Transcription

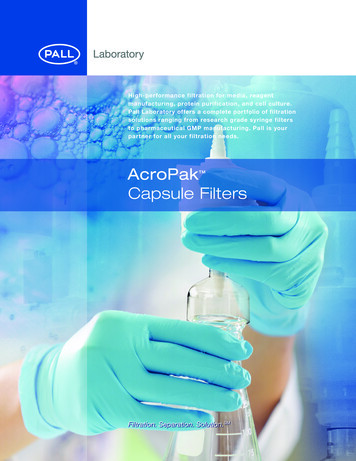

High-performance filtration for media, reagentmanufacturing, protein purification, and cell culture.Pall Laboratory offers a complete portfolio of filtrationsolutions ranging from research grade syringe filtersto pharmaceutical GMP manufacturing. Pall is yourpartner for all your filtration needs.AcroPak Capsule FiltersSMFiltration. Separation. Solution.SM

A Filter for EveryStep in Your ProcessFrom drug discovery and basic research to processdevelopment and production, Pall Corporation isthe single source for all your filtration needs.Buffer, Media,and ReagentManufacturingPrimary ApplicationsSterile filtration of media,Stbuffers, or reagentsPre-filtrationand clarificationPPre-AcroPak AdvantagesProteinPurificationPrimary ApplicationsPurification of proteinsffrom CHO and HEK cellsCelland bioburden removalCell debrisdeIncreased throughput improves productivityHigh filtration capacity forlonger production runsWider range of solution compatibilityAcroPak AdvantagesFast filtration & throughputGreat cell-and debris-holding capacityHigh recovery of proteins(low protein binding)Single-capsule filtrationfor entire batchCell Cultureand BioburdenFiltrationPrimary ApplicationsSteSterilizationof cell culturesUpsttrea and downstream filtrationUpstreamBioburden removalAcroPak AdvantagesFast, efficient sterile filtration ofcell culture additivesProtect cell culture qualityMultiple pore size optionsfor bioburden removalScale up Filtration for Easier Validation, Tech Transfer, and Faster Time-to-MarketPall Laboratory offers products that use the same membranes and materials that scale up from syringe filters to GMP manufacturing-scale filters.This means scientists can research, develop, and validate their processes with lab-scale filters and then, as volumes increase or processes moveto manufacturing scale, the same filters are available in larger sizes with pharmaceutical certificates. This advantage ensures identical filtration performance,chemical and biological compatibilities, and efficiencies as a process scales up in size — shortening redevelopment and accelerating time to market.www.pall.com/lab

Buffer, Reagent, andMedia ManufacturingSterility is critical in buffer/reagent manufacturing and media preparation to ensure thepurity and integrity of the final product. Leachables and extractables must be minimizedto prevent contamination.Filter efficiency: filtration must beMembrane compatibility: buffersLow-binding: A filter should be inert andperformed quickly and have high volumeand reagents have different chemicalnot bind endogenous components, such ascapacity so that no matter the solution,contents with varying pH levels. Theproteins. Media frequently contains serumturbidity, or volume only one capsule filtercapsule’s construction, material, andor large proteins that must be efficientlyis required. This eliminates waste andinternal membrane must be compatiblefiltered. This is particularly critical when lowprocess variability from changing capsulewith a wide range of solutions to eliminatequantities of protein are added to the media.filters mid-run.time-consuming change outs for eachnew application or batch lot.Filter Performance Varies Widely Among ManufacturersAcroPak capsule filters are designed for highTotal Throughput Using 3% Tryptic Soy Broth (TSB)performance across all buffer, reagent, andmedia manufacturing applications. Great throughput sterilizes solutions faster,improving productivity High-performance membranesallow longer production runs withoutchange outs Low-binding filtration minimizescapture of proteins from solutionsVolume Filtered (mL) Consistent pore sizes ensure solution sterility60005000400030002000Lot ALot B1000Lot C0Pall PESSupor MembraneEFA 200 cm 2PallFluorodyne IIPVDF MembraneEFA 200 cm2WhyAcroPakcapsules?WhyAcroPakcapsules?With70 70yearsof ormancefor rmancefor ermembranecompatibility.Consistentpore consistentsize ensuressterility.Plus, our productsfeatureExceptionallyporesize maximizessterility. bleslow proteinbinding.feature lowandandextractablesandlow protein binding.

ProteinPurificationFilter efficiency: filtration must be performed quickly and have high volume capacityso that no matter the solution, turbidity, or volume; only one capsule filter is required.This eliminates protein recovery loss and process variability from changing capsulefilters mid-run.AcroPak capsule filters maintaintheir effectiveness with high-densitycell culturesLow protein binding membrane is criticalAcroPak capsules withstand theto ensure high protein recovery.challenges of variable, high cell densityPall Laboratory’s AcroPak capsules withprotein purification.The ability to filter an entire cell culturedual-layer membranes allow quick, Built-in pre-filters enable low viability,broth through a single capsule, no matterefficient filtering of a wide range of cellhigh-turbidity solution filtration throughthe turbidity level, is important to avoiddensities and viabilities. These productsone capsulethe risk of product loss that results fromhave built-in pre-filters that remove celldebris and bioburden first, ensuring the final High recovery of proteins from CHOfilter change outs and process delays.Filtering a wide range of cell culturefiltration layer will not clog prematurely.and HEK cells (lowest protein binding) Fast flow and throughput improvedensities and viabilities through one capsulelab productivityis essential to ensure a standardized, Optional Supracap depth filterefficient purification process.capsule can be added inline toeliminate the need for upstreamcentrifugationResearchers want more proteins, which come from highercell densities. But this can lead to lower viability that canprematurely clog the filter and stop the entire process.Pall Laboratory Acropak capsules are designed to handlehighly turbid cell cultures.16Pre-Filter Increases ThroughputVolume Filtered Prior toClogging (mL/om2)141210864200.2 µmSupor Membrane0.8 µm/0.2 µmSupor MembraneMembrane Type: 47 µm discThroughput determined using 2% Tryptic Soy Broth (TSB)

Cell Culture Sterile Filtrationand Bioburden ReductionSterility is the primary objective for cellBioburden Reductionculture filtration. The media (serum,AcroPak capsule filters are also availablePBS, water, etc.) that comes into contactwith larger membrane pore sizes towith the broth must be sterile to avoidprovide fast, efficient, bioburden reductioncontaminating the cell solution. A 0.2 µmfor upstream filtration processes.sterile filter can eliminate biologicalcontamination, environmental contamination,or foreign matter due to contaminatedupstream products or improper user handling.Mycoplasma ReductionAcroPak capsules are available with 0.1µm membrane for mycoplasma retention.AcroPak capsule’s high performance filtrationis ideal to ensure your cell culture sterility. Cell culture sterility is assured by filteringmedia and additives, eliminating the riskof contamination Culture quality is protected Filter sizes available from syringe to capsulesfor in-hood or bench-top processingAcroPak Capsule Quality*AcroPak filters come with rigorousquality claims and are tested toensure they meet high performancestandards:1 00% integrity tested (where noted) Endotoxin level: 0.25 EU/mL usingLimulus Amebocyte Lysate test Bacterial retention: 0.2 μm lot samplesretain 107 cfu/cm2 of B. diminuta permodified ASTM F838 Mycoplasma reduction: 0.1 μm lotsamples retain 107 cfu/cm2 A. Laidlawiiper modified ASTM F838 Biological safety: passes United StatesPharmacopeia (USP) biologicalreactivity test in vivo 88 Sterilization (where noted): bygamma irradiation*Refer to product data sheets for specific testsand claims on individual products.www.pall.com/lab

AcroPak ProductsFiltration MembranesPre-Filtration CapsulesPall Laboratory filters incorporatehigh-performance, proprietarymembrane technology.Whether solutions include high solid loads,particles, or whole cells (millions/mL),Pall Laboratory offers a complete lineof pre-filter capsules that allow efficientS upor PES (Polyethersulfone):With high flow and capacity, broad fluidfiltration of the most difficult anddirty solutions:compatibility, low protein adsorption,S upracap depth filters:active ingredients, and stabilizers, Pall PES0.4 to 30 µm, Seitz depth mediamembranes are best suited for filtration of Mini-Profile capsules:preparative fluids such as buffers, media,and bioprocess intermediates.S upor EKV Asymmetric PES:PES filters with asymmetric membranelayers have the same benefits of SuporPES (above), but with additional debrisholding. This makes them ideal for highturbidity, high bioburden solutions.0.5 to 5 µm, polypropyleneCapsule pore size and EFA* sizes AcroPak with Supor 0.8/0.2, 0.8/0.45, 0.2/0.2For example, AcroPak capsules withand 0.1/0.1 µm 20, 200, 500, 1000 and 1500 EFASupor membrane have a 0.8 µmpre-filter and 0.2 µm sterile membrane,and the AcroPak capsules with SuporF luorodyne II PVDF (hydrophilicpolyvinylidene fluoride)Low extractables, low product andexcipient adsorption, simple validation AcroPak with Supor EKV Asymmetric 0.65/0.2 µmEKV has an asymmetric 0.65 µm pre-filterwith a 0.2 µm sterile membrane. 20, 200, 400, 800and 1500 EFAfor the sterilization of a wide range offormulations make PVDF membranesideal for final filtration AcroPak with Fluorodyne II 0.1 and 0.2 µm 20, 200, 400 and 800 EFA*EFA- effective filtration areaVisit us on the Web at www.pall.com/labE-mail us at LabCustomerSupport@pall.comCorporate Headquarters25 Harbor Park DrivePort Washington, New York 11050 2019, Pall Corporation. Pall,, AcroPak, Polypure, Supracap, Seitz, and Supor are trademarks ofPall Corporation. indicates a trademark registered in the USA. Filtration.Separation.Solution. is a servicemark of Pall Corporation.04/19, PDF

feature low leachables and extractables and low protein binding. filtration technology achieves outstanding performance for high throughput, superior capacity, and great membrane compatibility. Consistent pore size ensures sterility. Plus, our products feature low leachables and extractables and low protein binding. 6000 5000 4000 3000 2000 .