Transcription

MASTICPATCHINGWITHSEALANTBINDER

Two ProblemsTwo CrewsTwo Machines?In Pavement Maintenance thetwo most troubling problemsare Cracks and Potholes.There are different methods foreach repair, and differentmachines for these repairtypes. The C1 will combinethese two processes into onemachine with the performanceand results the user isexpecting.CracksPotholes Crack Seal (hot)Crack Pour (hot or cold)Throw and RollSpray InjectionRemove and ReplaceMastic Sealant

The Cimline C-1Crack Sealer /Mastic PatcherThe C1 Combination Machine combines twocrews into one by utilizing your crack sealingcrew with best practices to provide solutions forcrack seal and mastic patch using one machine.This is done by using the proper sealant binderand local crushed stone material that isavailable in your area. No longer is factorypackaged mastic your only repair choice.

1/3SealantWhat is itFactoryPackagedMastic2/3"Engineered" AggregateFactory packaged mastic todayin its standard application is1/3 sealant and 2/3 engineeredaggregate.Example of Factory PackagedMastic Sealant Block

What is itMastic Patchingwith the C1Aggregate LocalCrushedSealant Climateand TypeThe patent pending designblends aggregate and sealantto make mastic patch.Crushed aggregate that issized to specification andwashed. 1/8” crushed ¼” crushed 3/8” crushed ½” crushedSealant specified for theclimate region, surface, andapplication. Type 1 Parking Lot Type 2 DOT ”3405”Most Common Job specific sealantsAviation

How ItWorksAggregateAggregate is moved from therock hopper through theheating chamber using acenterless screw. Eachrevolution drops a measuredamount of dried, pre-heatedstone into the mixing chamber.A hopper guard preventsoversized stone from enteringthe system.HopperHeating Sized ScreenedAggregateDamp is OKFines will produce astiffer mixHopper Guard keeps outoversize Diesel burnerAggregate is heated to aminimum of 240 degreesRemoves all moistureEnsures proper blendingHeated Tool Carrier

How ItWorksSealantA measured flow of sealantbinder is introduced into themixing trough at the samelocation as the pre-heatedaggregate. The mix has 100%binder coverage in the firstthird of the mixing system. Themix continues to flow down thesecond centerless screw to theplacement chuteMixingPlacing Metered Sealant Flowintroduced at applicationtemperatureCenterless screw foldssealant through mixingchamberMixing chamber isinsulated and heated Electrically heatedplacement chutetransfers mastic tobuggy or screed boxChute swings left to rightfrom lane center line tocenter rear of machine

How ItWorksRatioFlow controls for rock andsealant can be set for a varietyof mixture rates and applicationspeeds. This also allows theuser to specifically blendmastic to the characteristics ofthe application. Potholes Transverse cracks forsmooth ride Centerline segregation Bridge Joints Curb to street or transitionleveling

InstallationBestPracticesCLEAN! Like all pavementpreservation techniques,operators should follow bestpractices in job sitepreparation.Good-CompressorBest-Heat Lance Clean dry surfacespromote a strong bond tosurrounding pavementA 100 CFM compressoris ample in size Heat lances clean withcompressed air whileheating the repair areaThis dries wherenecessary, softens theasphalt, and exposesfresh binder whichpromotes bond tosealant

InstallationBestPracticesPlacement. Mastic isHOT. Safety first.Gloves, long sleeves, andsafety glasses. Thisoperator is using a 10”placement screed box ona curb to asphalttransition.Screed Box 10”Hot Iron Keep your tools HOT!There is a heat chamberon all machines Heat lances clean withcompressed air whileheating the repair areaThis dries wherenecessary, softens theasphalt, and exposesfresh binder whichpromotes bond tosealant

InstallationBestPracticesAggregate Selection isan important step.Remember to consideryour traffic load, averagedepth, and surfacefriction when choosingyour stone. Maximizeyour production andperformance.1/4-1/8” Stone1/8” Only Stone Higher skid resistance Higher static load capacity Impermeable to water Smoother texture Best for banding onsmaller cracks anddepressions Impermeable to water

CustomerValueThe C1 offers value tothe customer through theentire process. Less Disruption Safer Faster Material SavingsLess DisruptionSafety One closure for twoprocesses One Crew One disruption to thepublic Lowest load height Best visibility to operatorwith moveable placementchute Electric heated placementchute Simple operator control

CustomerValueThe C1 offers value tothe customer through theentire process. Less Disruption Safer Faster Material SavingsFaster C1 1 Tank 450 Gallons Others Tank 200Gallons C1 on demand heatsmaterial faster 1 Machine does the workof 2

CustomerValueThe C1 offers value tothe customer through theentire process. Less Disruption Safer Faster Material Savings Material Savings Local Aggregate Cost 40 Ton or 0.02 per poundLocal Sealant Cost 0.55 per pound C1 Mastic Cost 0.20 lb.

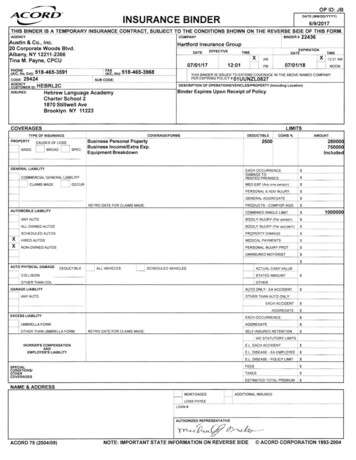

Mastic Start up (follow Material Start-up from page 10)1. Assure rock heating chamber is full ofrock.A. Turn Rotary switch to “Rock Only” andopen gate until rock begins to dump fromthe rock heating chamber into the mixingchamber.CustomerResourcesPRODUCT DATA SHEETNOVEMBER 2017Overview: Cimline On Demand Mas c System prepares and dispenses repair mas c material on demand.The mas c system incorporates locally approved cracksealant material and aggregate in a self -contained machine. Unlike other systems that require a prepackagedproduct that includes aggregate and the mas c binder,Cimline’s mas c system prepares the mas c binderand the aggregate in the machine at the jobsite, thusreducing handling and shipping of a batched pre-packaged product and allows on-demand supply. The finaloutcome is a finished product that is economical,locally sourced, and of highest quality.B. Turn Rotary switch to “Off”Use Cimline Repair Mas c System is used for sealing, filling, and repairing asphalt and concrete distresses on pavements aswell as bridge deck surfaces. Typical uses include repair of wide transverse and longitudinal cracks and joints, pothole repair,u lity cuts, patch repairs, curb and gu er to pavement alignment, leveling manhole and u lity covers, as well as leveling ofbridge approaches, spalled concrete joints, pop outs, corner breaks or other faulted areas that require needed maintenance.A er proper applica on, the mas c forms a flexible, waterproof, durable, well bonded product that will give years of service tothe exis ng pavements.2. Turn “ON” rock burnerA) Allow Rock Burner to preheat for aminimum of 45 minutesB) This can be running while the rubbermaterial is warming up.Generally Recommended Properties:3. Set flow control on material to “5”.Mas c Binder: Any locally approved packaged crack sealant material may be used that conforms to your clima c condi ons.Please refer to your local supplier and/or your Cimline dealer for addi onal informa on.A) Make sure material is up to the materialmanufacture predetermined temperature.This will be listed on the material packaging. Cost of Operation C1 OperatorInstructions Product andApplicationInstructionsAggregate: Any locally sourced graded aggregate that is clean, wear resistant and free flowing with a minimum aggregate sizeof 1/8” (3.17mm) and a maximum aggregate size of 5/8” (15.88mm) may be used. Please refer to your local aggregate supplier or asphalt mix producer for guidance and aggregate specifica ons. For best performance, the aggregate grada ons shallcorrespond to the patch depth and surface structure loads that are encountered on the roadway.Finished Mas c: The finished mas c is the combina on of the mas c binder and the aggregate. The material will form astrong, durable, water resistant membrane that will have years of service life. Being that the finished mas c is blended in thefield using local approved crack sealant and locally approved aggregate the finished mas c is not limited in scope as is a prepackaged mas c material. The finished mas c will be poured and leveled in the repair area and be traffic ready upon coolingand solidifica on.Surface Prepara on: All surfaces shall be free from moisture, loose material, fugi ve dust, dirt, vegeta on, and other materialsthat inhibits the bonding of the mas c to the exis ng surface. Repairs for concrete pavements may require a surface condioner. This may be deemed an appropriate ac on if deemed by the Contract administrator, inspector, or contractor to obtainnecessary bonding characteris cs.Installa on and Equipment Instruc ons: Prior to use the operator shall refer to the Installa on Instruc ons Document fordetailed informa on. This document will be necessary to review and understand prior to and during opera on.TOTAL COST OF OPERATION COMPARISON FOR 5 YEAR TERMAnnual Man Hours patchingAnnual Man Hours crack sealingLabor Rate /hr (average)Reference - Equivalent "Days Performing Task"Crew of 8Crew of 4Crew of 211 days22 days44 days16 days31 days63 days7001000 Limita on: Do not apply the material to a wet surface or over coal tar sealers as delamina on may occur. The applicator shalltake necessary precau ons to confirm suitability of use.40.00lbsCrack SealerMasticAnnual Material UsagePricer per ton of Crushed AggregateCost of Acquisition for a Mastic Machine AND a Crack SealerCost of Acquisition for CPMG C1 Combination MachineCost/lb45,00045,000 25 105,00085,000 Packaging: The mas c binder will normally consist of a modified asphalt crack sealant prepackaged in meltable plas c bagsin a cardboard box weighing approximately 40 pounds. Please refer to your local crack filler supplier for informa on regardingthe needed product.0.550.61Performance: Using best opera ng prac ces, such as surface prepara on, crack sealant and aggregate selec on, the finishedmas c material life cycle analysis is normally 4-5 years.Production MATERIAL CostApplication ProcessSeparate Crack Sealer and Mastic MachineCPMG Mastic Combo Mastic27,450- Application ProcessSeparate Crack Sealer and Mastic MachineCPMG Mastic Combo Mastic 28,000- Crack Sealer24,75032,999Aggregate Production LABOR CostCrack Sealing 40,000- ANNUAL TOTAL375 Combined Application 48,000ANNUAL TOTAL 68,000 48,000Capital Expense over 5 YearsApplication ProcessSeparate Crack Sealer and Mastic MachineCPMG Mastic Combo 105,00085,000 Application ProcessSeparate Crack Sealer and Mastic MachineCPMG Mastic ComboMaterial CostLabor Cost 261,000 340,000 166,871 240,000 52,20033,3745 YR Trade-in/Residual ValueAcquisition CostCost of Capital89,25072,250 5 YEAR TOTAL261,000166,871 5 YEAR TOTAL340,000240,000Cost of Capital15,75012,750True Cost of Operation* Total Costs690,250479,121 89,25072,250 Savings 211,129% Savings31% SavingsFOR ADDITIONAL INFORMATIONwww.CimlinePMG.com or Contact your local Cimline dealer

CPMGSERVING PAVEMENTPRESERVATION877-841-0848www.CimlinePMG.com

to make mastic patch. Aggregate Local Crushed Crushed aggregate that is sized to specification and washed. 1/8" crushed ¼" crushed 3/8" crushed ½" crushed Sealant Climate and Type Sealant specified for the climate region, surface, and application. Type 1 Parking Lot Type 2 DOT "3405" Most Common Job .