Transcription

COMBI OVENSMINIJET “FastPAD”ELECTRICMANUFACTURERS INSTRUCTIONSPart D: Maintenance manual- WARRANTY To ensure the guarantee on this equipment, you should comply with the MANUFACTURER’SINSTRUCTIONS in this manual.However if you cannot undertake the required maintenance operations, our installation and servicenetwork is available to provide you with a personalized contract.- WARNING - The product delivered to you complies with current standards. If any modifications are madethe manufacturer cannot accept any responsibility whatsoever. The manufacturer cannot beheld responsible in the event of an incorrect use of the appliance. Keep your documents. Translation of the original manual3VE390969NMF37517 04/2017 3VE390969NM

Page 13VE390969NM – 04/17CONTENTSCOMBI OVENSMINIJET “FastPAD”1ELECTRICAL DIAGRAMS . 31.11.22PROGRAMME SETTINGS . 62.12.22.33MINIJET OVENS . 19PREVENTIVE MAINTENANCE . 207.17.28ERROR SCREENS . 15ERROR MESSAGES . 15HYDRAULIC DIAGRAMS. 196.17ACCESS TO THE MAINTENANCE SCREENS . 13ERROR MESSAGES . 155.15.26ELECTRONIC CARDS . 9CHECKING THE SOFWARE VERSION . 11POSITION OF THE MICRO SWITCHES ON A FASTPAD 2 POWER UNIT . 11UPDATING THE SOFTWARE . 12MAINTENANCE SCREENS . 134.15SETTING THE SOFTWARE LANGUAGE . 6OVEN SETTINGS . 6WATER TREATMENT COUNTER . 8MAINTENANCE PROGRAMMES . 93.13.23.33.44LIST OF PARTS . 3MINIJET . 4LIST OF ACTIONS . 20WORKING ON THE DETERGENT PUMPS . 21PROCEDURE FOR CHANGING COMPONENTS . ION OF TECHNICAL COMPONENTS . 22ACCESS TO COMPONENTS . 22CODER . 23SCREEN CARD . 23RELAY CARD (complete assembly with box) . 24LED STRIP (IN THE DOOR) . 25CLOSING MECHANISM . 25INTERNAL GLASS . 25DOOR CATCH . 26DOOR . 26VENT VALVE MOTOR . 26FLOW METER . 27TEMPERATURE PROBE . 27VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 28.148.158.168.178.188.1993VE390969NM – 04/17CLEANING PRODUCT PUMP . 27HEATING ELEMENT . 28FAN . 28MOTOR SEAL. 29MOTOR . 29CAVITY SEAL . 29CHECKING THE TEMPERATURE SENSORS. 309.110PT100 PROBE . 30FRONT LINE PARTS . 32VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

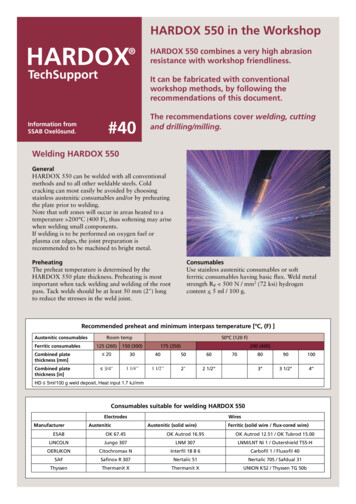

Page 311.13VE390969NM – 04/17ELECTRICAL DIAGRAMSLIST OF PARTSDesignation of common D screen cardFastPAD II maxi relay cardCapacity sensor PT 100Volumetric doserCondenser 12.5 µFLighting lampFuse 3.15 AmpsFuse 1 Amps time delayFuse 10 Amps time delayFuse 0.2 Amps speed ultra fast fuseFuse 3.15 AmpsFuse 2 AmpsFuse 1 Amps time delayFuse 0.25 Amps time delayFuse 10 AmpsSafety thermostatVentilator motor sensorPump thermostatVentilation motorMotorised Vent valve motorTechnical ventilatorTechnical ventilatorDosing pumpTransformerTransformerTransformerHeating elements 6 kW Diam 340Reed bulb (Flexible blade switch)Supply terminal stripSupply terminal stripCore probe terminal stripSilicone coverSupply 8491308492302276300676306087301477366554309639Flow meterLED stripDescaler230V/24VDoor closing safety systemList of contactorsRef.KrKsZrZsDesignationCavity heating contactorSafety contactorInterference suppressorInterference suppressorMinijet230V1111Minijet400V1111VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201Code300 698300 698300 769300 769

Page 41.23VE390969NM – 04/17MINIJETWIRING DIAGRAMDoor sensorLED LightingLighting transformerTechnical fanSafetyDry heatingTechnical fanSolenoid, drain tube cleaningMotorised Vent valve motorCleaning solenoid valveCooling solenoid valveChemical dosing pumpWater injection solenoid valveCooling of condensatessolenoid valveCavity sensorCore probe sensor(accessory)Flow meterEncoderVULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 53VE390969NM – 04/17POWER DIAGRAMCAVITY VENTILATION SINGLE-PHASE DIAGRAM WITH AUTO REVERSEVULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 623VE390969NM – 04/17PROGRAMME SETTINGSThis is required if a relay card, or a facia card is changed or there is an upgrade of the FastPAD software.Before programming check the software is in the local language and change if necessary.2.1SETTING THE SOFTWARE LANGUAGE- Go into the "TOOL BOX" screen- Select the "Client parameters" screen- Enter the password “CHEF” Permanent pass word (Upper or lower case)- Validate “V”: if the code is correct the menu can be accessed if not return to inputting the PIN- Modify the programme language if necessary (Fr: French by default)* Select the zone to be modified* Adjust the value using the coder.2.2OVEN SETTINGS- Go into the "TOOL BOX" screen- Select the "Technical parameters" screen- Enter the password “SAVB” password- Validate “V”: if the code is correct the menu can be accessed if not return to inputting the PIN- Reconfigure the oven* Select the zone to be modified* Adjust the value using the coder.VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 73VE390969NM – 04/17Commercial identification ofthe ovenModel: Number of levels andsize. Minijet 6 1/1Download on USB errormessage history (file extension compatible with Excel)Download on USB counters(file extension compatible with Excel) Error message historyCountersDisplay of error messagesin the order that theyappearedList of counters Quality of communicationsignal between the facia andrelay cardsFor a signal strength 85%see fault E46Pressing the «Back» buttonreturns to the previous T05:Total operating time in hoursTime of cooking in Convection mode in hoursTime of cooking in Steam mode in hoursTime of cooking in Combi mode in hoursNumber of door openingsNumber of activation of the Gas security inletCPT06: Operating Time with electronic 70 C inhoursCPT07: Operating Time of S21 outlet in hoursCPT08: Operating Time of S10 outlet in hoursCPT09: Operating Time of S30 outlet in hours(number of E67 error occurrences)VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 82.33VE390969NM – 04/17WATER TREATMENT COUNTERThis only functions if there are 2 separate supplies to the oven.- Open the service tab- Select the Client parameters button- Enter the “CHEF” PIN code « permanent » (lower or uppercase)- Validate “V”: When entered if the code is correct access the menu, if not re-enter the PIN code.Water treatment capacity- To modify or enter the value for the capacity of the water treatment system (in litres). Set to zero by default (if theoven does not have a dedicated water treatment system).* Select the zone to be changed* Adjust with the coder knob.- After any regeneration of the water treatment, reset the counter as required.* Press « RESET »* Confirm by pressing « YES »The water treatment system’s capacity in litresReset.By default set to zero (if there is no dedicated treatedwater supply to the oven)VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201

Page 933.13VE390969NM – 04/17MAINTENANCE PROGRAMMESELECTRONIC CARDSThe state of the LEDs represent the communication between the electronic cards and helps with diagnostics inthe event of a breakdown3.1.1 RELAY CARDIdentification of the LEDs for communication, supply and safeties and the fuses on the card.Communication LED (Emission)CommunicationLED (Reception)“Supply” LEDStatus LED (F3)Status LED (F5)Status LED (F2)Fuse10 AmpsF3Time delayFuse1 AmpsTime delayF2Status LED (F4)Status LED (F1)Fuse3.15 AmpsF1Fuse3.15 AmpsF5IHM – FlashcardDiagnostic LEDs(on screen support card)UC cardScreen supportcard3.1.2 SCREEN CARDDiagnostic LEDs(on UC card)Communication LEDs(on facia card)VULCANA division of ITW Food Equipment Group LLCP.O. Box 696Louisville, KY 40201FuseUltra fast0.2 AmpsF4

Page 103VE390969NM – 04/17Significance of the LEDs on the electronic relay card and the graphic facia card:LED RedPower onLED yellow/OrangeEmittingLED GreenReceivingLED steadyLED steady or flashingA flashing LED is considered active as is a steady one.Diagnostic of

Page 4 3VE390969NM – 04/17 VULCAN A division of ITW Food Equipment Group LLC P.O. Box 696 Louisville, KY 40201 1.2 MINIJET WIRING DIAGRAM