Transcription

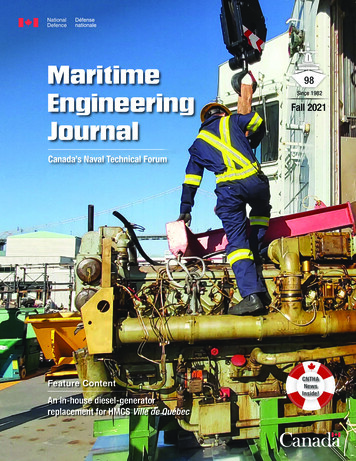

NationalDefenceMaritimeEngineeringJournal98Since 1982Fall 2021Canada’s Naval Technical ForumFeature ContentAn in-house diesel-generatorreplacement for HMCS Ville de QuébecCNTHANewsInside!

The Last CorvetteThe museum ship HMCS Sackville is safely back in the water following an amazing overhaul byFleet Maintenance Facility Cape Scott in Halifax, NS. The last remaining wartime Flower-classcorvette, managed and operated by the Canadian Naval Memorial Trust, underwent extensive hullrepairs to keep the ship afloat for the enjoyment of visitors for years to come.See News Briefs page 16Photo courtesy Sandy McClearn

MaritimeEngineeringJournal98(Established 1982)Fall 2021Commodore’s CornerA salute to the Royal Canadian Navy’s Marine Techniciansby Commodore Lou Carosielli, CD. 2ForumDirector General MaritimeEquipment ProgramManagementCmdre Lou Carosielli, CDSenior EditorCapt(N) Andrew Monteiro, CDChief of Staff MEPMNCM Editorial AdvisorsCPO1 Monika QuillanDGMEPM Unit ChiefCPO1 Herbert ConnorsDNPS 3-3-4, DGMEPMProject ManagerLCdr Samuel PoulinProduction Editor/EnquiriesBrian McCulloughMEJ.Submissions@gmail.comGraphic Designand Production Servicesd2k Graphic Design & Webwww.d2k.caTel. (819) 771-5710Maritime Engineering Journalon me-engineering-journal.htmlOur complete back catalogueis maintained blication.html and by theCanadian Naval TechnicalHistory Association at:http://www.cntha.ca/publications/m-e-j/Have Pipes, Will Travelby LCdr Rob Waller.3Feature ArticlesAfter Auxiliary Machinery Room Diesel-Generator Replacement onHMCS Ville de Québecby Lt(N) Michael McKenna .6A Land Based Test Capability for the Canadian Surface Combatant Projectby Stephen Harrison, Flavio Stasi and LCdr Yohan Desjardins .11BooksTitles of Interest.14News BriefsHMCS Sackville safely back in the water . 16HMCS Fredericton Hull Insert Repair — A Team Effortby Greg Stymest, FMF Cape Scott .17FMF Cape Breton docks USN submarine camelsby Brian McCullough, with Lt(N) Peter Summers and Ashley Evans . 20Your Navy Today – Featured Video. 22CNTHA NewsA Few Experiences of a Young Lieutenant(N) Naval Architectby Commodore (Ret’d) W.J. Broughton.23Staff from Fleet Maintenance Facility Cape Scott inHalifax remove the old MWM 602 diesel engine fromHMCS Ville de Québec's after auxiliary machinery room.(Photo courtesy FMF Cape Scott)The Maritime Engineering Journal (ISSN 0713-0058) is a NATO UNCLASSIFIED publicationof the Canadian Armed Forces, published by the Director General Maritime EquipmentProgram Management, 101 Colonel By Drive, Ottawa, Ontario, Canada, K1A 0K2. Viewsexpressed are those of the writers and do not necessarily reflect official opinion or policy.For all enquiries, including free subscriptions, please contact: MEJ.Submissions@gmail.com.To request a free subscription, change a delivery address, or cancel a subscription,please contact: MEJ.Submissions@gmail.com.

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021COMMODORE'S CORNERA salute to the Royal Canadian Navy’sMarine TechniciansBy Commodore Lou Carosielli, CDTCanadian Armed Forces photo by S1 Bryan Underwoodhe delivery in July of the second of theNavy’s Arctic and offshore patrol vessels fromIrving Shipbuilding—the soon-to-be-commissionedHMCS Margaret Brooke (AOPV-431)—reminds us that evenduring these stressful, uncertain times, the Royal CanadianNavy (RCN) still has a mission to fulfill in maintaining capablemaritime forces in support of Canadian security operationsanywhere in the world at any time.Like the decorated wartime RCN nursing sister inwhose honour the ship is named, the people charged withtaking our Navy’s ships to sea, and equally those whosupport the fleet from ashore, understand what it means todig deep when the challenges are many, and the pats on theback are seemingly few and far between. In this sense, theRCN is extremely blessed in having a naval technicalsupport community that is comprised of sailors, civilianemployees and defence partners who are dedicated totheir work, and who are extremely good at what they do.They know how to get on with the task at hand.Since then, MTAT has been extremely busy analyzingthe information it has gathered, and exploring initiatives—many of which are now underway—to lead the occupationtoward recovery. At the moment, the focus is on formulatingrecommendations specifically related to Mar Tech trainingand employment for a second briefing to CRCN this fall.While it would be easy to say that a “can-do” attitudecontributes greatly to our overall success, and leave it atthat, there is one segment of our Navy technical team thatdeserves recognition for going above and beyond: I amreferring to the non-commissioned members of the RCN’sMarine Technician (Mar Tech) occupation. These stalwart,talented engineering technicians operate and maintainsome of the most sophisticated equipment in the CanadianArmed Forces inventory, and they do so against a backdropof occupational and quality-of-life concerns stemming fromthe creation of the newly structured occupation in 2017.The new in-house Mar Tech Newsletter promises “open,honest, transparent communications about the trade,” andit is doing just that by encouraging candid feedback, andsharing people’s views and recommendations. By betterunderstanding the very real challenges being faced byindividual Mar Techs, we stand a better chance of reducingstressors, enhancing employment, improving quality of life,and encouraging retention so that our Marine Technicianscan enjoy fulfilling careers that offer reliable force sustainment for the RCN over the long term.In March of this year, the RCN stood up a full-timeMar Tech Action Team (MTAT) to address the challengesfacing the occupation. Through a well-received continuingseries of town hall meetings and one-on-one interviews,MTAT is engaging with members of the Mar Tech communityto hear their views on the issues that are affecting themthe most, and making note of their ideas for improvement.A summary of this activity, along with short-termrecommendations, formed the basis for an initial briefingmade to the Commander of the RCN (CRCN) last May.Maritime Engineering JournalSo here is a well-deserved Bravo Zulu to the Mar Techsof the Royal Canadian Navy, the people we depend onevery single day in our mission to deliver agile technical,materiel and personnel support to the fleet, both at sea andashore. Without the Marine Technicians, our warshipswould be unable to float, move and fight.2Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021FORUMHave Pipes, Will TravelPhotos courtesy the authorBy LCdr Rob WallerThe author as piper at the Virginia International Tattoo, Norfolk, VA, April 2016.In my first year at RMC, I actually played trumpet withthe college’s Brass and Reed band, and was able to takepart in our "Concert In Scarlets" trip to Victoria, BC inMarch 1998. It would prove to be a game-changer. Whilewe were billeted at Work Point Barracks, I have a distinctmemory of hanging out in the hallway of Maisonneuveblock with members of the RMC Pipes and Drums band.It occurred to me that they seemed to be having a lot offun, and also got to wear cool uniforms. Not long after wereturned to Kingston I met with their pipe major, and wassoon learning on a practice chanter. I never looked back, andam still piping 24 years later, mostly with military pipe bandswherever I happen to be posted. Over the years, I knew morethan a dozen other NTO pipers who came out of RMC."Choose a career, live the adventure!"Ihave to admit, the promise of a life of adventure thatwas advertised on the Canadian Armed Forces (CAF)recruiting poster was an allure that made me happyto give up some of my personal freedoms, and serve mycountry as a Maritime Engineer—a Naval TechnicalOfficer (NTO) in today’s Royal Canadian Navy (RCN).After almost a quarter-century of wearing a naval uniform,I can say that the promise was true, but not always in theway I expected. As I discovered early on, there are alternateways within the bounds of the CAF to travel to exoticplaces on the cheap, create lifelong friendships, and gain astorage locker full of cool stories. Some athletic-mindedmembers choose sports as their pathway, but I’m talkingabout how my passion for playing the bagpipes hasenhanced my naval career.After graduating, and while I was attending DalTechin Halifax, NS and completing my Applications course,I would take the bus across to the Dartmouth side everyTuesday to play with the 12 Wing Pipes and Drums atCanadian Forces Base Shearwater. Aside from performinglocally, being a volunteer in this organization took me tofar-off places such as Maxville, ON and Montreal, QCfor competitions. Also, as this aligned with the academictours that were part of the Applications course, in 2003a “dudelsacking” buddy and I were able to drive up toKingston for the weekend to attend the RMC Band’s50th anniversary celebrations.(Continues next page.)They say that if you love what you do, you’ll never worka day in your life. I have been privileged in that piping hastaken me to almost as many places as the Navy has. Unlikesome people who start learning the bagpipes at the earlyage of 8 or 9, I didn’t pick up a set of pipes until I went offto start my military education at Royal Military College(RMC) in Kingston, ON.Maritime Engineering Journal3Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021Upon getting posted to Victoria for my Phase VI training,I joined the Canadian Scottish Regiment (Princess Mary’s)Pipes and Drums (C Scot R)—the same regiment thatPiper James Richardson was a member of when he wasawarded the Victoria Cross for his bravery as a piper in thetrenches during the First World War. Sadly, he went out toretrieve his pipes that he had been forced to leave behind inthe field, and was never heard from again. It is his honouredlikeness that appears in the artwork for Piper’s Pale Alefrom Vancouver Island Brewery.Shortly after joining the band, I was thrilled to performwith them at a highland gathering in Pleasanton, California,and as I got attach posted to various ships on the West Coastto get my required 60 days of sea time, I was sure to bring mypipes along. I “fondly” recall playing on the bridge top ofHMCS Ottawa (FFH-341) to pipe us in during the long—very long—entrance to Pearl Harbor, Hawaii in 2004.Vancouver Island Caledonia Pipes and Drums "Tartan Day"performance, Victoria, BC, May 2015.Military Bands (FIMMQ), the Kincardine (Ontario)Highland Games in a quiet “Scottish” town on the shoresof Lake Huron, and performing for the Prime Minister,Governor General and thousands of Canadians everyCanada Day and Remembrance Day. Within DGMEPMlines, I also volunteered to provide some entertainmentduring the DGMEPM Change of Appointment ceremonybetween Cmdre Richard Greenwood and Cmdre Pat Finn.(At one time or another, I had the honour of piping for allthree naval Greenwood brothers, including Nigel.)One of the most significant events linking my two passionsof naval engineering and highland bagpiping happened in thesummer of 2004 as I was prepping for my Phase VI board inHMCS Winnipeg (FFH-338). The C Scot R Pipes and Drumshad been invited to perform in the Royal Edinburgh MilitaryTattoo, and while my initial response was to stay the courseand do my board on time, my piping and NTO mentor,then Cdr Rick Houseman, chose to speak to my ship’scommanding officer, Cdr Kevin Greenwood, about thisonce-in-a-lifetime opportunity. I was duly “convinced” torepresent the CAF for a month in Scotland.After heading back to the West Coast at the end of2010 for my Combat Systems Engineering Officer (CSEO)tour in HMCS Algonquin (DDG-283), I found my free timecut to a minimum, so didn’t get to contribute with C Scot RPipes and Drums as much as I would have liked until I wasposted to New Capability Introduction (West) (NCI(W))in the summer of 2012. When Algonquin deployed forOperation Caribbe in 2011, I played for our onboard WEngTech transition ceremony—complete with an Up Spirits wetfrom the commanding officer. I rejoined C Scot R just intime to take part in the Regiment’s centennial celebration,which included a long parade march up Douglas Street.It was a truly amazing experience, but it required a fairamount of perseverance. Since my board wasn’t going away,I requested access to a classroom at Redford Barracks whereI did practice boards in an empty room all day, ate supper,and then prepped with the band for our performances until11 p.m. We would socialize afterward until about 2 a.m., andthen it was up at 7 a.m. to start the routine all over again.As things turned out, I was able to come home a few daysearly and successfully challenge my board. My last duty as amember of HMCS Winnipeg was to pipe the ship’s companythrough Dockyard Esquimalt as they marched to theirworkups lectures at the Chief & Petty Officers Mess.It was at this time that I also started piping for mysupper at the annual West Coast NTO and WeaponsEngineering non-commissioned member mess dinners,and entertaining the public doing Symphony Splash inVictoria Harbour, Tartan Day parades and RemembranceDay ceremonies. In 2015, several friends and I started ourown Vancouver Island Caledonia Pipes and Drums band,and got a few performances under our belt before I wasposted back to the National Capital Region (NCR) thatsummer. I was left with fond memories, akin to starting agarage band with your buddies and seeing it take off.When I was posted to DGMEPM in Ottawa, ON in2006, I looked at the many local pipe band options andchose to play with the Air Command Pipes and Drums,practising out of CFB Uplands. While I was learning theropes of project management and growing my family,I regularly got gussied up to represent the CAF at differentevents, including the Quebec City International Festival ofMaritime Engineering Journal4Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021The author with other brightly costumed performers at the 2018 Virginia International Tattoo.Since January 2019, I have been playing with theRCMP Pipes and Drums, an activity that has been difficultbut not impossible during the COVID-19 pandemic. I gotto don my fourth pipe band uniform when I played for aRemembrance Day ceremony at a group home last year.My most recent in-person piping engagement was a sadaffair in November 2020, saying goodbye to our brotherCSE, LCdr Daniel Kim, who left us far too soon at theage of 44.The band continued to grow, and won the Grade 3 PipeBand Competition at the Victoria Highland Games in 2017.Returning to the NCR in 2015, I rejoined the oldAir Command band under their new name, the RoyalCanadian Air Force Pipes and Drums, and continued myhabit of being the piper for the NCR Naval Technical MessDinner, the ADM(Mat) Mess Dinner, and for wardroomRobbie Burns Day events. Band trip highlights includedgetting to perform in the Virginia International Tattooin 2016 and 2018, and repeating what I had done over adecade earlier when I was still at RMC by travelling tothe US Naval Academy and West Point to conductmentorship sessions with their pipers and drummers.As part of an overall work/life balance plan, I believeplaying bagpipes is a great extracurricular pastime that issteeped in military tradition, rooted in Canadian culture,and lets me express myself creatively while building strongfriendships and treasured memories. Pipers might not allbe high-calibre athletes, but we clean up nicely in a kiltand know how to have a good time. Looking back, I amthankful that piping has enabled me to visit some exoticplaces in support of the RCN and CAF, and collect perdiem while doing it. It continues to be one of my ticketsto adventure as a career naval officer.Have Pipes, Will Travel!LCdr Waller is currently Director Defence ProgramCoordination 2-4 (DDPC 2-4), Chief of Program (C Prog),with the Canadian Armed Forces in Ottawa.Piping mentor Rick Houseman and the author in theirCanadian Scottish Regiment regalia in 2005.Maritime Engineering Journal5Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021FEATURE ARTICLEAfter Auxiliary Machinery Room Diesel-GeneratorReplacement on HMCS Ville de QuébecBy Lt(N) M.E. McKenna, Fleet Maintenance Facility Cape ScottDuring preparations for the Halifax-classmid-life refits, several studies were conductedby the Director Maritime Equipment andProgram Management (DMEPM) to assess the feasibilityof replacing the aging MWM 602 diesel engines used forelectrical power generation on board Royal CanadianNavy frigates. Maintenance costs for these engines hadbeen steadily rising, and their age was beginning to causeparts obsolescence issues. After considering the economicchallenges and decreasing engine availability, a decisionwas made in 2012 to upgrade the MWM 602 to a moremodern engine.Following a series of consultations with industry,a request for proposals was released in 2014, seekingindustry bids to replace the diesel-generator (DG) sets onboard the 12 Halifax-class frigates, provide equipment andinstruction for training purposes, and deliver in-servicemaintenance support to the Department of NationalDefence (DND). After reviewing submissions from threebidders, in June 2015 a contract was awarded to HewittEquipment (now Toromont Industries) to replace theexisting DGs with C32 ACERT Caterpillar engines,coupled to Hitzinger generators. Additional projecthistory, and an overview of the procurement contractwere discussed in MEJ 92.The level of effort required to replace each ship’s fourDG sets—two each in the forward and after auxiliarymachinery rooms—meant that the job could only be feasiblyscheduled during a docking work period (DWP). The firstDG replacements took place on the West Coast in 2017,and were completed by Victoria Shipyards Ltd. Subsequentinstallations for the East Coast fleet were conducted byIrving Shipbuilding Inc. (ISI). On both coasts, the localfleet maintenance facility (FMF) provided assistance andtechnical support as required, but the heavy productionwork was completed by the contracted repair facility.Figure 1. FMFCS personnel remove the soft patch intoHMCS Ville de Québec’s after auxiliary machinery room (AAMR).ship would have to travel up the St. Lawrence River toreach the shipyard, and then sail back under its own poweron completion of the DWP. This was a significant deviationfrom previous frigate docking work periods that took place inthe ships’ local home port areas of Halifax, NS or Esquimalt,BC, and would complicate an already challenging workperiod. One of the biggest risks with this was the plannedDG replacement.During the spring of 2019, DND was planning theupcoming DWP for HMCS Ville de Québec (FFH-332),which at the time was scheduled to take place at the Davieshipyard in Lévis, Québec. This meant that the Halifax-basedMaritime Engineering Journal6Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021gaining additional experience with the new equipmentahead of any future planned maintenance, or unscheduledmaintenance during a deployment.Although a decision was subsequently taken toconduct Ville de Québec’s DWP locally in Halifax, DMEPMauthorized FMFCS to replace the two diesel-generatorsin the ship’s after auxiliary machinery room (AAMR).FMFCS immediately created a dedicated multifunctionalproject team comprised of members from multipleproduction shops, including Internal Combustion Engines,Electrical, Pipe Fitters, Plate, Sheet Metal, MechanicalFitters, Shipwrights and Rigging Loft.Virginia Nash, a member of the sheet metal shop, waschosen as the team leader for the project. Her role involvedthe coordination of approximately 20 personnel on aday-to-day basis, along with overall project oversight.“The Ville de Québec DG change-out was by far the mostexciting and challenging task to date in my 12 years withFMFCS,” Nash said. “When I was asked to lead this team,I was nervous about taking on such a large engineeringchange. However, knowing the capabilities and years ofexperience of our technicians, I was confident we couldcomplete this huge task in a time-sensitive manner.”Although preparatory work began in September 2020,the AAMR DG replacement began in earnest in November2020. The first phase of the project involved removing softpatches and preparing the access route into the AAMR(Figure 1), then stripping away the old engine intakes, exhaustsand about a hundred metres of heavy electrical cabling. Thisinvolved hundreds of person-hours from the multidisciplinaryteam to prepare the space for the larger job to come.Once all of the preliminary removals were complete,the next major task was to disassemble and remove the oldengine enclosures, along with the MWM 602 engines andgenerators (Figure 2). Although FMFCS had replaced dieselengines and generators in the past, complete disassemblyand removal of the DG enclosures was far less common.Nevertheless, the multidisciplinary team at FMFCS embracedthe challenge. The sheet metal shop took the lead in removingthe old enclosures, while the internal combustion engine shopfocused on disconnecting, disassembling and removing theold DGs. The pipe shop removed the old fine-water spraysystem, while the rigging shop assisted throughout tosafely lift equipment out of the ship.Figure 2a and b. A legacy MWM 602 engine is rigged and ready tobe lifted out of the AAMR, and then craned ashore.Unlike Victoria Shipyards and ISI, Davie Shipyard hadnever replaced a DG set on board a Halifax-class frigate.To reduce the risk, FMF Cape Scott (FMFCS) approachedDMEPM and proposed that the diesel-generators bereplaced before the ship departed for the shipyard at Lévis.FMFCS had substantial experience replacing dieselgenerators (albeit not entire DG engine enclosures), andwas very familiar with the DG replacement project throughits supporting role during previous change-outs at theIrving shipyard. This would be a valuable opportunity todemonstrate the strategic capability of the FMFs, whileMaritime Engineering Journal(Continues next page.)7Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021Figure 4. A new Caterpillar CAT ACERT32 engine, still in itsprotective wrap, is rigged into the AAMR. Note the tight clearances.After the old diesel-generators were removed, the teamturned its attention to the concrete base and DG mountingarrangement. Since the lower raft-mount assemblies usedto support the old DGs would not meet the RCN’s shockstandard with the new diesel-generator sets installed, newassemblies had to be specially designed. Once the old DGrafts were removed, the old mount assemblies connectingthe engines’ concrete bases to the ship’s hull, along with themounts connecting them to the DG raft were replaced bythe mechanical fitter shop. This experience proved to beincredibly valuable when FMFCS personnel were latercalled on to assist Davie Shipyard with another DGreplacement aboard HMCS St. John’s (FFH-340).Following delivery of the new generator sets toFMFCS, the internal combustion engine shopmeticulously disassembled them just enough for riggingand eventual installation on board (Figures 3, 4 and 5).Once the AAMR was prepared, the shop rebuilt the newengines inside the space with assistance from the riggingshop and the mechanical engineering section. The sheetmetal shop assembled the new acoustic enclosures(Figure 6), while the pipe fitters and welding shopinstalled the new NOVEC fire-suppression system.Because the Caterpillar ACERT 32 engine has adifferent intake and exhaust configuration than theold MWM 602 engine, new engine intake and exhaustducting had to be fabricated (Figure 7). To make this newductwork, jigs were initially constructed in the AAMR todetermine the distances and angles from the engine flangeto the existing ducting that could be retained. Once thenew pathway had been established, each segment of thenew intake and exhaust ducting was fabricated by theFigure 3a and b. A new Hitzinger generator is moved through theship’s hangar, and lowered into the AAMR.Maritime Engineering Journal8Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021Figure 5. A new engine and generator are positionedon the machinery raft.Figure 6. In the foreground, the new engine enclosurescan be seen mid-assembly.FMFCS plate shop and connected by the welding shop.Post-fabrication, it was rigged into place, and then connectedto the engine on newly installed support brackets.technical support during the engine reassembly and mountreplacement, while the electrical and control systemsengineering sections verified cable installations, andcompleted early-stage set-to-work activities includingsignal verifications, testing of ancillary equipment, andrunning the engine to prove the safety systems.Once the DGs were assembled in the AAMR, the nextmajor step was the installation of new electrical cablingand terminations. The cable replacement work was oneof the most labour-intensive portions of the overall DGreplacement project, and required substantial coordinationamong the various shops to ensure that the requisitepreparatory work and installations were completed beforethe terminations and cables were installed. Thanks todiligent project management, on-site coordination, and theextensive experience of the cabling shop, FMFCS was ableto complete the cable runs on schedule.All consumable parts and supplies not provided by theproject were acquired by FMFCS’s materiel acquisition,procurement and supply section following establishedGovernment of Canada procurement policies. Throughoutthe DG replacement project, the FMFCS project teamwas supported by personnel from the Assistant DeputyMinister Materiel organization. Brant Frenette, theDMEPM Major Surface Combatant coastal contractcoordinator who has been heavily involved in all East CoastDG replacements, had some positive feedback regardingboth the quality of the FMFCS trades work, and thesmooth coordination and oversight by the FMFCS team.In addition to the hands-on work completed bythe production department, the FMFCS planning,procurement and engineering departments were alsoinstrumental in the successful completion of this project.The mechanical engineering section was able to provideMaritime Engineering Journal(Continues next page.)9Canada’s Naval Technical Forum

MARITIME ENGINEERING JOURNAL NO. 98 – FALL 2021power to ship’s services, even though at the time the shiphad two different versions of the integrated platformmanagement control system installed on board. Theset-to-work and other commissioning trials will beconducted once the two DGs in the forward auxiliarymachinery room have been installed by ISI.Although some work remains to be done before the shipis returned to the RCN, by the time this article was beingdrafted, FMFCS had invested some 10,000 person-hoursin preparatory and production work on Ville de Québec’sAAMR DG replacement. The total cost for this wasapproximately 1.35 Million, which is less than theGovernment of Canada has historically paid to commercialshipyards to reach the same stage of work.Beyond the financial considerations, this project hasbeen a great opportunity for FMFCS to gain furtherexperience with the new diesel-generators, whilesimultaneously demonstrating the shipyard’s importantstrategic capabilities to the RCN. The teamwork anddedication demonstrated by all personnel involved in theAAMR DG replacement has been commendable, whilethe experience gained during this project will be incrediblyuseful moving forward, if and when FMFCS is required tocomplete major DG repairs in a deployed setting.Figure 7. A portion of the new engine intake and exhaustfabricated by Fleet Maintenance Facility Cape Scott.By the end of March 2021, FMFCS had completed themajority of production work required to replace the twodiesel-generators in Ville de Québec’s AAMR, and care andcustody of the ship was transferred to Irving Shipbuildingfor the remainder of the DWP. During the short transit tothe Irving yard, one of the new DGs was used to supplyOver the course of the project, FMFCS has proventhat it has the experience and technical skillsets requiredto successfully complete major engineering changes thathave traditionally been contracted to non-DND shipyards.This capability will undoubtedly improve the operationaleffectiveness of the RCN in the years to come.Lt(N) M.E. McKenna is the Deputy Marine SystemsEngineering Officer at FMF Cape Scott in Halifax, NS.Submissions to the JournalThe Journal welcomes unclassified submissions in English or French.To avoid duplication of effort and ensure suitability of subject matter,contributors are asked to first contact the production editor atMEJ.Submissions@gmail.com.Maritime Engineering Journal10Canada’s Naval Technical Foru

Maritime Engineering Journal. 2. Canada's Naval Technical Forum. By Commodore Lou Carosielli, CD. COMMODORE'S CORNER. A salute to the Royal Canadian Navy's . Marine Technicians. T. he delivery in July of the second of the . Navy's Arctic and offshore patrol vessels from Irving Shipbuilding—the soon-to-be-commissioned HMCS . Margaret Brooke