Transcription

SMUD’s Pilot Natural RefrigerantIncentive ProgramInvestigating Direct GHG Emission Reductions inCommercial RefrigerationET SummitNovember 17, 2021

About SMUD3

Pathway to zero carbon by 20304

SMUD’s Pilot Natural Refrigerant IncentiveProgram Launched in March 2017 at NASRCWorkshop hosted at SMUD Built on SMUD’s existing CustomIncentive and Savings By Designprograms– Maintains incentive for energy (kWh)and demand (kW) Additional incentive for directGHG emission reductions fromnew or retrofitted low-GWPsystemsHigh-GWP refrigerants are projected to resultin annual GHG emissions of over 1 million– SMUD pays for energy performance MtCO2e in Sacramento alone by 2050metering and data collection tounderstand performance of lowGWP systemsProgram created withtechnical assistance from6

SMUD Program Objectives Spur market transformation to support SMUD’s EnvironmentalLeadership Directive (SD-7) Establish a cost-effective pathway for Natural Refrigerants Create a model incentive for others to reference Build a network of manufacturers, engineers, technicians, and customers Position SMUD to leverage potential state funding on our customer’sbehalf Support transition to a carbon metric for program evaluation“SMUD will provide leadership in the reduction of the region’s total emissions ofgreenhouse gases through proactive programs in all SMUD activities anddevelopment and support of national, State, and regional climate change policiesand initiatives.” SMUD Strategic Directive 77

Customer Benefits End the expensive cycle of refrigeration system upgrades and retrofits due torefrigerant phase outs and replacements with a permanent long-term solution Assist with the initial cost of new equipment installation Support emerging technologies that enable customers to improve energy efficiencyand reduce direct GHG reductions Lower customer energy bills and refrigerant costs Eliminate liability associated with leak inspections, fines, and enforcements Provide Access to network of equipment manufacturers, engineers, technicians, andsuccessful project implementations8

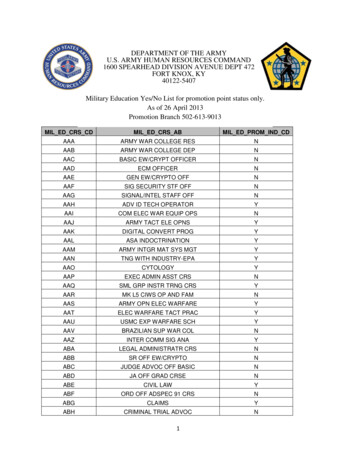

Incentive Eligibility and StructureProgramParametersExisting Program RequirementsRefrigerant Incentive RequirementsRetrofitMeet the existing requirements of the CustomIncentive ProgramSystem uses natural refrigerant (CO2,ammonia, hydrocarbon)New systemMeet the existing requirements of the SavingsBy Design ProgramSystem uses natural refrigerant (CO2,ammonia, hydrocarbon)Required systemmonitoringNoneThree years, SMUD nt physical system change required sooperation doesn’t revert to the baselinetechnologyPhysical system component or change must bemade that prevents reverting to high-GWPrefrigerantCustom Program IncentiveIncentives are based on decreasing yourenergy use:Direct GHG Emissions Reductions IncentiveIncentives are based on decreasing direct emissions fromrefrigerants over the system lifetime: 0.10/kWh Energy Reduction Incentiveand 25/MtCO2e emissions reduction from refrigerants 200/kW Demand Reduction IncentiveTotal incentive limited to 30% of project cost or 150,000, whichever is less Total incentive limited to 30% of projectcost or 150,000, whichever is lessAll projects located in disadvantaged communities (withpreference for those in the top 10%) and implemented bysmall-to-medium sized business owners will receive a25% incentive bonusCombined incentive limited to 50% of project cost or 250,000, whichever is less9

Developing an Appropriate Direct IncentiveRate Level Direct incentive rate was evaluated in two ways, bothsupported a valuation of approximately 25/MtCO2e1.Based on SMUD current energy incentives (Custom Incentiveand Saving By Design) 2. 0.10/kWh converted to /MtCO2e using marginal emission factor for15 year lifeBased on California GHG Allowance Price Floor Average of price floor for 15 years based on annual escalation of 5%plus inflation10

Current Status Two active projects utilizing the incentive– Research plan adapted to leverage unique opportunity forcomparison APPA DEED grant secured to assist with incrementalsystem cost, support research and technology transfer First year of monitoring complete for both systems,continuing for another year Demand is strong – new projects have been proposed inSacramento County and around the State from interestedparties (stores, food processors) New system funding on hold– New Zero Carbon Goal prioritized plus awaiting final findings11

Grocery Outlet PairTwo pairs of stores:12

Raley’s Pair13

Natural Refrigerant: CO214

Refrigerant Racks15

Compressors16

Ammonia Compressors17

Energy Monitoring18

Data Collection: Energy Monitoring19

Data Collection: Other Resources Control System Staff interviews Thermal Imaging20

Grocery Outlet Technical Specs* Equipment varies in age by decades.21

Raley’s Technical Specs22

Year 1 Results: Energy Consumption: 28% savings shown for GroceryOutlet pair, 16% loss for Raley’s pair. It’scomplicated Emissions: 62% Reduction, dominated by normalleakage rather than energy impact. This is for a 1-yeartime period which doesn’t include decommissioning. Equipment Costs: -9% for GO to 16% for Raley’s23

Results Discussion Water & natural gas savings not quantified in thisstudy Focus on refrigeration system performance (especiallycompressors) Control group of 1 is very small. Normalized byrefrigeration capacity and traffic, but a larger controlgroup would reduce uncertainty24

Whole-Building Approach: Raley’s Freeport store: Large solar array, no naturalgas usage, hot water heated with process heat,minimal water consumption compared to evaporativecooler Higher up-front cost. Potential for higher maintenance,but equipment is still new.25

Anecdotes Leakage reporting: Odd experience collecting data,but huge (3000x) influence on global warmingpotential Maintenance: new and different psychology, fear ofammonia CO2 as heat transfer media: can loose it all. Nocompressor, just a pump.26

Thank you for listening!27

For More Information:Kathleen AveClimate Program Manager, Energy Research & Developmentw. 916-732-5302Kathleen.Ave@smud.orgRyan Hammond, P.E.Senior Mechanical Engineer, Integrated Design Solutionsw. 916-732-5647Ryan.Hammond@smud.orgDaniel Chapman, P.E.Senior Mechanical Engineer, ADM Associates Inc.w. 916-889-7618Daniel.Chapman@admenergy.com28

SMUD Program Objectives Spur market transformation to support SMUD's Environmental Leadership Directive (SD-7) Establish a cost-effective pathway for Natural Refrigerants Create a model incentive for others to reference Build a network of manufacturers, engineers, technicians, and customers