Transcription

ProductsSolutionsPortfolioFood & BeverageServices

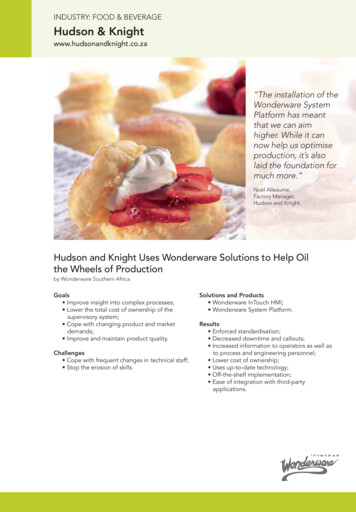

2EditorialDear reader,The demand for consistent product quality and taste posesmajor challenges for the Food & Beverage industry. Foodsafety is more than an obligation. It is crucial to the brandand profitability of every food producer.Food and beverage products must meet specificrequirements. For this reason, food producers must followhygiene regulations and standards to ensure food safetyand reliability while maintaining efficiency.Endress Hauser is a complete provider for the Food& Beverage industry. Our full range of instruments,tailor-made solutions and services meet global hygieneregulations and ensure consistent product quality and plantavailability, while conserving resources and lowering costs.Learn more about ourdigitalization know-howPage 28Our brochure presents a visual overview of the mostrelevant processes in food and beverage production andhelps you choose the instruments that best fit your needs.Endress Hauser is your trusted partner for all measurementtasks. In-depth application know-how, extensive experienceand a global presence are what set us apart. This allows youto adapt optimally to every challenge and environment.Ensuring your success is our mission.Discover our customers'experiences.Page 46Want to know more about Food & Beverage?www.endress.com/food-beverage

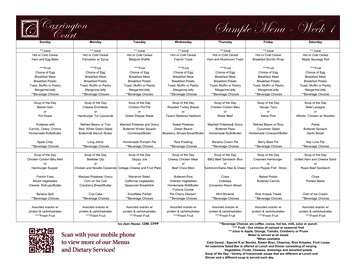

36 All frome one source8 Dairy process46 ReferencesBenefit from our encompassingportfolio of products, solutionsand services throughout thewhole lifecycle of your plant.Ensure high quality dairy processingwith accurate process control.Strong collaboration with ourcustomers. Read some of theirthoughts on our offering.Juice26 Juice concentrate intake andmixingCIP44 Cleaning in Place – CIP processTable of contentsAll from one source6 All from one sourceDairy8 Dairy process10 Milk intake12 Milk heating and pasteurization14 Milk standardization andhomogenizationBrewery16 Brewhouse18 Beer mashing and lautering20 FermentationService22 Service by your sideSoftdrinks24 Syrup preparation and mixingDigitalization/IIoT28 How sweet is the taste ofdigitalization?Sugar30 Sugar production32 Evaporation34 CrystallizationSolutions36 SolutionsEdible Oil38 Edible oil refining40 Oil bleaching42 Oil deodorizationIndustry requirementsEndress Hauser’s entire hygienic product offering fulfills the foodand beverage industry’s requirements. Meet 3-A sanitary standards and assessed according to test procedureof EHEDG Food contact material compliant with FDA "GRAS", EC 1935/2004 andChina GB4806References46 Customer insights

4

5

6All from one sourceAll from one sourceBenefit from our extensive portfolio of products, solutions andservices throughout your plant's entire life cycleExpectations and demands are growing. Be it shrinkingbudgets or shorter timelines, your job is becoming moredemanding than ever. To meet your goals, you need apartner that simplifies your life instead of making it morecomplicated.That’s why you can rely on Endress Hauser, because whenit comes to instrumentation, we are the only primary suppliercapable of covering all critical parameters in food and beveragemanufacturing.How does this help you? Simple. It starts with the selectionand ordering process. There is no need to contact multiplesuppliers and valuable time is saved during the entire orderprocess. You have only one point of contact right from the start.In addition, we not only offer multiple parameters, but alsomultiple technologies for your measuring tasks. That meansour experienced technicians can recommend the optimalsolution for your applications.Take flow measurement for example. For some tasks,magnetic inductive flowmeters are the ideal technology.For others, the Coriolis principle is more advantageous.When thinking about commissioning, having instrumentsfrom only one supplier results in a smoother overall process.And to be sure that all of the bases are covered, ourexperienced service technicians can even install andcommission instruments from a wide range of suppliers.After your plant or application is up and running, you canstill benefit from relying on a primary instrumentationvendor like Endress Hauser. Thanks to our modularinstrumentation platform, you can reduce the number ofspare parts you need to keep in stock. And services likemaintenance, verification and calibration are also easier tomanage if you rely on a single provider.

7Why different measuring technologies matterThey are many voices in our industry that liketo talk about one measuring technology onlyand they recommend it for every application. AtEndress Hauser we take a different approach.We know that every measuring technology has itsadvantages and disadvantages. That’s why it is soimportant to take a closer look at the application andfind the optimal technology. For level measurementsas an example, radar and ultrasound technologiesare available. While ultrasound works best for shorterdistances in small, confined spaces, radar works bestat longer distances and in demanding applications.In addition, radar is not influenced by dust or foam.Our technicians support you in defining the righttechnology for your applications based on theirexperience and industry knowledge.

8DairyDairy processEnsure high quality dairy processing with accurate process controlDairy production is a business with tight margins and high-quality expectations. Processes can be optimized for costcontrol while keeping the product quality at a consistently high level.Milk intakeMilk truckMilk storageRaw milkreceptionAireliminator3Storage tank1266FilterInjector66CoolingSteamBalance tank648Milk heatingHeat exchanger126459M71 10Temperatureholding tube12Milk powderMilk standardization& homogenizationCooling systemCreamSeparator10Expansion chamberHeatingsystem13Milk packagingCream / s flowBalancetankFermentedprocessing1Filling line9Evaporator2Fermented culture dosing5SeconddryerSeparatorHomogenizerTo milkpowderpackagingFilterCoolingsystem17To productionline127612961CultureTemperatureholding tube56Incubationtank65SeparatorCoolerPackaging

9FlowFlow in powder process, fermented processing, fermented culture dosing,filling line1Proline Promag H 100Flow in drying, standardization2Proline Promass F 100Level control in air eliminator3Liquicap FMI51Point level control in air eliminator, evaporator4Liquiphant FTL50HLevel control in raw milk storage, fermented processing, fermented culturedosing, sterile tank5Deltapilot FMB50Point level control raw milk reception, milk storage tank, balance tank,evaporator, fermented culture dosing, pump dry-run protection6Liquiphant FTL33pH control in milk intake, fermented processing, fermented culture dosing7Memosens CPS77EConductivity control for product identification8Smartec CLD134Buildup monitoring in filling line, holding tube, storage tank9Liquitrend QMW43LevelLiquid analysisPressurePressure in chiller loop supply, evaporator10 Cerabar PMP51BPressure in powder process, fermented processing, fermented culture dosing11 Cerabar PMP23TemperatureTemperature in raw milk tank, heat exchanger, powder process, fermentedprocessing, fermented culture dosing, sterile tank12 iTHERM TM411Temperature in chiller loop return, heat exchanger, fermented processing13 iTHERM TM401

10DairyMilk intakeEnsuring highest quality and accurate quantity14L4AireliminatorT5LT3PLSTLS6LS4A CondPCoolingFilter23FT4LSPA pHRaw milktank1 – Liquicap FMI51Capacitance probe for fast and reliable continuous level measurements Plug and play device, no need for calibration (factory pre-configuration) Not affected by foam and turbulenceswww.endress.com/fmi512 – Proline Promass Q 300Coriolis flowmeter for stable measurement of milk with entrained air and forreliable mass balancing Direct mass flow measurement Optimized measuring performance for fluids with entrained gas thanksto unique Multi Frequency Technology (MFT) Available with custody transfer approvalswww.endress.com/promass-q300

113 – iTHERM TM311Pt100 compact thermometer, with optional integrated IO-Link and 4–20 mAtransmitter, programmable via PC Fast installation and easy commissioning Excellent metrological properties thanks to innovative sensor technology Reliable operation ensured by approvals and certificateswww.endress.com/tm3114 – Liquipoint FTW23Cost effective point level switch for water-based liquids Easy installation thanks to compact design, even in confined spaces or withrestricted access CIP and SIP cleanability ensured - up to protection class IP69 Plug-and-play device without the need for medium adjustment LED indication for on-site function check IO-Link functionality reduces costs and complexity due to easy configurationand operation (optional)www.endress.com/ftw235 – Deltapilot FMB50Compact pressure sensor with Contite measuring cell for hydrostatic levelmeasurements Hermetically-sealed Contite measuring cell with full condensate-resistanceand minimum temperature effects High reference accuracy for precise hydrostatic level measurements Seamless and independent system integration with HART, IO-Link, Profibus, etc.www.endress.com/fmb506 – Smartec CLD134Reliable conductivity measurements for product identification in the milkintake process Conductivity measurements for raw milk or cream Unique hygienic design prevents recontamination Increased product yield thanks to advanced functionalities like remoteparameter set changewww.endress.com/cld134

12DairyMilk heating and pasteurizationGuaranteed milk safety and shelf life extensionFromstoragetankSteamLSInjectorPLST4Heat amberTTHomogenizerLSPFHeat exchanger3A pHTemperatureholding tubeCooling systemLSterile tankTRFFilling linePTCooling3TP1 – Proline Promag H 100The proven flow specialist for the food and beverage industry Fewer measuring points thanks to multivariable measurement of volume flow,temperature and conductivity Energy-saving measurements – no pressure loss due to full-bore design Heartbeat Technology for device verification without process interruptionwww.endress.com/promag-h1002 – Memograph M RSG45Advanced Data Manager: stores, visualizes, analyzes and communicates Stainless steel front with touch-screen operationPlant and apparatus engineering and construction, e.g. milk pasteurization plantsBatch analysisHigh degree of data securitywww.endress.com/rsg45

133 – Cerabar PMP23Compact and cost-effective hygienic pressure transducer Fully welded design maximizes process safety by minimizing the use of gaskets IP69 ingress protection for heavy washdown conditions IO-Link functionality reduces costs and complexity due to easy configurationand operation (optional)www.endress.com/pmp23measurements4 – iTHERM TrustSens TM371Hygienic compact RTD thermometer: 100% compliance, 0% effort Risk and cost reduction thanks to self-calibration and Heartbeat Technology Automated documentation and storage of 350 calibration points Elimination of non-conformities or undetected failureswww.endress.com/tm3715 – Liquitrend QMW43Compact multiparameter sensor for continuous buildup measurements Reliable measurement of buildup thickness regardless of media typeVerification of cleaning status, no need to open tanks, pipes or heat exchangersCompact and flush-mounted stainless-steel sensor with minimal process immersionDigital communication via IO-Link (optional)www.endress.com/qmw43

14DairyMilk standardization and homogenizationAdjust cream content and ensure consistent distributionSeparatorFromraw milk tank3F1TSkimmilkHeating gCoolingP4F3T1StandardizationHomogenizerF5P4To storage tank1 – iTHERM TM311Pt100 compact thermometer, with optional integrated IO-Link and 4–20 mAtransmitter, programmable via PC Fast installation and easy commissioning Excellent metrological properties thanks to innovative sensor technology Reliable operation ensured by approvals and certificateswww.endress.com/tm3112 – Proline Promass Q 300Coriolis flowmeter for unmatched mass flow and density measuring accuracyeven in demanding applications Optimal and reliable in-line product quality control Consistent and reliable measuring results even when the viscous fluid containsentrained air Multivariable measurement of density and volume flow Easy to cleanwww.endress.com/promass-q300

153 – Proline Promag H 100The proven flow specialist for the food and beverage industry Fewer measuring points thanks to multivariable measurements of volumeflow, temperature and conductivity Energy-saving measurement – no pressure loss due to full-bore design Heartbeat Technology for device verification without process interruptionwww.endress.com/promag-h1004 – Cerabar PMP23Compact and cost-effective hygienic pressure transducer Fully welded design maximizes process safety by minimizing the use of gaskets IP69 ingress protection for heavy washdown conditions IO-Link functionality reduces costs and complexity due to easy configurationand operation (optional)www.endress.com/pmp235 – Proline Promass F 100Robust Coriolis flowmeter with superior flow and density measuring accuracy Reliable, robust sensor: proven in hundreds of thousands of applications Less downtime: immediate availability after CIP/SIP cleaning Flexible mounting: no inlet and outlet runs requiredwww.endress.com/promass-f100

16BreweryBrewhouseAll beer manufacturing processes must be designed to ensure consistentlyhigh product qualityBeer is brewed using naturally grown products that vary from year to year and from harvest to harvest. The brewer must reactto these changes to produce a beer of stable quality, and moreover, the beer must taste the same year after year in order tomeet the customer's expectations.Malt / adjunct reception3Malt silosAdjunct silo44171744Malt weighing /cleaning43Beer mashing & h rlpoolWort kettle17Hot water2610Hops dosagePresampletank692Wort boiling281137PreruntankHotLauter tun2Steam /hot sate121376114To wortcooler

17FlowFlow in measurement hops dosing, wort to cellar1Proline Promag H 100Density measurement for boiling control2Proline Promass F 100Level control in grain silos, adjunct silo3Levelflex FMP56Point level control in malt silos, adjunct silo, mash tun4Soliphant FTM50Level control in mills5Micropilot FMR10Point level control in lauter tun, wort kettle, prerun tank, presample tank,pump-dry protection6Liquiphant FTL33Level control in mash tun, lauter tun low point level, wort kettle level control7Cerabar PMC51BLauter tun continuous level8Deltapilot FMB50Spent grain continuous level9Micropilot FMR20Spent grains high level switch10 Soliphant FTM20Wort kettle boil over detection11 Liquicap FTI51Whirlpool point level control12 Liquipoint FTW33LevelLiquid analysisWort kettle pH measurement13 Memosens CPS71EWhirlpool color measurement14 Color sensor OUSAF22PressureWort kettle pressure15 Cerabar PMP51Pressure hops dosing line16 Cerabar PMP23TemperatureTemperature in grain silos, adjunct silo, whirlpool, mash tun, prerun tank,presample tank17 iTHERM TM411Wort kettle temperature18 iTHERM TrustSens TM371

18BreweryBeer mashing and lauteringOptimize mash and quality of wortFrom malt siloFrom adjunct siloMillLLSLSColdFLMillFTWaterMash /AdjunctkettleTColdHotLSWaterHot1MashtunTLSLS3L2A pHTSteam /hot water3A pHTFPLFrom prerun tankPTLFColdSparge waterHotLauter tunLTo prerun tank65FA TUPDLSLS4Spent grains container1 – Liquiphant FTL50HModular vibronic point level device for hygienic applications in all liquids Reliable function unaffected by conductivity, buildup, turbulence, foamor changing media Mechanically robust due to seamless sensor construction made of stainlesssteel and no moving parts Plug-and-play device, no need for calibration or adjustmentwww.endress.com/ftl50h2 – iTHERM TM411Innovative advanced, modular RTD thermometer iTHERM QuickSens: fastest response times (t90 1.5 s) for optimalprocess control iTHERM QuickNeck – cost and time savings thanks to simple, tool-freerecalibrationwww.endress.com/tm411

193 – Memosens CPS61EpH measurements in sparge water The sensor's exceptional accuracy and reproducibility help you keep thepH value in the optimal range for maximum product yield Optimal performance even at high temperatures Pressurized version for sugar solutions to avoid blocking of the reference Reduced operating costs thanks to minimized process downtime and extendedsensor lifetimewww.endress.com/cps61e4 – Deltabar FMD71Electronic differential pressure system utilizing two robust ceramic sensor modules Abrasion and corrosion resistant sensorsFully vacuum resistantSuperior precision for accurate level measurementsOil free sensor technologywww.endress.com/fmd715 – Inline turbidity sensor OUSTF10Optical turbidity measurements in the supply line Measurement with forward scattered light according to Mebak guidelinesAccurate and highly sensitive turbidity measurements for better product qualityLow-maintenance sensor with long service life and stable operationSuitable for cleaning-in-place (CIP) and sterilization-in-place (SIP)www.endress.com/oustf106 – Proline Promass E 300Cost-efficient flowmeter with special concentration measuring functions Reliable, robust sensor: proven in hundreds of thousands of applications Less downtime: immediate availability after CIP/SIP cleaning Flexible mounting: no inlet and outlet runs requiredwww.endress.com/promass-e300

20BreweryFermentationEnsure consistent quality batch after batchFermentationtankFA O2PCO2 LSTFT5From wort cooler /yeast dosingA TuRefrigerationTo maturation1 – iTHERM TM411Innovative advanced, modular RTD thermometer iTHERM QuickSens: fastest response times (t90 1.5 s) for optimalprocess control iTHERM QuickNeck – cost and time savings thanks to simple, tool-freerecalibration International hygienic certifications and approvalswww.endress.com/tm4112 – Deltapilot FMB50Compact pressure sensor with Contite measuring cell for hydrostaticlevel measurements Hermetically sealed Contite measuring cell with full condensate-resistanceand minimum temperature effects High reference accuracy for precise hydrostatic level measurements Seamless and independent system integration with HART, IO-Link, Profibus, etc.www.endress.com/fmb50

213 – One rod probe 11371Point level detection of foams and conductive liquids Reliable on-rod probe with hygienic process connectionsFast response timesVariable insertion lengthsFor use with FTW325 transmitterwww.endress.com/113714 – Density computer FML621Density and concentration measurements in tanks and pipes using vibrationbased sensors Accurate and reliable density measurementsAlgorithms and tables for calculating different concentrations (e.g. Plato, Brix, etc.)Up to 8 individual measuring points connected to one mathematic moduleUse in combination with Liquiphant FTL5x / FTL6x with density electronicswww.endress.com/fml6215 – Suspended solids and color sensor OUSAF12Turbidity measurements for phase separation after fermentation tank Fast and accurate detection of phase separation between yeast and beerReliable measurement values even with changing types of beerUse of the EasyCal system for verification of the turbidity measurement (optional)Suitable for cleaning-in-place (CIP) and sterilization-in-place (SIP)www.endress.com/ousaf12

22ServiceService by your sideOur service portfolio was developed to ensure repeatability, improve plantavailability, support resource conservation and guarantee food safetyBy your side, with total commitment, today and into thefuture, Endress Hauser will help you both meet and surpassyour specific industry challenges. It is what drives us; it iswhat defines us. As the global 24/7 economy in which youcompete brings unprecedented margin pressures, we deliverthe incremental OPEX reductions and plant availability gainsto make the difference.As new regulations to protect people and the environmentforce industry to rethink its processes, we help you complywhile remaining competitive. Moreover, we are here to ensurethat relentless technological progress does not becomea threat but an opportunity. With Endress HauserServices, you give yourself every chance of success.

23Calibration servicesFrom on-site to fully accredited laboratory calibration,Endress Hauser provides timely, traceable, andcost-effective calibration services to ensure both highperformance and compliance of your quality criticalinstruments. Optimize calibration intervals to balance costsand risks Rely on Endress Hauser calibration competenceavailable anywhere in the world Benefit from ISO 17025 accreditation availablefor many parameters in many regions Continuously improve your calibration processand activities with expert insightsMaintenance and calibration optimizationHow can you find the right balance between costsand maintenance activities without compromisingsafety? A review and redesign of the maintenanceprocesses in a plant can help maintenance and plantmanagers to decide how to reach strategic assetmanagement goals. On one hand, Endress Hauserconsultants use in-depth metrological expertise andanalyze calibration data to help customers find theiroptimal calibration intervals. On the other hand,our asset management specialists review currentmaintenance processes to provide recommendationsto reduce operational costs.Support servicesThe global Endress Hauser support network oftechnical experts is on call to guide and to supportyou remotely with diagnostics and troubleshootingas well as with proactive alerts to optimize yourplant’s availability and performance, reduce outages,and minimize disruption. Customize a service agreement according to yourrequirements Rely on guaranteed support availability andresponse times Obtain guided service operations, remotediagnostic and troubleshooting support fromdedicated experts Receive proactive alerts thanks to remote healthmonitoring of your installed base

24SoftdrinksSyrup preparation and mixingPrecise dosing of ingredients6L5LSSugar tankFlavour 5Essence 5LSLSDyeLSFFF5TLS54FSugarTP4CO2FTPFPA CondA O2Degassed water5LSBuffer tankLSDFA ColorT123P4Packaging1 – Proline Promass Q300Coriolis flowmeter for highly accurate sugar content/density measurementsof beverages Easy cleaning - immediate availability after CIP/SIP cleaning Optimized for liquids with entrained gas bubbles Unrivalled Brix-measurements in real-time to ensure optimal product qualityunder real process conditionswww.endress.com/promass-q3002 – Color sensor OUSAF22Color measurements for outstanding and consistent product quality Accurate color measurements (e.g. ICUMSA) and purity monitoring to ensureproduct quality Fast and direct inline measurement avoids expensive sampling and laboratorymeasurements Outstanding filter performance provides superior linearity EasyCal system for verification of the color measurements (optional)www.endress.com/ousaf22

253 – iTHERM CompactLine TM311Pt100 compact thermometer, with optional integrated IO-Link and 4–20 mAtransmitter, programmable via PC Fast installation and easy commissioning Excellent metrological properties thanks to innovative sensor technology Reliable operation ensured by approvals and certificateswww.endress.com/tm3114 – Cerabar PMP23Compact and cost-effective hygienic pressure transducer Fully welded design maximizes process safety by minimizing the use of gaskets IP69 ingress protection for heavy washdown conditions product IO-Link functionality reduces costs and complexity due to easy configurationand operation (optional)www.endress.com/pmp235 – Liquiphant FTL33Compact vibronic point level device for hygienic applications in all liquids Reliable function unaffected by conductivity, buildup, turbulence, foamor changing media Mechanically robust due to seamless ssensor construction made of stainlesssteel and no moving parts Plug-and-play device, no need for calibration or adjustmentwww.endress.com/ftl336 – Micropilot FMR62High frequency radar for precise level measurements in liquids High accuracy of up to 2 mm in small and large tanks Unaffected by changing media properties (e.g. density, conductivity) Heartbeat Technology for advanced process controlwww.endress.com/fmr62

26JuiceJuice concentrate intake and mixingEnsure product quality by precise mixingLSLConcentratetankPTFTLST2A pH4PRefrigerationTCoolerLDegassed waterLSStorage tankAdditivesTTFFTPTLSCoolingMixer3TA CondFF126FA pHA O25Heating1 – Proline Promass F100Robust Coriolis flowmeter with superior flow and density measuring accuracy Sophisticated functions available for high density accuracy and flexibleconcentration measurements Reliable, robust sensor: proven in hundreds of thousands of applications Flexible mounting: no inlet and outlet runs requiredwww.endress.com/promass-f1002 – Memosens CPS77EpH measurement of the concentrate and the mixed juice to ensure productquality and shelf life Glass-free electrode, eliminating risk of glass splinters in the beverage Suitable for hot steam sterilization and autoclaving Increased process safety thanks to digital Memosens technologywww.endress.com/cps77e

273 – iTHERM TM311Pt100 compact thermometer, with optional integrated IO-Link and 4–20 mAtransmitter, programmable via PC Fast installation and easy commissioning Excellent metrological properties thanks to innovative sensor technology Reliable operation ensured by approvals and certificateswww.endress.com/tm3114 – Cerabar PMC51BDigital pressure transmitter with oil-free ceramic sensor Oil free sensor technologySuitable for cold applications due to Contite technologyImproved process safety due to self monitoring sensorFull hygienic compliance with all relevant approvalswww.endress.com/pmc51b5 – Liquiphant FTL50HModular vibronic point level device for hygienic applications in all liquids Reliable function unaffected by conductivity, buildup, turbulence, foamor changing media Mechanically robust due to seamless ssensor construction made of stainlesssteel and no moving parts Plug-and-play device, no need for calibration or adjustmentwww.endress.com/ftl50h6 – Memosens COS22ETrace measurement with the Memosens COS22E digital oxygen sensor to ensureshelf life and taste CO2 compatible trace sensor for the beverage industry High accuracy enables precise measurements resulting in superior product quality Low maintenance: modular sensor design enables fast exchange of membrane capand electrolytewww.endress.com/cos22e

28Digitalization/IIoTHow sweet is the taste of digitalization?Digital data deliver valuable insights into the food and beverage productionprocess. Expanding the control over the installed base means ensuring thequality of the products – and the taste.Digitalization is the next big challenge for every industry.For the production and processing of food and beverageit is of particular relevance. The Food & Beverage industryfaces the high pressure of running processes at maximumefficiency without compromising quality. In the past, thereappeared to be few options in addressing this challenge.Now that the Industrial Internet of Things is unlockingdata that was barely accessible before, new optimizationpotential is arising.One important dimension of process optimization isintact equipment. Regardless of the type of equipment –instrumentation, pumps, valves, etc. – failures on criticaltags can cause complete production downtimes in theworst case. Key equipment data can become a crucial leverfor increasing reliability. At this point, it is revealing toknow that 90 percent of the Endress Hauser field devicesare already digital. Their inherent intelligence can deliverrelevant information once it is unlocked.This is where Endress Hauser's field connectivity and theNetilion IIoT ecosystem come into play. Our technologyis capable of accessing crucial equipment data such asself-diagnostics or obsolescence status and instrumentdocumentation.Making the information and files digitally available in a safeway expands the control over the processes. Quick responsesin cases of emergencies, as well as strategic operationalactivities, can be based on precise data and perfectly manageddocuments. This is how an IIoT ecosystem creates opportunitiesto increase plant availability.In addition, the measurement data is more precise whenaccessed digitally, thus leading to greater process efficiency.Through remote monitoring for instance, inventoriescan be optimized so that material resources are handledideally without risking overstocking or supply gaps. Therelation between ingredients and yield can be calculatedmore precisely. And digital monitoring is not limited toinventory data. Automatic tracking and documentation ofother measurement values, such as temperature, can easereporting tasks.

29A digitalized factory opens the door to multiple optimizationopportunities, even in industries that can already lookback on a history of continuous improvement. Producingand processing food and beverage is not only a matter ofrecipes and ingredients. The entire production environment– starting with the field and ending up with documentation– plays its part in ensuring the quality and the taste of theproducts. And an IIoT ecosystem enables optimization ofthe entire facility. This is how digitalization is tied to thetaste of foods and beverages.Endress Hauser is a trustworthy partner in implementingdigital services. The development process of the productshas been certified group-wide according to IEC62443-4-1.Our IIoT ecosystem Netilion fulfills the requirements ofISO 27017. Furthermore Endress Hauser D

After your plant or application is up and running, you can still benefit from relying on a primary instrumentation vendor like Endress Hauser. Thanks to our modular instrumentation platform, you can reduce the number of spare parts you need to keep in stock. And services like maintenance, verification and calibration are also easier to