar. See Fig.1306. RISER SUPPORTS - Vertical runs ofpipe inside of a building normally aresupported on floor sleeves or off of curbssurrounding a pipe chase through the floor.Riser supports or riser guides when requiredare fixed to the pipe using the same shearcollars as used with anchors. However thecollar need only be applied to the top side ofthe support so that the weight of the risercan be carried by the riser support. The rulefor riser guide spacing is the same as otherguides unless the pipe is subjected to windloads where more frequent guiding isrequired. It is important to note that loadsfor riser supports can be very high,especially in large diameter pipe. Loads inBritt Engineering Associates, Inc.

Britt Engineering Associates, Inc.Birmingham, ALexcess of support ratings will require specialdesigns and should be brought to theattention of Britt Engineering Associates7. SUPPORTS for INSULATED PIPE Special supports are used to accommodateup to 4" of insulation. In all except veryspecial cases the supports, anchors, andguides are attached to the pipe and are notdesigned to clamp or support the outside ofthe insulation. When heat tracing is requiredthe tracing passes outside of the support. ***Important *** If heat tracing is requiredcontact Britt Engineering Associates forspecial details and designs.8. COMPONENT SUPPORTS - It is veryimportant that all valves and inlinecomponents be supported independently ofthe pipe. In some instances, it is necessaryto anchor the component where heavyactuators are cantilevered off of the valve orcomponent or where external loads ordynamics might damage the pipe.Components in vertical and horizontal piperuns require support although components invertical runs may not require independentsupport of each component,9. EXPANSION - The thermal expansionof FRP is two times that of steel andrequires special attention especially where afully anchored system is not used.Expansion joints and expansion loops aresometimes specified, but these add a1-27-2018Page 5 of 16weakness to the system. Expansion loops inaddition to adding extra piping will add asmany as four fittings and at least eight morejoints. Each joint is an additional point ofweakness. If lack of structural restraintpresents a problem where anchor loadsmight preclude the use of the anchoredsystem, there are several other designmethods that can be employed, but in mostcases, the anchored system can beincorporated. The description of the otherdesign methods is beyond the scope of thismanual because these are special cases. Ifthere is a problem in using the anchoredtechnique call Britt Engineering Associatesand we will be glad to discuss specificapplications.10. COATINGS – Hot dip galvanizes is themost common finish but a high-qualityprime coat that is applied by spray coating isavailable. Paint systems are in compliancewith EPA regulations regarding VOC andhazardous materials. It is very importantthat the designer selects a corrosion resistantcoating that will withstand theenvironmental conditions in the area wherethe pipe supports are to be installed. Ifspecial high-performance coatings arerequired these should be specified in thepurchase documents. Britt EngineeringAssociates is able to provide any coatingsystem that might be required and can alsoprovide assistance in the selection of specialcoatings.Britt Engineering Associates, Inc.

Britt Engineering Associates, Inc.Birmingham, A

Design Guide: Supporting FRP Piping Systems By: Frank Britt PE This paper presents a method of analysis and illustrations of typical supports that were developed specifically for Fiberglass Reinforced Plastic (FRP) Pipe. Britt Engineering Associates manufacturers a complete family of pipe and duct supports. These designs include