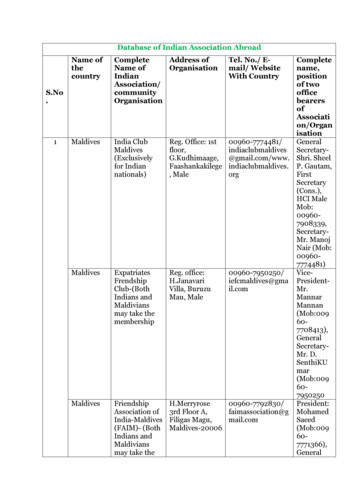

Transcription

THE COMPLETE BOOK OF THEMODEL 1911THE CUSTOM EDITIONED BROWN CENTENNIALWILSON COMBATCONTEMPORARY CLASSICCENTENNIALFROM THE PUBLISHERS OFGUNS & AMMO ANNUALUSA/CANADA 8.99DISPLAY UNTIL 11/07/2011LES BAER CUSTOMCENTENNIAL

GARTHWAITE’SPISTOLSMITHINGCLASSLearning to build a custom 1911.BY DAVID KENIKReaders of this magazine usually have a love/hate relationship with the 1911. The issue is that the 1911 is a finickydesign and has earned itself a reputation as a handgunthat may or may not run properly out of the box. Whenmy interest in 1911s started decades ago, I learned not to evenwaste my time and ammunition test firing them because, chanceswere, they wouldn’t work reliably. Instead, I took them from thegun store counter to a gunsmith for a reliability package. Usually,a trigger job and some component changes.Tom Givens, owner of Range Master in Memphis, Tennessee,its lead instructor and 1911 aficionado, recently proclaimed, “The1911 design does not lend itself well to modern manufacturingmethods. Most over-the-counter 1911s still need some attentionfrom a qualified hand-fitter [pistolsmith].” That may be a bitextreme, as manufacturing techniques have improved and mostcontemporary 1911s work just fine. But there is a quantitativebenefit to hand-building a 1911.The MysteryIt’s easy to build a reliable 1911. It’s easy to build an accurate1911. However, it takes the skill and handwork of an experiencedartisan to obtain the ultimate accuracy out of the 1911 whilemaintaining complete reliability. The proliferation and success ofhigh-end, high-cost, custom 1911s is a testament to that fact.The exact process of accurizing and increasing reliability has always been shrouded in mystery to me. I understood the concepts,but not the details. Perusing the Web site of custom gunsmith JimGarthwaite, I noticed that he offered a 1911 pistolsmithing class.Having met Jim at several training events, I knew of his work andjumped at the chance to attend.Jim Garthwaite, PistolsmithJim opened his shop in 1978 with a specialty in defensive Model1911s and Browning Hi-Powers. He continues to be a one-manshow. Every facet of the work is done personally, and every gunhe works on is treated like his own. As a founding member of theAmerican Tactical Shooting Association, he is a practicing tactician and the lessons he learns perfecting the craft go into every oneof his guns. As a self-taught ’smith, he takes special pride in hisselection as the American Pistolsmith Guild 2004 Pistolsmith ofthe Year.78BOOK OF THE 1911

GARTHWAITE’S PISTOLSMITHING CLASSStudents learn firsthand how custom pistolsmiths fit and blend parts such as abeavertail grip safety and internal components such as the barrel lugs and barrellink. Although much of the work is done by hand, Garthwaite still uses machineryfor certain aspects of the build process.Jim Garthwaite limits the number of students in his class to six so that everyone gets personalizedattention. The project started with a 1911-A1 from Springfield Armory and included many new, oversize components that would have to be hand-fitted. Although the slide and frame already workedtogether, more work was required to tighten the rail for better accuracy.Pistolsmithing ClassJim’s class runs five days in his centralPennsylvania shop and is billed as providing “a thorough knowledge and understanding of the procedures to build andmaintain the Browning-designed pistol.”The tuition includes a forged 1911 frameand slide, Kart or Bar-Sto match barrel,Heinie or Novak fixed rear sights, all component parts, cocobolo stocks, Teflon coating or bluing, and personal instruction.Scheduled four times a year, the classis limited to six participants so Jim canoffer plenty of personal attention. Theclass I took started on February 14 of thisyear, which, by coincidence, was the 100thanniversary of John Browning’s patent forthe 1911 pistol.The primary lessons of the class includesight installation, frame-to-slide fitting,precision barrel fitting, trigger work,component shaping and malfunctiondiagnosis. Participants thus learn to custom fit a 1911 and leave the class with the80 BOOK OF THE 1911satisfaction of hand-fitting and assemblingit themselves.slides, as he finds them easier for studentsto fit and work by hand.Springfield Armory ComponentsOn the BenchAll Garthwaite pistols start life as a fullyassembled, bare-bones, basic SpringfieldArmory pistol. Jim works with SpringfieldArmory because of his opinion of the quality and consistency of its products.Jim starts with complete guns since theyare no more expensive than purchasing theparts separately. Besides the forged slideand frame, firing pin, guide rod, magazinecatch, springs and pins, all factory components are replaced with oversize parts thatare meticulously hand-fitted for perfect fitand function, which affords Jim’s pistolstheir superb accuracy and reliability. Theclass was to follow the same path, witheach of us learning the hand-fitting processof every part.In Jim’s work he uses various materials,depending on client requirements, but forthe class he prefers carbon steel frames andPrior to the start of instruction, Jim removed the factory sights, milled dovetailsin the slide for the new sights and widenedand flared the ejection ports of each student’s pistol. He also recontoured the rearsights to allow the slide to be racked by thefront edge of the sight.Day one started off with a hands-ondemonstration of a complete 1911 disassembly and reassembly. We then movedonto fitting a Heinie rear sight and MGWblank dovetail front sight. The dovetails,like all machining that was to be done,were cut slightly undersize so we couldhand-file them for a perfect fit. We keptfiling and fitting until light no longerfiltered through between the parts.Both sights need to be snug enoughthat they don’t drift, yet loose enough tobe able to make windage adjustments.gunsandammo.comThe height of the front sight was purposely left taller than needed so its heightcould be adjusted during test firing tomatch our carry ammunition preference.I have to admit that I thought that sightinstallation was one of the easier jobs fora gunsmith, but it turns out to be muchmore involved than I imagined. The pricea good gunsmith typically charges for theservice is certainly justifiable.Job two was fitting the slide to theframe. Since the gun started as a finishedpistol, the slide did fit onto the frame.The process entailed measuring theheight of the rails in the slide, shimmingthe rail slot in the frame to match the railheight and planishing down the frame’srails with a hammer until the slide fit wastight, even and without wiggle. Next wefiled off the misplaced steel and lappedthe slide and frame together with 600grit aluminum oxide compound. The process was repeated several times until theslide fit properly. When just a touch ofgunsandammo.complay was left, Jim stated that the minimalresidual movement would be removedonce the barrel was fit. Surprised again,my slide was not that far off, and thefitting process was much easier and fasterthan I anticipated. However, that’s notalways the case. Sometimes the factoryslide fit is quite loose, and the tighteningprocess becomes lengthy.In addition to the quality of the barrelitself, one of the most important elementsof a pistol’s accuracy is the fit of the barrelto the slide. Extraneous movement mustbe eliminated so the barrel returns to battery consistently with every shot.Starting with an oversize Kart matchbarrel, the first step was to measure thehood width and length and compare itwith the breech face to determine howmuch material needed to be removed.Rather than doing all the work manually,whenever possible Jim prefers to do about90 percent of the cutting by machine andleave a few thousandths of an inch of mate-rial for hand-fitting. This greatly speeds upthe workflow, yet leaves the final fitting tobe perfected by hand.After the excess barrel hood materialwas machined, the final portion washand-filed and -lapped. With the barrelinstalled and held in battery, the barrellugs were then hand-cut. This was donewith both the slide and barrel positionedon the frame. We used a lever to aid inpushing the slide and barrel into the special lug cutter as it was rotated by hand.This ensured that the lugs were cut to thecorrect position and enabled the thumbsafety to be engaged. Again, hand-filingand -lapping finished and smoothed outthe operation. After fitting the barrellink, the last process in the barrel installation was the sizing and fitting of thebarrel bushing. The barrel fitting was atime-consuming process, but absolutelynecessary to assure accuracy.With the barrel fitting completed, wewere able to assemble the barrel and recoilBOOK OF THE 191181

GARTHWAITE’S PISTOLSMITHING CLASS10 Karat .080 GoldBead Custom InsertAs part of tuition, studentsget the choice of finishingtheir 1911 with a black oxideor black Teflon coating. Theauthor chose black Teflon forits low reflectivity and high lubricity. The front sight featuresa brass bead, and the rearHeinie sight can be used forone-handed slide manipulation. Everything down to thefitted Kart .45 National Matchbarrel suggests that this wasbuilt by the hands of a welltrained 1911 pistolsmith.Building a custom 1911 in Garthwaite’s pistolsmithing class is more than how to make it aesthetically pleasing. He teaches how to make thepistol function safely, reliably and accurately. Before the class is over, students take their 1911s to the range to fit the sights to a particularload. A sight adjustment tool joins the class on the bench for any necessary windage adjustments.spring within the slide and mate it to theframe to check the function. This step wasencouraging, as we saw for the first timethat the barrel lowered and returned tobattery perfectly with the cycling of theslide. It was also exciting to see that the final fitting of the barrel tightened the slidefit to the point that there was absolutelyno extraneous movement—a hallmark of awell-built pistol.Checking the head space with go/nogo gauges, we determined that the chamber in my barrel needed to be reamed tofit the cartridge properly since we reducedthe barrel hood length. We increased thechamber’s depth by hand-reaming it afew thousandths of an inch deeper. To82BOOK OF THE 1911ensure that we didn’t cut too deeply, wereamed it in multiple steps until the barrel locked perfectly with the go gauge inthe chamber.Installing a Wilson Combat grip safetywas next on the list. The contour of thegrip safety that surrounds the hinge location was smaller and shaped differentlythan the frame, so we used a bolt-on jig asa guide and removed most of the excessframe material with a belt sander. Theframe and entire length of the grip safetywere then reshaped by hand-filing untilthey melded together perfectly. Thoughnot necessary for reliability or accuracy, acustom-fit grip safety gives the pistol a professional presentation and greatly affectshow the firearm feels in the hand.With all the hand-filing we did, Ireceived plenty of experience with a gunsmith’s best friend, Dykem. This coloredliquid is applied along parts that need tobe fitted together. Quickly drying to a verythin coating, the Dykem is removed wherethe parts rub together, leaving a visualindication of the exact location whereadditional filing is required. Difficult-tofit parts such as the grip safety requirednumerous applications.After shaping and fitting the safety,the fire-control parts were installed. Westarted by cleaning out the frame’s triggerbow slot and fitted an oversize trigger,making sure it functioned with a magazinegunsandammo.comgunsandammo.comBOOK OF THE 191183

GARTHWAITE’S PISTOLSMITHING CLASSin place. Those that didn’t had their bowsadjusted. The hammer, sear and disconnector that we used are specially built for Jimto his exacting specifications. In additionto being used in his custom pistols, theyare also available through his Web site.We first tested the sear engagementto the hammer with the use of jigs thatmounted onto the frame for easy inspection of the parts. The jigs inserted into thesear and hammer pin holes so they heldthe parts outside the frames in the preciserelationship they will be in when installed.As it turned out, the sears and hammersneeded almost no adjustment due to theoutstanding precision of the ElectricalDischarge Machining (EDM) used intheir manufacture. With the fire-controlsystem in place and the trigger breakingclean at about four pounds, we adjustedthe trigger’s takeup and overtravel andEl Paso Saddlery (EPS) makes classicholsters, cowboy rigs, concealmentholsters, duty holsters, military-styleand hunting holsters, and what caught myeye: exotic-skinned holsters for stylishcarry. In addition to holsters, EPS offersbelts, magazine holders, scabbards, saddlebags, pouches, slings and ammunition carriers. Each of these categories has numerous incarnations to fit just about anyone’stactical, sport or practical desires. A fewclicks on the EPS Web site will take youthrough a series of drop-down menus andreveal a vast catalog of offerings.Located in El Paso, Texas, El Paso Saddlerywas started in 1889. Not a misprint: 1889.Today it employs the work of 16—the cutting, stamping, carving and fitting are alldone by hand. All holsters and other productsare made to order. It can accommodate justabout every model handgun, and its worktypically takes about six to eight weeks.For my custom 1911 project, I ordered aholster, belt and magazine pouch done in theExotic Crosshairstyle in brown Spanish Bull.Spanish Bull is also available in black. Otherexotic-hide offerings include black or brownostrich; black, cognac or chocolate crocodile;black or chocolate shark; and stingray.The Exotic Crosshair holsters are leatherlined, and both the front and back are covered with the customer’s choice of skin. Auser-adjustable tension screw combinedwith hand-molding securely cradles thegun. The holster is designed with a flatback

1911 design does not lend itself well to modern manufacturing methods. Most over-the-counter 1911s still need some attention from a qualified hand-fitter [pistolsmith].” That may be a bit extreme, as manufacturing techniques have improved and most contemporary 1911s work just fine. But there is a quantitative benefit to hand-building a 1911. The Mystery. It’s easy to build a reliable 1911 .