Transcription

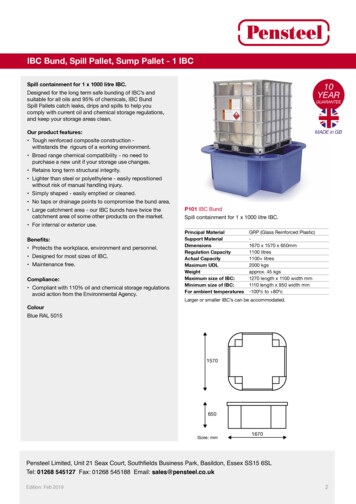

IBC SPILL PALLET PLUSSPECSSPILL apacityUDLSumpCapacityNoyellow62”28”62”320 lbs8,500 lbs365 gallonsYesyellow62”28”62”320 lbs8,500 lbs365 gallonsDescription: A containment sump with deck surface used for storing and containing any leaks, spills ordrips from Intermediate Bulk Containers (IBC’s).Application: Contain leaks, spills or drips from IBC containers.Product Features: 28” high — lower profile for easier access and dispensing All-poly construction — chemical-resistant, won’t rust or corrode Full, flat grate deck surface (52” x 52”) — easy to position IBCs; no open voids in surface Compact 62” x 62” footprint 8500 lb. UDL weight capacity 2-way forklift entry for easy movement when not loaded Available with optional drain Available with optional bucket shelf to capture spills from dispensingComposition: PolyethyleneHelps you comply with: Meets SPCC and EPA Container Storage Regulation 40 CFR 264.175 SpillContainment Regulations.Disclaimers:Flammables Notice: If using thisproduct with flammable liquids,please consider the regulations thatapply to storage and handling offlammable liquids and the safetyof this application, specificallyflammable vapors, static dischargeand heat sources.Forklift Pockets:For more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

IBC SPILL PALLET PLUSBUCKET SHELF ATTACHMENTSPILL positionBlack16”19”13”9 lbs5 gallonsLDPEAttach this shelf to your IBC Spill Pallet for easy, mess free filling into 5-gallon buckets. Bucket shelf attaches directly to IBC Spill Pallet for easy filling of 5-gallon pails Catches leaks and drips during dispensing to keep floors dry and safe For more containment, shelf can be connected to main sump; optional configuration requiresbulkhead fittingsDisclaimers:Flammables Notice: If using this product with flammable liquids, please consider the regulations thatapply to storage and handling of flammable liquids and the safety of this application, specificallyflammable vapors, static discharge and heat sources.For more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

MAINTENANCE/CARESPILL CONTAINMENTPOLYETHYLENE SPILL CONTAINMENT PRODUCTS1. There is no specific need to clean one of our polyethylene spill containment products that has not hada spill or leak as the polyethylene plastic material it is constructed from is designed to last for yearsin most indoor or outdoor environment. The polyethylene has a UV protective additive for prolongedoutdoor exposure.2. The products are rated for use in temperatures from -40 F to 160 F.3. The sump area of the product should be inspected weekly for any spills or leaks. If a spill or leak isdiscovered, it should be cleaned up within 24 hours. If inspection shows the sump area has a crack orhole or other damage that could affect the functionality of the unit, it should be immediately removedfrom service.4. To clean up a spill or a leak, use all safety precautions required for handling the particular chemicalinvolved. Using a safe pumping method for the chemical involved, pump the spilled contents out of thecontainment sump and into a drum or container for proper disposal or reuse. If the chemical involvedis not safe to pump, use absorbents or other means to remove the chemical from the containmentsump safely. Dispose of any chemicals, used sorbents or other disposables in compliance with yourlocal or federal regulations.5. Once the chemical has been removed, use a sorbent mat or pad to wipe down the inside of thecontainment unit to remove any remaining chemical residue. Finish by washing with soap and waterand allow the unit to dry before placing back into service.6. The unit’s grating should be cleaned of any residual chemical and cleaned with soap and water.7. If the unit had a drain plug that was removed to drain off any chemical or soap/water, be sure toreplace the drain plug securely.8. Spill Deck Bladder System special instructions:a. Use a hand pump with a ½” diameter tube and insert the tube into the opening of the bladder frominside the Spill Deck after removing the grate.b. Pump the contents of the bladder and the Spill Deck into a drum or container for proper disposalor reuse.c. If there is some remaining residue inside the bladder, lift the outside end of the bladder and allowthe residue to pour back into the Spill Deck sump where it can be pumped out or absorbed withsorbents.d. Remove the bladder from the Spill Deck by uncrewing the bulkhead fitting and dispose of thebladder properly according to local and federal regulations. DO NOT REUSE A BLADDER. After theSpill Deck has been cleaned up, place a new bladder into the Bladder Attachment and attach it tothe Spill Deck following the instructions that accompany the replacement bladder.For more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

CHEMICAL COMPATABILITYSPILL CONTAINMENTPOLYETHYLENE SPILL CONTAINMENT PRODUCTSThis listing was prepared to provide guidance to the chemical compatibility of Ultra EnvironmentalContainment Products which are manufactured and constructed of a molded polyethylene.Polyethylene is susceptible to attack by some chemicals which may cause stress cracking, swelling, oxidationor may permeate the polyethylene. These reactions may reduce the physical properties of polyethylene.When considering an UltraTech polyethylene product for use in secondary containment applications, itis important to note that most secondary containment products are designed to hold leaked chemicalsfor only hours, a day, at most a week. These secondary containment units would then be cleaned of anychemical. In these short term applications, a greater variety of chemicals may be used with the polyethylenesince the exposure time of the chemical to the polyethylene is limited.A. Suitable for long term storage at 100 degrees F or less.B. Suitable for short term storage less than one year.C. Do NOT store these chemicals in UltraTech containers.D. User testing may prove some of these chemicals are suitable for secondary containment applicationswith exposure time of one week or less.Acetaldehyde (40%), AAcetamide, AAcetic Acid (50%), AAcetic Acid Anhydride, BAcetic Ether, BAcetone, AAcetylene Tetrabromide, BAcrylic Emulsions, BAcrylonitrile, AAdipic Acid, AAliphatic Hydrocarbons, AAlkaline, AAllyl Alcohol (96%), AAluminum Chloride (20%), AAluminum Fluride, AAluminum Hydrogen Solution (10%),AAluminum Hydroxide, AAlums (All Types), AAmmonia (Aqueous), AAmmonium Acetate, AAmmonium Bifluoride, AAmmonium Carbonate (50%), AAmmonium Chloride, AAmmonium Hydrogen Fluoride(50%), AAmmonium Hydroxide, AAmmonium Metaphsophate Sat’d, AAmmonium Nitrate Sat’d, AAmmonium Persulfate Sat’d, AAmmonium Phosphate, AAmmonium Salts, AAmmonium Sulfate Sat’d, AAmmonium Sulfide, Sat’d, AAmmonium Thiocyanate Sat’d, AAmyl Acetate, AAmyl Alcohol (100%), AAmyl Chloride, CAniline (100%), BAniline Hydrochloride, BAnti Freeze, AAntimony Salts, AAntimony Trichloride (90%), AAqua Regia, CAqueous Alkalies (NaOH), AArsenic Acid, ABarium Carbonate, ABarium Chloride, ABarium Cyanide, ABarium Hydroxide, ABarium Nitrate, ABarium Salts, ABarium Sulfate, ABarium Sulfide, ABattery Fluid, Acid, BBenzaldehyde, ABenzene Sulfonic Acid, BBenzene, BBenzoic Acid, ABenzyl Alcohol, ABenzyl Chloroformate, ABoric Acid Conc., ABoric Acid Dilute, ABorzx Cold Sat’d, ABromine, Liquid, CBromine, Water, CBromobenzene, CBromoform, CButadiene, AButanediol (100%), AButanol, AButyl Acetate, AButyl Alcohol (100%), AButyl Phenol, CButylene Glycol, AButylene Liquid, CButylene, CButyric Acid, ACalcium Carbonate, ACalcium Chloride, Acalcium Hydroxide, ACalcium Hypochlorite, ACalcium Nitrate (50%), ACalcium Sulfate, AFor more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

CHEMICAL COMPATABILITYSPILL CONTAINMENTCONTINUED.A. Suitable for long term storage at 100 degrees F or less.B. Suitable for short term storage less than one year.C. Do NOT store these chemicals in UltraTech containers.D. User testing may prove some of these chemicals are suitable for secondary containment applicationswith exposure time of one week or less.Carbon Bisulfide, CCarbon Disulfide, CCarbon Monoxide, ACarbon Tetrachloride, CCarbonic Acid (Aq. C02), ACaustic (Aqueous), ACaustic Potash Sol. (50%), ACaustic Soda Sol. (10%), AChloroacetic Acid, AChlorobezene, AChloroform, CChloromethane, CChlorsulfonic Acid (100%), CChrome Alum Sat’d, AChromic Acid (50%), BClycolic Acid (All Conc.), ACopper Cyanide, ACresylic Acid, ACrotonic Aldehyde, ACuprous Chloride Sat’d, ACyclohenanone, BCyclohexane, ACyclohexanol, ADextrin Sat’d, ADextrose Sat’d, ADi Isobutyl Ketone, BDibutyl Ether, CDibutyl Sebacate, BDibutylphthalate, BDichloroacetic Acid, BDichlorobenzene, Liquid, CDichloroethylene, CDiesel Fuel, BDiesel Oil, BDiethanolamine, BDiethyl Carbonate, ADiethylene Glycol, ADigycolic Acid (30%), ADimethyl Formamide, BDimethylamine, BDinonyl Phthalate, CDioctyl Phthalate, CDioxane, ADiphenyl Oxide, CDisodium Phosphate, AElectrolyte, AEthanol, AEther, CEthyl Acetate (100%), BEthyl Alcohol, AEthyl Butyrate, BEthyl Chloride, CEthyl Ether, CEthylene Chloride, CEthylene Chlorohydrin, AEthylene Diamine, AEthylene Dichloride, CEthylene Glycol, AEthylene Oxide, CFatty Acids, AFerric Sulfate, AFerrous Salts, AFerrous Sulfate, AFluoboric Acid, AFluosilicic Acid (All Conc.), AFormaldehyde (40%), AFormamide, AFormic Acid (All Conc.), AFuel Oil, AFurfural (100%), AFurfuryl Alcohol, CGallic Acid Sat’d, AGasoline, AGluconic Acid (All Conc.), AGlycerine, AGlycol, AHeptane, AHexane, AHydrazone Hydrate, AHydrobromic Acid (50%), AHydrochloric Acid (All Conc.), AHydrocyanic Acid Sat’d, AHydrofluoric Acid (All Conc.), AHydrofluorisilicic Acid (All Conc.), AHydrogen Bromide (10%), AHydrogen Peroxide (90%), AHydrogen Phosphide (100%), AHydrogen Sulfide, AHydroiodic Acid (All Conc.), AHydroquinone, AHydrosulfite (10%), AHydroxylamine Sulfate, AHydrozine (35%), AHydrozine Hydrochloride, AHypochlorous Acid, AIso Octane, BIsopropyl Acetate, AIsopropyl Alcohol, AIsopropyl Ether, CJet Fuel, BKerosene, BLactic Acid (All Conc.), ALead Acetate Sat’d, AMagnesium Carbonate, AMagnesium Hydroxide, AMagnesium Nitrate, AMagnesium Oxide, AMagnesium Salts, AMagnesium Sulfate, AMaleic Acid, AMethanol, AMethyl Acetate, AMethyl Alcohol (100%), AMethyl Amine (32%), AMethyl Bromide, CMethyl Chloride, CMethyl Ethyl Ketone, BMethyl Isobutyl Ketone, BMethyl Isopropyl Ketone, BMethyl Sulfate, AMethyl Sulfuric Acid (All Conc.), AMethylene Chloride, CMineral Oils, AMonochloroacetic Acid Ethyl Ester, AMonochloroacetic Acid Methyl Ester,AMowilith D, ANaptha, BNapthalene, BFor more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

CHEMICAL COMPATABILITYSPILL CONTAINMENTCONTINUED.A. Suitable for long term storage at 100 degrees F or less.B. Suitable for short term storage less than one year.C. Do NOT store these chemicals in UltraTech containers.D. User testing may prove some of these chemicals are suitable for secondary containment applicationswith exposure time of one week or less.Nicotine Dilute, ANicotinic Acid, ANitric Acid 50%, ANitrobenzene, BNitrotoluene, BOctyl Cresol, AOleic Acid (All Conc.), AOleum Conc., COxalic Acid (All Conc.), APalmitic Acid, CParaffin Emulsions, APerchloric Acid (50%), APerchloroethylene, BPetroleum Ether, BPetroleum, APhenylhydrazine, CPhosphoric Acid (All Conc.), APhosphorous (Yellow 100%), APhosphorous Chlorides, BPhosphorous Pentoxide, APhotographic Solutions, APhthalic Acid (All Conc.), APhthalic Anhydride, APickling Baths Sulfuric Acid, A Hydrochloric Acid, APicric Acid (1%), APlating Solutions, APotassium Aluminum Sulfates (50%),APotassium Bichromate, APotassium Borate (10%), APotassium Bromide, APotassium Chlorate, APotassium Chloride, APotassium Chromate, APotassium Cyanide, APotassium Dichromate (40%), APotassium Ferri Ferro Cyanide Sat’d,APotassium Fluoride, APotassium Hydroxide, APotassium Nitrate Sat’d, APotassium Perborate Sat’d, APotassium Perchlorate, APotassium Phosphates, APotassium Sulfate, APropanol, APropargyl Alcohol (7%), APropionic Acid (50%), APropyl Alcohol, APropylene Dichlrode (100%), APropylene Glycol, APropylene Oxide, APyridine, BSelenic Acid, ASewage, ASilicic Acid, ASilver Nitrate, ASoda Ash, ASodium Acetate Sat’d, ASodium Benzoate, ASodium Bisulfate (10%), ASodium Bisulfite, ASodium Bromate, BSodium Chloride, ASodium Chlorite, ASodium Chromate, ASodium Disulfite, ASodium Dithionite (10%), ASodium Fluoride Sat’d, ASodium Hydroxide Conc., ASodium Hypochlorite, ASodium Nitrate, ASodium Oxalate, ASodium Persulfate, ASodium Phosphate, ASodium Sulfonates, AStearic Acid (All Conc.), ASuccinic Acid, ASulfuric Acid (98%), BSulfuric Acid, Fuming, CSulfurous Acid, ASulfuryl Chloride, CTartaric Acid Sat’d, ATetrachlorethylene, CTetrachloroethane, CTetrahydrofurane, CTetrahydronaphthalene, CThionyl Chloride, CTitanium Salts, BToluene Sulfonic Acid (All Conc.), BToluene, BTransformer Oil, ATributylphosphate, ATrichloroacetic Acid, BTrichloroethane, CTrichloroethylene, CTrichloroethylene, CTricresyl Phosphate, ATriethanolamine, ATrioctyl Phosphate, CTrisodium Phosphate Sat’d, ATurpentine Oil, CXylene, CPlease check the followingwebsite for a complete and up todate olyethylene/For more information about our products, c ontact Inside Sales at 800.448.3636 or email at info@acfenv.com

IBC SPILL PALLET PLUS SPILL CONTAINMENT SPECS Drain Colors Length Width Height Weight Load Capacity UDL Sump Capacity No yellow 62" 28" 62" 320 lbs 8,500 lbs 365 gallons Yes yellow 62" 28" 62" 320 lbs 8,500 lbs 365 gallons Description: A containment sump with deck surface used for storing and containing any leaks, spills or