Transcription

THE ROLE OF COOLING AND HEATINGIN MODERN WINERIES1.ABSTRACTThroughout the world wine production is growing, and continuous research into new technologiesis being pursued to obtain better quality. The most advanced technologies are cooling and heatingsystems that produce wines of higher quality to satisfy the large market demand.After an in-depth examination of the vast influence of temperature in different wine productionprocesses, this paper shows the various techniques for obtaining high quality wines by the skillfulapplication of cooling and heating. Recommendations for typical cooling and heating plants aregiven to complete the picture.Triacca, Bianzone – Italy: 14th CENTURY MONASTERY, NOW WINE ESTATE AND AGEING CELLAR2.INTRODUCTIONWine has been produced for thousands of years throughout the entire Mediterranean basin and“Bacchanalia”, the big wine festivals, have been described by ancient writers.In addition, wine has always been the subject of trade among many nations, as proven byarchaeological findings from Greek and Roman vessels, carrying amphorae of wine, oil and grain,which sank in the Mediterranean Sea,.The wine trade is respected for its high quality wines, and this paper will show the strong role thatthe application of the most advanced technologies of cooling and heating now plays in achievingthis result.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES1/10

3.WINE PRODUCTION BY COOLING AND HEATING3.1.White winesMechanized cooling systems have already been used for making white wines for many years.Previously, vines producing prestigious grapes for white wines were cultivated almostexclusively in areas with moderate temperatures to avoid sudden temperature changes. Whitewine consumers are also moving towards full-bodied wines and, for this reason, vine growingfor white wine, has also moved further south.In these areas, however, temperatures at harvesting time are too high which prevents thewines from having an intense and persistent aroma.The harvested white grapes are delivered to the wineries wher e they are deposited in bigcollecting augers where they are pressed and stripped of the stalks and sent to the pressingmachine.During this phase, there is normally a considerable temperature drop so before arriving at theaugers the grapes go through headers to lower the temperature.Dry ice should be added to the grapes during transportation or failing that, in the augers onarrival at the winery. It’s evident that reducing the temperature immediately after picking isextremely important to safeguard the wine’s aroma.In prestige areas the grapes are collected in crates and then stored for a period of 3 -4 days,before pressing, in special warehouses with temperatures controlled between 6-9 C.A new technology using CO 2 has recently been introduced. This consists of freezing the grapesurface to preserve its physical and chemical characteristics.In white wine production, another widespread technique, hyperoxidation, has been recentlyintroduced. An extensive use of cooling is necessary for this process.The grapes are pressed immediately and the must is quickly cooled, and preserved at 3 -5 Cfor 6-10 days. After this period, the must is heated to 15-18 C and fermentation starts.A controlled temperature of 16-18 C for white wine making is essential.The production of sparkling wines, the Charmat method, with fermentation in an autoclave,must be controlled at a low temperature to obtain fresh wines rich in primary and secondaryaromas.The temperature control is also fundamental in the production of classic sparkling wines andChampagnes. Not all areas are like those in the Champagne region, where the most winerieshave caves or undergrounds tunnels where the natural internal temperature coincides with theoptimal temperature for wine preservation, both during fermentation and the long storage ofbottles waiting for the “disgorgement” and refilling before selling.3.2Rosé winesThe rosé wine making process is similar to that of white wine, as aroma and freshness are theirspecific characteristics. Red grapes are picked, stripped, pressed and stored in tanks, the mustremains in contact with the grape skins for only for few hours. It is immediately tapped to avoid theextraction of excessive tannin and color from the grapes. Controlled fermentation at 14-18 Cfollows until the end of alcoholic fermentation.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES2/10

3.3Red winesThe cooling system in red wines production has not been used much up to now. Mainly in hotclimate areas such as the south of Italy and other similar places throughout the world, strong redwines were mainly produced for blending rather than quality. Recently there has been an importanttrend change, and southern Italy is now oriented to producing high quality wines, and for thisreason, a rational and dedicated technique, where the temperature plays an important role, isnecessary for the production process.Recently, in Milan, a biennial show exhibiting tools and equipment for wine production has clearlyconfirmed that the most wine producers are equipped with a temperature control system.3.3.1 CryoextractionThis consists of the extraction of the varietal aromas from the pressed grapes before fermentation.The grapes are pressed, stripped, destalked and stored in the fermentation tank. The temperature ofthe grapes is lowered to 4-5 C for a period of 4-6 days and as a result the autochthon yeasts of thegrapes are quiescent due to the low temperature, while the aroma from the skin of pressed grapes istransferred to the must. After several days the fermentation starts raising the temperature and theselected yeasts are introduced.3.3.2 Controlled temperature in wine makingMuch heat is generated by the alcoholic fermentation and the yeast survives and works intemperatures not exceeding 31-33 C. At higher temperatures, there is the risk of fermentationstopping, which is the big problem for the winery technicians. It is quite difficult to restart analcoholic fermentation which has been stopped by too high a temperature, hence the importance ofcooling the fermentative mass. During the first few days this can be done by heat exchangers insidethe tanks, or even better by using double-wall tanks. In winery designing it is important to realizethat the bigger the capacity of the tank, the greater the cooling demand to maintain the temperature,as the heat produced by the fermentation is directly related to the quantity of the must.Triacca, Bianzone – Italy:“BARRIQUE” CELLAR FOR AGEING RED WINESTHE ROLE OF COOLING AND HEATING IN MODERN WINERIES3/10

4.TEMPERATURE ROLES IN WINE MAKINGRecently it has been noticed that winery technicians exploit the various alcoholic fermentationphases to extract aromas, anthocyanins, polyphenols, colors etc. at the best moment and mostconvenient temperature for each component to enhance the final product. In this way aromas areextracted when the must is cold before start of alcoholic fermentation. Removing the large quantityof grape seeds deposited in the bottom avoids the massive extraction of crude and unnecessarytannins after that the temperature is raised up to 42-44 C for a period of 8-12 hours to extract theanthocyanins. Then the temperature is reduced at 25-26 C, thus starting the regular alcoholicfermentation.Before the grape pressing the temperature is raised again to 34-36 C to extract, if required, anadditional quantity of polyphenols if the characteristic of wine requires it.Typical grapes must temperatures in wine productionRED WINECryoextractionColor extractionAlcoholic fermentationAdd. col. ExtractionMalolactic fermentationWine conservation 4/ 5 C 37/ 38 C 25/ 27 C 38/ 40 C 18/ 19 C 14/ 16 CROSE’ WINECryoextractionAlcoholic fermentationMalolactic fermentationWine conservation 4/ 5 C 14/ 16 C 17/ 18 C 12/ 14 CWHITE WINEHyperoxidationAlcoholic fermentationMalolactic fermentationWine conservation 4/ 5 C 14/ 16 C 17/ 18 C 12/ 14 CTriacca, Villa Di Tirano – Italy: FERMENTATION PLANTTHE ROLE OF COOLING AND HEATING IN MODERN WINERIES4/10

5.WINE MAKING PROCESS5.1Malolactic fermentationThe malolactic fermentation is the biodegradation of malic acid into lactic acid which frombiological point of view produces more stable wines (mainly red wines) with the correct acidity forthe taste. Bacteria that attack the malic acid increase and are active when the wine temperature is atleast 18 C. In double-wall tanks, a water-glycol solution at 20-22 C is circulating to maintain atemperature of 18-20 C inside the tank. As the chemical reaction is endothermic, a small amount ofheat is required.5.2Malolactic fermentation inhibitionIn the production of white and rosé wines malolactic fermentation is usually inhibited or stopped, asthis fermentation is the biodegradation of the malic acid in lactic acid and carbon dioxide, topreserve the acidity and freshness typical of these wines. Also, this process which in the past wasdone by adding large quantities of sulfur dioxide, is now done by cooling the mass thus avoidingthe a.m. biodegradation.5.3Wine’s tartaric stabilizationGenerally, wines, mainly those that are not aged, contain too much potassium. If bottled withoutremoving it, the excessive tartrates will turn into crystals. To avoid this visual defect, the wine ischilled before bottling. This entails dropping wine temperature to minus 2-3 C for approximately10 days., aiding the crystallization of tartrates by adding other crystals which work as crystallizationcenters.Today, stabilization is achieved by the so-called continuous method that consists of cooling thewine and adding crystals through a shell-and-tube heat exchanger, so that the newly generatedcrystals are immediately separated in a continuous process.In middle sized and small wineries, this process is done intermittently by the contact system,consisting of dropping the wine temperature close to 0 C, introducing the crystallizers and shakingthe wine continuously for about an hour in order to combine the wine with the small crystalsintroduced to generate new crystals: in this way, the potassium excess is stabilized.Red wine alcoholic fermentation:typical cycle13579THE ROLE OF COOLING AND HEATING IN MODERN WINERIES111315Days5/10

Explanatory comments of the cycle shown on the graphPOSITION 1Temperature of pressed grapes.POSITION 2The temperature of pressed grapes stored in a stainless steel, double-wall tank isdropped at 4-5 C and maintained for 4-6 days. During this period, the varietalaromas contained in the grape skin transfer to the must, and thus to the wine that willbe produced. This process is called cryoextraction: at the end of this phase, the usedgrapes contain an excess of tannin: it is possible to separate part of the grapes seedssettled on the bottom of the tank. Thus the tannin content is reduced before thefermentation phase.POSITION 3At the end of this phase the mass is heated up to 42-44 C for a period that variesbetween 8-15 hours depending on the quality of the grapes which are milledcontinuously, to avoid the cooked flavor, that could be caused by the excessiveheating of the mass close to the exterior of tank.The temperature of the heating solution circulating in the tank’s double-wall shouldnot exceed 48 C. During those 8-15 hours the colour from the grape skins includingall the constituents required for the finished product will be extracted. This processtakes place during the pre fermentation phase.POSITION 4After the programmed time, the temperature must be immediately reduced to 2425 C for the fermentation phase. With the addition of appropriate selected yeasts thisprocess lasts 2-3 days. This temperature must be maintained at this level, in order toavoid a vigorous fermentation at too high a temperature that could prejudice the winequality.POSITION 5If, at the end of the fermentation process, the product is low in tannin andpolyphenols, it is possible to restart the heating process up to 38-40 C. During thisshort phase additional polyphenols can be extracted from the previously fermentedmarc and grape seeds, to produce a longer lasting wine.Obviously, fermentation is not a mathematic process, but is based on the experience of the winerytechnicians who know the quality of the grapes, the seasonal trend, the type of wine required andthe market trends.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES6/10

6.FERMENTATION TANKSDe Franceschi, Bronzolo – FERMENTATION TANK - SECTIONModern tanks for wine production, technically called fermenters, shown in the diagram, areengineered with double wall and double external liquid circuit for refrigeration and heating,AISI 316 totally manufactured.Depending on the demand of the wine production cycle, the regulation valve opens or closes thecooling or heating circuit, automatically controlled by a centralized control panel.The cooling and heating sources are quite expensive but on the other hand the fermentation time isreduced. What is important is that the expertise of the winery technicians makes it possible tomanage the fermentation to follow the market trend and produce top quality wines.Obviously, even the most advanced technology is under human control and therefore it is up to theexpert to monitor the process, checking the fragrance and flavor, and deciding when to stop theprocess.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES7/10

7.CHILLING AND HEATING PLANTSMcQuay – AMMONIA SCREW LIQUID CHILLEREvery plant depends on the wine producers’ requirements as to the quantity, type and quality of thewine to be produced. Each installation should be engineered to achieve the correct balance of thecooling and heating capacity.Alcoholic fermentation corresponds to following exothermic chemical reaction:C6H12O62CH3CH2OH 2CO2 33 KcalFor example, a fermenter tank with 15.000 litres of must containing 220 grams of sugar per litre(molecular weight: 180), during the fermentation develops:220180x 33 x 1.163 x 15000 703.5 kWIn practice, about 47 kW for each 1000 Kg of must.The chiller employed during the wine processing (20-25 days a year) should also be used for the airconditioning of the wine cellar, where the finished wines are stored in oak casks for ageing.In this case, a controlled climate is absolutely necessary, with the temperature not exceeding 1214 C for white wines, and 14-16 C for red wines with humidity of about 40-60%.To avoid wasting energy, a correct calculation of wine chilling process and air conditioning loads isnecessary and highly recommended.The selection of the liquid chiller, which could be water or air cooled, depends on the location ofinstallation: for example, in areas like Northern Italy, with plenty of rivers, lakes and undergroundwaters, cooling towers are preferred, because they offer efficiency with a low kW input. For thewater-to-water system, an evaporative condenser instead of a cooling tower would be much moreefficient. In other areas, like Southern Italy, where water represents a problem, the only possiblesolution is to install air-cooled chillers, even if the total COP is quite low compared to the watercooled systems.Ammonia screw chillers are also suggested because of their efficiency, but the installation must becarried out in accordance with the safety regulations of relevant country.A control panel enables changing the temperatures setting point between approximately –15 C and 10 C, to comply with the different requirements of cooling for the wine production or for the cellar airconditioning.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES8/10

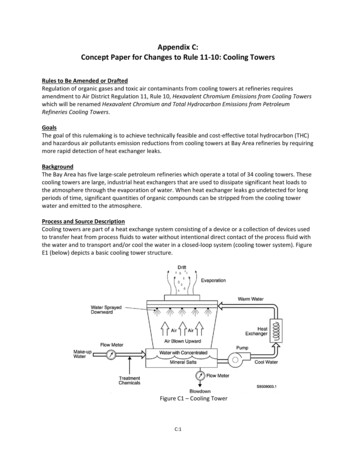

Since the first stage of wine-making process requires a huge cooling, the installation of cold storagetanks is recommended to provide the potential energy needed for the rapid cooling of the winetanks.The fluid normally used in wineries is a water-glycol solution of 30-35% with a freezing point of –25 C to protect the liquid chiller evaporator. With regard to pollution, there are no problems whenusing the glycol solution, as the wine fermentation tanks are built with double wall and theantifreeze liquid is circulating in the sealed cavity between them.It is strongly recommended to calculate the correct capacity required with respect to the quantity ofwine to be heated. Modern condensing gas fired boilers work very efficiently with low watertemperatures.The installation of a heat exchanger is necessary, preferably an AISI 316 plate type with the secondarycircuit filled with water-glycol solution, identical in percentage to the cooling circuit.This avoids the use of different liquids which would result in an increase in operational andmaintenance costs.The solution temperature in/out from the heat exchanger is quite low, usually between 40-45 C andthis facilitates every heat demand.To avoid health-related problems due to the big quantities of CO2 arising from fermentation, it isabsolutely essential to install an air exhaust duct system in the area of the fermentation tank,preferably using centrifugal fans with inverter-driven electric motors, to allow a continuousadjustment of the exhaust air flow according to the detected CO 2 quantities.COOLING – HEATING BASIC PLANTCOOLING TEMPERATURES RANGENORMALTARTARIC STAB.-5/0 C-7/-3 CHEATING TEMPERATURES RANGEGRAPES FERM.MALOLACTIC FERM.40/45 C21/22 CDOUBLE ERLIQUIDLIQUIDCHILLERCHILLERThe above considerations are intended to be only brief notes about the role of cooling and heating inwine production, and they do not claim to be exhaustive, since this is an extensive subject.THE ROLE OF COOLING AND HEATING IN MODERN WINERIES9/10

REFERENCESF.lli Triacca - Campascio-Graubünden - SWITZERLANDDe Franceschi - Bronzolo (BZ) - ITALYGiuseppe Arpelli – University of Bologna ITALYMichel Bernard Couasnon – Manager of CEICE, Puillac 33 FRANCEAUTHORSRenato Giovanni Merati, industrial consultant, Desio – Milan ITALY50 years worldwide experience in HVAC, Industrial Refrigeration, snow plants, skating rinks,steam boilers, power plants and refinery;Former President of AICARR (Italy);Member of ASHRAE (U.S.A.);Fellow of REHVA (EU).E-Mail: renato.merati@gmail.comDomenico Triacca, wine maker, Campascio-Graubünden SWITZERLAND47 years experience in wine production with wineries in Lombardy and Tuscany – ItalyTHE ROLE OF COOLING AND HEATING IN MODERN WINERIES10/10

THE ROLE OF COOLING AND HEATING IN MODERN WINERIES 2/10 3. WINE PRODUCTION BY COOLING AND HEATING 3.1. White wines Mechanized cooling systems have already been used for making white wines for many years. Previously, vines producing prestigious grapes for white wines were cultivated almost