Transcription

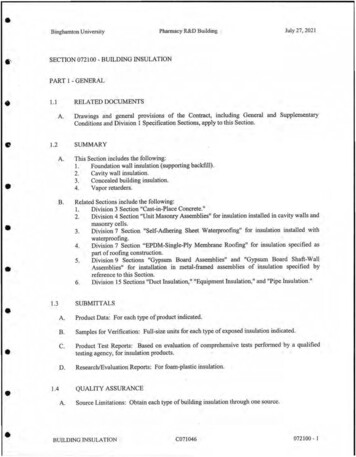

Binghamton UniversityPhamlSCY R&D BuildingJuly 27, 2021SECTION 072100 · BU1LDrNG rNSULATIONPART 1 . GENERAL RELATED DOCUMENTSl.lA.Drawings and general provisions of the Contract, including General and SupplementaryConditions and Division 1 Specification Sections, apply to this Section.1.2SUMMARYA. B. This Section includes the following:I.Foundation wall insulation (supporting backfiU)2.Cavity walJ insulation.3.4.Concealed building insulation.Vapor retarders.Related Sections include the following:1.Division 3 Section "Cast-in-Place Concrete."2.Division 4 Section "Unit Masonry Assemblies" for insulation installed in cavity walls andmasonry cells.3.4.5. 6.1.3 Division 7 Section "Self-Adhering Sheet Waterproofing" for insulation installed withwaterproofmg.Division 7 Section " EPDM·Single·Ply Membrane Roofing" for insulation speci fied aspart of roofing construction.Di vision 9 Sections "Gypsum Board Assemblies" and "Gypsum Board Shaft·WallAssemblies" for installation in metal·framed assemblies of insulation specified byreference to this Section.Divjsion IS Sections "Duct lnsulation/, "Equipment Insulation," and "Pipe Insulation ."SUBMmALSA.Product Data: For each type of product indicated.B.Samples for Verification: Full-size units for each type of exposed insulation indicated.C.Product Test Reports: Based on eva luation of comprehensive tests perfonned by a qualifiedtesting agency, for insulation products.D.Research/Evaluation Reports: For foam-plastic insulation .QUALITY ASSURANCE1.4A.Source Limitations: Obtain each type of building insulation through one source.BUILDING INSULATIONC07l046072 100 - 1

Pharmacy R&D BuildingBinghamton UniversityB. Fire-Test-Responsc Characteri stics: Provide insulation and related materials with the fire-testresponse characteristics indicated, as detennined by testing identical products per test methodindicated below by UL or another testing and inspecting agency acceptable to authorities havingjurisdiction. Identify materials with appropriate markings of applicable testing and ng Characteristics: ASTM E 84.Fire-Resistance Ratings: ASTM E 119.Combustion Characteristics: ASTM E 136. DELIVERY, STORAGE, AND HANDLINGA.PrQtect insulation materials from physical damage and from deterioration by moisture, soiling,and other sources. Store inside and in a dry location. Comply with manufacturer's writteninstructions for handling, storing, and protecting during installation.B.Protect plastic insulation as follows:1.2.3.Do not expose to sunlight, except to extent necessary for period of instaUation andconcealment.Protect against ignilion at all times. 00 not deliver plastic insulating materials to Proj ectsite before installation time.Complete instal lation and concealment of plastic materials as rapidly as possible in eacharea of construction . PART 2 - PRODUCTSMANUFACTURERS2.1A.Available Manufacturers: SubJect to compliance with requirements, manufacturers offeringproducts that may be incorporated into the Work include, but are not limited to, the fo llowing:B.Manufacturers:following:Subject to compliance w ith requirements, provide products by one of the1.Extruded-Po lystyrene Board insulation:Dow Chemica l Company.a.Owens Conting.b.Tenneco Building Products.c.2.Polyisocyanurate Board insulation:Apache Products Company.a.Celo tex Corporation.b.Johns Manville Corporation.c.3.Glass-Fiber ln sulation:CertainTeed Corporation.a.10lms Manville Corporation.b.BU ILDING INSULATIONC07 1046 072100 ·2

c.2.2 Owens Coming.General : Provide insulating materia1s that comply with requirements and with referencedstandards.J, Extruded-Polystyrene Board Insulation: ASTM C 578. of type and density indicated below,with maximum flame-spread and smoke-developed indices of 75 and 450, respectively.C,Molded-Polystyrene Board Insulation: ASTM C 578, of type and density indicated below, withmaximum flame-spread and smoke-developed indices of75 and 450, respectively:D.Type I, 0.90 Ib/eu. ft .Faced, Glass-Fiber Blanket Insulation: ASTM C 665 , Type III (blankets with reflectivemembrane facing) , Class A (membrane-faced surface with a flame-spread index of 25 or less);Category I (membrane is a vapor barrier), fa ced with foil-scrirn-kraft. foil -scrim, or foil-scrimpolyethylene vapor-retarder membrane on I face.AUXILIARY INSULATING MATERJALS2.3 Prefonned Units: Sizes to fit applications indicated; selected from manufacturer'sstandard thicknesses, widths, and lengths.B.I.A.Adhesive for Bonding lnsulation: Product with demonstrated capability to bond insulationsecurely to substrates indicated without damaging insu lation and substrates.B.Protection Board: Premolded, semirigid asphalt/fiber composition board, 114 inch thick, fonnedunder heat and pressure, of standard sizes.2.4INSULATION FASTENERSA.Available Products:Subject to compliance with requirements, products that may beincorporated into the Work include. but are not limi ted to, the following:B.Products: Subject to compliance with requirements, provide one of the following: 1. 2.Adhesively Attached, Spindle-Type Anchors;a.h.c.AGM Industries, Inc.; Series T TACTOO Insul-Hangers.Eckel Industries of Canada Limitcd; Stic- Klip Type N Fasteners.Gemco; Spindle Type.Adhesively Attached, Angle-Shaped , Spindle-Type Anchor:a.3. July 27, 2021INSULATING MA TERlALSA. Pharmacy R&D BuildingBinghamton UniversityGemco; 90-Degree Insulation Hangers.Insu lation-Retaining Washers:BUILDING INSULATIONC071046072100· )

Binghamton Universitya.b.c.d.e.4.b.c.2.AGM Industries, Inc.; TACTOO Adhesive.Eckel Industries of Canada Limited; Stic-Klip Type S Adhesive.Gemco; Tuff Bond Hanger Adhesive.Plate: Perforated galvanized carbon-steel sheet, 0.030 Inch thick by 2 inches square.Spindle: Copper-coated,low carbon steel, fully annealed, 0.105 inch in diameter, lengthto suit depth of insulation indicated.Angle: Formed from O.030-inch- thick, perforated, galvanIzed carbon-steel sheet witheach leg 2 inches square.Spindle: Copper-coated, low carbon steel, full y annealed, 0.105 inch in diameter, lengthto suit depth of insulation indicated. Insulation-Retaining Washers: Self-locking washers formed from O.OI6-ioch- thick galvanizedsteel sheet, with beveled edge for increased stiffness, sized as required to hold insulationsecurely in place, but not less than 1-1 /2 inches square or in diameter.J.Protect ends with capped self-locking washers incorporating a spring steel insert toensure permanent retention of cap in the following locations:a.b.c.d.F. Gemco; Clutch Clip.Adhesively Attached, Angle-Shaped, Spindle-Type Anchors: Angle welded to projectingspindle; capable of holding insulation of thickness indicated securely in position indicated withself-locking washer in place; and complying with the following requirements:I.E.Gemco; Dome-Cap.Gemco; R-150.Gemco; S-1 50.'Adhesively Attached, Spindle-Type Anchors: Plate welded to projecling spindle; capable ofholding insulation of thickness indicated securely in position indicated with self-locking washerin place; and complying with the following requirements:1.2.D.AGM Industries, Inc.; RC 150.AGM Industries,Inc. ; Se 150. Anchor Adhesives:a.C.July 27, 2021Insulation Standoff:a.5.Phannacy R&D BuildingCrawlspaces.Ceiling plenums.Attic spaces.Where indicated. Insulation Standoff: Spacer fabricated from galvanized mild-steel sheet for fitting over spindleof insulation anchor to maintain air space of dimension indicated between face of insulatio n andsubstrate to which anchor is attached .1.Air Space: 2 inches.BUILDrNG INSULATIONC071046

Binghamton UniversityG. Pharmacy R&D Buildin&July 27, 2021Anchor Adhesive: Product with demonstrated capability to bond insulation anchors securely tosubstrates indicated without damaging insulation, fasteners , and substrates.PART 3 - EXECUTION EXAMINATION3. 1 A.Examine substrates and conditions, with Installer present, for compliance with requirements forSections in which substrates and related work are specified and other conditions affectingperfonnance.B.Proceed with installation only after unsatisfactory conditions have been corrected.3.2 PREPARATIONA.Clean substrates of substances harmful to insulations or vapor retarders, including removingprojections capable of puncturing vapor retarders or of interfering with insulation auachment.B.Close off openings in cavities receiving poured-in-place insulation to prevent escape ofinsulation.Provide bronze or stainless-steel screens (inside) where openings ust bemaintained for drainage or ventilation.3.3 INSTALLATION, GENERALA.Comply with insulation manufacturers written instruqtions applicable to products aDdapplication indicated.B.Install insulation that is undamaged, dry, and unsoiled and that has not been left exposed at anytime to ice and snow.c.Extend insulation in thickness indicated to envelop entire area to be insulated. Cut and fittightly around obstructions and fill voids with insulation. Remove projections that interferewith placement.O.Water-Piping Coordination: If water piping is located on inside of insulated exterior walls,coordinate location of piping to ensure that it is placed on wann side of insulation and insulationencapsulates piping.E.Apply single layer of insulation to produce thickness indicated, unless multiple layers areotherwise shown or required to make up total thickness. 3.4 INSTALLATION OF GENERAL BUILDING INSULATIONA.Apply insulation units to substrates by method indicated, complying with manufacturer's writteninstructions. If no specific method is indicated, bond units to substrate with adhesive or usemechanical anchorage to provide pennanenl placement and support ofunils.BUILDING INSULATIONC07 1046072100 - 5

Binghamton UniversityPharmacy R&D BuildingJuly27 , 2021B.Seal joints between closed-cell (nonbreathing) insulation units by applying adhesive, mastic, orsea lant to edges of each unit to form a tight seal as units are shoved into place. Fill voids incompleted installation with adhesive, mastic, or sealant as recommended by insulationmanufacturer.C.Set vapor-retarder-faced units with vapor retarder to warm side of construction, unlessotberwise indicated. Do not obstruct ventilation spaces, except for firestopping.I.3.5Tape joints and ruptures in vapor retarder, and seaJ each continuous area of insulation tosurrounding construction to ensure airtight installation.INSTALLATION OF VAPOR RETARDERSA.General: Extend vapor retarder to extremities of areas to be protected from vapor transmission.Secure in place with adhesives or other anchorage system as indicated. Extend vapor retarder tocover miscellaneous voids in insulated substrates, including those fiU ed with loose-fiberinsulation.8.Seal vertical joints in vapor retarders over framing by lapping not less than two wall studs.Fasten vapor retarders to framing at top, end, and bottom edges; at perimeter of wall openings;. and at lap joints. Space fasteners 16 inches o.c.C.Seal overlapping joi nts in vapor retarders with adhesives or vapor-retarder tape according tovapor-retarder manufacturer's instructions. Seal butt joints and fastener penetrations witbvapor-retarder tape. Locate all joints over framing members or other solid substrales.D.Finn ly attach vapor retarders to substrates with mechanical fasteners or adhesives asrcconunended by vapor-retarder manufacturer.E.Seal joints caused by pipes, conduits, electrical boxes, and similar items penetrating vaporretarders with vapor-retarder tape to create an airtight seal between penetrating objects alldvapor retarder.F.Repair any tears or punctures in vapor retarders immediately before concealment by other work.Cover with vapor-retarder tape or another layer of vapor retarder.3.6 PROTECTIONA.Protect installed insulation and vapor retarders from damage due to hannfu1 weather exposures,physical abuse, and other causes. Provide temporary coverings or enclosures where insulationis subject to abuse and cannot be concealed and protected by pennaneol constructionimmediately after installation. END OF SECTION 07210 BUUDING INSULATIONC071046

Binghamton University Pharmacy R&D Building July27, 2021 B. Seal joints between closed-cell (nonbreathing) insulation units by applying adhesive, mastic, or sealant to edges of each unit to form a tight seal as units are shoved into place.Fill voids in completed installation with adhesive, mastic, or sealant as recommended by insulation