Transcription

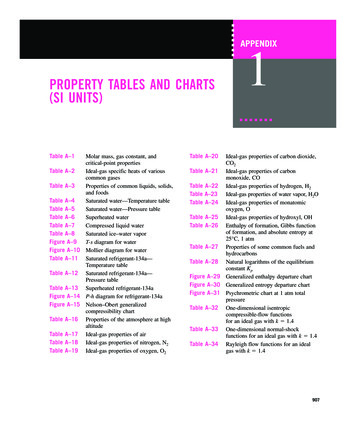

INDEX: SEVERE SERVICE DATA TABLESTABLE TITLETABLE NUMBERInsulation FactorsCavitation RegimesAcoustic power Ratio, rw15-0115-0215-03Noise Attenuation vs. P1/P2 ratio for MegaStream trimNoise Attenuation vs. P1/P2 ratio for MegaStream small hole trimNoise Attenuation Adjustment Factor for MegaStream trimNoise Attenuation vs. P1/P2 ratio for TigerTooth trim15-0415-0515-0615-07Materials of Construction for CavControl TrimMaterials of Construction for MicroCav TrimMaterials of Construction for CavStream TrimMaterials of Construction for ChannelStream TrimMaterials of Construction for Kämmer 11000 SeriesMaterials of Construction for Kämmer 15000 SeriesMaterials of Construction for MegaStream TrimMaterials of Construction for TigerTooth TrimMaterials of Construction for Stealth eedwater Material Selection: ChannelStream Pressure-Balanced ValvesFeedwater Material Selection: CavControl Pressure-Balanced Valves15-1715-18Sizing & Selection: Severe Service Data Tables, 15-IndexSS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-01: INSULATION FACTORSOperating80Temperature thru( F)250InsulationClassPipe 141618202430Over HC4PP4HC5PP5HC6PP6HC7PP7HC8PP8HC9 HC10 HC11 HC12 HC13PP9 PP10 PP11 PP12 PP13Single 22.5222.5222.5222.5Operating0Temperature thru C121122thru204205thru260851thru900901 951 1001thru thru thru950 1000 tion Thickness (inches)Multiple 28thru454NOTE: A maximum of 15 dBA (3 inches insulation) may be deducted from the calculated SPL whenusing thermal insulation. For acoustic insulation, the SPL reduction depends upon the “R” value ofthe insulation used.Sizing & Selection: Severe Service Data Tables, 15-Table 01SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-02 CAVITATION vitationIncipientCavitationNoCavitation(P1 – PV)σ PTABLE 15-03: ACOUSTIC POWER RATIO, rWValverwValverwGlobe0.25Butterfly0.50Segmented ball 90 0.25Eccentric rotary plug0.25Expanders1.00Sizing & Selection: Severe Service Data Tables, 15-Tables 02-03SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-04 NOISE ATTENUATION VS. P1/P2 RATIO FOR MEGASTREAM TRIMTABLE 15-05 NOISE ATTENUATION VS. P1/P2 RATIO FOR MEGASTREAM SMALL HOLE TRIMSizing & Selection: Severe Service Data Tables, 15-Tables 04-05SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-06 MEGASTREAM ATTENUATION ADJUSTMENT FACTORTABLE 15-07 NOISE REDUCTION VS. P1/P2 RATIO FOR TIGERTOOTH TRIMSizing & Selection: Severe Service Data Tables, 15-Tables 06-07SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-08 CAVCONTROL STANDARD MATERIALS OF CONSTRUCTIONSeat Retainer316 SS or 416 Hardened SSPlug316 SS with Alloy 6 FacingSeat Ring316 SS with Alloy 6 FacingTABLE 15-09 MICROCAV STANDARD MATERIALS OF CONSTRUCTIONValve Sizes½”, ¾”, 1”, 1-½”, 2” (Larger Sizes Available)Body StylesAngle and GlobePressure RatingsANSI 150#, 300#, 600#, 900#, 1500#, 2500#Seat Materials316 SS / Alloy 6, 400 SSPlug Materials316 SS / Alloy 6, 17-4 PH, 400 SSRangeability40:1CharacteristicModified Equal PercentageTABLE 15-10 CAVSTREAM STANDARD MATERIALS OF CONSTRUCTIONValve Sizes0.5", 0.75", 1.0", 1-1.5", 2" (Larger Sizes Available)Body StylesPressure RatingsSeat MaterialsPlug MaterialsRangeabilityCharacteristicAngle & GlobeANSI 150#, 300#, 600#, 900#, 1500#, 2500#316 SS / Alloy 6, 400 SSOuter Stage: 17-4 PH, 400 SSInner Stages: 316 SS30:1Linear, Bi-LinearTABLE 15-11 CHANNELSTREAM STANDARD MATERIALS OF CONSTRUCTIONTrim PartAvailable MaterialsCartridge316 SS, 400 SS, Ni-Al-bronze, Inconel, MonelPlug316 SS with Alloy 6 overlay, 400 SS, other alloys as requiredCartridge/Plug416 SSSeat Ring316 SS with Alloy 6 overlay, 400 SS, other alloys as requiredTABLE 15-12 KÄMMER 11000 SERIES STANDARD MATERIALS OF CONSTRUCTIONValve Sizes0.125 to 0.5-inch: up to 60,000 psig; 4 – 15 DN: up to 4,140 barBody StylesPressure RatingsAngleBody MaterialsTrim MaterialsPacking MaterialsGasket MaterialsBonnet StylesEnd ConnectionsActuatorsRangeabilityTrim Characteristics60,000 psig; up to 4,140 bar316 and 316 LN stainless steels, Hastelloy C, other castable materials according topressure rating316 SS, cobalt 6, Hastelloy B/C, nickel alloys, titanium, tungsten carbide (plug tip andseat insert), ceramic (plug tip and seat insert), PTFE (seat insert only)PTFE, graphitePTFE, stainless steelStandard, extended with normalizing fins, metal bellows sealIntegral flange (ANSI and DIN), screwed flanges, screwed internalKämmer 30/30-IP Series diaphragm actuator, 50 Series electric actuator25:1 for micro-flow services; 50:1 for low-flow servicesEqual percentage, linear, on-offSizing & Selection: Severe Service Data Tables, 15-Tables 08-12SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-13 KÄMMER 15000 SERIES STANDARD MATERIALS OF CONSTRUCTIONValve Sizes0.5 – 2-inch: ANSI Class 1500 – 2500; 15 – 50 DN: PN 250 – 400Body StylesPressure RatingsAngleBody MaterialsTrim MaterialsPacking MaterialsGasket MaterialsBonnet StylesEnd ConnectionsActuatorsRangeabilityTrim CharacteristicsANSI Class 1500 – 2500; PN 250 – 400316 and 316 LN stainless steels, Hastelloy C, other castable materials according topressure rating316 stainless steel, cobalt 6, Hastelloy B/C, nickel alloys, titanium, tungsten carbide(plug tip and seat insert), ceramic (plug tip and seat insert), PTFE (seat insert only)PTFE, graphitePTFE, stainless steelStandard, extended with normalizing fins, metal bellows sealIntegral flange (ANSI and DIN), screwed flangesKämmer 30/30-IP Series diaphragm actuator, 50 Series electric actuator50:1Equal percentage, linear, on-offTABLE 15-14 MEGASTREAM STANDARD MATERIALS OF CONSTRUCTIONPlug and Seat Ring316 SS or 316 SS with Alloy 6, Inconel, other alloys as requiredRetainerNickel-plated carbon steel, 316 SS, InconelGuidesBronze, Grafoil lined SS Alloy 6, Teflon-lined SSPackingTeflon, Teflon AFP, Glass filled Teflon, Graphite/AFP w/Inconel wire, GrafoilPacking Spacer316 SS or same as alloy bodyGasketsSS and asbestos spiral-wound Teflon, AFGTABLE 15-15 TIGERTOOTH STANDARD MATERIALS OF CONSTRUCTIONStackPlugSeat RingBronze, 400 SS, Inconel, 316 SS, 316 SS with Alloy 6 overlay, and otheralloys as required316 SS steel, 400 SS, Inconel, 316 SS with Alloy 6 overlay, and other alloysas required316 SS steel, 400 SS, Inconel, 316 SS steel with Alloy 6 overlay, and otheralloys as requiredTABLE 15-16 STEALTH STANDARD MATERIALS OF CONSTRUCTIONStackPlugSeat RingBronze, 400 SS, Inconel, 316 SS, 316 SS with Alloy 6 overlay, and otheralloys as required316 SS steel, 400 SS, Inconel, 316 SS with Alloy 6 overlay, and other alloysas required316 SS steel, 400 SS, Inconel, 316 SS steel with Alloy 6 overlay, and otheralloys as requiredSizing & Selection: Severe Service Data Tables, 15-Tables 13-16SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-17 FEEDWATER MATERIAL SELECTION CHANNELSTREAM PRESSURE-BALANCED VALVESValve Pressure Number TrimSizeClass of Stages 7.256.756.255.75StemDiameter1.1252Plug Mat'l Stem Mat'l Seat Ring RetainerSleeveCodeCodeMat'l Code Mat'l Code Mat'l /CFC230/1403685201CGC156/CFC230/140Sizing & Selection: Severe Service Data Tables, 15-Table 17SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

(Continued)TABLE 15-17 FEEDWATER MATERIAL SELECTION CHANNELSTREAM PRESSURE-BALANCED VALVESValve Pressure Number TrimSizeClass of Stages .259.508.758.007.38StemDiameterPlug Mat'l Stem Mat'l Seat Ring RetainerSleeveCodeCodeMat'l Code Mat'l Code Mat'l C140Sizing & Selection: Severe Service Data Tables, 15-Table 17SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

TABLE 15-18 FEEDWATER MATERIAL SELECTION CAVCONTROL PRESSURE-BALANCED .50B11.50C11.50DStemDiameterPlug Mat'l Stem Mat'l Seat Ring Retainer/Sleeve Mat'lCodeCode Mat'l Sizing & Selection: Severe Service Data Tables, 15-Table 18SS015, Rev 09/2002Flowserve Corporation, Flow Control Division, Tel. USA 801.489.8611

Noise Attenuation vs. P1/P2 ratio for MegaStream trim 15-04 . 801 thru 850 851 thru 900 901 thru 950 951 thru 1000 1001 thru 1050 Insulation Class HC1 PP1 HC2 PP2 HC3 PP3 HC4 PP4 HC5 PP5 HC6 PP6 HC7 PP7 HC8 PP8 HC9 PP9 HC10 PP10 HC11 PP11 HC12 PP12 HC13