Transcription

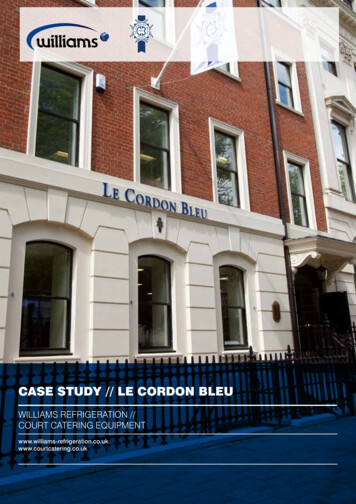

CASE STUDY // LE CORDON BLEUWILLIAMS REFRIGERATION //COURT CATERING catering.co.uk

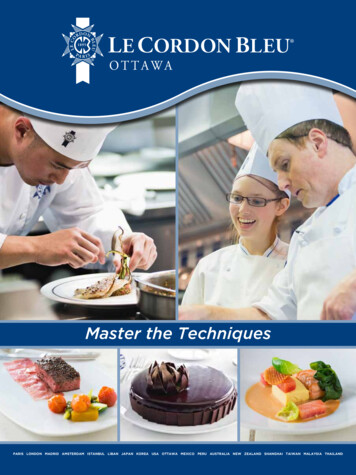

ABOUT THE PROJECTLe Cordon BleuLe Cordon Bleu has been teachingclassic culinary techniques for over100 years. A world renowned networkof educational institutions that providesthe highest level of culinary andhospitality instruction, operating 40schools in 20 countries and teachingover 20,000 students annually.When Le Cordon Bleu decided tocreate an International FlagshipInstitute in London, they choseWilliams to supply the refrigeration forthe new kitchens.“Internationally Le Cordon Bleu offersin excess of 50 different courses, andthe London campus has facilitiessuch as classrooms with interactivetechnology,” says Larry Montack,Head of Institute. “This means wecan increase the breadth of coursesavailable to include those in wine andmanagement. Prior to the developmentwe had in depth discussions withcolleagues from around the world toresearch everything we had achievedover the past ten years in terms of newsites and courses.London was an opportunity to reviewour developments, to select the bestand most successful initiatives andensure that we were developingan Institute for the future, includingthe most technologically advancedcatering equipment.”The equipment was supplied andinstalled by Court Catering, whosemanaging director Nick Howe says:“As you would expect with sucha prestigious project, the client’srequirements were very demanding.The shopping cart included 53cabinets / counters, 6 blast chillers,7 retarder provers and 5 modularcoldrooms.”THE FLEXIBILITY OF WILLIAMS’ COLDROOM DESIGNS MEANTTHE COMPANY WAS ABLE TO SUPPLY FIVE UNITS, EACHTAILORED FOR A SPECIFIC STORAGE PURPOSEA suite of kitchens to teachtomorrow’s 5* chefsThe kitchens in the new instituteinclude: Basement production kitchen,producing ingredients for classesWorld cuisine kitchen withequipment such as a tandooriovenBoulangerie, bakery and patisserieareasPolyvalent kitchenVariety of demonstration areasMontack says: “The third floorPolyvalent kitchen is designed toadapt to whatever is required – fromcuisine kitchen to patisserie. In fact,all the kitchens are multi-purpose.Given the huge range of courseswe offer, they have to be. Again, theequipment we specified had to be ableto accommodate that flexibility.”Williams’ coldroom designs weretypical of this flexibility. The companywas able to supply five units, eachtailored for a specific storage purpose:fruit and vegetables, fish, meat,general products and a freezer room.

Coldroom Installation

CABINETS & BLASTCOUNTERS CHILLERSRETARDERPROVERSCOLDROOMS

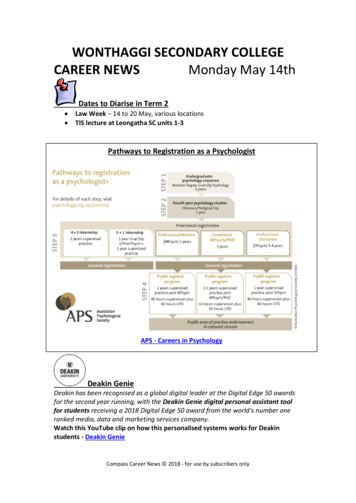

THE EQUIPMENTThe EquipmentThe Williams equipment at LeCordon Bleu features the latestrefrigeration technologies. Cabinetsand counters were supplied withCoolSmart controllers, which monitorthe equipment operation, only turningon the refrigeration system when it isneeded in order to minimise powerconsumption, saving up to 15% inenergy. The institute’s new blastchillers use WEB (Williams Easy Blast)controllers, which are extremely simpleto operate.“50% of our students go on to 4 or 5star establishments like the Dorchesterand the Savoy, a further 40% opentheir own businesses,” says Montack.“They expect to be using the verybest facilities. At the same time, thekitchens are in constant, heavy use. Sothe catering equipment has to be topquality, robust and absolutely reliable.”Equipment IncludesModelModel TypeNumber of UnitsH02UTwo door counter3HRMR1TSingle door roll in14HAZ5CTAztra undercounter34WBC1010kg Blast Chiller2WBC4040kg Blast Chiller4RPC1TSingle door Retarder Prover7HBTC22 Door Biscuit Top Counter1HBTC33 Door Biscuit Top Counter1Coldrooms1 Freezer; 1 General Purpose;1 Fruit & veg; 1Meat; 1 Fish5SustainabilityAnother key factor in terms ofequipment specification wassustainability. “As an organisationwe are committed to minimisingour carbon footprint and protectingthe environment,” says Montack.“Sustainable technology goes handin hand with financial efficiency soinvesting in quality, longer lastingequipment makes sound businesssense to us.”Williams’ Greenlogic initiativefocuses on helping operators reducetheir carbon footprint. As well asdeveloping ‘greener’ technologies, thisinvolves helping customers to betterunderstand their buying choices: howparticular model variations will impacton sustainability, waste reduction,power consumption and so on.

“THE CATERING EQUIPMENT HAS TO BE TOP QUALITY, ROBUST ANDABSOLUTELY RELIABLE ”

Design Excellence : Cool Technologywww.williams-refrigeration.co.ukFor further information about this, other case studies or toview the complete range of Williams products please visitwww.williams-refrigeration.co.ukWilliams Refrigeration is a trading name of AFE Group Limited.Registered in England & Wales under Registered Number 3872673.Registered Office Address - Bryggen Road, North Lynn Industrial Estate, King’s Lynn, Norfolk, PE30 2HZWilliams RefrigerationBryggen RoadNorth Lynn Industrial EstateKing’s LynnNorfolk PE30 2HZT 44 (0) 1553 817 000F 44 (0) 1553 817 111E info@williams-refrigeration.co.ukMK/Lit/LCB CaseStudy0712/V1

The Williams equipment at Le Cordon Bleu features the latest refrigeration technologies. Cabinets and counters were supplied with CoolSmart controllers, which monitor the equipment operation, only turning on the refrigeration system when it is needed in order to minimise power consumption, saving up to 15% in energy. The institute's new blast