Transcription

Atwood Edge13441hioO.,cdIn097anies, Clevel .696.5rts6Indu nue, : 21ood ain Ave 30 Fax 9wtcomA6.50 .205 ries.5M131 216.69 0.362 indust0Tel: Free: 8 atwood aol.com.llTo : www satw@ebeaW ail: s lE-mThe Tooling Specialist

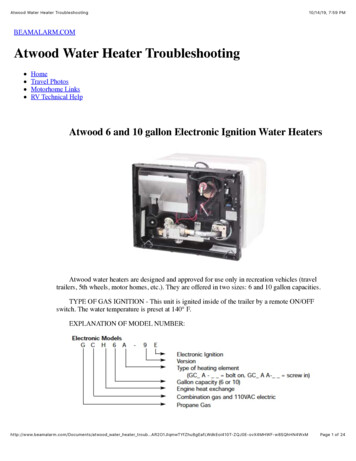

Production Improvement SpecialistsToday, more and more suppliers arejust selling tools. That’s it. And,they’re doing it without the necessaryknowledge and experience to provideyou with the best cutting tools foryour specific applications. Yourproduction remains the same, butwouldn’t you rather see it improve?That’s where our technicalexpertise makes a difference.We constantly search for ways toboth increase production levels anddecrease production costs.That’s The Atwood Edge.The Right Tool Can SignificantlyImprove Your Production.Many companies don’t even realize that the toolsthey’re currently using could be limiting production.After all, those are the tools they’ve always used.With Atwood, you can trust that our toolrecommendations will always be centered aroundimproving your productivity.Our Production Improvement Specialists willevaluate your tool situation and make sure you’reusing the best tool for the job. Because, when yourequipment is working at optimum efficiency, it canbe the difference between paying off that equipmentinvestment in five years - instead of ten.We’ll Keep You on the Cutting-Edge ofRapidly Advancing Tool Technology.Today, tools are becoming obsoletefaster than ever. In fact, 70% ofyour current tools will be replacedby improved versions within thenext five years. If your supplierdoesn’t keep up with changes, yourproduction will suffer.Atwood can help.Our specialists will updateyou with product innovations andimprovements so that you alwaysuse the latest, most effective toolsand related products available.Our Repair Services Can DramaticallyCut Your Costs.Consider this situation: you are continually replacinga certain tool with a new, expensive one on a regularbasis. Many suppliers consider this business asusual. We do not.In fact, our specialists often identify tool inefficiencysituations and then provide solutions, such as repairingor sharpening existing tools. This solution is a proven,cost-effective alternative to always purchasing costlynew tools.It’s also another example of The Atwood Edge at workfor you.On-Site Technical SupportWhen you have problems in production, know that theAtwood specialists are available to come to your facilityand provide solutions.Documentation is Proof of Your Savings.Our tool recommendations and product solutionsproduce real, significant savings. We can provide fulldocumentation on a regular basis as to how they directlyand positively affect your operation’s bottom line.Atwood Technical Services Consulting/Engineering Services Repair Capabilities On-site Technical Support Documentation In-plant Customized Training

Streamlined Inventory ManagementContinually-advancing technology meansthat the tools you have in-stock now maybe obsolete next year, or next week. So,what good is a supplier who simplyreplenishes your inventory with the sameold tools?That’s where Atwood’s technicalexpertise can help.We stay current with productinnovations and improvements soyou won’t have just any tools in yourinventory, you’ll have the right ones.We’ll also help with your otherinventory concerns - too manyunnecessary parts, lack of organization,poor employee accessibility, pooraccountability of tools, no standardization.These all contribute to an inefficientinventory system that is costing you timeand, most importantly, money.Our inventory solutions will help youbetter manage your inventory anddrastically cut costs.That’s The Atwood Edge.Our Vending Machines ProvideQuick, Easy Access to the LatestTool Technology.A tool vending machine is a great convenience.But, filling it with the same old parts time andagain doesn’t do you much good.You need a supplier with the technical expertiseto replace outdated tools with the latest, mosteffective cutting tools available - Atwood.We’ll keep our “WebVend” and “Tool Boss”Vending Machines stocked with the best tools, soproduction has access to the latest technology.Software Simplifies Tool CribManagement.Atwood also has the tool crib software toimprove your tool crib management, includingparts standardization, stocking, tool location,accountability and replenishment.And, with our technical expertise, we’ll keep itcurrent - replacing outdated tools whenever a newer,better one is available.Customized, Local Inventory ReducesYour Inventory Costs.Atwood is a local supplier, so your products arealways nearby and available. Plus, we can customizeour in-house inventory to meet your specificproduct needs, thus eliminating your cost of stockingall of your products at your facility.Atwood Inventory ManagementPrograms “WebVend” and “Tool Boss” Tool Vending Machines “Cribware” Tool Crib Software Local Inventory Barcode Technology Parts Substitution/Standardization Blanket Orders/J.I.T. Obsolete/Overstock Elimination Accountability

Simplified Purchasing InitiativesCutting costs in purchasing is essentialfor a healthy bottom line, and manysuppliers can help. But, what else doyou get from them? Very little.With Atwood, you getour technical expertise that ensures youget the best tools, at competitive prices,so all areas of your operation benefit production, inventory managementand purchasing.And, through supplier consolidationand e-commerce, we’ll further simplifythe purchasing process and reducemany costs - which can add up toCompetitive Pricing.Because of our strong relationships with onlythe best manufacturers, we can deliver the highestquality cutting tools at competitive prices. WithAtwood, you’ll satisfy production’s need for the besttools, and purchasing’s need to keep costs in check.And, there are a number of ways that we can keepour prices at competitive levels, includingvolume leveraging, supporting national contractagreements, tri-level negotiations, consistentdiscount structures and volume incentive rebates.Deal with Just One,Consolidated Supplier.The benefits of having just one supplier aremany - less paperwork and processing, easierordering, simplified billing. Plus, you only dealwith one supplier instead of several.Atwood has the capability to be yourone-source supplier for all your product needs,which will help reduce much of the time and costassociated with purchasing.With E-Commerce,We’re Just a Click Away.Now you have 24/7 access to Atwood Industriesthrough our website. You can order ourproducts directly, obtain product specs withlinks to over 100 of our manufacturers,and e-mail us with questions.Visit us at www.atwoodindustries.comso you can conveniently conduct businesswith us on-line, anytime.significant savings over the long term.Atwood Purchasing InitiativesThat’s The Atwood Edge. Competitive Pricing Supplier Consolidation E-Commerce EDI Bar Code Purchasing and Receiving Monthly Billing Detailed Reporting A/E, Visa, M/C

Continuous Improvement ProgramsThe Tooling Specialist1315 Main AvenueCleveland, Ohio 44113216.696.5030 Fax: 216.696.5097email: salesatw@aol.comMilling Investment Return Analysis WorksheetCustomer: Key AccountIssued by: Atwood Tool Engineer Date: 10/08/08Contact: JohnMachine # Mazak Horizontal Test # Gem-Stone Mill #1Document #44300-016Increased speed & feed resulting in lower cutting timeComponent: Gem StoneOperation: MillMilling CutterMilling CodeManufacturerCutting GradeInsert codeNo. of insertsCutter DiameterCutting SpeedFeed/insertRPMFeed (IMP)Axial depth of cutRadial depth of cutMetal Removal Rate (cu.in./min)Criterion Tool ChangeMachine cost/hourCutting time/component (mins)Non cutting time/component (mins)No. of components/edgeTool changing time (mins)Total time/component (mins)Cutter CostHolder life, n (number of indexes)No. of InsertsInsert CostNo. of edges/insertMachine cost/componentTool Cost/componentTool change cost/componentTotal machining cost/componentNo. of components BatchInsert consumption BatchTool Cost/Component Reduction %Saved Time / Batch Hrs.Productivity Increase %Savings/componentSavings / BatchMaterial: Cast IronHardness:45 degree milling .0007860.0116600.041.80.104.8020.04Productivity & Finish 60.000.2911051.79 591.00100006 7.984 1.29 1.20 0.50 2.99400060067%57.3332% 3.35 13,404.36CMC Code:90 degree milling cutterF90-D5.00-1.50-MIscarIC520MADKT 1505 PDR-HM95.0005510.0055420.620.80.054.805.00 60.001.1511052.65 400.00100009 8.202 2.15 3.69 0.50 6.3440001,800As a key Atwood customer, you benefit greatly from our technical expertise. Because of it,we can cut costs in all areas of your operation-production, inventory and purchasing.We can also provide documentation. Here are some examples of how our initiatives have saved money.And, as part of our commitment to your continuous improvement, we are always looking for new, innovativeways to cut your costs so that you operate more productively, more efficiently and more profitably.That’s the Atwood Edge.ATWOOD INDUSTRIES, INC.COST IMPROVEMENT SUMMARYINTEGRATED SUPPLY CRIPTIONTested & converted to Sandvik RA390 cutter from R290Tested & converted to Sandvik SNMG 543PR 4025 insert from ValeniteImplemented monthly billing - A/P processing and cash flow savingsTested & converted to Sandvik indexable U-Drill from CarboloyRepair of Waukesha helical end mills vs. replacing newTested & converted to CBN insert from Kennametal insertTested & converted to Sandvik RA200 button cutter from Dapra ball millTested & converted to Hitachi mill from Iscar - reduced machining timeCost savings due to installation of automated tool vending machineTested & converted component 558 to Sandvik TNMG from Kennametal TNMAImplemented key supplier contract price agreementsInventory reduction due to Manufacturer & Atwood stocking agreementTested & converted to Vardex threading insert from CarboloyUpgraded to new Norton roll grinding wheel - increased life and performanceTested & converted to Union Butterfield coolant fed tap from standard HSS tapTested & converted to Sandvik RA245 mill from Iscar F90Tested & converted to Niagara tialn end mill from SGS carbide end millTested & converted to Emuge M16 tap from Greenfield - increased speed/feedTested & converted to Vega threadmill from OSG tapInstalled Cribware barcode inventory & purchasing systemAchieved tooling package discount for new MazakLowered price/leadtime/inventory requirement on special TPG insertTested & converted to Circle boring bar from Micro 100Tested & converted to Sandvik CNMG-MF from CarboloyTested & converted to Sandvik RA390 end mill from HSS end millTested & converted to Milacron coolants - improved life and performancesUnion Butterfield price reductionResharpen of drill/taps/end millsTested & converted to Sandvik grade 4005 from 4025 - doubled per edge lifeTested & converted to Sandvik indexable U-Drill from 194,317.41732.05YYYYYYYYYYYYYYYYYYYYYYYYYYYYYY 281,540.79

Tool Technology. A tool vending machine is a great convenience. But, filling it with the same old parts time and . We'll keep our "WebVend" and "Tool Boss" Vending Machines stocked with the best tools, so production has access to the latest technology. Software Simplifies Tool Crib Management. Atwood also has the tool crib software to