Transcription

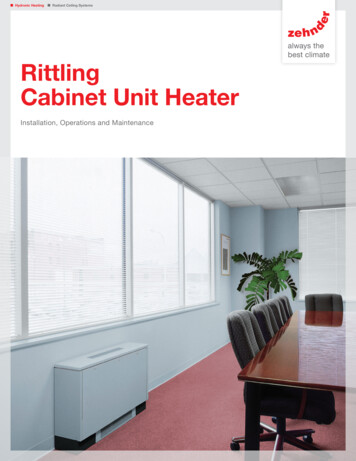

Hydronic HeatingRadiant Ceiling SystemsRittlingCabinet Unit HeaterInstallation, Operations and Maintenance

Zehnder decorative radiatorsHeating and cooling ceiling systemsComfortable indoor ventilationClean air solutionsAlways the best climate forIMPROVEDQUALITY OF LIFEWith Zehnder, you will find the perfectclimate for any space.www.zehnder-systems.com

IMPORTANT: Submittaldocumentation, specific to eachproject, supersedes the generalguidelines contained within thismanual.Models and arrangements 2Ratings 4Dimensions and data 6General information 13Receiving 13Safety considerations 14Unpacking and preparation 15Handling and installation 16Hot water connections 17Ductwork connections 18Electrical connections 19Wiring diagram 20Start-up 22Air system balancing 23Heating system 23Water system balancing 24Water treatment 24Controls operation 25Exposed unit touch-up 25Normal operation/maintenance 26Replacement parts 28Equipment start-up checklist 28Warranty 301

MODELS AND ARRANGEMENTSModels and airflow arrangementsWall modelsRW-260RW-270RRWI-330RW: WallRW-260 shownRW-270 and RW-280 availableRRWI: Wall, partially recessed, inverted flowRRWI-330 shownRW-280RWI-290 RWI-300RWI: Wall, inverted flowRWI-290 shownRWI-300 and RWI-310 availableRWI-310RRW-320RRW: Wall, partially recessedRRW-320 shown2RFRW-340RFRW: Wall, fully recessedRFRW-340 shownRFRWI-350RFRWI: Wall, fully recessed, inverted flowRFRWI-350 shown

Models and airflow arrangementsFloor modelsCeiling modelsRC-360RF-200RC-370RF-220RF: FloorRF-200 shown, RF-220 availableRC-380RC: CeilingRC-360 shownRC-370, RC-380, RC-390 andRC-400 availableRC-390RC-400RFI-240RFI-250RFI: Floor, inverted flowRFI-240 shown, RFI-250 availableRRC-400RS-200RRC: Ceiling, partially recessedRRC-440 shownRS: Floor, slopedRS-200 shownRFRC-410RFRC-420RSI-240RFRC: Ceiling, fully recessedRFRC-420 shownRFRC-430RSI: Floor, sloped, inverted flowRSI-240 shown3

STANDARD RATINGSStandard ratings and specificationsTable ASpecificationsMBHSteam capacityHot water capacity(1 row coil)Hot water capacity(2 row coil)Heating capacity(3 row main coil)Heating capacity(4 row main 8.41180CFM: 0600720875Low125140220350440480660CFM: high static PSC(@ 0.2" /2 Row CoilFace area, ft21.251.672.082.923.333.894.58Coil connections1/2" Cu1/2" Cu1/2" Cu1/2" Cu1/2" Cu1/2" Cu1/2" CuQuantity11221, FilterCabinet sizeWidth7.5"10.4"7.5"10.4"7.5", 10.4"7.5"Number1111111Length, in.22283446526070Width, in. - standard9.759.759.759.759.759.759.75Width, in. - floor with inlet grille7.257.257.257.257.257.257.25Merv 4RatingMerv 4Merv 4Merv 4Merv 4Merv 4Merv 4Thickness, in.1111111Length, in.38.244.250.262.268.276.286.2Width, in.10101010101010Height, in. - wall/ceiling24242424242424Height, in. - flat top floor26.526.526.526.526.526.526.5Height, in. - slope top 0155170195Shipping weight, lbs.Notes Airflows for floor mounted units with 1-row coil. Please check with factoryfor adjusted outputs on other models Heating capacity based on inlet air 60 F DB, 200 F entering water or 2 psigsteam, 180 F leaving water, standard motor at high fan speed4 Pressure drop (PD) shown in feet of water Overall length for fully and partially recessed units is length 3", addingin the trim kit. Wall rough-in hole dimension to be length 1/2" by 24-1/2"minimum. Maximum opening to be length by 2" by 26".

ELECTRICAL DATAElectrical dataTable BMotor TypePSCHPMotor FLA 120VECMPSCECMPower Input:Watts 120VMotor FLA120V/60Hz/1PhPower input: rd1/301/301/251/151/30, 1/15(2) 1/15(2) 1/15High-Static1/121/121/101/71/12, 1/7(2) 1/7(2) 1/7Standard1/41/41/41/4(2) 1/4(2) 1/4(2) 1/4High-Static1/41/41/41/4(2) 1/4(2) 1/4(2) 0.780.881.051.602.522.653.20High 123152158High static8890129151240293302Notes: Maximum circuit ampacity (MCA) 1.25 x (FLA motor 1 FLA motor 2 FLA electric heat) Maximum overcurrent protection (MOP) (2.25 x FLA motor 1) FLA motor 2 FLA electric heat If the calculated MOP is within 10% of the next smaller available fuse size,that fuse size shall be used. If not, the next larger fuse size above thecalulated MOP must be used. If the selected MOP is smaller than the MCA, the selected MOP must beincreased to the next larger available fuse size above the MCA. If the MOP is less than 15, it shall be rounded up to 15 amps. This is theminimum fuse or circuit breaker permitted by code. EC motor nameplate amperage indicates the motor hardware peakamperage while the motor full load amperage (FLA) is limited by the motor’sfactory programmed operating range, programmed specifically for each unitsize. The programmed operating range is generally only a portion of themotor hardware full potential resulting in the motor FLA being lower thanthe nameplate FLA. Motor FLA will be reflected on the Cabinet Unit Heaterserial tag and should be used when sizing building electrical requirements.5

DIMENSIONS AND DATADimensions anddatadataDimensionsandPiping accesssectionDModelsRF andModelsRFRFIandRFIFan speedaccess sectionOutlet opening centered10" 6"RF-200shownTop view(top outlet)3/8" wd. x 1" lg.mounting slot(4 places)C16"RF-220shown8"Front viewElectricalend pocket7 1/8"8"K2"(less front panel)3"2, 3 & 4 row hotwater supply20 13/16"(Front outlet)A08Dimensional dataBA 6" Ext. x2 BCStd. Unit size 6" 3/1644-3/1628-3/1629-5/80344-3/16 04 50-3/16 50-3/16 56-3/16 34-3/16 28-3/16 35-5/850-3/16 06 56-3/16 62-3/16 62-3/16 46-3/16 34-3/16 6-3/1676-3/1660-3/1661-5/81068-3/16 12 74-3/16 86-3/16 80-3/16 70-3/16 52-3/16 71-5/81076-3/160612Coil2 Row30364854D2026324450586819-1/164 Row19-1/16321 row hotwater returnand 1 rowsteam 3/169-7/8- 1, 2, 3 and 4 row coil supply and return 1/2" nominal (5/8" OD) all sizes.- Left hand piping connections shown, right hand electrical as standard.Notes:Piping hand determined when facing the air outlet. 1 and 2 row coil supply and return 1/2" nominal (5/8" OD) all sizes- Unit length: for 6" extended end pocket add 6" to dimension "A". Inlet grille optional- handAll listeddimensionsare approximateand aresubjectconnectionsto change without Unit shown with leftpipingconnectionsand right handelectricalas standardnotice. Modificationsto theelectricalproduct specificstionsbe acceptrdby Right hand piping connectionswith left handconnectionsmustavailableas an optionZehnderits baseoffice. Piping hand determinedwhenatfacingtheair outlet All listed dimensions are approximate and are subject to change without notice Modifications to the product specifications must be accepted by Zehnder Rittling at its base office See www.zehnder-rittling.com for any recent updates or changes62, 3 & 4 row hotwater return2688-3/1660-3/166258Dimensional data86-3/1692-3/1698-3/1670-3/167268CoilJKLMNPRT2 Row 18-1/4 4-7/16 19-1/16 5-3/16 9-7/8 5-3/16 10-11/16 4-7/16JMN 8-9/16 4-13/16PR3 RowK 19-1/16 L3-1/16 20-3/84-13/169-7/83-1/16 T3-1/16 5-3/1620-3/8 4-13/164-13/16 10-11/169-7/83-1/164-7/1618-1/4 4 Row4-7/1619-1/1619-1/169-7/88-9/165-3/163 RowFilter positions202"N0424D8 1/8"03Side view: Model RFC12 13/16"021 row hotwater supplyand 1 rowsteam returnFilterpositionFront viewUnit size2, 3 & 4 row hotwater return3 1/2"26 1/2"6"LADimensional data1 row hotwater returnand 1 rowsteam supplyMTP7 1/8"RNote: Inlet grille optionalBJ16 1/8"6 1/2"2, 3 & 4 row hotwater supply1 row hotwater supplyand 1 rowsteam returnSide view: Model RFI

Dimensions anddatadataDimensionsandPiping accesssection10"DOutlet opening centeredModels RS and RSIModels RS and RSIFan speedaccess section6"Top view(top outlet)C3/8" wd. x 1" lg.mounting slot(4 places)RS-200shown16"6 1/2"Note: Inlet grille optionalB8"Front view7 1/8"Electricalend pocketM1 row hotwater returnand 1 rowsteam supplyK8"2"(less front panel)A82-3/160612Coil2 Row3 Row2430364854D2026324450586816 1/8"Filter position202, 3 & 4 row hotwater return26321 row hotwater returnand 1 rowsteam supply445088-3/1660-3/166258Dimensional data86-3/1692-3/1698-3/1670-3/167268CoilJKLMNPRT2 Row 18-1/4 4-7/16 19-1/16 5-3/16 9-7/8 5-3/16 10-11/16 4-7/163 RowK 19-1/16 L3-1/16 20-3/84-13/169-7/8JMN 8-9/16 4-13/16PR 3-1/16T4 Row 19-1/16 3-1/16 20-3/8 4-13/16 8-9/16 4-13/16 /1610-11/1619-1/16 , 3 and 420-3/8row coil supplyand return1/2" nominal(5/8" OD) allsizes.19-1/16 - 1,3-1/164-13/168-9/163-1/164-13/169-7/8- Left hand piping connections shown, right hand electrical as standard.Notes:Piping hand determined when facing the air outlet. 1 and 2 row coil supplyreturnnominalend(5/8"OD) addall sizes- Unitandlength:for 1/2"6" extendedpocket6" to dimension "A". Inlet grille optional - All listed dimensions are approximate and are subject to change without Unit shown with left handconnectionsrightspecificstionshand electricalconnectionsnotice.pipingModificationsto theandproductmustbe acceptrd asby standard Right hand piping connectionsleft office.hand electrical connections available as an optionZehnder at withits base Piping hand determined when facing the air outlet All listed dimensions are approximate and are subject to change without notice Modifications to the product specifications must be accepted by Zehnder Rittling at its base office See www.zehnder-rittling.com for any recent updates or changes4 RowLD2"R76-3/1604CN1003Side view: Model RS8 1/8"08A6" nal dataBBC6" Ext. x222-3/1623-5/850-3/1628-3/16 22-3/1629-5/834-3/16 3/1653-5/874-3/1660-3/16 46-3/1661-5/870-3/16 52-3/1671-5/880-3/1612 13/16"AUnit size0238-3/16 0344-3/16 040650-3/160862-3/16 1068-3/16 1202J20 13/16"(Front outlet)Dimensional data1 row hotwater supplyand 1 rowsteam returnFilterpositionFront viewUnit size2, 3 & 4 row hotwater return3 1/2"29 1/4"2, 3 & 4 row hotwater supply2, 3 & 4 row hotwater supplyTP7 1/8"1 row hotwater supplyand 1 rowsteam returnSide view: Model RSI7

DIMENSIONS AND DATADimensions anddatadataDimensionsandPiping accesssectionModels RW,and andRC RCModelsRW,RWIRWIFan speedaccess sectionDOutlet opening centered10" 6"RC-360shownTop view(top outlet)3/8" wd. x 1" lg.mounting slot(4 places)C16"RW-280shown4"8"BElectricalend pocket8"Front view7 1/8"1 row hotwater returnand 1 rowsteam supplyMK2"(less front panel)A2, 3 & 4 row hotwater supply3"2, 3 & 4 row hotwater return18 3/8"LJ13 5/8"6"24"1 row hotwater supplyand 1 rowsteam return6"Front view(Front 3-5/84461-5/85071-5/8582 Row60-3/1662Dimensional86-3/16 92-3/1698-3/1670-3/1672data68CoilJKLMNP2 Row 15-3/4 4-7/16 16-9/16 5-3/16 7-7/16 5-3/16JMN 6-1/8 P3 RowK 16-9/16 L3-1/16 17-1/84-13/164-13/1615-3/4 4 Row4-7/1616-9/1616-9/167-7/16 6-1/85-3/163-1/16 5-3/1617-1/8 4-13/164-13/163 Row16-9/1612CoilDucted openingE666666D 6-3/16G82, 3 & 4 row hotwater return5-1/85-1/81 row hotwater returnand 1 rowsteam supply5-1/85-1/82"5-1/8666-3/165-1/8RT8-1/4 4-7/16R 3-1/16T7-7/168-1/4 3-1/16 -13/1616-9/16 - 1, 2, 3 and 4 row coil supply and return 1/2" nominal (5/8" OD) all sizes.- Left hand piping connections shown, right hand electrical as llairsizesoutlet. 1 and 2 row coil supplyandhandreturn1/2" nominalOD) Inlet grille optional - Unit length: for 6" extended end pocket add 6" to dimension "A".All listeddimensionsare approximateand electricalare subjectconnectionsto change without Unit shown with left- handpipingconnectionsand right handas standardnotice. Modificationsto theelectricalproduct specificstionsbe acceptrdby Right hand piping connectionswith left handconnections mustavailableas an option Piping hand determinedwhenatfacingtheoffice.air outletZehnderits base All listed dimensions are approximate and are subject to change without notice Modifications to the product specifications must be accepted by Zehnder Rittling at its base office See www.zehnder-rittling.com for any recent updates or changes4 RowFilter positions5-1/8TP7 1/8"R03046" 868-3/161074-3/161282-3/1610 3/8"02AStd.Side view: Model RW and RC5 5/8"Dimensional dataUnit sizeFilterpositions2 3/8"2, 3 & 4 row hotwater supply1 row hotwater supplyand 1 rowsteam returnSide view: Model RWI

Models RRW, RFRW, RRC,RFRC, RRWI and RFRWIDimensionsand dataDimensions and dataPipingsectionD or FModels RRW, RFRW, RRC,RFRC, RRWI and RFRWIFan speedsectionOutlet opening centered10"Top viewE or G(top outlet)RFRW-340shown3/8" wd. x 1" lg.mounting slot(4 places)C16"RFRC-410shown4"8"BFront viewElectricalend pocket8"7 1/8"1 row hotwater returnand 1 rowsteam supplyMK2"(less front panel)HA2, 3 & 4 row hotwater supply3"2, 3 & 4 row hotwater return18 3/8"LJ13 5/8"6"27" 24"1 row hotwater supplyand 1 rowsteam return6"Front 286-3/16 92-3/16CH6" Ext.6" Ext. 61 row hotwater returnand 1 rowsteam supply77-3/1683-3/162"91-3/163 Row4 Row16-9/162 Row2, 3 & 4 row hotwater return65-3/1670-3/16 72 68 6 66-3/16 5-1/8 89-3/16 95-3/16 101-3/16Dimensional dataCoilJKLMNPRTJK 15-3/4 L4-7/16 16-9/16MN 7-7/16 P5-3/16 8-1/4R 4-7/16T2 Row5-3/163-1/16 5-3/1617-1/8 4-13/164-13/16 7-7/1615-3/4 3 Row4-7/1616-9/1616-9/167-7/16 6-1/85-3/168-1/4 3-1/16 4-7/164 Row 16-9/16 3-1/16 17-1/8 4-13/16 6-1/8 4-13/16 7-7/16 4-13/16CoilFilter urn1/2"nominal(5/8"OD)allsizes.Notes:- Leftandhandpiping1/2"connectionsshown,right 1 and 2 row coil supplyreturnnominal (5/8"OD)all handsizeselectrical as standard.Pipingpipinghand determinedwhenthe airelectricaloutlet. connections as standard Unit shown with left handconnectionsand facingright hand- Unit length:withfor 6"extendedend pocketadd 6" to dimension"A"anand"H". Right hand piping connectionslefthand electricalconnectionsavailable asoption Piping hand determinedwhendimensionsfacing the areair outlet- All listedapproximate and are subject to change without All listed dimensions notice.are approximateandtoarechange withoutnoticeModificationsthe subjectproduct tospecificstionsmust beacceptrd by Modifications to the productmust be accepted by Zehnder Rittling at its base officeZehnder specificationsat its base office. See www.zehnder-rittling.com for any recent updates or changesTP7 1/8"R38-3/16Louvers DuctDimensionaldata openingLouversDuctDEFG 3/16 23-5/8 20618-3/165-1/828-3/1626 6 2624-3/165-1/8 47-3/1628-3/1630 29-5/8624-3/165-1/834-3/1636 35-5/8630-3/165-1/834-3/1632 6 3230-3/165-1/8 53-3/1646-3/16 47-5/8 /16 53-5/8 50648-3/165-1/852-3/1650 6 5848-3/165-1/8 71-3/1660-3/1654 61-5/8656-3/165-1/870-3/1662 71-5/8666-3/165-1/860-3/1658 6 6856-3/165-1/8 79-3/16BN02AUnit 6" Ext.Ax26" Ext.size44-3/1602 50-3/1638-3/1650-3/1603 56-3/1644-3/1604 /1674-3/1610 80-3/1676-3/1612 88-3/1686-3/1682-3/1610 3/8"Std.5 5/8"UnitsizeSide view: Model RRW, RFRW, RRC and RFRC(Front outlet)Dimensional dataFilterpositions2 3/8"2, 3 & 4 row hotwater supply1 row hotwater supplyand 1 rowsteam returnSide view: Model RRWI and RFRWI9

DIMENSIONS AND DATADimensions and dataDamperFront viewA29-1/4"(Slope top unit)26-1/2"Damper opening1-7/8"D3/8"Motorized damperManual damperMotor endDimensional dataUnit -3/1670-3/87233-5/8Notes: Damper motor always on right side when viewing unit from front side. All listed dimensions are approximate and are subject to change withoutnotice. Modifications to the product specifications must be accepted byZehnder Rittling at its base office. Available for models RF and RS only.10

Dimensions and dataOutside air wall boxTelescoping inner andouter aluminum boxUnpainted aluminum louveredinlet grille with internal bug screen4" to 8"Dimensional data1/2"2 5/8"2 13/16"ModelARough openingWB-02032422-1/2 x 3WB-04062927-1/2 x 3WB-0810123937-1/2 x 3Side ViewA3 1/2"Front ViewWeep holes11

DIMENSIONS AND DATADimensions and dataWall seal kitShips loose for field mountingFront viewRFRW-340shownDimensional dataAHTop viewUnit 161286-3/1689-3/1610" For fully recessed units locate frameflush with front For partially recessed units locateframe as needed Use sheet metal screws (by others)to secure trimframe to the unit.2"AH1227"24"Side view

GENERAL INFORMATION / RECEIVINGGeneral informationThis installation and start-up instructions literature is for horizontal and vertical Cabinet Unit Heaters. Cabinet Unit Heatersare hydronic terminal units designed for year-round heating. Your equipment is initially protected under the Zehnder Rittlingstandard 2-year warranty provided the steps outlined in this manual for initial inspection, installation, periodic maintenanceand normal every day operation of the equipment are followed. This manual should be thoroughly reviewed prior to theinstallation, start-up or maintenance of the equipment. If any questions arise, please contact your local Zehnder Rittling salesrepresentative or the factory before proceeding any further.There are a multitude of options and accessories available with the equipment covered in this manual. For more specificdetails on the included options and accessories, refer to the order acknowledgment, approved submittals and catalogs.ReceivingUpon delivery, examine the shipment against the bill of lading to make sure all of the units have been received and then checkeach unit carefully for shipping damage. Any damage should be reported to the freight carrier and a claim should be filedwith them. Ensure the shipping company makes proper notation of any shortages or damage on all copies of the freight bill.Concealed damage not discovered during unloading must be reported to the shipping company within 15 days of receipt ofthe shipment.All units are shipped F.O.B. factory. Therefore, Zehnder Rittling is not responsible for damage during transit. It is theresponsibility of the installing contractor to inspect and verify that the units shipped were in fact the correct model number,voltage, etc. Any discrepancies should be reported to the local Sales Representative for immediate resolution prior tounpackaging and installation. The factory should be notified of any warranty repairs required in writing before any correctiveaction is taken. The factory must be fully informed of the expected costs before the work is begun. Zehnder Rittling is notresponsible for any repairs or alterations made by the purchaser without Zehnder Rittling’s written consent and will not acceptany back charges associated with these repairs or alterations. The return of damaged equipment will not be accepted withoutwritten authorization from Zehnder Rittling.A unit that has received a written Return Goods Authorization will be inspected by Zehnder Rittling upon receipt. Any damage,missing parts, reworking or repackaging resulting from prior installation will constitute just cause for Zehnder Rittling to issuepartial credit.Several components are shipped loose for field installation and to offer added protection during shipment and job sitestorage. These items may include; thermostat, valve packages, remote temp sensors, etc.13

SAFETY CONSIDERATIONSSafety considerationsThe installation of Cabinet Unit Heaters and all associatedcomponents, parts and accessories which make up theinstallation, shall be in accordance with the regulationsof all authorities having jurisdiction and must conform toall applicable codes. Only trained and qualified servicepersonnel using good judgment and safe practices shouldinstall, repair and/or service air conditioning equipment.Untrained personnel can perform basic maintenancefunctions such as cleaning coils and cleaning or replacingfilters. All other operations should be performed by trainedservice personnel. When working on air conditioningequipment, observe precautions in the literature, tagsand labels attached to the equipment and all other safetyprecautions that may apply.Improper installation, adjustment, alteration, service,maintenance, or use can cause explosion, fire, electricalshock or other hazardous conditions which may causeserious personal injury and/or property damage. Consult aqualified installer, service agency, or your sales representativefor information or assistance.The equipment must always be properly supported by riggingand lifting equipment. Any temporary supports used duringinstallation or maintenance must be designed to adequatelyhold the equipment in place until equipment is permanentlyfastened and set in its final location. All supports must meetapplicable local codes and ordinances.All fastening devices must be designed to mechanically holdthe assembly in place without the ability to loosen or breakaway due to system operation or vibration.All power must be disconnected and locked out before anyinstallation or service is performed to avoid electrocution orshock. More than one power source may be supplied to aunit. Power to remote mounted units may not be suppliedthrough the unit.Never use bulky or loose fitting clothing when working on anymechanical equipment. Gloves should always be worn forprotection against heat, sharp edges and all other possiblehazards. Safety glasses should always be worn, especiallywhen drilling, cutting or working with chemicals.14Never pressurize equipment beyond specified pressures asshown on unit rating plate. Always pressure test with an inertfluid such as water or dry nitrogen to avoid possible damageor injury in the event of a leak or component failure duringtesting.Always protect adjacent flammable material when weldingor soldering. Use a suitable heat shield material to containsparks or drops of solder. Have a fire extinguisher readilyavailable.Please follow standard safe practices regarding the handling,installing or servicing of mechanical equipment. Read theseinstructions thoroughly and follow all warnings or cautionsattached to the equipment. Consult local building codes andthe National Electrical Code(NEC) for special installationrequirements.Understand the signal words: danger, warning and caution.Identifies the most serious hazards which will result in severepersonal injury or death.Signifies hazards that could result in personal injury or death.Used to identify unsafe practices, which would result in minorpersonal injury or product and property damage.The manufacturer assumes no responsibility for personalinjury or property damage resulting from improper orunsafe practices during the handling, installation, serviceor operation of the equipment. The installation of CabinetUnit Heaters and all associated components, parts andaccessories shall be in accordance with the regulations ofall authorities having jurisdiction and must conform to allapplicable codes. It is the responsibility of the installingcontractor to determine and comply with all applicable codesand regulations.

UNPACKING AND PREPARATIONUnpacking and preparationAll units are carefully inspected at the factory throughout theentire fabrication and assembly processes under ZehnderRittling’s stringent quality assurance program. All majorcomponents and subassemblies such as motors, blowers,coil, controls, valve package and paint quality are carefullytested for proper operation, visually inspected and verifiedfor full compliance with factory standards. Operationaltesting for some customer furnished components such aspneumatic valves and DDC controllers may be a possibleexception.Cabinet Unit Heaters are usually shipped on pallets of upto 5 units. Each unit is factory tagged according to thecustomer’s purchase order. This allows the unit, uponremoval from the pallet, to be taken directly to its’ assignedspace for immediate installation. Units should not beinstalled at locations other than that designated on the tag.Each unit is carefully packaged in a polyethylene plastic bagfor surface protection, placed in a cardboard container andfilled with kraft paper padding for shipment to avoid damageduring normal handling in the shipment process. It is thesole responsibility of the customer to provide the protectionnecessary to prevent vandalism and weather deteriorationof the equipment. Under no condition should the units beleft unprotected from the elements. If the equipment isnot needed immediately at the job site, it should be left inits shipping carton and stored in a clean, dry area of thebuilding or in a warehouse. Do not remove any equipmentfrom its shipping package until it is needed for installation.The equipment is NOT suitable for outdoor installations.Once the equipment is properly positioned on the job site,cover the units with either a shipping carton, vinyl film, oran equivalent protective covering. Cap open ends of pipingthat is stored on a job site. Take special care to preventforeign materials from entering the units in areas wherepainting, dry walling, or spraying of fireproof material,etc., has not yet been completed as these materials mayaccumulate on the motors and blower wheels. Foreignmaterial that accumulates within the units can preventproper start-up, necessitate costly clean-up operations, orresult in immediate or premature component failure. Beforeinstalling any of the system components, be sure to examineeach pipe, fitting and valve, and remove any dirt or foreignmaterial found in or on these components. All manufacturer’swarranties are void if foreign material is allowed to bedeposited on the motor or blower wheels of any unit. Somejob conditions may require some form of temporary unitcovering during construction.DO NOT store or install units in corrosive environments or inlocations subject to temperature or humidity extremes (e.g.,attics, garages, rooftops, etc.). Corrosive conditions andhigh temperature or humidity can significantly reduce systemperformance, reliability and overall service life.After determining the condition of the cardboard containerexterior, carefully remove each unit from the containerand inspect for hidden damage. At this time, check that allshipped loose items such as wall mounted thermostats,aquastats, remote temperature sensors, valve package, etc.,are accounted for and placed in a safe area. Any hiddendamage should be recorded and immediately reported tothe carrier and a claim should be filed. In the event a claimfor shipping damage is filed, the unit, cardboard container,and all packing must be kept for physical inspection by thefreight carrier.15

HANDLING AND INSTALLATIONHandling and installationWhile all equipment is designed for durability and fabricatedwith heavy gauge materials and may present a robustappearance, great care must be taken to assure that noundue force is applied to the coil, piping, or other delicatecomponents such as control boards during handling.Wherever possible, all units should be maintained in anupright position and handled by the chassis, plenumsections or as close as possible to the mounting points.In the case of a fully exposed cabinet unit, the unit mustobviously by handled by the exterior casing. Gloves shouldbe worn when handling finished, painted units and shouldnever be set down on unclean, hard surfaces. Failure tofollow these instructions may lead to scratching or gougingof the finished surface.Although Zehnder Rittling does not become involvedwith the design and selection of support methods and/orcomponents, it should be recognized that unacceptableoperating characteristics and/or performance may resultfrom poorly implemented unit support. Additionally, properclearance must be provided for service and removal of theequipment.Anchoring the equipment in place is accomplished by usingthe mounting points provided, and positioning the unit ona LEVEL plane. Vertical units are designed to be bolted tothe wall structure through the slotted wall mounting holes inthe chassis, used for anchoring to pre-installed wall studs.Horizontal units are provided with slotted ceiling mountingbrackets where hanging

Hot water connections 17 Ductwork connections 18 Electrical connections 19 Wiring diagram 20 . Hot water capacity (1 row coil) MBH 16.2 22.4 30.7 45.5 54.8 64.5 80.1 GPM 1.7 2.3 3.2 4.8 5.7 6.7 8.4 . serial tag and should be used when sizing building electrical requirements. ELECTRICAL DATA Motor Type 02 03 04 06 08 10 12 HP PSC