Transcription

2011 American Control Conferenceon O'Farrell Street, San Francisco, CA, USAJune 29 - July 01, 2011A Model Predictive Controller of Plastic Sheet Temperature for aThermoforming ProcessMd Muminul Islam Chy, Benoit Boulet, Senior Member, IEEE, and Ahmad HaidarAbstract— This paper presents a method to control thesurface temperature of a plastic sheet using model predictivecontrol (MPC). Although control techniques have beendeveloped for the heating phase of the thermoformingprocess, oven heater temperatures in the thermoformingindustry are still largely adjusted by trial and error based onthe experience of the operator. MPC is one of the advancedmethods for process control that has been used in differentplants since the 1980s. Even though the MPC controller canhandle a multivariable process, the large number ofcomputations makes it difficult to apply to large systems suchas multi-zone temperature control in a thermoformingmachine. In this paper, the design of a model predictivecontroller is reported and implemented on a complexthermoforming oven with a large number of inputs andoutputs for precise control of sheet temperatures under hardconstraints on heater temperature and their rates.PI. INTRODUCTIONLASTIC products are increasingly supplantingproducts made of conventional and expensivematerials such as aluminum, glass, wood and paperbecause of their numerous advantages. This encouragesresearchers to develop cost-effective and accuratecontrollers for polymer forming processes [1-6]. Thethermoforming process consists of three phases, namelyheating, forming, and solidification. The first and mostimportant part in thermoforming is heating the sheet to thesoftening temperature, which is the heating phase. Asheating is the first phase of the process, the remainingphases depend on the outcome of the heating phase.At present, in some cases standard proportionalintegral-derivative (PID) controllers are used. But thistype of controller cannot handle process constraints suchas the maximum and minimum heater temperatures, aswell as limited heating and cooling rates of the heaters.Because of the limited heating and cooling rate, it istypically observed that the heaters fail to track the controlinputs from the controller. Moreover, PID controllers donot take into consideration the model information tocalculate the optimal control input. PID controllers alsohave a serious drawback in controlling an MIMO systemas the inverse heating problem (IHP) has to be solved inreal time to decouple the system. Even though PIDcontrollers usually work well in near steady-stateconditions, the plastic sheet will melt before it reachessteady state, forcing the controller to operate in transientcondition within the cycle time [8]. Some researchers haveManuscript received September 27, 2010. This paper was supported inpart by the Natural Sciences and Engineering Research Council ofCanada.M. M. I. Chy, B. Boulet and A. Haidar are with McGill University’sCentre for Intelligent Machines, 3480 University Street, Montreal,Quebec, Canada H3A 2A7. (email: benoit.boulet@mcgill.ca)978-1-4577-0079-8/11/ 26.00 2011 AACCdeveloped cycle-to-cycle control techniques to control thethermoforming process [6,9].The idea is to use information from past cycles to help theclosed-loop system better track the desired trajectoryacross cycles. Control during sheet reheat is alsocomplicated by the fact that there is a high level ofuncertainty surrounding the process, particularly with thematerial properties. The fact that this is a multi-input,multi-output (MIMO) problem with a high degree ofcoupling between inputs and outputs also talconditions may change between cycles because of thenonlinearity and time dependency of the system that makethe controller delay in achieving the correct input signal.Sometimes a cycle-to-cycle controller converges veryslowly resulting in lots of discarded parts.MPC has some nice features. For example, it canautomatically compensate for process interaction andmeasure the disturbances as well as handle difficultprocess dynamics, e.g., dead-time dominant. Anotherimportant advantage of this type of control is its ability tocope with hard constraints on controls and states. So MPCcan optimize the performance by allowing for operationclose to the system constraints.An MPC predicts future control inputs solving theoptimization problem over an output horizon. Thisinvolves the minimization of a cost function using themodel of the system at each sampling instant. Thecomputation of the optimization problem at everysampling instant may require complex calculationsdemanding a very fast processor [10]. Due to the onlineoptimization at every sampling instant, MPC has not beenan effective technique to deal with large multivariableconstrained systems that increase computationalcomplexity in solving the optimization problem.Moreover, although several issues like stability, feasiblyand performance of linear MPC control are welldeveloped and understood [11, 12], much work needs tobe done in the field of nonlinear MPC to make it popularin industry. Thus, the large system size and the presenceof nonlinearities in the heating phase of thermoformingseem to have discouraged control engineers from usingoptimal control techniques for this kind of system.Recently, some works [13-16] have developed explicitsolutions of the optimization problem and proposed a newframework to deal with a nonlinear system as acombination of piecewise affine hybrid systems. Theseresults extend the applicability of the MPC controller tolow-cost, slow processors and improve softwareadaptability and ratability in real-time implementation.Multi-parametric quadratic programming helps in solving4410

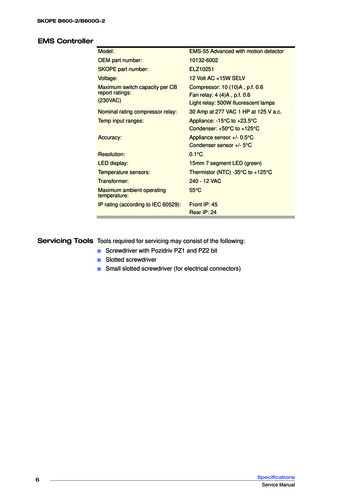

the model predictive optimization problem offline whichreduces the real-time computational burden of thecontroller. Thus, in this paper, we explore MPC using theexplicit solution of the optimization problem fortemperature control of a thermoforming machine. Insection II, we introduce MPC for controlling the processwhereas in section III and IV, we discuss the multiparametric quadratic programming used to solve theonline optimization with an offline strategy in thedevelopment of MPC for the heating phase ofthermoforming process. Section V reviews the model ofthe heating phase whereas in section VI, a multiparametric MPC is developed for the heating phase of thethermoforming process. The performance of the controlleris investigated thereafter.PHASE OF THERMOFORMINGMPC is a good choice for controlling the heating phase.Although the heating phase of thermoforming machines isa slow process, the number of system equations is highwhen multiple sensors are used. Thus, much computationand expensive hardware is required to implement MPC forthe system due to the online minimization of the costfunction. Even though an advanced nonlinearprogramming algorithm for optimization may be used, thespeed and accuracy of the solution is not guaranteed.Multi-parametric quadratic programming was introducedto compute the online optimization offline to express thesolution as a combination of affine functions of the stateand input to overcome the implementation problem of theconventional MPC controller [13]. The solution iscomputed offline and the controller obtains its controlmove based on the value of the state using some affinefunction, which eases the computational burden of onlineoptimization. In this paper, multi-parametric quadraticMPC for heating phase of the thermoforming machine isproposed. The model developed for the heating phase ofthe thermoforming machine is nonlinear [8]. So the modelequations are linearized around the operating point( x * , u * ) to control the system using multi-parametricquadratic MPC.x x*u u* f ( x, u )B u x x**C u u h( x) x1 T 1 x (t )Yx(t ) min U T HU xT (t ) FU U2 2 such that GU W Ex(t ) ,Twhere, U [ut ,.ut NU 1 ] is the optimization vectorandH , F , Y , G, W , E are obtained from the weighting 1where S E G Hn n, B \n mby 1F T and1x ( t ) T (Y F H2 1F T ) x (t ) ,and the current state x(t ) xo can be taken as a vectorof parameters. If there are q inequalities in (4), thenz \ m. N , H \ m. N m. N , G \ q m. N , W \ q 1 ,S \ q n and F \ n q . In [14], it is shown that theexplicit solution of the optimization is a continuouspiecewise affine function defined over the partition of theparameter space. Following [14], we propose an algorithmfor the offline computation of the optimization problemfor the heating phase of the thermoforming process andhence implement it in MPC control of the process. Thewhole algorithm is described by the flow chart in Fig.1.StartSet the piecewise affine function andthe corresponding critical region inmemoryMeasure the value of the current stateIdentify the critical region or partitionwhich the state belongs toRetrieve the corresponding affinefunction to get the solution of theoptimizationx x*Obtain the control input by evaluatingthe function with the given state(1)In the rest of the paper, we use t as the present valueand t k for k -th future value predicted at time t . Thelinear state-space equations for the system are,x (t 1) Ax (t ) Bu (t ) ,y (t ) Cx (t )(2)where A \equation,Tmatrices Q, R . Defining z U H F x(t ) , theproblem can be transformed into1(3)V z ( x ( t )) min z T Hzz2such that Gz W Sx(t ) ,(4)V z ( x ( t )) V ( x ( t )) II. MULTI-PARAMETRIC QUADRATIC MPC FOR HEATING f ( x , u )A xV ( x(t )) Apply the control input to the systemEnd. With the linearized systemsubstituting(a)(b)k 1x (t k ) t A k x (t ) A j But k 1 j ,thej 0optimization problem of MPC can be reformulatedfollowing some algebraic manipulation as [13]:Fig.1: (a) Algorithm for offline optimization of the objective function forMPC (b) Algorithm for incorporating the solution of offline optimizationinto the controller4411

III. MODELING OF SHEET REHEAT PHASE INTHERMOFORMINGAs the MPC uses the process model to predict theoutput over the output horizon for an input vector andoptimize the performance objective function, it isimportant to discuss the model used in designing theMPC. The model used in this section is primarilydeveloped in [8]. The interested reader can get details ofthe model therein, but it is briefly discussed here toillustrate the proposed multi-parametric quadratic MPC.Each IR temperature sensor points at an area on the plasticsheet to perform the temperature measurement. Each sucharea is designated as a “zone”. To facilitate modeling, weassume that there are two IR sensors for each zone of theplastic sheet, one looking at the sheet from above and theother from below (Fig.2).To analyze the propagation of the heat inside the plasticsheet, heat transfer equations must be defined for somepoints inside the sheet. To do so, each zone is dividedinto layers throughout the thickness of the sheet (Fig.3).For each node, a differential equation describes the heatexchange of the corresponding layer. Since the surface ofthe plastic sheet is an important boundary of energyexchange, a node is located directly at the surface, seeFig.3. For each node, a differential equation describes theheat exchange of the corresponding layer. There are threeways (conduction, convection and radiation) to exchangeenergy between heaters, ambient air and nodes.Combining all three forms of heat transfer into theequation for 2M heaters, Z zones and 2 nodes for eachzone, and taking the transmissivity into account in theenergy transfer from the radiant heaters to the plasticsheet, the model for the k-th zone in the heating phasebecomes,dTk ,topdt kA 2 (Tk 2 Tk , top ) hst T top Tk , top ΔzρVC p β1QRTk β1 (1 β1 )QRBk() kA Δz (Tk , N 1 Tk ,bottom ) dTk ,bottom2 hsb (T bottom Tk , bottom ) ρVC p dt β1 (1 β1 )QRTk β1QRBk M Ah hht θ j T , top j 1 dT , top1 2 Aair ha Tair T , top dtρ airVair C pair Z A h T T zone sti , top , top i 1 2M Ah hhb (θ j T ,bottom ) j M 1 dT , bottom1 2 Aair ha (Tair T , bottom ) dtρ airVair C pair Z A h (T zone sbi , bottom T , bottom ) i 1 ()()()(4)Fig.2: Zone and IR temperature sensorsFig. 3: Layers and nodeswhere, M Q RTk σε eff Ah (θ j4 Tk4,top ) Fkj j 1 2M Q RB k σε eff Ah (θ j4 Tk4,bottom ) Fkj 1jM β 1 : 1 e A Δ z / 2The meaning of the symbols used in the model equationcan be found in reference [8]. Details of the method forcalculating effective emissivity and view factors can befound in [9].IV. DESIGN OF MULTI-PARAMETRIC QUADRATIC MPC FORHEATING PHASE OF THERMOFORMING MACHINEThe design of the MPC controller is discussed in thissection. At first, the system equation is linearized to obtaina linear system equation of the system so that multiparametric MPC can be developed using the systemequation. The next step is to incorporate the constraintsinto the controller. The oven heaters have maximum andminimum temperature constraints. The heating andcooling rate of the heaters also have some limitations. Theconventional MPC requires an online solution of theoptimization problem within a sampling period. As thesize of the model of heating phase of the thermoformingprocess is large, it is difficult to use online optimization toimplement MPC. So, the next step is to compute theoptimization offline using multi-parametric programming.This recently developed technique allows solving anoptimization problem offline for a constrained systemwithin a certain range of the parameters. The solution ofthe optimization problem will be provided by a piecewiseaffine function by analyzing several properties of thegeometry of the polyhedral partition and its relation to thecombination of the active constraints for differentpolyhedral region. Then, the MPC controller based on themodel is tuned in such a way that the desired performanceis achieved.4412

(1) Linearization of the system:The nonlinear system equations of the thermoformingprocess need to be linearized at an operating point of thesystem to incorporate the model in the design of the MPCcontroller. On the other hand, because of the nonlinearproperty of the system, the equation obtained bylinearizing the system at a particular operating point maynot properly sustain the properties of the actual system atanother operating point far from the linearization point.Thus, the system is linearized at different operating pointand different controllers are developed for each linearsystem. Based one the operating point, the control inputwill switch among different controllers. In this paper,differentoperatingpointsareselected:[Tk 50D C,θ j 200D C ],[Tk 100 D C , θ j 250 D C ], and[Tk 150 D C , θ j 300 D C ](2) Incorporating Constraints:There are some input-constraints in sheet heating of thethermoforming process such as the maximum andminimum heater temperatures as well as maximum heatingand cooling rates because of the limited input to theheater. The heaters are usually made of ceramic that couldbe damaged if heated more than 500 C, which results in aconstraint in the input heater temperature. On the otherhand, the heater cannot be cooled less than theenvironment temperature. Ajersch performed someexperiments to determine the maximum rate of heatingand cooling to develop a model of the heater bank [8].Although it can give some primary idea about themaximum heating and cooling rate, these rates depend onthe operating condition of the system like the input power,heat consumed by the sheet, heat consumed by oven airand oven wall (that largely depend on sheet, oven air andoven wall temperature). As the maximum electrical powerinput to the heater is bounded, it is quite understandablethat the maximum heating rate is bounded too. The boundon the maximum heating and cooling rates of the heaterdepend on the amount of heat transfer to plastic sheet,oven wall by radiation and to oven air by convection.With the increase of the heater temperature, the maximumcooling rate increases as the heater can lose heat faster tothe sheet, oven wall and to the environment. As the heaterloss increases at higher temperature, the maximum heatingrate will be reduced. On the contrary, at lower temperatureof the heater the maximum heating rate increases andmaximum cooling rate decreases. So the input constraintsabout heating and cooling rate are function of the currentheater temperature. Unfortunately, MPC cannot handlethis kind of input-constraints that depend on present valueof the input heater temperature. But the whole operatingrange of the heater can be divided into different sub-rangeand different maximum heating and cooling rateconstrains could be incorporated in the design of thecontroller.(3) Reduction of the number of partitions in offlinesolution of multi-parametric quadratic MPC:The number of polyhedral regions depends on a number ofparameters that include system state, previous controlinput, reference output, measured disturbance andprediction horizon as well as the number of free input,constraint. The number of polyhedral regions also dependson the range of the parameters in the multi-parametricquadratic programming used to solve the optimizationproblem. Because of the large number of inputs, statevariables and constraints in thermoforming, multiparametric quadratic programming (mp-QP) results in alarge number of polyhedral regions, with a piecewiseaffine function for each region, which is practically notpossible to implement. So the next challenge inimplementing MPC for this process is to reduce thenumber of region in the offline solution. One of thepossible ways to reduce the number of regions is to reducethe size of the system input and hence reduce the numberof parameters as well as number of the input constraints.The model of the heating phase of the thermoformingprocess has all of the constraints in its inputs. It can beproven that as the rank of the S matrix in the constraint ofequation (4) is less than or equal to the number ofconstraints, the number of regions for piecewise affinesolutions will remain the same for any number ofparameters that is higher than the number of theconstraints. In the case of the heating phase of thisprocess, the number of parameters is much higher than thenumber of constraints. Therefore, the number of partitionsor region of the parameter space defining the optimalcontroller is insensitive to the dimension of the parametervector or the number of parameters involved in the mpQP. Thus, if we can reduce the number of inputconstraints, the number of partitions will be reduced. Inthe case of the MPC design for the thermoformingmachine, only two of the heaters (top heater and itsopposite bottom heater) are used at a time to control thetemperature of the sheet and all other heater temperatureare considered to stay constant. As the temperature of aheater can change at most 1 K per second (where theactual heater temperature is within the range350 K 700 K), it is reasonable to consider the heatertemperature to be constant within a sampling period(which is 1 second). For each pair of heaters, a differentMPC will be designed whereas other heater temperatureswill be considered constant at the starting temperature ofthe sample. If there are 2M heaters in the thermoformingoven, then there will be M controllers that have just 2inputs with the constraint applicable for those inputs.Thus, it is observed that the number of partitions orregions is significantly reduced for every MPC controller.(4) Choosing the weight matrix of the controllerThere are M controllers for the process and eachcontroller computes reference heater temperatures for apair of heaters. If the same weights are given for outputtracking at every point’s temperature of the sheet, then thecontroller will try to force the heater temperature in such a4413

amplitude 130 C is used as command sheet temperaturefor PI and MPC controller whereas a constant 130 C isused for ILC to heat the sheet to a uniform sheettemperature at 130 C at the end of the cycle. At thebeginning of each cycle, the sheet is entered into the oven.So the temperature of the sheet is same as the environmenttemperature of the industry at the start of the cycle and thetemperature of the sheet increases over the cycle. Thecontrollers control the heater temperature of the oven tohave a uniform 130 C temperature over the whole sheet. Itis observed that the PI controller gives the largestdeviation of 10 C.160140Sheet temperature at the sensor ponts (C)way that it tries to heat every point of the sheet to achievethe desired temperature. But some zones on the sheet areso far from the heater that the heater has very littleinfluence on them, so the sensitivity of those parts of thesheet is very low with the change of heater temperature.This will force the heater to attain a very high temperature,even at the cost of a higher temperature at the nearest zoneon the sheet from the heater. This could even burn someparts of the sheet. As the heaters are distributed all overthe oven, every heater can be used more to heat thosezones of the sheet that are closer to them. This could beattained by using an appropriate weight matrix forreference outputs. The elements of the weight matrix arechosen in such a way that the weight matrix entries for asheet zone temperature will be inversely proportional tothe distance between the sheet point and the heater.(5)Tuning parameters of the controller:The parameters of the controller, such as outputprediction horizon, control horizon and constraint horizonlength are tuned in this step such that the controllerprovides its desired performance. With the increase of thehorizon length, the performance improves at the cost of anincrease in the number of constraints that will increase thenumber of polyhedral regions. So the complexity of thefinal piecewise affine functions for the MPC controllerincreases dramatically, characterizing a tradeoff betweenperformance and computational complexity. The length ofthe output prediction horizon, control horizon andconstraint horizon length are chosen such that it is thesmallest number giving a convenient number ofpolyhedral regions as well as providing the desiredperformance. After computing the controller using multiparametric programming, the optimum control inputcommand heater temperature to the system will beobtained as an affine function of system state, previouscontrol input, reference output and measured 07000Time (S,)(a)200Sheet temperature at sensor point of the sheet (C)1801601401201008060V. SIMULATION RESULTS40The effectiveness of the proposed MPC controller forthe thermoforming heating process is investigatedextensively in simulation. First, a simulation model isdeveloped using Matlab/Simulink. Then, the performancelevels of the proposed and conventional methods arecompared using the developed model. The oven consistsof top and bottom heater. Each heater consists of 6 (3x2)heater banks. There are 9 equidistant sensors (3x3)considered on each side of the sheet. The conventional PIcontroller and cycle-to-cycle iterative learning controller(ILC) are used to compare the performance with theproposed MPC controller.After the design anddevelopment of the MPC controller, each pair of controlinputs will be formulated in an explicit expression of 30system state variables (18 outputs, 2 air temperatures and10 other inputs), 2 previous control inputs and 18reference outputs. The output sheet temperature at thesensor points for the first 10 cycles with a cycle durationof 700s are shown in fig.4 for PI, ILC and MPCcontrollers, respectively. A ramp with 7000Time (S,)(b)140Sheet temperature art different sensor point (C)120100806040200100020003000Time (S,)(c)Fig.4: The sheet temperature at sensor location for (a) PI (b) ILC (c)MPC4414

case of MPC, the heater can follow the command heatertemperature from the controller and the error is as low as5 C.1000VI. CONCLUSIONError between actual andcommand heater temperature (C)800In this paper, a step-by-step approach is proposed forthe development of a multi-parametric MPC for thethermoforming process. The main challenges in thedeployment of the MPC controller for the process arediscussed. The explicit implementation of the MPCcontroller, in the form of a piecewise affine control lawcomputed offline, obviates the need for 500060007000Time(S,)(a)REFERENCES60[1]40Erro between actual andcommand heater temperature 0060007000Time (S,)[5](b)54Error between command and actualtemperature of the heater 0[9]7000Time (S,)(c)Fig.5: Error between control input and the actual temperature of a heaterfor (a) PI (b) ILC (c) MPCThe ILC controller gives very bad performance in the firstfew cycles, but it is getting better along the followingcycles. In contrast, the proposed MPC controller gives abetter performance as the sheet temperature obtained atthe end of the cycle remains pretty close to the desiredtemperature. In Fig. 5, it is observed that the heatertemperature of the PI controller cannot follow thecommand heater temperature from the controller output asthe controller did not consider the constraint of the heaterin calculating the control input. So the error between thecommand heater temperature and actual heatertemperature is as high as 1000 C. In case of ILC, the erroris large at the beginning but it gets better with time, eventhough the controller did not consider the constraint of theheater in calculating the control input. But it takes fivecycles to attain the command heater temperature. In the[10][11][12][13][14][15][16]4415G. J. Nam and J. W. Lee, “Numerical and Experimental Studies of3-Dimensional Thermoforming Process” Journal of ReinforcedPlastics and Composites, Vol. 20, No. 14-15, pp-1182-1190, 2001.X. T. Pham, P. Bates and A. Chesney, “Modeling ofThermoforming of Low-density Glass Mat Thermoplastic” J.Reinforced Plastics and Composites, Vol. 24, No. 3, pp287-298,2005.O. Rozant, P. E. Bourban, J. A. E. Manson, “Pre-Heating ofThermoplastic Sandwich Materials for Rapid Thermoforming” J.Thermoplastic Composite Materials, vol.13, no. 6, pp-510-523,2000.Duarte, F.M. and J.A. Covas, “IR sheet heating in roll fedthermoforming, Part 1 –Solving direct and Inverse heatingproblems”. Plastics, Rubber and Composites, vol.31, no.7, pp. 307317, 2002.Duarte, F.M. and J.A. Covas, “Infrared sheet heating in roll fedthermoforming, Part 2 – Factors influencing inverse heatingsolution.” Plastics, Rubber and Composites, vol: 32, no.:1, pp. 3239, 2003.P. Girard, V. Thomson and Benoit Boulet, “Advanced In-cycle andCycle-to cycle On-line adaptive Control for Thermoforming oflarge Thermoplastic Sheets.”SAE Advances in PlasticComponents, Processes and Technologies, 2005.B. Boulet, V. Thomson, P. Girard, R. Diraddo and A. Haurani, “OnLine Adaptive Control For Thermoforming Of Large ThermoplasticSheets”, Intelligent Processing and Manufacturing of Materials.2005, Monterey, CA.Ajersch, M., Modeling and Real-Time Control of Sheet ReheatPhase in Thermoforming, M.Eng. thesis, Department of Electricaland Computer Engineering, McGill University, 2004.Guy Gauthier, Terminal iterative learning for cycle-to-cycle controlof industrial processes, PhD thesis, Department of Electrical andComputer Engineering. McGill University, Montreal, Canada,2008.M. Morari and J. Lee, “Model predictive control: Past, present andfuture” Computational Chemical Engineering 23 (1999), p. 667.D.Q. Mayne, J.B. Rawlings, C.V. Rao and P.O.M. Scokaert,Constrained model predictive control: Stability and optimality,Automatica 36 (2000), p. 789A. Bemporad, F. Borrelli, and M. Morari, “Optimal controllers forhybrid systems: Stability and piecewise linear explicit form,” inProc. Conference on Decision and Control, Sydney, 2000.A. Bemporad, M. Morari, V. Dua and E.N. Pistikopoulos, Theexplicit linear quadratic regulator for constrained systems,Automatica vol. 38, p.4, 2002.P. Dua, . Model based and parametric control for drug deliverysystems. PhD thesis. Centre for Process Systems Engineering,Imperial College London. 2005.V. Dua, N.A. Bozinis and E.N. Pistikopoulos, A multiparametricprogramming approach for mixed integer and quadratic engineeringproblems, Computers & Chemical Engineering 26 (2002), p. 715V. Dua, K. P. Papalexandri and E. N. Pistikopoulos, Globaloptimization issues in multiparametric continuous and mixedinteger optimization problems, Journal of Global Optimization, vol30 (2004), p. 59.

function, which eases the computational burden of online optimization. In this paper, multi-parametric quadratic MPC for heating phase of the thermoforming machine is proposed. The model developed for the heating phase of the thermoforming machine is nonlinear [8]. So the model equations are linearized around the operating point