Transcription

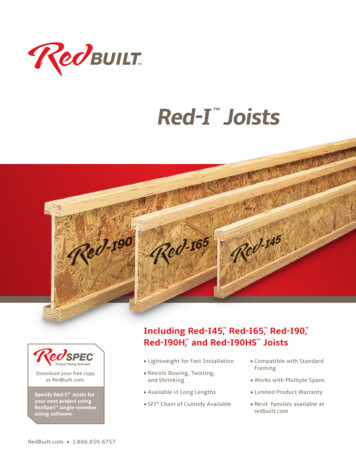

Red-I Joists Including Red-I45, Red-I65, Red-I90, Red-I90H, and Red-I90HS Joists Lightweight for Fast InstallationDownload your free copyat RedBuilt.com.Specify Red-I Joists foryour next project usingRedSpec single-membersizing software.RedBuilt.com 1.866.859.6757 Resists Bowing, Twisting,and Shrinking Compatiblewith StandardFraming Workswith Multiple Spans Available in Long Lengths LimitedProduct Warranty SFI Chain of Custody Available Revitfamilies available atredbuilt.com

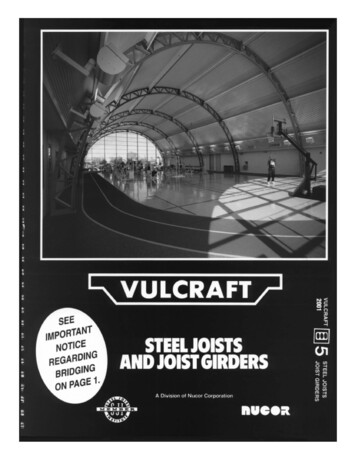

Welcome to RedBuiltRedBuilt is an exciting business offering building solutions for a broad rangeof commercial and custom residential applications. In addition to pioneeringunique manufacturing technologies, RedBuilt provides world-class service andtechnical support for architects, specifiers and builders.RedBuilt gives you access to reliable, innovative products, including RedBuilt open-web trusses, Red-I joists, and RedLam LVL beams and headers. Andwe keep things simple: You'll work with just one service-oriented supplier toget all these products—plus the support you need to build smarter.RedBuilt: A family of brand-name building products a source for innovativeideas and solutions a supplier that’s simpler to do business with.The RedBuilt Red-I Joist AdvantageRed-I joists are lightweight joists suitable for use in roofs and floors incustom residential, multifamily, institutional, and commercial applications.This product is available in multiple series so you can design the most costeffective system. Other Red-I joist benefits include: Dependable Delivery—RedBuilt plants are located in key market areas,enabling us to deliver materials quickly. Each plant is staffed withexperienced personnel who can help solve problems and talk with youabout any special project requirements. Minimum Waste—Red-I joists are manufactured to resist twisting andshrinking, and they can be cut to size at the factory so there’s virtually notime or material waste prior to installation. Compatibility—All Red-I joists fit into wood frame, masonry, or steelconstruction, and they can accommodate a wide variety of decking andceiling materials—including wood, plywood, steel, and gypsum.TABLE OF CONTENTSIntroductionFeatures and BenefitsDesign Center ServicesRed-I Joist DescriptionsDesign PropertiesLoad Tables8' On-Center Roof Span TableFloor DetailsCantilevers and OutriggersRoof DetailsRim BoardRed-I Blocking PanelsWeb StiffenersNailing InformationWind or Seismic ConnectionsFire and SoundAllowable HolesDeflection CriteriaSnowdrift LoadingTechnical Support and AnalysisQ&ARed-I Joist SpecificationsMaterial WeightsRedSpec Sizing SoftwareProduct Warranty234456–9910–1212 –13141515161617181920202122–2324252628 Easy Mechanical Access—Knockout holes for ventilation and flexible conduitare provided in the web of the Red-I joists. The web can also be cut ordrilled to accommodate larger ductwork (see page 19), so costly suspendedceilings can often be eliminated.ABOUT THIS GUIDEThe Red-I Joist Specifier's guide is one of several guides that offer technical informationand design recommendations for RedBuilt products. This guide provides architects,designers, and engineers with information regarding Red-I joists for commercial andcustom residential applications.2

FEATURES AND BENEFITSProduct SelectionThis guide provides specifiers with technical information about the RedBuilt Red-I joist product line.However, complex or custom applications can often make specifying the the right products in the right places achallenge — especially when you have factors such as span, wind, load-carrying capacity and other design constraintsto consider. But whatever your project entails, RedBuilt is here to help. Your local RedBuilt technical representative,along with our Design Center team, can assist you in choosing the best products and designing the best system foryour specific application.Contact us for help with any of the following: Product selection Building department calculations Complete cost analysis System selection (system packages can include horizontal framing,load-carrying beams, headers, wall framing, mansard framing, and accessories)Products for Every ApplicationIn addition to Red-I joists, RedBuilt offers a variety of other engineeredlumber products that are ideal for use in commercial and custom residentialprojects. For more information, contact your RedBuilt technical representativeor visit redbuilt.com to download literature for products such as taperedRed-I joists, open-web trusses, and RedLam LVL.Unsurpassed Technical SupportRedBuilt has one of the largest networks of technical representatives in thebusiness. Their services include consultation, computer-assisted designand layout, delivery coordination, and installation review. They can suggestcost-reduction techniques and check special application requirements. Inaddition, they’re backed by a staff of professional engineers who providecomprehensive technical support when needed. Special requests areaccommodated wherever practical, and they offer cost analysis, engineeringanalysis, assistance with building code approvals—even the creation of specialproduct applications for more creative designs. The goal of RedBuilt technicalsupport is to help architects and engineers achieve quality design applicationswith the most cost-efficient product selection possible.Our network of technical representatives offers awide range of services to help guide your projectsthrough planning and construction.Resource EfficiencyConsider all the positive attributes of wood when selecting your building material of choice. In addition to itsstructural properties, high strength-to-weight ratio, and ease of construction, wood is a naturally occurring,renewable resource that requires less energy to produce than steel or concrete. And it sequesters carbon — whetheron the stump or in your structure.Our Red-I joists, as well as other RedBuilt products, are made with responsibly sourced fiber and are availableas SFI Chain of Custody certified material. Whether you’re looking for LEED certification or simply want to ensureefficient use of raw materials, we can help. By making better use of every tree, RedBuilt produces cost-effective,consistently available engineered wood products that reduce environmental impact. The result is a quality woodproduct that offers superior strength and reliable performance. 3

DESIGN CENTER SERVICESInstallation ReviewUpon request, RedBuilt can provide the following services forthe products described in this guide: Acompletedesignpackageincludinglayoutdrawings (placementdiagrams) and detailed design calculations. Review and analysis of the application. Drawings and/or calculations sealed by a professional engineer.Although responsibility for proper installation lies with thecontractor-builder, RedBuilt provides detailed suggestionsand guidelines for installation. If requested, a RedBuiltrepresentative will visit the site to verify the contractor’sunderstanding of proper installation. RedBuilt professionalengineers also are available to help solve jobsite applicationproblems.Engineering Responsibility Position StatementRedBuilt is a manufacturer of proprietary structuralcomponents.It employs a staff of professional engineers to aid in thedevelopment, manufacture, and marketing of its products.RedBuilt does not replace or accept the responsibility of thedesign professional of record for any structure.RedBuilt accepts the delegation of engineering responsibilityonly for the products it manufactures, provided that theapplication conditions are specified by the design professionalof record, or other responsible party when a design professionalis not engaged. RedBuilt provides engineering in the design ofits products and does not displace the need on any project for adesign professional of record.Our technical support team offers professional capabilities in thedesign and application of all RedBuilt products.RED-I JOIST DESCRIPTIONSThis guide covers five series of joists: Red-I45 , Red-I65 , Red-I90 , Red-I90H , and Red-I90HS . These joists are primarilyintended for commercial applications such as retail stores, office buildings, schools, restaurants, multi-family, hotels, warehouses,and nursing homes. They are typically designed, manufactured, and sold by RedBuilt for each specific job. Contact your RedBuiltrepresentative for more information.Some series of Red-I joists are available with tapered profiles for use in certain roof applications. Contact your RedBuilt representative for determining availability and for application assistance or see the Tapered Red-I65T Joists guide.Red-I joists are normally produced without camber. However, camber is available at 2,250' radius as a special order for Red-I45 ,Red-I65 , Red-I90 , Red-I90H , series joists. Camber is not recommended for floors, or for multiple-span or cantilever applications.1¾"3 8"1½" (minimum)1½" (minimum)1½"9½",117 8",14"–16"7 16"117 8",14"–30"3½"3½"3½"2½"2½"1¾"117 8",14"–30"7 16"7 16"117 8",14"–30"½"117 8",14"–32"Red-I45 Red-I65 Red-I90 Red-I90H Red-I90HS Top and bottom flanges of1½" x 1¾" RedLam LVLwith 3 8" OSB web.Top and bottom flanges of1½" (minimum) x 2½"RedLam LVL with7 16" OSB web.Top and bottom flanges of1½" (minimum) x 3½"RedLam LVL with7 16" OSB web.Top and bottom flanges of1¾" x 3½" RedLam LVLwith 7 16" OSB web.Top and bottom flanges of2½" x 3½" RedLam LVLwith ½" OSB web. Red-I65 available in tapered profile. Check with your technical representative for availability. Red-I90HS provides increased bending strength and stiffness for heavy loads and 8' on-center roof sytems. roof sytems Joist depths from 14" to 32" are available in 2" increments.WARNING: Drilling, sawing, sanding or machining wood products can expose you to wood dust, asubstance known to the State of California to cause cancer. Avoid inhaling wood dust or use a dust maskor other safeguards for personal protection. For more information go to www.P65Warnings.ca.gov/wood.Building Codes and Product Acceptance: See ICC ESR-2994 and LABC/LARC Supplements, DSA IR 23-94

DESIGN PROPERTIESReference Design ValuesEnd Reaction (lb)(4)(5)Red-I JoistRed-I Joist with1¾" Bearing3½" Bearingwith NailedGlue-Nailed Floor(7)Web StiffenersWeb Stiffeners(7)EIFloor SheathingSheathing(106 in2-lb)(106 in2 - lb)(106 in2 - )Moment(1)Mr (ft-lb)Shear(2)Vr (lb)9½"117 1,9602,120185319474653221375553756117 24,434117 324,8955,732117 4,5905,4366,363117 082,6543,3994,2445,1946,2497,4128,68710,075Red-I45 ,225Red-I65 16NA1,7504,056NA1,7504,762NA1,750Red-I90 ,387NA2,4505,191NA2,4506,073NA2,450Red-I90H ,850NA2,4505,737NA2,4506,710NA2,450Red-I90HS Joist1,0341,835(6) 2,320(6)1,5381,836(6) 2,565(6)2,1131,837(6) 2,790(6)2,7871,838(6) 3,020 A3,500 (6)(1) Do not increase joist resistive moment properties by a repetitive-member-use factor.(2) For possible increases in shear capacity see shear design information at right.(3) For deflection calculation only. Assumes 24" joist spacing with a 24" span-rated panel.(4) Interpolation between bearing lengths is permitted for allowable design reactions.(5) Reaction capacity has been determined based on RedBuilt products. Allowable bearing onsupporting members shall be checked.(6) 2½" bearing length is required at end reactions.(7) Refer to page 16 for web stiffener details.(8) 5¼" bearing length is required at intermediate reactions.(9) 7" bearing length is required at intermediate reactions. The stated allowable design properties are for loads of normal duration. Adjustments to theallowable design values shall be in accordance with the applicable code.Intermediate Reaction (lb)(4)(5)3½" Bearing5¼" BearingWeb Stiffeners(7)Web )8,005(9)8,335(9)Red-I Joist Shear DesignWhen joists are used as simple span members, the design shear is equal tothe shear at the face of the support.When joists up to 24" in depth are used as multiple-span members, thedesign shear is the calculated shear at the interior support reduced by thefollowing:R 5W 18%V12100Where: R percent reductionW uniform load, plfV12 reference design shear for an117 8" deep joist, lb

LOAD TABLESInstructions for Load Tables on pages 7– 9To size floor joists: Calculate total load and live load in pounds per linear foot (plf).To size roof joists: Calculate total load in pounds per linear foot (plf). Check both total load (100% TL) and live load (100% LL). Live load (100% LL)values may be increased with a glue-nailed floor system; contact yourRedBuilt representative for assistance. Check the appropriate snow load area (115% TL) value or non-snow load area(125% TL) value to determine the maximum allowable total load.100% TL (Total Load)Use this and the 100% LL to selectfloor member. This is the maximumallowable total load in pounds perlinear foot of joist. Values are limited bydeflection equal to L/240 at total load.115% TL (Total Load)117 8"Span12'14"16"100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL320 368 354 407 388 446252 401 350 442 * 485316 303100% LL (Live Load)14'Use this and the 100% TL to select floor member. Thisnumber is the maximum allowable live load capacity16'in pounds per linear foot of joist. Value is based on theCommercial Floor Deflection Limit shown on page 20.Use this to select roof member in snowload areas. This is the maximum allowabletotal load in pounds per linear foot ofjoist. Values are limited by deflectionequal to L/180 at total load.332125% TL (Total Load)Use this to select roof member in non-snow loadareas. This is the maximum allowable total load inpounds per linear foot of joist. Values are limited bydeflection equal to L/180 at total load.Consult local codes to verify deflection limits required for specific applications.General Notes for Load Tables on pages 7 – 9 Values shown are maximum allowable load capacities based on the following assumptions:– Simple span; horizontal clear distance between supports.– Uniformly loaded conditions with 2½" bearing length. Web stiffeners are assumed for joist depths greater than 9½". Other capacities may be possible with different criteria; contact your RedBuilt representative.– Positive drainage in roof applications (¼" per foot slope minimum).– Composite action is not considered for deflection.– Floor Total Load deflection limit is L/240.– Floor Live Load deflection limit is based on commercial deflection criteria shown on page 20.– Roof Total Load deflection limit is L/180. Camber (2,250' radius) is available for simple-span applications only (not available for Red-I90HS ). Contact your RedBuilt representative for availability. For span or loading conditions not covered by these tables (such as multiple spans or concentrated loads), contact your RedBuilt representative for assistance.Visit RedBuilt.com to find your local representative.6

LOAD TABLESRed-I45 Joist Allowable Uniform Load (PLF)Table FootnotesDepthSpan9½"117 8"14"16"* Indicates total load (TL) value controls. Red numbers refer to 115% total load (TL).100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% 4157119130See Load Table Instructions andGeneral Notes on page 6.Red-I65 Joist Allowable Uniform Load (PLF)DepthSpan117 8"14"16"18"20"22"24"26"28"30"100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% 19321017318915216613514712113110811898106

LOAD TABLESRed-I90 Joist Allowable Uniform Load (PLF)DepthSpan14'16'18'20'22'24'26'117 8"14"16"18"20"22"24"26"28"30"100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% 213184201172187154168139151126137Red-I90H Joist Allowable Uniform Load 38'40'42'117 8"14"16"18"20"22"24"26"28"30"100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% 3184201174189165179157171146159Table Footnotes* Indicates total load (TL) value controls. Red numbers refer to 115% total load (TL).See Load Table Instructions andGeneral Notes on page 6.

LOAD TABLESRed-I90HS Joist Allowable Uniform Load '42'44'117 8"14"16"18"Depth22"20"24"26"28"30"Table Footnotes32"100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL 100% TL 115% TL100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% TL 100% LL 125% 241210229200217190207182198174189167181160174* Indicates total load (TL) value controls. Red numbers refer to 115% total load (TL).See Load Table Instructions andGeneral Notes on page 6.8' ON-CENTER ROOF SPAN TABLERed-I90HS Joist, 8' On-Center Roof SpanRed-I90HS Joist Depth16"18"20"22"24"26"28"30"32"12 PSFDead Load27'- 0''29'- 10''32'- 4''35'- 4''38'- 0''40'- 2''42'- 0''43'- 8''45'- 4''14 PSFDead Load26'- 0''28'- 6''30'- 1''33- 7''35'- 8''37'- 9''39'- 9''41'- 9''41'- 9''Simpson Strong-Tie HWP or HWPH hanger16 PSFDead Load24'- 6''26'- 8''28'- 1''31'- 4''33'- 3''35'- 1''36'- 11''38'- 8''38'- 8''Web stiffenerTable is based on:General Notes Uniformly loaded, simple-span joists Red-I90HS joists spaced at 8' on-center Spans limited by total load deflection of L/180 Spans reflect 125% duration of load adjustment Roof live load of 20 psf with live load reductions applied per2018 IBC Section 1607.13.2 Roof slopes of ¼" per foot DF/SP (or equivalent) support for hanger. S pan is defined as horizontal clear distance between inside face of beam/wallsupports. Reaction based on hanger bearing length and web stiffeners. See webstiffener information on page 16. Bold italic numbers indicate HWPH hanger required. Fill all nail holes in hanger. Use 0.148" x 1½" nails into joists and 0.162" x 3½"nails into header.9

FLOOR DETAILSTypical Floor SystemEach side of the bottom flange of the Red-I joistcan support a 250 lb maximum load at 5' on-center(provided the load is included in normal designloads). See detail 9 on page 12 for loads exceedingthis limit.Header and Red-I JoistRefer to detail 8 on page 12Backer blocksField-installed backerblocks at header locationRim BoardWARNINGSafety bracing is required toensure adequate stabilityduring constructionHanger on BeamRefer to detail 4on page 11Red-I joist overhang must beprotected fromthe weatherCantileverRefer to page 12Red-I Blocking PanelRefer to page 15Sheathing providessway bracingOutriggersRefer to page 13General Notes Details shown on pages 10 –14 are conceptual. Attachments and connectionsshall be made to the supporting structure in accordance with the specificdesign requirements.See Red-I Joist InstallationInformation (available online atredbuilt.com) for additional installationguidelines. Rim board or Red-I blocking panels (or an equivalent alternative) mustalways be used to prevent rollover and to provide structural attachment ofthe deck sheathing to the supporting structure in accordance with the specificdesign requirements.10

FLOOR DETAILS1 Nailing Red-I Joist to Bearing Plate1½" rim board 2 Hanger on Stud WallWeb stiffener eachside of joist (ifrequired)Web stiffener. See page 16.Attach with one nail each sideof Red-I joist at bearing. Nailsize per flange thickness: 1½" : 0.128" x 3" 1¾" : 0.128" x 3¼" 2½" : 0.135" x 3½"Maintain 1½" minimum enddistance to minimize splitting.Nails may need to bedriven at an angle tominimize splitting ofbearing plateJoist hangerThe potential for top plate rotation may reduce hanger capacities.Contact RedBuilt for assistance. 3 Hanger on

Red-I Joists Specify Red-I Joists for your next project using RedSpec single-member sizing software. Download your free copy at RedBuilt.com. Including Red-I45, Red-I65 , Red-I90 , Red-I90H, and Red-I90HS Joists