Transcription

TECHNICIAN CERTIFICATIONVER10917

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YTable of ContentsBrief Overview of the ATC Conversion and OperationReceiving the VehicleATC WarrantyATC Warranty ProcedureVehicle OperationSuggested ToolsPrimary ComponentsPrimary Components 2Primary Components 3Troubleshooting - GeneralTroubleshooting - DoorTroubleshooting - LiftAirbag Warning DiagnosisAirbag Warning Diagnosis (continued)Airbag Components & Door Magnet (Driver Side Conversion)DTC CodesHydraulicsHydraulic ComponentsHydraulic Cylinder AdjustmentsHydraulic Swing Cylinder ComponentsManual Hydraulic System OperationLimit Switch Function & AdjustmentLatch SystemDoor Seal LeakDealer Certification onversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80932

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggBrief Overview of the ATC Conversion and OperationThe door opening is controlled independently from the lift operation. This is to allow someone to open and close the door without having to deploythe lift. It also enables a user to avoid having to open the door completely in the case where they may encounter an obstruction. However, to insurethe door is opened far enough to prevent the lift from hitting it on deployment, there is a tilt switch mounted on the door that insures it is openedfar enough to prevent damage. To prevent injury and damage to the door, it will not open if the seat belt is plugged into its receptacle. A seat beltextension plugged in will also prevent the door from opening.Once the door has moved far enough to satisfy the tilt switch, the user can hit the lift out button. The lift will then move outwards until it hits the outlimit switch. At this point the controller will automatically turn off the horizontal switch and start lowering the lift. The lift will continue to lower untileither the user stops it, or it runs out of stroke. There is no down limit switch to allow the unit to reach the ground on various terrain. When the unitruns out of stroke the pump will go into bypass mode, which is a valve that limits the amount of up pressure the pump will generate. There is also ahold valve in the unit that will prevent cylinder movement whenever the control button is released.With the door open and the system deployed, the user will hit the in button for the lift. The controller will turn on the pump and open the verticalup valve making the lift rise. This will continue until the unit hits the up limit switch at which point the controller will stop the vertical cylinder andstart the horizontal cylinder moving inward. The lift will continue to move inward until the user releases the button or the lift reaches the inner limitswitch. Once the inner limit switch is activated, the controller will allow the door to close. The door will continue to close as long as the key-fobbutton is held and the door has not activated the door closed limit switch. Once this switch is activated the controller will turn the pump off.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80933

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YReceiving the VehicleDEALER CHECK IN:The procedure for receiving the vehicle is fairly straightforward andinvolves 4 documents. First, the Check in Sheet. The purpose of thissheet is to make sure there is no damage to the vehicle during shipping,and also to make sure the vehicle is prepared correctly for deliveryto the customer and that the customer has been properly trained tounderstand and operate the vehicle.WARRANTY REGISTRATION:This document is required to validate the warranty. It also registersimportant customer data and helps to insure they have been properlyinstructed in the use of their vehicle.All ATC documents can be found atatconversions.com/dealer-documentsDealer Check In & Warranty Registration must be filled out completely and submitted back to ATC within 72 hours of customer delivery.Submit to service@atconversions.comATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80934

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggATC WarrantyWARRANTY/SERVICE GUIDELINES:This explains how our procedure works. Our goal is to help the customer get repairs as quickly as possible. Failure to follow the procedure canresult in delays in getting parts, repairs, and payment. Warranty payment can also be invalidated by failure to follow the correct procedure.ATC WARRANTY:It is important for the costumer to understand what the warranty covers and how long.All ATC documents can be found atatconversions.com/dealer-documentsThe Warranty/Service Guidelines form must be filled out completely and submitted back to ATC within 72 hours of customer delivery.Submit to service@atconversions.comATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80935

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggATC Warranty ProcedureWARRANTY PROCEDURE AND RATE CHART:Dealers are allowed one hour to diagnose and/or make simple repairs. This hour does not require pre-approval. Beyond that, pre-approvalis required. The purpose of this is to help determine the most efficient procedure to effect repairs of the vehicle. The rate chart explains themaximum accepted times for many common repairs.All ATC documents can be found atatconversions.com/dealer-documentsThe Warranty Prior Authorization form must be submitted BEFORE any work can be performed.Submit to service@atconversions.comATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80936

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YVehicle OperationKEY FOB BUTTONSLIFT SPECIFICATIONS “DOT Private Use lift” Operator must back into lift Lift rating: 750 Pounds Minimum unobstructed platform operating volume: 57,000cubic inches.OPERATING THE LIFTALWAYS START VEHICLE PRIOR TO OPENING OR CLOSING DOORAND RAMP.ACCIDENTALLY DEPRESSING THE OPEN SWITCH COULD CAUSEDAMAGE.KEY FOB BUTTON DESCRIPTIONTo ensure that the lift is operated in a safe manner, the followingprecautions should be understood and followed.1. Press and hold OPEN for thegullwing door to Open.VEHICLE SETUP2. Press and hold CLOSE for thegullwing door to Close.To increase safety, your vehicle and wheelchair should beconfigured for safe driving by a professional. This includes requiredcontrols and wheelchair configuration on the lifting platform. Seatbelt modification or extension may be required depending on thesize of the wheelchair and individual application which should alsobe configured by a professional.NOTE: An aftermarket seatbelt and/or extension must not be usedunless it latches into the OEM receptacle. When this OEM receptacleis latched, it is a safety feature which will not allow the door to open.If the door opens with the seatbelt positioned in any other way, itcould possibly cause injury to the occupant or damage to the vehicle.3. Press and hold for the lift to goUp and In.31424. Press and hold for the lift to goOut and Down.An aftermarket Alarm/Remote Start system may have been installedto interface with the TouchTronics control modules if the truck was notoriginally equipped with a remote start system. The aftermarket FOBsmay be used but are not needed.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80937

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggSuggested ToolsThe following lists are tools, supplies and equipment that may be needed to repair or adjust an ATC converted vehicle.BASIC TOOLSscrewdrivershex keysopen end wrenches, line wrenchesratchet driver in 1/4 and 3/8, maybe 1/2cutting pliersextensionssocketstorque wrenchwork light, fluorescent or LEDplierschannel lockscrescent wrenchbreaker bar or impact gunSAFETY GEAReye protectionfire extinguisheroil spill collectorglovesragsELECTRICAL TOOLScircuit testerdigital multimeterwire snipscrimping toolwire strippersSolder gun and solderSUPPLIESATF (Automatic Transmission Fluid)rubber cementbed liner touch up sprayundercoating touch up spraysilicone sealantpenetrating oilautomotive bulb sealblack seam sealelectrical tapeATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80938

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YPrimary ComponentsThe following pages contain images that show the locations of the primary components that make up the ATC system. A technicianshould familiarize themselves with these components, their function, and the typical location of them. Due to the variety of vehiclesthat ATC converts, there will be some minor differences in where some of these components are located, but they are usually in thesame general area.CONVERSION DOORLIFT ARMLIFT CYLINDERLIFT POSTHYDRAULIC MANIFOLDTRANSFER CASE COVERSWING CYLINDERFLOOR PAN DRY SIDEFLOOR PANLIFT POST DRY SLIDELIFT PANSEAT PANATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-80939

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YPrimary Components 2The following pages contain images that show the locations of the primary components that make up the ATC system. A technicianshould familiarize themselves with these components, their function, and the typical location of them. Due to the variety of vehiclesthat ATC converts, there will be some minor differences in where some of these components are located, but they are usually in thesame general area.DOOR CLOSE LIMIT SWITCHLATCH MECHANISMPAN OUT LIMIT SWITCHDOOR TILT SWITCHPAN PIVOT ARMDOOR LIFT TURNBUCKLEDOOR CYLINDER ADJUSTMENTLIFT ROLLERSATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809310

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggPrimary Components 3The following pages contain images that show the locations of the primary components that make up the ATC system. A technicianshould familiarize themselves with these components, their function, and the typical location of them. Due to the variety of vehiclesthat ATC converts, there will be some minor differences in where some of these components are located, but they are usually in thesame general area.MAIN BREAK &TERMINAL BLOCKLIFT PAN IN LIMIT SWITCHMANUAL OVERIDE VALVESSWING CYLINDER ADJUSTMENTLIFT PAN UP LIMIT SWITCHMANUAL PUMPATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809311

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggTroubleshooting - GeneralVEHICLE DOESN’T GO INTO GEAR.In order to put the vehicle in gear, the brake must be pressed and the ignition key on. If the door is closed and the hydraulic pump will still run whenthe door closed button is pressed, the door in limit switch needs adjusted or replaced.BATTERY CHARGE IS GETTING LOW.If the lift is operated multiple times without the vehicle running it will drain the battery. We always recommend having the vehicle running whenusing the lift.OPERATION IS JERKY/INTERMEDIATE.This is often caused by a weak battery in the key fob, or not being close enough to the vehicle. Other items that can cause this is interference isfrom other electronics such as other remotes, alarm systems, garage door openers, airports, etc.Air in the hydraulic system is the most common problem and can also cause unpredictable motion. An easy way to make sure is to bleed thesystem.Hydraulic System Air Bleeding Procedure1. Make sure the lift is up and in the truck.ATC recommends Lock Tite hydraulicsealant. Do not use teflon tape.2. Make sure the door is closed.3. Ensure all 6 of the manual valve controls are open.4. Once all are open, hold the open button for 20 to 30 seconds. The lift should not move, but this process will work a majority of the airout of the system and is a good start if air is suspected.5. Once you are finished, check the fluid level in the reservoir and make sure it’s still adequately filled. Sometimes air will get trapped inother places that the above process is unable to get out. In these cases each fitting will have to be slightly cracked to let a few dropsof fluid out. If the fluid bubbles out, it’s a sign of trapped air. When it comes out solid fluid, tighten the fitting and move on to the nexttroubleshooting item if needed.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809312

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggTroubleshooting - DoorDOOR DOESN’T CLOSE ALL THE WAY.The door closed limit switch may need adjustment: If the door stops and the hydraulic pump also stops, yet the door is not closed all the way,this is an indication that the door closed limit switch needs adjusted inward. If the door stops moving inward and the pump is still running, this isan indication that something has physically stopped the door from moving further inward. Often this is caused by the lift not being all the way in,usually caused by a defective or out of adjustment in limit switch. When the lift is moved up and in, the pump should automatically shut off oncethe lift pan is in. If it does not, then a limit switch is the likely problem – the controller will not allow the door to close until it is told by the lift in limitswitch that the lift pan is in its proper place. Also Look for items that may be blocking the door or the linkage. An incorrect adjustment on the doorclosing cylinder swivel can also cause the cylinder to bottom out before the limit switch makes contact.DOOR DOESN’T STAY TIGHT.This can be caused by the door magnet on the forward portion of the door not functioning correctly. Also, air in the hydraulic system can allow thecylinder to creep back. Bleeding the air out of the system can remedy this. (See hydraulic system bleeding guide). This can also be caused by apiston seal leak inside the cylinder that would allow pressure to bleed off and the door to creep open. A faulty hold valve in the manifold can alsocause this.DOOR MOVES WHEN DRIVING.This could be caused by the same factors as above, as well as the front door magnet may be out of adjustment or not function. If the front of thedoor can easily be moved with the vehicle running, and in drive, then the magnet is likely not holding the door. To test it, apply the brake and placethe vehicle in gear with the door open. Touch the magnet with a piece of steel and see if it is energized. If so, then the magnet will need adjusted tomake full contact with the striker plate.DOOR WILL NOT OPEN.If the door will not open, make sure the seat belt isn’t plugged in – there is a safety switch to prevent door from opening if the seat belt is hookedto prevent personal injury as well as damage to the door system. Also make sure the vehicle is in park and the brake pedal is not depressed. Todetermine if the issue is electrical or hydraulic, check the latch release signal on the door controller. If it is lit up, and the hydraulic pump is running,but the door doesn’t open, the issue is with the hydraulic system.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809313

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggTroubleshooting - LiftGENERALMake sure that the manual valve operation knobs are all in. Any of these being pulled out can cause erratic and unpredictable hydraulic issues. Mostoften the cause of hydraulics systems not performing correctly is having air in the hydraulic system.LIFT DOESN’T GO IN.Usually caused by the up limit switch needing adjustment or replaced. If the pump is turning on but the lift is not moving in, the likely problem is thevalve in the manifold. If there is 12 volts on the manifold solenoid, with the pump running and the lift isn’t moving in, the valve cartridge likely needsreplaced.LIFT DOESN’T GO OUT.This is most commonly caused by the tilt switch, which is mounted to the linkage connecting to the door. This switch ensures that the door is openfar enough before allowing the lift to come out so the lift doesn’t damage the door. To determine if the tilt switch is faulty, open the door and see ifthe door open switch on the lift controller is lit. If it does not, look for damage to the wiring going to it, or it could be a faulty switch.LIFT DOESN’T GO UP.If the lift won’t go up, often the cause is a weak battery. We recommend always having the vehicle running when using our system. A belt buckleplugged can also cause the lift to not operate.LIFT DOESN’T GO DOWN.This is normally caused by the out limit switch needing adjustment or replacement. If the pump is running and the lift still won’t go down thesolenoid valve on the manifold would be suspect. If it has 12vdc going to it and still not operating, the valve probably needs replaced.LOW POWER ON LIFT.This is often caused by low pressure in the hydraulic system, which can be corrected by adjusting the pressure setting on the pump. It can also becaused by air in the system (see hydraulic system bleeding guide). Other causes can be debris in the guide mechanisms causing binding, needingadditional lubrication on the plastic bearing strips and low fluid.* Instructional/adjustment videos about our conversion can be found at www.atconversions.com/servicedeskATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809314

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggAirbag Warning DiagnosisHIGHRESISTANCECHECK SOLDER CONNECTIONSThese wires are located under the console, over to the floor kick panel, up to the head liner and inside the door panel where connected to the seatbelt roller.The connections should be hand soldered with heat shrink to eliminate excessive resistance.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809315

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YAirbag Warning Diagnosis (continued)Seat BeltRetractor FailureMALFUNCTIONING SEAT BELT RETRACTORShould the seat belt retractor be subjected to excessive moisture, the Service Air Bag warning will illuminate.Retractor WiringRetractor LocationRetractor Moisture ProtectionATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809316

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggAirbag Components & Door Magnet (Driver Side Conversion)RETRACTOR WIRE COLORSRed 18 ga. and Grey 18 ga.DOOR MAGNET WIRE COLORSOrange Green 18 ga. to Black ground.Red and Black to Red Power.PRETENSIONERYellow w/ Orange 18 ga. &Orange w/ Yellow 18 ga.Dielectric Grease mustbe used on connectorATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809317

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YDTC CodesThe following are pertinent DTC codes encountered with our system and their description. Knowing the locations and type of problem can help trackdown where a wiring issue may be.RELATED SDM TROUBLE CODESDTC B008F Rollover Protection Disable Switch CircuitDTC B0098 Passenger Air Bag Disable Switch CircuitDTC B0014 Right Air Bag Deployment LoopDTC B0021 Left Air Bag Deployment LoopDTC B0085 Left front side impact sensorDTC B0086 Right front side impact sensorDTC B0087 Left rear side impact sensorDTC B0088 Right rear side impact sensorDTC B0083 Left front Impact SensorDTC B0084 Right front Impact SensorDTC B0081 Passenger Presence ModuleDTC B0079 Driver seat position sensorDTC B0080 Passenger seat position sensorDTC B0015 Driver seat belt retractor pretensioner deployment loopDTC B0022 Passenger Seat belt retractor pretensioner deployment loopDTC B001A Driver anchor pretensioner Deployment loopDTC B001B Passenger anchor pretensioner Deployment loopDTC B0052 00 Deployment commandedDTC B0052 56 Deployment commanded too many timesDTC B0071 Passenger seat belt tension sensor circuitDTC B0019 (stage 1) Passenger instrument panel air bag deployment loopDTC B0020 (stage 2) Passenger instrument panel air bag deployment loopDTC B0016 Left roof rail air bag deployment loopDTC B0023 Right roof rail air bag deployment loopDTC EXTENSIONS:Open/High Resistance: 0D, 04, 05, 71Short to Voltage: 01Short to Ground: 02, 03, 0EOpen/high resistance or short to ground: 06Signal bad: 39, 08, 0FPassenger presence sensor malfunction: 00Passenger presence sensor above threshold: 11Passenger presence sensor incorrect component installed: 3APassenger presence sensor calibration not learned: 4BPassenger presence sensor plausibility failure: 5APassenger presence sensor invalid serial data received: 71ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809318

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggHydraulics POWER UNIT: The power unit consists of the pump, motor, and reservoir. The motor turns the pump, the pump creates bothpressure and flow, and the reservoir holds the excess fluid required for the system. As a cylinder moves, there is a difference ofvolume from one side to the other due to the volume occupied by the cylinder rod. As it moves, the reservoir either supplies theextra fluid needed, or stores the excess fluid depending on the direction of the cylinder movement. The fluid used in our system iscommon Automatic transmission fluid (ATF). MANIFOLD: The inlet and outlet of the power unit goes directly to the manifold. The manifold is primarily a controller that channelsthe fluid to where it’s supposed to go. It does this using valve cartridges that are all standard and replaceable. In the ATC trucks,there are 3 circuits. One is for the horizontal control, one for the vertical, and one for the door. The valves are controlled by thesolenoids which allow the signals from the controller to turn the desired circuit on and off. In the case of controller issues, these canalso be manipulated manually by opening the appropriate red knob. CYLINDERS: These convert the hydraulic pressure and flow into movement. ATC cylinders are all custom made and are dual acting,requiring pressure to move either way. VELOCITY FUSES: These are safety devices that our mounted on the rod side inlets to the vertical and door cylinder. Their jobis to monitor the flow and shut it off in the case of excess flow (like if a hose gets cut). If a hose or hydraulic failure causes a freeflow, these valves will hold the cylinder in place to prevent injury. They will continue to hold until the problem is corrected. Once theproblem has been fixed, the cylinder needs to be moved a little in the opposite direction to reset it, and it will be back to functioningnormally. STARTER SOLENOID: This is usually found mounted directly to the motor, or can be mounted remotely. Its basically a relay to takea low current signal and switch on the higher current that the motor requires. CAUTION: Before removing any fittings, hoses, etc. on a hydraulic system, make sure that the position of the item controlled bythe circuit being worked on is in a safe position. When a hydraulic system is open, there is nothing to hold the item in place. Forexample, opening a connection on the door circuit may cause the door to slam down due to gravity. If you are working on the liftcircuits, have the lift out and down. On the door circuit, have the door down or well supported. Before opening the lines to a circuit,the lift should be up and in truck. You can then open the manual valves for that circuit to help bleed off any residual pressure. Beprepared for some pressure to remain creating possible spraying of fluid. Have plenty of rags around and protect anything that canget damaged.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809319

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YHydraulic ComponentsHYDRAULIC PUMPHYDRAULIC MANIFOLDPUMP SOLENOIDPUMP GROUNDPRESSURE ADJUSTMENTVALVE SOLENOID (x6)ATF FILL CAPVALVE MANUAL OVERRIDE (x6)MANUAL HAND PUMPATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809320

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YHydraulic Cylinder AdjustmentsDOOR LIFT CYLINDERSWING CYLINDERTURNBUCKLE JOINTLENGTH ADJUSTMENTTURNBUCKLE JOINTLENGTH ADJUSTMENTThe opposite mounting endof each cylinder is static andcannot be adjusted.The Pan Lift Cylinder cannot beadjustedATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809321

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggHydraulic Swing Cylinder ComponentsSWING CYLINDERThe swing cylinder has internal cushions thatdampen the start and stop motion when actuatedORIFICE TYPESSWING CYLINDERATF FLUID INLETA Velocity Fuse is located on the base end line of both thevertical and horizontal cylinder.It’s purpose it to stop the motion of the cylinder in case a hoseruptures. To reset the velocity fuse after it has been triggered,run the cylinder in the opposite direction.SPEED REDUCTION ORIFICEATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809322

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggManual Hydraulic System OperationThe hydraulic hand pump can be used to operate any of the hydraulic circuits in case of emergency or loss of battery power. Manual operation should not be usedfor daily operation of the hydraulic system.In a situation where manual operation of the hydraulic system is necessary, first ensure electrical power to the system has been shut off, and all electrical controlsare off.PINPull Red Pin to Acuate*A1Door OpenA2Tray / Chair UpA3Horizontal Tray OutB1Door CloseB2Tray / Chair DownB3Horizontal Tray In* Make sure to move Pincounterclockwise back tothe original position beforeoperation.A detailed video forManual Pump Operation can befound on our website atatconversions.com/servicedeskTO OPERATE PUMP:1. Ensure there is adequate automatic transmissionfluid in the reservoir tank, located under thehood.2. Ensure there are no objects or persons in the wayof operating the ramp.A1B13. Insert handle for hand pump into pump handlereceptacle.A2B2A3B34. Operate pump and ensure the pump is buildingpressure (resistance to pumping) beforeoperating any of the manual valves. It may takeadditional strokes of the hand pump to fullyprime the system if it has not been used recently.5. Select which hydraulic cylinder or operation youwish to move and select appropriate valve tooperate (A or B). Do not operate more than one valve at a time.Hydraulic ManifoldHand Pump Location6. Pull the appropriate red Pin while simultaneously operating the hand pumpto move the cylinders while verifying safe motion of the ramp. The red Pin may be pulled out and turnedclockwise to lock position so it does not have to be held while pumping.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809323

e a cil eanrtecDhniTT rr aa ii nn ii nn ggATCINNOVATIVE MOBILIT YLimit Switch Function & Adjustment The limit switches give the controller feedback as to where the system components are in theirarticulation. The controller uses this information to determine what cylinder to operate. These switches work by completing the circuits path to ground. Limit switch contact should be adjusted by turning the target bolts. Ensure there is nointerference with motion of the tray and target, and that the limit switch is touching the target toensure proper ground signal to the controller.1Switches are adjusted bythreads for and distance tocontact or target.32541. Door Closed Limit Switch: Turns theHydraulic pump off when closed.3. Pan In Limit Switch: controls how far thepan gets stowed inside.2. Pan Out Limit Switch: controls how farthe pan gets deployed and allows the panlowering sequence to begin.4. Pan Up Limit Switch: controls how high thepan is lifted.5. Tilt Limit Switch: allows the pan to deploywhen the door is fully open.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809324

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggLatch SystemDOOR LATCH ADJUSTMENT PROCEDURE:121. Arm striker position: This is mounted to the armthat opens and closes the door. This striker bracketis slotted so it can be adjusted along the arm. Itshould be set as low as it can go but not “bottomingout” on the latch cam surface when it closes thedoor. If this is too low the extreme forces presentwill bend some of the latch components. If the armstriker does not move inward far enough to move thelatch plate correctly the door cylinder may need to beadjusted.2. Latch striker position: This is mounted to thedoor and allows the latch cam to pull the door inand secure it. It is also slotted to allow adjustment.It should be set such that the slot in the cam plateengages it fully, but the striker does not bottom outin the slot on the cam plate. If it is allowed to bottomout it will bend many of the components.3. Once the Latch adjustments are complete, thedoor closed position needs to be set. This isaccomplished by moving the entire latch assembly inor out as required to position the door correctly.4. After completing the adjustments, double check tomake sure that nothing is bottoming out on the latchcreating any binding. If all is properly adjusted, makesure all fasteners are tightened.ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-809325

ATCINNOVATIVE MOBILIT Ye a cil eanrtecDhniTT rr aa ii nn ii nn ggDoor Seal LeakWater intrusion into the door is normal for all vehicles. ATC utilizes the existing door seal and joins both endswith an additional piece of seal. These are glued with rubber cement.Water enters the door from the window seals and collects inside the door. Weep holes are added i

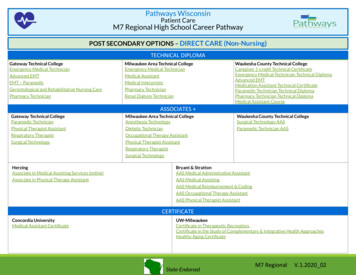

TECHNICIAN CERTIFICATION VER10917. INNOVATIVE MOBILITY AT C Dealer Training ATConversions 3901 Commerce Park Dr. Raleigh, NC 27610 Dealer Services: (855) 879-8093 2 technician Training Table of Contents Brief Overview of the ATC Conversion and Operation 3 Receiving the Vehicle 4 ATC Warranty 5 ATC Warranty Procedure 6