Transcription

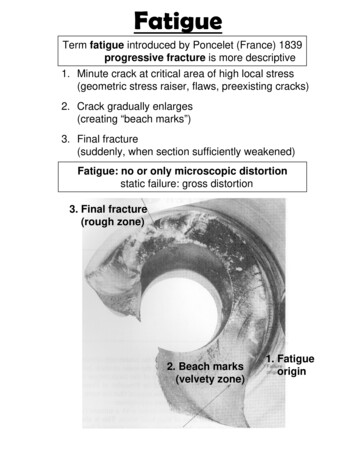

FatigueTerm fatigue introduced by Poncelet (France) 1839progressive fracture is more descriptive1. Minute crack at critical area of high local stress(geometric stress raiser, flaws, preexisting cracks)2. Crack gradually enlarges(creating “beach marks”)3. Final fracture(suddenly, when section sufficiently weakened)Fatigue: no or only microscopic distortionstatic failure: gross distortion3. Final fracture(rough zone)2. Beach marks(velvety zone)1. Fatigueorigin

Fatigue Repeated plastic deformation Thousands/millions of microscopic yielding(far below conventional yield or elastic point) Highly localized plastic yielding(holes, sharp corners, threads, keyways, scratches, corrosion) Strengthen vulnerable location often as effectiveas choosing a stronger material (If local yielding is sufficiently minutestrain-strengthen may stop the yielding)

Standard Fatigue Strength Sn’Empirical data from R.R. Moore fatigue test(Highly standardized and restricted conditions)Rotating-beam fatigue-testing machinePure bending (zero traverse shear)1750 rpmvariousN cycles of tension-to-compression-to-tension

Standard Fatigue Strength Sn’Fatigue strength,or Peak alternating stress S (ksi)Endurance Limit Sn’Linear coordinates(not used for obvious reason)Scattered dataEndurance Limit Sn’Semilog coordinatesKnee: 106 N 107Endurance Limit Sn’Log-log coordinatesFerrous materials: for life cycleN 106σ Sn’

Fatigue StrengthS-N curve approximation for steelSn‘ 0.5 x Su(0.4 x Su for cast iron)Su/ksi 0.5 x HB Brinell Hardness (also Bhn)Hence Sn‘ /ksi 0.25 xHBfor HB 400S/Su(log)106103-cycle fatigue: S1000 0.9 x Su

Endurance LimitS-N curve for nonferrousmetals No Sharply defined knee and No True endurance limit (Fatigue strength at N 5x108 often used)aluminum alloysLife N (cycles)Fatigue strength at N 5x108Sn‘ 0.4 x Su (for Su 48 ksi)(like for cast iron)Tensile Strenght Su (ksi)Su (MPa)

Endurance LimitS-N curve approximationEndurance limitSteelSn‘ 0.5x SuTitaniumSn‘ 0.45 0.6 x Su@ N 106Cast IronSn‘ 0.4x SuMagnesiumSn‘ 0.35x SuNickel alloysSn‘ 0.35 0.5 x SuAluminumCooper alloys Sn‘ 0.25 0.5 x Su@ N 108

Endurance LimitRotating Bending (Moore testing)maximum stresses on surfaceweakest pointfatigue startReversed Bending (not rotating bending like in Moore testing)maximum stresses only @ top and bottomhigh probability not weakest pointFatigue strength usually slightly greaterdeliberately neglectedsafe sideReversed Axial Loadingmaximum stresses entire cross sectionno reserve !Fatigue strength about 10% lesseccentric loads about 20 30% lessCG 0.7 0.9gradient factorReversed Torsional Loadingmaximum stresses on surfaceshear stressesfatigue startreversed biaxial stressdistortion energy theory58%CL 0.58load factor

Endurance Limit

Fatigue StrengthJuvinall p.312Fig. 8.12SteelSus 0.8 SuOther ductile materialSus 0.7 Su

Fatigue StrengthInfluence of SurfaceSo far special “mirror polish” surfaceMinimizes(only in laboratory ! )1.) surface scratches (stress concentration)2.) differences of surface & interior material3.) residual stresses from finishingCommercial surfaces have localized pointsof greater fatigue vulnerability.Surface factor CS cast ironUse only for endurance limit !

FatigueStrengthInfluence of SizeReversed Axial Loadingmaximum stresses entire cross sectionno reserve !Fatigue strength about 10% lesseccentric loads about 20 30% lessCG 0.7 0.9gradient factorBending & Torsional Reversed Loading0.3” test specimenUse equivalent round section !large specimen 0.4” CG 0.92.4” CG 0.84.6” CG 0.7small specimen 0.3” CG 1

Fatigue StrengthSummery use Table 8.1 Juvinall p.316106-cycle strength (endurance limit)Sn Sn’CLCGCSSn’ Moore endurance limitBendingAxialTorsionCL (load factor)110.58CG (gradient factor) 0.4”10.7 0.910.90.7 0.9r e d u c e - 0.1r e d u c e - 0.20.90.4” 2”2” 4”4” 6”CS (surface factor)see Fig. 8.131000-cycle strengthCL (load factor)BendingAxialTorsion0.9Su0.75Su0.9Sussteel: Sus 0.8Suother ductile metals: Sus 0.7Su

ExampleKnown: D 25mm, Su 950MPa, Sy 600MPa,reversed axially loaded, steel, hot-rolled surfaceFind: Sn(2x105 life cycles)P 8.18

Fatigue StrengthEffect of meanstressFluctuating stress static stress completely reversed stressmean alternating

Fatigue StrengthEffect of meanstressStatic tensile stress reduces amplitude of reversed stressthat can be superimposedSuempiric conceptSySnσaσmMacroscopic Yieldingon first load applicationMicroscopic Yielding-Sn

Fatigue StrengthEffect of meanstress(only static failure Suc )Values from S-N curve (σm 0)SyNo macroscopic yieldingempiric conceptSnGandmooExtends infinite for fatigueCompressive mean stress does not reduce amplitudethat can be n)constant-life fatigue diagramJuvinall p.318 Fig. 8.16SySu

Fatigue StrengthJuvinall p.312Fig. 8.12

FatigueStrengthEffect of mean stressσmaxGonamdoSuil neSntest datasteel alloyaxial loadingσσamσminNote: Brittle materials are usually on Goodman line

FatigueStrengthfor N 10 & 10Effect of mean stress63d ? 2in polishedS 0.75Su 0.75x150ksi 112ksi1000 5000lbaxial loadSF 2Sy 120 ksiSu 150 ksiSn Sn’CLCGCS (0.5x150ksi)x1x0.9x0.9 61ksiσa SFxFASyaσσm SFxFAmm 4000lbA6000lbAσa 0.67σmσa-Sy-σmσm(compression)(tension)σa(N 106) 38ksiσa(Sy) 48ksid 0.367in 3/8 ind 0.326in 11/32inSySu

Fatigue StrengthStress concentrationK f 1 (K t 1) qKf Ktq sensitivity factorgeometric or theoretic factortorsionqS u/ksihigly notch sensetiveq 1ngidben loadlaxi aCast iron q 0notch r [in]Apply Kf to mean stress σm and to alternating stress σa

Rotating Bending (Moore testing) maximum stresses on surface weakest point fatigue start Fatigue strength usually slightly greater deliberately neglected safe side Reversed Axial Loading maximum stresses entire cross section no reserve ! Fatigue strength about 10% less eccentric loads about 20 30% less C G 0.7 0.9 gradient factor