Transcription

TECHNICAL SPECIFICATIONARMOREDFIBER OPTIC CABLEMARMLTxxxSM

Multicom Fiber Optic Armored Cable - MARMLTxxxSM1. GENERAL1.1SCOPEThis listed specification covers the design requirements and performance standard for the supply ofoptical fiber cable in the industry. It also includes Multicom’s premium designed cable with optical,mechanical and geometrical characteristics.1.2CABLE DESCRIPTIONMulticom cable possesses high tensile strength and flexibility in compact cable sizes. At the sametime, it provides excellent optical transmission and physical performance.1.3QUALITYExcellent quality control is achieved through intense in-house quality check and stringent auditacceptance by ISO 9001.1.4RELIABILITYInitial and periodic product qualification tests for performance and durability are performed rigorouslyto ensure product reliability.1.5REFERENCEMULTICOM c a b l e is designed, manufactured and tested according to international standardsas follows:IEC 60793-1Optical fiber Part 1: Generic specificationsIEC 60793-2Optical fiber Part 2: Product specificationsIEC 60794-3-10Outdoor cables- family specification for duct and directly buried opticaltelecommunication cableITU-T G.650Definition and test methods for the relevant parameters of single-mode fibersITU-T G.652Characteristics of a single-mode optical fiber and cableEIA/TIA 598Color code of fiber optic cables

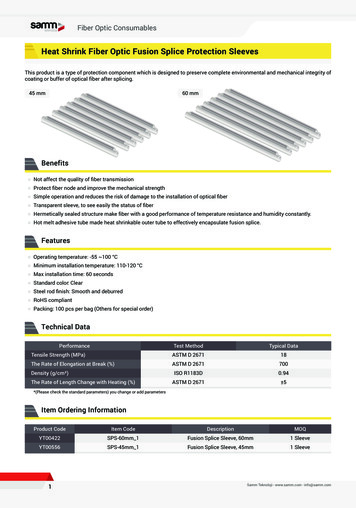

Multicom Fiber Optic Armored Cable - MARMLTxxxSM2. OPTICAL FIBERThe optical fiber is made of high pure silica and germanium doped silica. UV curable acrylate materialis applied over fiber cladding as optical fiber primary protective coating. The detail data of optical fiberperformance are shown in the following table.SpecificationsCategoryDescription@1310 nm 0.34 dB/km 0.36 dB/kmAttenuation@1550 nm 0.20 dB/km 0.22 dB/km1300 1324 nm 0.092 ps/nm2 kmZero Dispersion SlopePMD (Polarization Mode Dispersion)MechanicalSpecifications 0.2 ps/ kmCable Cutoff Wavelength (λcc) 1260 nmMacro bending Loss(100 turns; Ф50 mm)(100 turns; Ф50 mm)@1550 nm@1625 nm 0.05 dB 0.10 dBMode Field Diameter@1310 nm9.2 0.4μmCladding DiameterDimensionalSpecificationsAfter cablingAttenuationZero Dispersion WavelengthOpticalSpecificationsBefore cabling125 1μmCore/clad concentricity error 0.6μmCladding Non-Circularity 1.0%Proof stress 0.69Gpa

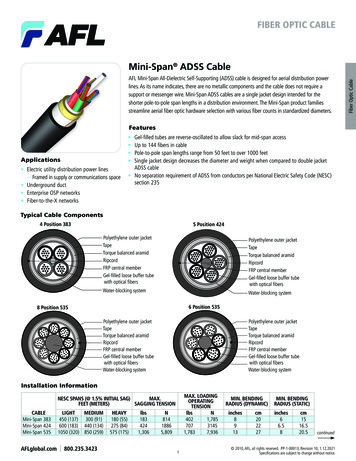

Multicom Fiber Optic Armored Cable - MARMLTxxxSM3. CABLE STRUCTUREPicture is only for referenceTechnical Characteristics The unique extruding technologyprovides the fibers in the tube with goodflexibility and bending endurance The unique fiber excess length controlmethod provides the cable with excellentmechanical and environmental properties Multiple water blocking material fillingprovides dual water blocking function 12345678Construction:1. Outer sheath (PE)2. Corrugated steel tape3. Water blocking tape4. Loose tube, fiber and water blocking yarn5. Central strength member (FRP or Coated FRP)6. Water blocking yarn7. Strength member (Glass yarns)8. Rip cordProvide good tension performanceDimension and PropertiesFiber count (G.652D)1224487296No of loose tube / filler1/52/44/26/08/0Fiber No. per tube12Loose tube diameterPhysical2.5 0.2mmCable ODCable weightMechanical12.5mm 5%14.2mm 5%144kg/km 15%178kg/km 15%Operation temperature range-60 deg C to 70 deg CInstallation temperature range-30 deg C to 60 deg CTransport and storage temperature range-40 deg C to 75 deg CMax. tensile loadShort term: 2700N, long term: 800NCrush resistance2200 N/10cmMinimal installation bending radius15 x ODMinimal operation bending radius10 x ODColor code scheme:Fiber oletpinkaquaTube colorblueorangegreenbrowngraywhiteredblack////

Multicom Fiber Optic Armored Cable - MARMLTxxxSM4. TEST REQUIREMENTSApproved by various professional optical and communication product institution, MULTICOM alsoconducts various in-house testing. MULTICOM possess the technology to keep its fiber attenuationloss within Industry Standards.The cable is in accordance with applicable standard of cable and requirement of customer. Thefollowing test items are carried out according to corresponding reference.Routine tests of optical fiberMode field diameterIEC 60793-1-45Mode field Core/clad concentricityIEC 60793-1-20Cladding diameterIEC 60793-1-20Cladding non-circularityIEC 60793-1-20Attenuation coefficientIEC 60793-1-40Chromatic dispersionIEC 60793-1-42Cable cut-off wavelengthIEC 60793-1-44

Multicom Fiber Optic Armored Cable - MARMLTxxxSMTEST LIST4.1 Tension Loading TestTest StandardIEC 60794-1-2 E1Sample lengthNo less than 50 metersLoadMax. tension loadDuration time1 minuteFiber strain: 0.60%Test resultsAdditional attenuation: 0.1dBNo damage to outer jacket and inner elements4.2 Crush/Compression TestTest StandardIEC 60794-1-2 E3LoadCrush loadDuration time1minuteTest number3Test resultsAdditional attenuation: 0.05dB after testNo damage to outer jacket and inner elements4.3 Impact Resistance TestTest StandardIEC 60794-1-2 E4Impact energy10JRadius300mmImpact points3Impact number1Test resultAdditional attenuation: 0.05dB after testNo damage to outer jacket and inner elements4.4 Repeated Bending TestTest StandardIEC 60794-1-2 E6Bending radius15 X diameter of cableCycles25 cyclesTest resultNo damage to outer jacket and inner elements

Multicom Fiber Optic Armored Cable - MARMLTxxxSM4.5 Torsion/Twist TestTest StandardIEC 60794-1-2 E7Sample length2mAngles 180 degreecycles5Test resultNo damage to outer jacket and inner elements4.6 Bend TestTest StandardIEC 60794-1-2 E11Mandrel diameter20 X diameter of cableTurn number4Number of cycles3Additional attenuation: 0.05dB after testTest resultNo damage to outer jacket and inner elements4.7 Temperature cycling TestTest StandardIEC 60794-1-2 F1Temperature step 20 -60 70 20 Time per each step12 hrsCycles2Test resultAttenuation variation for reference value (the attenuation to be measuredbefore test at 20 3 ) 0.15 dB/km and is reversible during last cycle4.8 Water penetration TestTest StandardIEC 60794-1-2 F5Height of water column1mSample length3mTest time24 hrsTest resultNo water leakage from the opposite of the sample

Multicom Fiber Optic Armored Cable - MARMLTxxxSM5. PACKING AND DRUM5.1 MULTICOM cables are coiled on bakelite, wooden or ironwood drum. During transportation, righttools should be used to avoid damaging the package and to handle with ease. Cables should beprotected from moisture; kept away from high temperature and fire sparks; protected from overbending and crushing; protected from mechanical stress and damage.Wooden strip sealWooden flangeInner tubCable fixing pointAxle holeCable trough5.2 The color of cable marking is white. (The printing shall be carried out at interval of 1 meter on theouter sheath of cable) The inner end of cable is then sealed with heat shrinkable end cap to preventingress of water and is made available for testing. The outer end of cable is equipped with heatshrinkable end cap. Outer sheath marking legend can be changed according to user’s requests.5.3 Outdoor cable packingBakelite, wooden or ironwood drumStrong wooden batten protection

EIA/TIA 598 Color code of fiber optic cables. . The cable is in accordance with applicable standard of cable and requirement of customer. The following test items are carried out according to corresponding reference. Routine tests of optical fiber Mode field diameter IEC 60793-1-45

![Fiber Optic - Perimeter Intrusion Detection System [Fopids]](/img/57/foss-presentation.jpg)