Transcription

Use of steel microfibers, steel macrofibers,PVA fibers, and hybrid fibers in UHPC:Experience from shear tests and bond strengthtests of UHPC beamsManuel BermudezMpendulo DlaminiChung-Chan HungPh.D. CandidateMSc.Professor

1. The presence of fibers disturbs UHPC’s microstructure2. Distribution of the steel microfibers is statistically moreuniform when compared to other types of fibers. In the last three decades, UHPC structural membershave been mainly reinforced with steel microfibers.

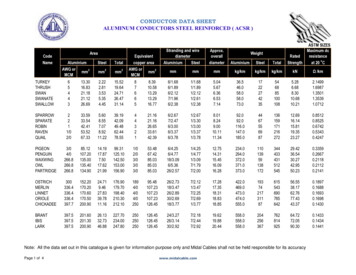

ACI Committee 544 considers the fiber diameter of 0.3 mm as theseparating limit between microfibers and macrofibers.MacrofibersMicrofibersFiber typeDiameterLengthNotationSteel microfibers PVA microfibers0.22 mm13 mmmF0.038 mm8 mmmPVAHooked end Doubled hookedsteelend steel0.38 mm30 mmSF0.90 mm60 mmLF

Mixing UHPC with steel microfibers

Mixing UHPC with steel microfibersSteel microfibers Uniform distribution ofthe fibers Slump than 60 cm f’c 120 160 MPawhen Vf 0.75%

Mixing UHPC reinforced with different types of fibersDouble hooked end macrofibersFiber balling

Mixing UHPC reinforced with different types of fibersHooked end steel macrofibersPVA fibers

UHPC reinforced with Vf 2.25%LFAfter adjusting the SP contentSlump 35 40 cmGood workability

UHPC reinforced with Vf 2.25%PVASlump 40 45 cm

UHPC reinforced withVf 0.75%SF 0.75%LFReduction in the slump (25 30 cm)

UHPC reinforced withVf 0.75%SF 1.50LFSlump 35 40 cm

UHPC reinforced withVf 1.50%SF 0.75%LFSlump 40 45 cmGood workability

UHPC reinforced withVf 0.75%SF 0.75%LF 0.75%PVASlump 55 65 cm

Experience on Sheartests of UHPC beamsTHE WORLD’S GATHERING PLACE FOR ADVANCING CONCRETE

Effective net of fiberreinforcementShear Resisting Mechanismsof beams without stirrups

UHPC beams with (a/d 1.5)S – 0% FAt peak loadS – 2.25% mPVAS – 2.25% LFAt peak loadAt peak loadAt failureAt failureS – 0.75%SF 1.50%LFAt peak loadAt failureAt failureUHPC beams withhybrid fibersS – 0.75SF 0.75LF 0.75mPVAAt peak loadAt failure

UHPC beams with (a/d 3.3)L – 0% FAt peak loadL – 2.25% PVAL – 2.25% LFAt peak loadAt peak loadAt failureAt failureL – 0.75%SF 1.50%LFAt peak loadAt failureAt failureUHPC beams withhybrid fibersL – 0.75SF 0.75LF 0.75mPVAAt peak loadAt failure

Slender UHPC beam with 0.75%SF 1.50%LF𝜌𝑙 7.6%

Can we use other types of fibers as shear reinforcement?Monofibers(a/d 1.5)(a/d 3.3)Hybrid fibers

Experience in bondstrength and splicinglength of rebars in UHPCTHE WORLD’S GATHERING PLACE FOR ADVANCING CONCRETE

The development of reinforcement stipulated by ACI 318 (2019)in section 25.4 has an upper limit of compressive strength up to70 MPa. This limit is too conservative when considering the outstandingmechanical properties exhibited by UHPC.Development length(ACI 318-2019)𝑓′𝑐 limited to 70 MPaBond strength(ACI 318-2019)

High Strength SteelReinforcing BarsBar type#5(D16)SD785#8(D25)SD685NominalDepth ofWidth ofareaeach ribeach rib(mm2 )ℎ𝑟 (mm)𝑤𝑟 (mm)198.50.722.7490.723Bar gbetweenArea of ribsRelative arearibs 𝑆𝑟𝐴𝑟 (mm2 )of ribs 𝑅𝑟6.5320.096101480.184(mm)Yield StrengthUltimate 1707902710905707902

UHPC reinforced with2% of steel microfiber𝑙𝑑 𝐴𝐶𝐼 318 𝑓′𝑐 70 MPa𝑙𝑑 𝐴𝐶𝐼 318 using real 𝑓′𝑐Bar #5 (D16)Splicing lengths44𝑑𝑏 / 32 𝑑𝑏 / 19 𝑑𝑏Bar #8 (D25)Splicing lengths48𝑑𝑏 / 36 𝑑𝑏 / 24 𝑑𝑏74% / 53% / 32%106% / 71% / 44%73% / 55% / 36%107% / 77% / 51%

Side view(D16) SD785#5, Grade 12044𝑑𝑏32𝑑𝑏19𝑑𝑏(D25) SD685#8, Grade 10048𝑑𝑏36𝑑𝑏24𝑑𝑏Bottom view

In some lap-splice beams, we failed to allow the UHPC beams to fail inbond failure because the very high bond strength of UHPC: UHPCbeams with either bar #5(D16) or #8(D25) had only flexural cracks withno splitting cracks and tension reinforcement yielding before failure. The superior performance of UHPC can also represent an obstacle intrying to investigate the design parameters such as the bond strengthand shear strength. It was found that in UHPC beam tests that had the splice length of only40% of the required length per ACI 318 for normal concrete, flexuralcapacity developed by the reinforcing bars prevented bond failure.

Thank you!This study was sponsored in part by theMinistry of Science and Technology,Taiwan, under GrantNo. 104-2628-E-006-002-MY3.THE WORLD’S GATHERING PLACE FOR ADVANCING CONCRETE

f 0.75%SF 0.75%LF 0.75%PVA Slump 55 65 cm. THE WORLD'S GATHERING PLACE FOR ADVANCING CONCRETE Experience on Shear tests of UHPC beams. Shear Resisting Mechanisms of beams without stirrups Effective net of fiber reinforcement. UHPC beams with (a/d 1.5) S -0% F At peak load At failure S -2.25% mPVA At peak load