Transcription

BPEC Level 2 Diploma in Plumbing FoundationSection 7 – F/602/2884Understand and apply domestic hotwater system installation andmaintenance techniques1

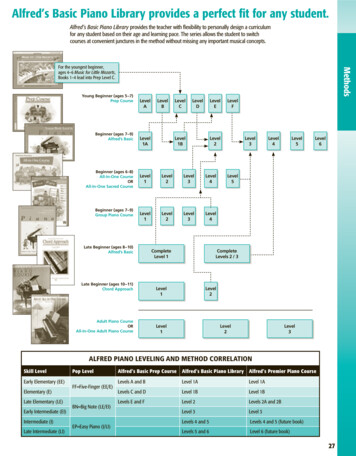

BPEC Level 2 Diploma in Plumbing Foundation2F/602/2884 - Understand and apply domestic hot water systeminstallation and maintenance techniquesThis combination unit provides learning in the installation, maintenance, decommissioning and soundnesstesting of a basic range of hot water system/component types in dwellings and industrial/commercialproperties (of similar size and scope to domestic dwellings). The unit covers systems in building up to 3storey’s in height with pipework up to 28mm diameter. Upon completion the learner will:LO1.Know the types of hot water system and their layout requirementsLO2.Know the site preparation techniques for hot water systems and componentsLO3.Be able to apply site preparation techniques for hot water systems and componentsLO4.Know the installation requirements of hot water systems and componentsLO5.Be able to install hot water systems and componentsLO6.Know the service and maintenance requirements of hot water systems and componentsLO7.Be able to service and maintain hot water systems and componentsLO8.Know the decommissioning requirements of hot water systems and componentsLO9.Be able to decommission hot water systems and componentsLO10.Know the inspection and soundness testing requirements of hot water systems andcomponentsLO11.Be able to inspect and soundness test hot water systems and components.Learning Outcomes highlighted in Red indicate that these are covered by practical tasks from the learnerpractical portfolio.

BPEC Level 2 Diploma in Plumbing FoundationLearning Outcome 1Know the types of hot water system andtheir layout requirements3

BPEC Level 2 Diploma in Plumbing Foundation4There are fourteen Assessment Criteria in Learning Outcome 1:AC1.1.Identify the type of hot water system from layout diagramsAC1.2.State the factors that need to be considered when the type of hot water system is selected foruse in a buildingAC1.3.Identify the working principles of hot water system componentsAC1.4.State the typical pipe sizes used in centralised open vented hot water systems in dwellings.AC1.5.State the system layout features for the open vent and cold feed pipes of primary andsecondary open vented hot water circuits.AC1.6.State the connection requirements for feed and expansion cisterns into open vented primaryhot water circuits.AC1.7.State the system layout features for plastic feed and expansion cisterns:AC1.8.Identify the type and typical sizes of open vented storage cylinder used in hot water systemsin dwellingsAC1.9.State the system layout features for hot water heatersAC1.10.State the typical pipe sizes used with mains fed instantaneous hot water heaters and openvented point of use water heaters in dwellings.AC1.11.Identify the need for temperature control of hot water systemsAC1.12.State the factors that can lead to backflow from hot water outlets and equipment in dwellings.AC1.13.Identify the standard backflow prevention devices that are used in hot water systems indwellings supplying water to appliancesAC1.14.State the system layout features for the installation of hot water componentsBefore we begin The theory behind hot water systems will contain terminology that will be unfamiliar to you. Understandingthe terminology is key to understanding hot water installations, so, before we investigate hot water systems,let us first look at some of the key phrases that you will come across as you work through this section.TerminologyMeaningCentralised hot water systemsA centralised hot water system that supplies every hotwater outlet from a hot water vessel, heater or boilerusually sited in a central position in the property.Localised hot water systemsA localised hot water system that supplies hot water to asingle appliance, such as a kitchen sink in an office orfactory and is usually sited near to where the hot water isneeded. They are only used for small amounts of hotwater.

BPEC Level 2 Diploma in Plumbing FoundationOpen Vented systems5An open vented system contains a vent pipe that ispermanently open to the atmosphere. This means thatthe water in the system can never exceed 100oC. They arefed with water from a cold feed cistern (see Unit 05 ColdWater installations).Unvented systemsAn unvented hot water system does not contain a ventpipe. These systems are supplied with water directly fromthe mains supply.Instantaneous hot water systemsInstantaneous hot water systems heat the water instantlyas it is required when a tap is turned on. There is no hotwater storage. These can be both localised andcentralised multipointStorage hot water systemsStorage hot water systems store an amount of hot waterin a central location for distribution to all hot wateroutlets and taps. They can be both open vented systemsand unvented systems.AC1.1 Identify the type of hot water system from layout diagramsThere are a number of hot water systems in use in the UK. Some of these are open vented systems thatremain open to the atmosphere and some provide instantaneous hot water through combination boilers andmultipoint water heaters. The differences between each system will become apparent as we work throughthe system layouts. We will look at: Direct systemsoContaining a back boileroContaining a hot water immersion heaterIn-direct systemsoSingle feed, self-venting systemsoDouble feed systems with a hot water heating coil Thermal store Instantaneous hot water heaters oSingle point (point of use) heatersoMultipoint heatersCombination (Combi) boilersOpen Vented Direct hot water storage systemsDirect open vented hot water storage systems are named after the type of hot water storage cylinders thatthe systems use. They use a direct-type hot water storage cylinder, which is heated either by a) a small hotwater only boiler, or b) an electric immersion heater

BPEC Level 2 Diploma in Plumbing Foundation6The direct hot water storage cylinder does not containa heat exchanger. The water is heated directly by eitherthe hot water only boiler or an electric immersionheater. This type of cylinder is NOT suitable for use oncentral heating systems. The connections to thecylinder are usually male-type threads for the cold feedpipe and the hot water draw-off connections andfemale-type threads for the primary flow and primaryreturn connections. A drawing of the hot water storagecylinder is shown left.Direct system hot water storage systemwith small hot water only boilerThe direct cylinderHere, the water is heated by ahot water only boiler. Thesecan either be a small gas firedboiler called a ‘circulator’designed to heat the waterdirectly or the water can beheated by a small back boilersituated behind a solid fuelfire. However, back boilers ionoffuelL:andpower, and should not befitted on new installations asthey cannot be adequatelytemperature controlled andare susceptible to boiling.Because the water in thecylinder is in direct contactwith the heat source, anyboiler that is installed mustNOT be made of a materialthat is likely to rust orcontaminate the domestic hotDirect hot water storage system with small water boilerwater supply. This is to preventdirty or rusty water being

BPEC Level 2 Diploma in Plumbing Foundation7drawn from any hot outlet or tap. Suitable materials are: Copper, Bronze, or; Stainless steelThe hot water circulates from the heat source via gravity using the principle of convection (see Unit 03:Scientific Principles). The heated water in the boiler rises through the primary flow connection, heating thewater before cooling and returning to the boiler through the primary return pipe. In this way, the water inthe storage cylinder heats up to the required temperature. However, the cylinder does not heat up uniformly.The hottest top part of the cylinder is around 10oC hotter than the bottom. This is called ‘stratification’ andis necessary in hot water storage vessels to maintain good circulation.The primary flow and return pipework should be of 28mm size to ensure good circulation. An Open VentedDirect hot water storage system using a gas fired circulator is shown on page 482:b) Direct system hotwater storage systemwith electric immersionheaterThese systems use a 3KWimmersion heater to heat thewater instead of a hot wateronlyboiler.Manyexistingsystems are fitted with a singletop entry immersion heater butmodern systems utilise twosmaller300mmimmersionheaters installed on the side ofthe storage cylinder. The topimmersion heater only heats thetop third of the cylinder fordaytime hot water top up, whilstthe bottom cylinder heats uptheentirecylinder.Theimmersion heaters are timeThe direct hot water storage system with immersion heaterscontrolled to take advantage ofcheaper over-night electricity.The temperature settings on the immersion heaters should be limited to no more than 55-60oC.

BPEC Level 2 Diploma in Plumbing Foundation8Open Vented Indirect hot water storage systemsAgain, like the Direct systems, Open Vented Indirect Hot Water Storage systems are named after the hotwater storage cylinders that are fitted to the system. There are two very different systems using two equallydifferent storage cylinders. These are:a) The Open Vented Double Feed Indirect Hot Water System incorporating an Indirect Double Feed HotWater Storage Cylinder, and;b) The Open Vented Single Feed (self-venting) Indirect Hot Water System incorporating an IndirectSingle Feed (Primatic) Hot Water Storage CylinderIndirect hot water storage cylinders, outwardly, look very similar to Direct types. The difference between thecylinders is internal. Indirect Hot Water Storage Cylinders contain a heat exchanger to transfer the heat intothe water. Indirect Cylinders can be used with central heating systems and it is the central heating boiler thatis the primary heat source for the system. The heat exchanger in the storage cylinder separates the domestichot water that we use at taps and outlets (known as secondary hot water) from the primary heating waterfrom the boiler.a)The Open Vented Double Feed Indirect Hot Water System incorporating anIndirect Double Feed Hot Water Storage CylinderThis system utilises a double feed indirect hot water storagecylinder shown in the diagram.The coil, which is made from copper tube (stainless steel storagecylinders with stainless steel coils are also available), is theprimary heat exchanger for the hot water supply. This type ofhot water storage cylinder is suitable for use with central heatingsystems. It is called indirect because the water is heatedindirectly by the primary water in the boiler via the heatexchanger.The double feed indirect system has two cisterns. A large coldfeed cistern that supplies the cold water to the hot water systemThe double feed indirect hot water storage cylindervia the cold feed pipe and a smaller feed and expansion cisternto supply water to the boiler, hot water heat exchanger and central heating system. Here the hot watercirculates via the primary flow and return pipes, with the aid of a circulating pump or without a circulatingpump through gravity (see Unit 003 Scientific Principles). The system is shown in the drawing below.The Double Feed Indirect Hot Water Storage Cylinder allows the use of central heating boilers that usediffering metals, such as copper and aluminium. There is no risk of rusty or contaminated water reaching anyof the hot water outlets because the water in the cylinder is separate from the water in the heating system.

BPEC Level 2 Diploma in Plumbing Foundation9The system is designed so that the water in the central heating system is not changed once the system is full.Some water is lost through evaporation.The indirect hot water system with pumped primary circulationThe secondary hot water that is drawn through the hot water outlets is heated by the coil through conduction(see Scientific Principles) as the water in the cylinder is in contact with the coil heat exchanger. It is the coilthat heats the water.The feed and expansion cistern feeds the primary part of the system and must be large enough toaccommodate any expansion of water when the water is heated. Modern systems use a sealed centralheating system which eliminates the need for a feed and expansion cistern, the system being filled via a fillingloop and the expansion of water being accommodated in an expansion vessel (see drawing left). This updatedsystem does not rely on gravity circulation to heat the water. Instead, the water is circulated through the coilby means of a circulating pump.

BPEC Level 2 Diploma in Plumbing Foundation10The indirect hot water system with gravity primary circulationb)The Open Vented Single Feed (self-venting)IndirectHotWaterSystemincorporating an Indirect Single Feed(Primatic) Hot Water Storage Cylinder.The Single Feed system incorporates a storage cylinder witha special heat exchanger that uses air entrapment toseparate the secondary water from the primary (heating)The single feed self venting indirect hot water cylinderwater.

BPEC Level 2 Diploma in Plumbing Foundation11Because the cylinderonly requires a singlecoldfeed,itisinstalled in the sameway as a direct hotwater storage vessel.There is no need toinstall a second (feedandexpansion)cistern. When thesystem is filled withwater, the secondarywater is separatedfromtheprimarywater by two bubblesof air that form at thetop and bottom ofthe heat exchanger. Itis these two pocketsof air that preventthe two systems frommixing.Thefullsystem is shown left.Occasionally, the airbubblesrupturecausing the primarywater and secondaryThe indirect, single feed hot water systemwater to mix. Whenthis happens, dirtywater can be seen at the hot water outlets. This often occurs if the heating system is too big for the cylinderheat exchanger. The excessive expansion of water when it is heated forces the bubbles downwards into thesecondary water, eventually causing the bubbles to burst. If the bubbles rupture, the system should be leftto cool down. The air bubbles will then reform naturally allowing the water to be heated again.Building Regulation Document L: Conservation of fuel and power no longer allows this system to be installedand you will only come across it during routine maintenance and replacement of the boiler or the hot waterstorage cylinder. The hot water circuit is gravity only. Pumped circulation through the heat exchanger is notpossible as this would destroy the air bubbles at the heart of the system.Instantaneous hot water heatersInstantaneous water heaters do not contain any stored hot water. They heat the water directly from the cold

BPEC Level 2 Diploma in Plumbing Foundation12supply as and when it is needed. There are several different types:a) Thermal storesb) Instantaneous multipoint water heatersc) Combination (combi) boilersd) Single point (point of use) heatersa)Thermal storesThermal stores (also knownas waterheaters)jacketed tubearecentralisedinstantaneousmultipointwater heaters that work bypassing water direct fromthe cold water main througha series of heat exchangers.These heat exchangers arecompletely surrounded bywater at around 80oC insidea large hot water vessel thatis directly heated by a boiler.They look very similar toindirect hot water storagecylinders but actually workA thermal store also known as a water jacketed tube heaterin reverse. Water from themains cold supply enters the thermal store, passing through the first heat exchanger where the water iswarmed. After passing through the expansion chamber, the water flows through the second heat exchangerwhere it is heated to full hot water temperature. Because hot water should not exceed a temperature of 60– 65oC, the water is blended with cold water through an adjustable thermostatic blending valve on the outletof the thermal store.The water in the hot water vessel is completely separate from the domestic hot water and is heated by aboiler. The system can be used for properties with central heating systems.b)Gas-fired Instantaneous multipoint water heatersFired by gas, instantaneous multipoint water heaters use the principle of pressure difference. When a tap isopened, the movement of water through a venturi tube creates a difference in pressure over a rubberdiaphragm inside the pressure differential valve. The difference in pressure flexes the diaphragm inside thevalve and this opens a gas valve. The gas passes through to the gas burner where it is ignited by either a pilotlight or piezo ignitor. The water is then heated. When the tap is closed, the pressure across the pressuredifferential valve equalises and a spring in the valve closes the valve, shutting off the flow of gas.

BPEC Level 2 Diploma in Plumbing Foundation13Instantaneous gas water heaters can provide enough hot water for a small domestic dwelling but the hottaps should only be used one at a time as these hot water heaters cannot generate enough flow rate tosupply two open hot taps simultaneously.Electric-type multipoint water heaters are alsoavailable.A gas fired instantaneous water heaterc)Combination (combi) boilersAn instantaneous hot water systemCombination boilers are fast becoming one of the main sources of hot water supply in small to medium sizeddwellings in the UK. They combine hot water supply andcentral heating in a single appliance that can be sitedvirtually anywhere in the property.‘Combi’ boilers use the same principle as thermal storesby heating the water through a water-to-water heatexchanger. Known as a ‘plate heat exchanger’, the heatexchanger can alternate the flow of water through ly or the central heating system. They arehot water priority appliances, which means that if thecentral heating is on and a hot tap is opened, all energycreated by the appliance will be transferred intogenerating hot water supply to the open tap.There are many different types of combination boilersavailable ranging from 24kW to 50kW in output. SomeA combination boiler

BPEC Level 2 Diploma in Plumbing Foundation14combis even have a small amount of hot water storage (less than 15 litres), which means hot water isdelivered quickly to the hot taps. They are fitted in the same way as multipoint instantaneous hot waterheaters.d)Single point (point of use) heatersLocalised hot water systems are installed in places where connection to themain source of hot water is difficult or impractical. They are often referredto as point of use heaters. They are usually installed over or under theappliance that they are serving with the water being discharged usuallyfrom a swivel spout for over sink types. They can be fuelled by either gas orelectricity and are usually inlet controlled, meaning that the water is turnedon as it enters the heater. Some storage type single point heaters are outletcontrolled. There are two specific types:a)Instantaneous single point water heatersb)Storage single point water heaters.Instantaneous single point water heatersAn electric showeroThese provide instant hot water to a single appliance and are usually fuelledby electricity. There are two basic types:Hand wash type – small water heaters, usually around 3kW output, that are fitted over a singlewashbasin. They are inlet controlled. The temperature of the water depends on the flowrate throughthe heater. The faster the flowrate, the cooler the water. Flow rates are generally poor but adequatefor hand washing.oElectric showers – outputs up to 12Kw, many electric showers feature sophisticated microchiptechnology allowing temperature stabilisation at low andhigh flow rates. Electric showers feature a low pressurecut-out to guard against scalding if the pressure or flowrate suddenly drop. Flow of water is controlled by anelectrically operated solenoid valve that operates whenthe electricity supply is on to the heater.Storage single point water heatersStorage point of use heaters are small water heaters thatstore a small amount of hot water, usually of less than 15litres capacity, for use at a single appliance or small rangeof appliances. They can be either outlet or inlet controlledA point of use water heaterdepending on the type. There are 3 basic types:

BPEC Level 2 Diploma in Plumbing Foundation151Over sink point of use storage waterheaters– usually inlet controlled, these have aswivel spout to direct the water to where it isneeded. One unusual feature of this type of heateris their tendency to drip water from the spout. Thisonly occurs when the water is being heated andstops when the water has reached its settemperature. It is a safety feature because thespout acts as a vent and releases the expandedwater when it is heated. It prevents the heaterfrom being over-pressurised due to the waterThe over sink storage water heaterheating up and expanding. These heaters MUST beinlet controlled to allow the outlet to vent out theexpanded water.2Under sink point of use storage waterheaters – Similar to the over sink type but fittedbelow the appliance rather than above it. They canbe sited in cupboards below kitchen sinks in officesand factories and small dwellings. These are inletcontrolled through a special tap that allows theheater to be vented through the tap spout (see thediagram left).3Unvented under sink point of use storagewater heaters –These are fitted directly to themains cold supply pipework and deliver hot waterThe under sink storage water heaterat or near to mains cold water pressure. They storeless than 15 litres of hot water so arenot subject to the Building Regulationsenforcement. The expansion of waterthat occurs can be taken up within thepipework providing the size of thepipework is sufficient to accommodateit. If not, then a small expansion vesselmust be fitted (see the diagram left).Like larger Unvented Hot WaterStorage Units, these small unventedThe unvented under sink storage water heater

BPEC Level 2 Diploma in Plumbing Foundation16storage heaters require certain controls both safety and functional:oA pressure reducing valve to limit the water pressure to the water heater.oA single check valve to prevent hot water from expanding back through the cold water supply as thiswould constitute contamination of the cold water supply.oAn expansion vessel to allow water to expand within the system without causing creating excessivepressure problems.oAn expansion relief valve to protect the heater in the event of expansion vessel failure and excessivepressure.oDischarge pipework to remove any water, which may be very hot, away from the location of theheater.Note: Unvented hot water storage systems are covered at Level 3AC1.2 State the factors that need to be considered when the type ofhot water system is selected for use in a buildingWhen choosing a hot water system, there are certain factors that must be considered:Quantity and usage of hot water requiredThe amount of hot water is based on the number of people living at the property. The more people there are,the more hot water will be needed.Distance of outlet from hot water sourceThe Water Supply (water fittings) Regulations gives a maximum distance that hot water pipework can be runwithout the need for a secondary return pipe work system. The longer the distance from the hot water sourceto the tap, the greater is the risk of wastage of water simply because the water in the run of pipe is cold andtherefore of no use in hot water system and in most cases, the occupier will simply run this to drain whilethey wait for the hot water to arrive. In these cases, only systems that can incorporate a secondary returnpipe work system should be considered. That excludes most systems that supply instantaneous hot water.This subject continues in the next heading.Need for a secondary circulation systemWhen a hot tap is turned on, there is a certain amount of cold water that is always drawn off before the hotwater arrives at the tap. This is called a dead leg. If the hot water takes longer than 30 seconds to reach thetap, then a secondary circulation system is required to circulate the hot water from the source to the tap andback again.Secondary circulation is required if the length of the hot water draw-off to the taps exceeds the distancesshown in the table below:

BPEC Level 2 Diploma in Plumbing Foundation17Maximum recommended lengthsof un-insulated hot water pipesOutside diameterMaximumof pipelengthmmm1220Over 12 up to and12including 22Over 22 up to and8including 28Over 283Secondary circulationThe secondary circulation system uses a bronze bodied pump positioned on thesecondary return pipe, close to the cylinder to circulate the water to the cylinder. Thesecondary circulation connection is usually positioned about 1/3 of the way down from thetop of the cylinder. Only a bronze bodied pump must be used to prevent rusty water beingA bronze pumpdrawn from the hot taps.The types of fuel usedWith hot water storage systems, it is often the case that more than one fuel can be used to heat the hot water.For instance, the main source might be a gas or oil fired boiler, that also incorporates a central heating system.This is often supplemented by an electric immersion heater(s) for use in the summer months when heating isnot required. Instantaneous systems do not have this capability and so choice of fuel is limited.The number of hot water outletsAnother important point to consider because the more outlets there are, the better the flow rate needed.Again, this may exclude combination boilers or instantaneous multipoint heaters simply because they cannotsupply the flow rate required by the system.Installation and maintenance costsThere are several questions here:1.What is the initial cost of the appliances and materials?2.How much will it cost to install them?3.Will the system meet the requirements of the specification?4.What are the long term running and maintenance costs?

BPEC Level 2 Diploma in Plumbing Foundation18These four questions need to be balanced against the system design to see which system offers the best costeffectiveness while meeting the customer’s requirements.Running costs and fuel efficiencySome new systems, such as solar hot water supply, offer a 60% saving on running costs over a 12 monthperiod, but this has to be balanced against the initial high cost of the solar collector and special storagecylinder. The development of more fuel efficient gas and oil boilers have also helped in the regard.Hot watersupplyLocalised or Singlepoint systemCentralised systemInstantaneousStorageCombinationVented 'fortic'SystemsThermal storeCombi boiler orinstantaneouswater heaterCombined PrimaryStorage UnitsDirectInstantaneousOpenVented/cistern fedsystemIndirectDirectsmall hot wateronly boilerSmall hot wateronly boilerImmersion heaterImmersion heaterGas storage waterheaterIndirectUnvented/mainsfed systemIndirectStorageGas firedOpen Vented hotwater heaterElectricUnvented hotwater heaterDirectAC1.3 Identify the working principles of hot water systemcomponentsMost of the appliances and components mentioned in this section, such as taps and valves, FoVs, showers,and backflow protection were covered in Unit H/602/2697 - Understand and apply domestic cold watersystem installation and maintenance techniques.Feed and expansion cisternsThese small cisterns that are designed for use with vented hot water heating systems. They supply cold feedwater to a heating system, and accommodates any expansion of the water due to the water being heated.The cistern must be large enough accommodate any expanded water and must be sized accordingly. See UnitH/602/2697 - Understand and apply domestic cold water system installation and maintenance techniques.Cold water feed cisternsCold feed cisterns are designed to feed cold water, via the cold feed pipe, to an open vent hot water storagesystem. See Unit H/602/2697 - Understand and apply domestic cold water system installation andmaintenance techniques.

BPEC Level 2 Diploma in Plumbing Foundation19Directly heated storage cylindersThe direct-type hot water storage cylinder is heated either by a small hot water onlyboiler, or an electric immersion heater. The direct hot water storage cylinder doesnot contain any form of heat exchanger. The water is heated directly by either thehot water only boiler or an electric immersion heater. This type of cylinder is NOTsuitable for use on central heating systems.Indirectly heated storage cylinders:Single feed cylinderBetter known as the Single Feed, self-venting cylinder or ‘primatic’, incorporates a storage cylinder with aspecial heat exchanger that uses air entrapment to separate the secondary water from the primary (heating)water. They are no longer fitted due to problems with efficiency and corrosion but still may be fitted in someolder properties.Double feed cylinderThis cylinder contains a coil-type heat exchangerThe coil, which is made from copper tube (stainless steel storage cylinders with stainlesssteel coils are also available), is the primary heat exchanger for the hot water supply.This type of hot water storage cylinder is suitable for use with central heating systems.It is called indirect because the water is heated indirectly by the primary water in theboiler via the heat exchanger.Combination cylinderNot to be derthehotcombineswaterstorage cylinder with the cold water feedcistern. They are used where space islimited and eliminate the need to installa cold water feed cistern in the roofspace. The cistern has an integrated ventpipe and cold feed pipe to vent thecylinder and feed the cylinder withwater. They are available in direct anddouble feed indirect type configurations

BPEC Level 2 Diploma in Plumbing Foundation20Instantaneous water heaters:Mains fed multipoint heatersThese can either be gas-fired or run by electricity. They heat the wa

Indirect hot water storage cylinders, outwardly, look very similar to Direct types. The difference between the cylinders is internal. Indirect Hot Water Storage Cylinders contain a heat exchanger to transfer the heat into the water. Indirect Cylinders can be used with central heating systems and it is the central heating boiler that