Transcription

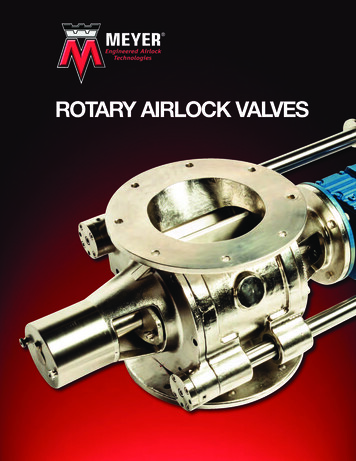

ROTARY AIRLOCK VALVES

ROTARY AIRLOCK VALVESFor over half a century, Meyer Rotary AirlockValves have been leading the industry in design,workmanship, functionality, longevity andserviceability. They have repeatedly proven to bethe best available. So it should come as no surprisethat we ship more units than any other companyin North America.three times as many in fact!Our rotary airlock valves are used in a wide rangeof applications where there is need to minimizesystem air loss while transferring materialbetween vessels with differing pressures. Theyare used as feeder valves to meter the flow ofmaterial between vessels with equivalentpressures. You will also find them doing doubleduty in systems where there is a need to minimize system air or gas loss while regulation theflow of material between vessels with differingpressures. You can count on Meyer to bring theright solution to your specific needs.AsphaltGrainPowder lPaperTobaccoDairyPharmaceutical WoodFoodPlasticUD SERIESFEnergyPAGE 4-7Universal DutyDust DutyHD SERIESPAGE 8-15Heavy-Duty Extra ToughHeavy-Duty Abrasion ResistantHeavy-Duty XPHeavy-Duty Blow-ThruHeavy-Duty Pellet ValveHeavy-Duty Side EntrySV SERIESPAGE 16-19Kwik-KleanKlean-In-Place IICV SERIESPAGE 20-25Fabricated ValvesHigh-PressureCustom Design2SYSTEM COMPONENTSPAGE 26SERVICE AND PARTSPAGE 27E

CDBAFEATURESA Oversize ShaftsB Outboard BearingsC Heavy Duty Oversize FlangesD Full Flow DesignE Cast ConstructionF High Capacity Rotors3

UDS E R I E S4MEYER Universal Duty Series airlock valves provide the customer agreat valve for low pressure conveying and dust collection applications.These units utilize one piece rotors with cast machined housings for asuperior seal. All units utilize permanently lubricated outboard bearingsinsuring low maintenance.

UDVThe UDV Universal Duty Drop-Thru Valves are designedfor economical and reliable material metering and airlockservice. The perfect solution for low pressure pneumaticconveying. Ideal for pollution control applications beneathdust collectors and cyclone separators.DDVThe DDV Dust Duty Drop-Thru Valves are designed toprovide a low cost airlock solution for simple light dutydust collection applications under baghouses andcyclones.5

UDV Universal Duty ValveSQUAREIdeal for pollution control applications in wood, grain, food,textile, paper, tobacco, rubber, and paint industries, the UDVvalve works beneath dust collectors and cyclone separatorswhere temperatures do not exceed 350 F and pressuredifferentials are less than 7 PSI.The UDV valves are available with square or round flanges;they feature rugged castings and larger shaft diameters thanthe 0141.54141.54COMMON SERVICE CONDITIONS:Pressure Rating: 7 PSIMaximum Operating Temperature: 350 FMaterials: Dry Free Flowing Mildly AbrasiveTYPICAL APPLICATIONS:Dust CollectionMeteringCycloneSeparatorLow PressureConveying SystemsRELEVANT INDUSTRIES:Available in five sizes from 6 through 14WoodGrainRound or square flange assures system compatibilityFoodTextile8 vane open end rotorPaperTobaccoFull flow throat design permits maximum flow to rotor pocketRubberPaintRugged cast iron construction and stainless steel provides maximumstructural stabilityOutboard sealed bearings never need lubricationApplication specific options including speed switches, motors,drives and accessoriesExternally replaceable packing with split compression designCFR6UNMATCHED COMPETITIVE ADVANTAGES:Oversize shaft diameters reduce deflection for maximum torque6ROUND0.0956The UDV Universal Duty Valves are designed for economicaland reliable material metering and airlock service.CFR

DDV Dust Duty ValveSQUAREThe DDV Dust Duty Valves are designed to provide a low costairlock solution for simple dust collection under baghousesand cyclones.This design is uniquely suited for a low pressure applicationwhere a quality air seal is necessary in light duty non-abrasivedust collection applications.The DDV valves are available in sizes 6 through 14 withsquare or round housings to match most collector 100.48100.48120.90120.90141.54141.54COMMON SERVICE CONDITIONS:Pressure Rating: 60”W.C.Maximum Operating Temperature: 300 FMaterials: Dry Free FlowingTYPICAL APPLICATIONS:Dust CollectionCyclone SeparatorUNMATCHED COMPETITIVE ADVANTAGES:Available in five sizes from 6 through 14Maintenance-Free direct drive at 22 RPM8-Vane open end rotor - beveled edgesReplaceable urethane sealstrips (optional)RELEVANT aintCast iron or stainless steel machined housings and endplatesC-Face standard motorRound or square flange assures system capabilitiesOutboard sealed bearings never need lubricationExternally replaceable packing with split compression design7

HDS E R I E S8The Meyer Heavy-Duty Series airlock valves provide maximum versatilityin the most severe applications. Each model offers an engineered costeffective solution to the customers needs. These units all have outboardbearing construction with an inboard packing design for maximum life andreduced maintenance. All rotor and shaft designs are oversized to eliminate shaft deflection and fatigue. The HD Series provides the right valvefor any application.

HDX HDAR HDXPThe HDX Heavy-Duty Drop-Thru Extra Tough, HDAR HeavyDuty Abrasion Resistant and HDXP Heavy-Duty ExplosionProof rotary airlock valves are designed to withstand hightemperatures and pressure differentials up to 15 psi. Thislegendary design sets the standard by which all others in theindustry are measured. It offers the heaviest gauge rotorvane stock of any competing product, extra thick endplates,flanges and housing walls, along with outboard mountedoversized bearings that are prelubricated and permanentlysealed to ensure low maintenance and prolonged life.HDBTThe HDBT Heavy-Duty Blow-Thru model rotary airlock valvesprovide a specialized solution to your unique needs. Thesemodels provide a cost effective valve for your pneumaticconveying, or low profile application requirements.HDPV HDSEThe HDPV Heavy-Duty Pellet Valve and the HDSE Heavy-DutySide-Entry model rotary airlock valve lines are speciallydesigned with offset inlet and discharge openings to reduceproduct shearing while maintaining an efficient product flow inconveying or metering applications.9

HDX Heavy-Duty Extra-ToughThe HDX Heavy-Duty Extra-Tough Drop-Thru rotary airlockvalves are designed to withstand high temperatures and pressure differentials up to 22 psi. This legendary design sets thestandard by which all others in the industry are measured. Itoffers the heaviest gauge rotor vane stock of any competingproduct, extra thick endplates, flanges and housing walls,along with outboard mounted oversized bearings that are prelubricated and permanently sealed to ensure low maintenanceand prolonged life.The HDX is available with 6-vane or 8-vane rotor design.Square or round flange housing with cast iron, 304/316 stainless steel or Ni-hard �–36X3620––COMMON SERVICE CONDITIONS:Pressure Rating: 22 PSIMaximum Operating Temperature: 1,000 FMaterials: Dry Free-Flowing Including:Corrosive, Hygroscopic, AbrasiveTYPICAL APPLICATIONS:Pneumatic ConveyingBlendingDust CollectionDryingPollution ControlWeighingMixingFeedingUNMATCHED COMPETITIVE ADVANTAGES:Available in twelve sizes from 6x6 through 36x36RELEVANT INDUSTRIES:Round or square flange assures system compatibilityAsphaltCementLarger diameter shafts for less deflection and optimum torque deliveryFoodPowerFull flow throat design permits maximum flow to rotor pocketBakingMiningPermanently sealed bearings ensure protection from contaminationChemicalPaintSpecial rotor designs including coatings, polishing, shallow pockets andclosed end to specifically match your applicationPlasticsPetrochemHousing coating options include hard chrome, nickel, teflon, tungstencarbide, chrome carbide and plasmaCast iron and stainless steel housings are standard providing maximumstructural stability with optional cast materials available including; inconel,hastelloy, cast steel or aluminum10

HDAR Heavy-Duty Abrasion-ResistantCERAMICCFRDURAKAST 18X182.06–The HDAR Heavy-Duty Abrasion Resistant Drop-Thru rotaryairlock valves are designed for severe applications wherehighly abrasive conditions exist. Offered in a choice of ceramic lined or DuraKast , both can significantly improve thewear factor on the valve and reduce the pre-mature equipment failure often associated with such applications.The ceramic version starts with any of our Heavy-Duty rotaryairlock valves. We bond ceramic tiles to the inside of the castiron housing and on the rotor tips. The DuraKast units arecompletely cast out of a hard chrome material suitable forapplications with higher pressure differentials. The DuraKastunits also have Stellite on the rotor tips for extended abrasion resistance. Both styles offer extended life over that of astandard cast iron rotary valve by as much as 6 times.COMMON SERVICE CONDITIONS:Pressure Rating: 22 PSIMaximum Operating Temperature:250 F (Ceramic),750 F (DuraKast)Materials: Dry Free-Flowing Extremely AbrasiveParticlesTYPICAL APPLICATIONS:Pneumatic ConveyingBlendingDust CHED COMPETITIVE ADVANTAGES:RELEVANT INDUSTRIES:CERAMICMining – Sand, Alumina, CopperPrecision-Cut ceramic tiles bonded in place minimizing gap exposurePower - Fly Ash, CoalClosed-End rotor designs with ceramic tiled end disc perimeter and tungsten carbide tips for prolonged wear resistanceCement – Kiln Dust, Raw and FinishedHVOF spray on packing area for extended shaft lifeAsphalt – Limestone, GraniteSteel – Oxides, Grinding Dust, SinterCeramic can be re-ground for additional lifeDURAKAST650 Bhn high chrome wear resistant casting for maximum lifeOversized square flange housing thickness designed to be re-ground formany years of service (round not available)Pre-Cast flange holes allow for easy field installation on new orreplacement unitsClosed-End rotor with welded hard faced stellite tips for maximum wearresistanceEnd plates are hard chrome lined with optional purging featureHigher pressure differentials for highly abrasive applications11

HDXP NFPAThe Meyer HDXP Heavy-Duty, NFPA design valves arecustom applied units to your specific application. Meyerengineers review the application and evaluate the designbased on Kst values for the material, temperature, pressureand ambient conditions. Units can be built in cast iron,stainless and cast steel to match the specific NFPA requirements. Special XP switches, controls and motors are alsoadded as needed to match the installation environment. Eachvalve is uniquely built and documented. The Meyer HDXP isideally suited for all your NFPA installations.UNMATCHED COMPETITIVE 29––22X224.34––COMMON SERVICE CONDITIONS:Pressure Rating: 15 PSIMaximum Operating Temperature: 500 FMaterials: Dry Free-Flowing Semi-AbrasiveTYPICAL APPLICATIONS:Pneumatic ConveyingPollution ControlBlendingWeighingDust CollectionMixingDryingFeedingAvailable in nine sizes from 6x6 through 22x22Round or square flange assures system compatibilityRELEVANT INDUSTRIES:Larger diameter shafts for less deflection and optimum torque deliveryCoalFull flow throat design permits maximum flow to rotor pocketGrainPermanently sealed bearings ensure protection from contaminationFoodHousing coating options include hard chrome, nickel, teflon, tungstencarbide, chrome carbide and plasmaTextileCast iron and stainless steel housings are standard providingmaximum structural stability with optional cast materials availableincluding; inconel, hastelloy or cast steelPaperPowerPetrochemicalMining12

HDBT Heavy-Duty .8SQUAREThe HDBT Heavy-Duty Blow-Thru rotary airlock valves areideal for the Pneumatic Conveying of free-flowing material infood, grain, chemical, milling, baking, plastics and pharmaceutical applications. These units are uniquely designed tohandle non-abrasive powders and where the product requiresan assist in clearing the rotor vane pockets. The HDBT designis especially suited for low headroom installations and retrofit applications.COMMON SERVICE CONDITIONS:Pressure Rating: 20 PSIMaximum Operating Temperature: 400 FMaterials: Dry Fine Free-Flowing Non-AbrasiveTYPICAL APPLICATIONS:Pneumatic ConveyingUNMATCHED COMPETITIVE ADVANTAGES:Round or square flange assures system compatibilityRugged cast iron or stainless steel construction provides maximumstructural stabilityRELEVANT INDUSTRIES:GrainPharmaceuticalOutboard sealed bearings never need lubricationFood8-Vane open end beveled rotor standardChemicalFull taper inlet throat opening for maximum material flow to rotor pocketsPlasticsIntegral mounting feet for easy installationPaintBakingMilling13

HDPV Heavy-Duty Pellet ValveThe HDPV Heavy-Duty Pellet rotary airlock valves are specially designed with offset inlet and discharge openings toreduce product shearing while permitting an even flow of pellets and chip materials into each rotor pocket. The designuses a slide gate to control the flow of pellets through theside inlet and into the rotor.The HDPV eliminates serious jamming problems experiencedwith standard rotary airlocks by having the material enter thepocket from the side through a “V” type inlet and exitingthrough the bottom. This design is especially beneficial inhandling pellets, chips, flakes and cubes resulting in reducedpocket MON SERVICE CONDITIONS:Pressure Rating: 15 PSIMaximum Operating Temperature: 750 FMaterials: Pellets, Chips, Flakes, CubesTYPICAL APPLICATIONS:Railcar UnloadingPneumatic ConveyingVacuum LoadersRELEVANT INDUSTRIES:UNMATCHED COMPETITIVE ADVANTAGES:PlasticsOffset side inlet and discharge provides optimal material product flowWoodRound flangeFoodOptional adjustable slide gate for optimal material feed rate controlPharmaceutical“V” Type inlet throat minimizes product shearing and degradationRubberHousing vent connection improves valve efficiencyChemicalRugged corrosion resistant cast stainless steel construction providesmaximum structural stabilityOutboard sealed bearings never need lubrication8-Vane open end rotor standard for optimal air seal and product feed14

HDSE Heavy-Duty Side EntryThe HDSE Heavy-Duty Side-Entry Drop-Thru rotary airlockvalves are designed for applications involving relatively largeparticles that cannot be reduced by the shearing actionbetween the rotor blades and the housing at the inlet. Theyare also suitable for applications where small fines producedby the shearing action could cause damage to the system orcreate hazards. The built-in “V” shaped product inlet reducesthe shearing to a single point virtually eliminating 2X120.6414X141.1216X161.6218X182.2922X224.34COMMON SERVICE CONDITIONS:Pressure Rating: 15 PSIMaximum Operating Temperature: 750 FMaterials: Pellets, Chips, Flakes, CubesTYPICAL APPLICATIONS:Railcar UnloadingPneumatic ConveyingUNMATCHED COMPETITIVE ADVANTAGES:Vacuum LoadersOffset V-type inlet design to eliminate shearingCast iron or stainless steel construction for maximum stabilityRELEVANT INDUSTRIES:Permanently sealed outboard bearings for reduced maintenancePlasticsOversize rotor and shafts for severe service dutyMiningSpecial rotor designs including coatings, polishing, shallow pockets andclosed end to specifically match your applicationFoodHousing coating options include hard chrome, nickel, teflon, tungstencarbide, chrome carbide and plasmaRubberPharmaceuticalChemical15

SVS E R I E S16The Meyer Sanitary Valve Series is designed for fast disassembly, cleaningand re-assembly of the material contact surfaces. The Kwik-Klean andKlean-In-Place II models are specifically designed to be cleaned withouttools and removal from service. Valves are available in standard cast iron,stainless and sanitary designs.

KKThe Kwik-Klean rotary airlock valves are designed for fastand simple disassembly and re-assembly, allowing for quickinspection, clean-up and maintenance without the use oftools or removal of the valve from service. The valves usehand-tightened fasteners to secure the headplate to thehousing. With the headplate and rotor convenientlyremoved, the entire housing interior is accessible. Reassembly takes just minutes and internal clearances areautomatically re-established every time.KIP IIThe KLEAN-IN-PLACE II rotary airlock valve is speciallydesigned for applications where frequent cleaning, sanitizing or inspection of the bulk handling system is required andminimum downtime is critical. The KLEAN-IN-PLACE II hasuniquely designed features making it compliant for FDA,USDA, 3A dairy and NFPA standards with materials neededfor food, dairy, chemical, and pharmaceutical applications.Our design incorporates a perfectly balanced 2-RAIL construction allowing the operator easy access to either cleanthe rotor, leaving it attached with the headplate or separating the rotor to completely remove for optimal cleaning.17

KK Kwik-KleanThe Kwik-Klean rotary airlock valves are designed for fastand simple disassembly and re-assembly, allowing for quickinspection, clean-up and maintenance without the use oftools or removal of the valve from service. The valves usehand-tightened fasteners to secure the headplate to thehousing. With the headplate and rotor conveniently removed,the entire housing interior is accessible. Re-assembly takesjust minutes and internal clearances are automatically reestablished every time.The valves are available in different design levels incorporating cast iron, stainless steel or polished sanitary COMMON SERVICE CONDITIONS:Pressure Rating: 15 PSIMaximum Operating Temperature: 400 FMaterials: Dry Free-Flowing Food Grade orContamination Sensitive PowdersTYPICAL APPLICATIONS:Pneumatic ConveyingBlendingDust CollectionUNMATCHED COMPETITIVE ADVANTAGES:Available in four sizes from 6x6 through 12x12Round or square flange assures system compatibilityCast iron, 304 SS or 316 SS housings are standard providing maximumstructural stabilityDryingWeighingMixingFeedingPackaging or BaggingDirect drive splined coupling for ease of assemblyAvailable with packing and U-cup teflon sealsRELEVANT INDUSTRIES:Tool-Free hand fasteners for rotor removal and regular inspectionsBakingSanitary and electro polishing optional for dairy and nently sealed bearings ensure protection from contaminationFoodSpecial rotor designs including coatings, polishing and shallow pocket tospecifically match your applicationPowder CoatingHousing coating options include nickel and teflonSpicesFour levels of constructionMeat ProcessingChemical18

KIP Klean-In-Place 10X100.48120.9012X120.90141.5414X141.546The KLEAN-IN-PLACE II rotary airlock valve is speciallydesigned for applications where frequent cleaning, sanitizing or inspection of the bulk handling system is requiredand minimum downtime is critical.COMMON SERVICE CONDITIONS:The KLEAN-IN-PLACE II has uniquely designed featuresmaking it compliant for FDA, USDA, 3A dairy and NFPAstandards with materials needed for food, dairy, chemical,and pharmaceutical applications. Our design incorporates aperfectly balanced 2-RAIL construction allowing the operator easy access to either clean the rotor, leaving it attachedwith the headplate or separating the rotor to completelyremove for optimal cleaning.Materials: Dry Free-Flowing Food Grade orContamination Sensitive PowdersUNMATCHED COMPETITIVE ADVANTAGES:DryingAvailable in five sizes from 6x6 through 14x14WeighingRound flange assures system compatibilityMixing316 SS housings are standard providing maximum structural stabilityFeedingSelf Aligning Drive, without the use of special toolsPackaging or BaggingPressure Rating: 15 PSIMaximum Operating Temperature: 400 FTYPICAL APPLICATIONS:Pneumatic ConveyingBlendingDust CollectionAvailable with packing and multiple seal designsTool-Free hand fasteners for rotor removal and regular inspectionsRELEVANT INDUSTRIES:Safety switch signaling when unit is ready to runBakingPermanently sealed bearings ensure protection from contaminationDairyPharmaceuticalFoodPowder CoatingSpicesMeat ProcessingChemical19

CVS E R I E S20The Meyer Custom Valve Series airlocks are highly specialized. These unitsare designed to handle oversized large material, high pressures or extremetemperatures. These products all provide an engineered solution to yourmost demanding system requirements.

FVThe Meyer FV Fabricated rotary airlock valves are designedfor use in low pressure dust collection, cyclone and pneumatic conveying applications. Their unique design allows oversized material to pass without binding issues experiencedwith other type of valves. These units provide the most economical solution in handling extremely large material rates.HPThe HP High-Pressure rotary airlock valves are designed forhigh pressure conveying systems up to 50 PSI. These unitsfeature oversized flanges and housings with reinforced ribdesign for maximum structural strength. The rotor designincorporates an oversized shaft and closed end rotor designto maintain a positive air seal. These valves are the perfectsolution to convey non-abrasive products in medium densephase conveying systems.CDMeyer CD Custom Design rotary airlock valves incorporateany of our standard product offerings but have significantmodifications to specialize the valve to your specific application. The modifications can be as simple as special paint torequirements for highly engineered casting materials, drives,transitions or coatings. Meyer engineers can solve your mostsevere wear, corrosion, material or conveying valve application needs.21

FV Fabricated ValvesMeyer FV Fabricated rotary airlock valves are especially suited to handle large volumes of light to medium density products including large irregular material typically found in dustcollection and low pressure pneumatic systems. Thesevalves are available in carbon steel, stainless steel or abrasionresistant steel as an economical solution. The precision cutand welded valves feature flange type bearings, ribbed housing and headplates, with replaceable neoprene, viton or urethane 5COMMON SERVICE CONDITIONS:Pressure Rating: 2 PSIMaximum Operating Temperature: 150 FMaterials: Light to Medium Density Products:Chips, Flakes, Strips, LumpsTYPICAL APPLICATIONS:Pneumatic ConveyingDust CollectionUNMATCHED COMPETITIVE ADVANTAGES:CycloneFour standard sizes with custom sizes available to meet your systemrequirementsOversized flange assures valve stabilityRELEVANT INDUSTRIES:Fabricated carbon steel, stainless steel or abrasion resistant steelconstruction to meet your specific applicationWoodFlange type bearings for extended valve lifeInsulationReplaceable neoprene, viton or urethane sealstrips for maximum sealingTextileOptional seal or packing available for special applicationsRecycleReinforced rotor with inter blade gussets insuring vane rigidityPlasticPaperGrain22

HP High-PressureThe HP High-Pressure rotary airlock valves are specificallydesigned for high-pressure plastic conveying systems wherenon-abrasive continuous material feed is required. The valvesfeature thicker ribbed housings and flanges specially suitedfor 50 PSI systems. Headplates feature a proprietary shaftbearing and rotor seal design minimizing air leakage. Highpressure rotor design, including oversized shaft and bladematerials, keep shaft deflection to a MMON SERVICE CONDITIONS:Pressure Rating: 50 PSIMaximum Operating Temperature: 200 FMaterials: Non-Abrasive Powders and GranularTYPICAL APPLICATIONS:Pneumatic ConveyingUNMATCHED COMPETITIVE ADVANTAGES:RELEVANT INDUSTRIES:Available in six sizes 6” through 20”PlasticsStandard venting ensuring proper material flowPetrochemicalHousing options include hard coat aluminum and stainless steelPharmaceuticalStainless steel rotor is standardChemicalProprietary shaft bearing and rotor seal design minimizes air leakage23

CD Custom Design SeriesThe CD Custom Design Series rotary airlock valves are aculmination of three generations of Meyer applicationexpertise. These valves are designed to handle extremeoperating conditions, unique customer needs or unusualinstallation requirements.Meyer sales engineers work directly with the customer totailor a custom solution to their problem.UNIQUE FEATURES AVAILABLE:High Temperature DesignSpecial HousingsSteam JacketingSpecial PaintSpecial CoatingsHigh TemperatureBearingPackingHeat ShieldsCastings for 1500 F OperationCustom TransitionsSpecial DrivesCustom GuardsSpecial RotorsSteam jacketed airlocks for sensitive conveyingand material applications.Special oil tight guards, taconite seals and flangeoptions to meet your custom applications.24

Customer specific motors and drives to meet themost stringent demands.Special valve controls and switches arepre-assembled to ease field installation.Special design rotors with shallow pockets,staggered vanes, shaft extensions and polishingare available to match the valve to the material.Wide variety of special coatings, polishing androtor treatments to enhance valve operation.Meyer matches any customer paint or specification for maximum durability in severe conditions.Air swept headplate purge design to eliminatematerial build-up and improve valve life.25

System ComponentsIn addition to Rotary Airlock Valves, Meyer designs, engineers and manufactures a wide variety of other products designed specifically for bulk processing applications. Like our rotary valves, these products are designed and built to withstand the rigors ofdemanding applications. The next time you are in the market to repair, replace or upgrade your process system components, giveus a call. We manufacture all the key components for pneumatic conveying, process metering and dust control.Double-FlapgateAirlock ValvesLine Diverter ValvesSwing GatesSlide GatesDouble ClamShell GatesRotary Plug ValvesKnife GatesGravity Flow Diverter ValvesScrewveyor Pumps26Blower Packages

Service and PartsSince 1946, Wm W. Meyer & Sons has been delivering quick, conscientious service and superiorcraftsmanship on replacement parts to customersthroughout the country. We understand the costsof downtime, and make it our highest priority tohelp you keep your plant running troublefree. Ouron-site preventative maintenance programs,responsive repair services and quick-ship replacement parts capabilities help us deliver the extravalue customers need in today’s competitive marketplace.In addition to maintaining and repairing our ownRotary Airlock Valves, we also provide expert repairservices on other manufacturers’ products.WE OFFER REPAIR SERVICES ON THESEAND OTHER SYSTEM COMPONENTS:Rotary AirlocksDouble-FlapgatesDivertersSlide GatesScrew PumpsValvesMany times, repairs can be done right on the spotto minimize production disruption and speed startup. However, when it is impractical to repair a uniton site, it will be shipped to our repair facility forimmediate attention. It will be torn down, carefullyinspected and restored to like-new condition,including a return to the original tolerances.COMPREHENSIVE EVALUATION ONEVERY UNIT:Complete disassemblyInspection of each componentComparison to original manufacturers’ specs andtolerancesRepair or replacement of worn or damaged component partsGenuine OEM PartsRe-assemblyFinal TestingService WarrantyIf your equipment is beyond repair or it is not economical to repair it, Meyer will give you the optionof choosing between a new or re-manufacturedpiece of equipment from available stock.27

Wm. W. Meyer & Sons, Inc.1700 Franklin Blvd.Libertyville, IL -006

SQUARE CFR 6 0.095 8 0.23 10 0.48 12 0.90 14 1.54 ROUND CFR 6 0.095 8 0.23 10 0.48 12 0.90 14 1.54 COMMON SERVICE CONDITIONS: Pressure Rating: 7 PSI Maximum Operating Temperature: 350 F