Transcription

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comMIL Spec MIL-I-46852 / A-A-59163 Silicone Rubber Self FusingCompression & Stretch Electrical Insulating Tape500 F / 260 C: FlameShield Self Binding / Self-Fusing / Self Amalgamating Tape High Temperature, Heat & Flame Resistant Self-bonds / self fuses / self amalgamating tape.No residue when removed. Starts fusing withinminutes; fully bonded within hours. Excellentcold temperature performance. Low waterabsorption. Tested to: ASTM D 149; provides minimum 400 V/mil.for .010” to .030” thick tape, 300 V/mil for.040” thick tape and 250 V/mil for .060” thicktape. ASTM D 412; provides minimum 700 psitensile strength and minimum 300%elongation. ASTM D 2240; Durometer (Shore A); 55.Other test data available. Excellent for sealing ends of firesleeve: preventssleeve from absorbing contamination andwicking liquids. Excellent for wrapping electrical& mechanical connections and splices. Makesclean and neat installations of cables, wires andhoses. Makes an instant separation bumper andprovides vibration dampening. Meets Mil-I-46852, AA59163 and ABS 5334specifications. Certificate of Conformityavailable. Cross Reference Equivalents Available to MOX600R and 600T levelwrap series; 602-1, 603-1,604-1, 605-1, 606-1, 607-1. McDonnel Douglas/ Boeing DMS-2186 Type I & II, McDonnellDouglas Helicopter HS5215, General DynamicsP5384, Martin Marietta MMS 517-6 Type II,McDonnell Douglas P.S. 17115, ST0130RB0078Type I, 3003M70P01, MS70T09-S, WS1363A,Premier Farnell 810112, Safe Flight 59562-5,PLYSIL3455, TYT200-1, 66N, 67N and variousNATO / National Stock Numbers (NSN). Standard roll length is 36 feet / 12 Yards / 10.9Metres; other lengths available. Amalgamating time: Room temperature; 24hours / at 120 C; 120 minutes / at 150 C; 35minutes / at 200 C; 20 minutes / at 250 C; 15minutes. Tested for short duration fluidresistance: Jet Fuel (JP5), Hydraulic Fluid(Skydrol 500B4), Mineral Oil (NATO 0142),Synthetic Oil (NATO 0156), MIL-C-87836 &Foran 141B cleaning fluids, MIL-A-8243 coolingfluid.These tapes are guaranteed to meet specification for 1 year from date of manufacture providing tapes are stored dry at21 C /- 3 C or 70 F /- 5 F. Standard tapes have an interleaved liner of polyethylene. Polyester liner available.Type II tapes have a center guideline stripe to assist in making 50% overwraps. The triangular profile version tape allowsfor minimal ridge lines, providing wire and cable splices and joints with an almost totally smooth surface (preventssnagging when splice is pulled through obstructions).Page 2-8Thermal Protection Solutions from A-B Thermal Technologies - Product Catalog & Price List # 22 / Feb 2019

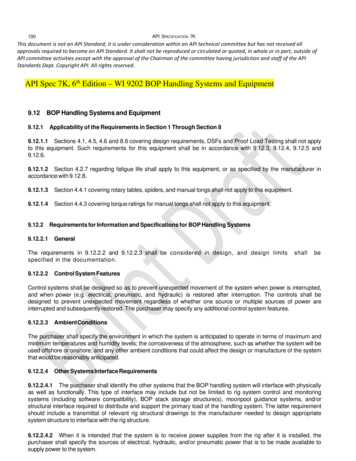

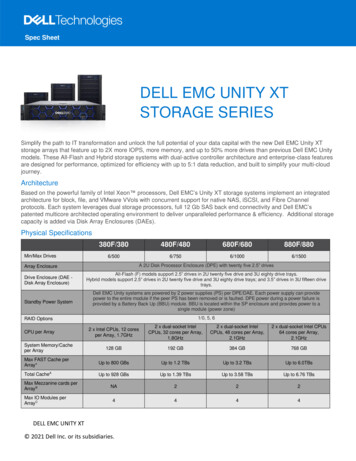

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comFlameShield MIL Spec High Temperature Silicone Self FusingCompression/Stretch Electrical Insulating TapeMeets MIL-I-46852 / A-A-59163 / ABS 5334 Specifications - Type I and Type IITape WidthInches / mmThicknessinches / mmColor / Type / ProfileSingle RollPrice Per RollT-SR-M013-08-RXX-201/2 / 12.70.020 / 0.508Black or Red / I / Rectangular 29.37T-SR-M013-08-RXX-301/2 / 12.70.030 / 0.760Black or Red / I / Rectangular 37.16T-SR-M016-10-RBK-205/8 / 15.70.020 / 0.508Black / I / Rectangular 30.17T-SR-M019-12-RBK-203/4 / 190.020 / 0.508Black / I / Rectangular 31.96T-SR-M025-16-RXX-101 / 25.40.010 / 0.250Black or Red / I / Rectangular 29.37T-SR-M025-16-TXX-201 / 25.40.020 / 0.508Black or Red / II / Triangular 33.80T-SR-M025-16-RXX-201 / 25.40.020 / 0.508Black or Red / I / Rectangular 34.71T-SR-M025-16-TXX-401 / 25.40.040 / 1.000Black or Red / II / Triangular 37.91T-SR-M025-16-RXX-401 / 25.40.040 / 1.000Black or Red / I / Rectangular 39.64T-SR-M038-24-RXX-201 ½ / 38.10.020 / 0.508Black or Red / I / Rectangular 48.77T-SR-M038-24-RXX-121 ½ / 38.10.012 / 0.304Black or Red / I / Rectangular 38.47T-SR-M051-32-RXX-202 / 50.80.020 / 0.508Black or Red / I / Rectangular 57.13T-SR-M051-32-TXX-202 / 50.80.020 / 0.508Black or Red / II / Triangular 48.86Part NumberTriangular Type II Tapes Only: .020" has a blue guideline / .040" has a green guidelinePlease enquire for pricing on widths and thicknessess other than those listed above. Standard roll length is 36 feet / 12 Yards / 10.9 Metres; other lengths available.For the XX value in the part number (color code): OR Oxide-Red, BK Black. Other colors available.Certificate of Conformity: Add 6.00 for individual roll CofC. Lot/Batch CofC 25.00 per order line item.Test Report: Add 75.00 per order line item.Amalgamating time: Room temperature; 24 hours / at 120 C; 120 minutes / at 150 C; 35 minutes / at 200 C; 20 minutes / at 250 C;15 minutes. Tested for short duration fluid resistance: Jet Fuel (JP5), Hydraulic Fluid (Skydrol 500B4), Mineral Oil (NATO 0142),Synthetic Oil (NATO 0156), MIL-C-87836 & Foran 141B cleaning fluids, MIL-A-8243 cooling fluid.These tapes are guaranteed to meet specification for 1 year from date of manufacture providing tapes are stored dry at 21 C /- 3 C or70 F /- 5 F. Standard tapes have an interleaved liner of polyethylene. Polyester liner available.Type II tapes have a center guideline stripe to assist in making 50% overwraps. The triangular profile version tape allows for minimalridge lines, providing wire and cable splices and joints with an almost totally smooth surface (prevents snagging when splice is pulledthrough obstructions).Thermal Protection Solutions from A-B Thermal Technologies - Product Catalog & Price List #22 / Feb 2019Page 2-9

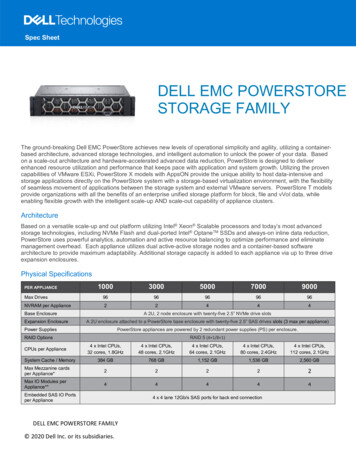

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comFlameShield MIL Spec Silicone Rubber Self Fusing Compression &Stretch Electrical Insulating Tape - Technical DataSpecifications for FlameShieldTMSilicone Rubber Tape (MIL-I-46852 & A-A-59163)Class 1 – Type I and Type IIPropertyStandardNominal TestResult orToleranceTest MethodThickness: 1” wide tape.010”.020”.030”.040”.020”.020” /- .002”N/AWidth0.50”, 0.75”, 1.00”, 1.50”,2.00” /- .020”N/ALength36 feet / 12 yards / 10.9m /- 6.00”N/AColorOxide-Red or BlackN/AN/AGuideline Color(Type II).020” Tapes: Blue.030” Tapes: White.040” Tapes: GreenN/AN/A-60ºC to 260ºC-76ºC to 500ºFN/AN/ABrittle Temperature-65ºC / -85ºFN/AN/AInterleave Material.002" thick MylarN/AN/A700 psi (minimum)1100ASTM D412 / D119.020” Tape: 400 V/mm.030” Tape: 400 V/mm.040” Tape: 300 V/mm575ASTM D-1491.5” wide tape2.0” wide tapeOperating TemperatureTensile StrengthDielectric StrengthDielectric Constant2.94 @ 1Khz14Volume Resistivity1 x 10ohms/cm143 x 10ASTM D150ASTM D149Elongation300% (minimum)700ASTM D412 / D119Tear Strength85 psi (minimum)146ASTM D624Bond Strength (1” Width)2 lbs (minimum)5.5ASTM D2148Shall not unwind morethan 1.0” after 3 minuteswith 600g load0.12”ASTM D21480.25ASTM D21480.9%FED-STD-601Method 6251 0.0004 @ 1 KhzASTM D15055ASTM D2148 / D2240PassFAA 60 Sec VerticalAdhesionInclined Mandrel TackTest (inch)Water absorption (by wt)3% MaximumDissipation FactorHardness, durometerShore AFlame TestPage 2-10355 - 65Thermal Protection Solutions from A-B Thermal Technologies - Product Catalog & Price List # 22 / Feb 2019

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comMIL-I-46852-1I0010 / MIL-I-46852-1I0020 / MIL-I-46852-1I0030MIL-I-46852-1I0040Class 1 - Type IMIL-I-46852-1II0020 / MIL-I-46852-1II0030 / MIL-I-46852-1II0040Class 1 - Type IISilicone Rubber Self Fusing Electrical Insulating Tape500 F / 260 C: FlameShield Self Binding / Self-Fusing / Self Amalgamating Tape High Temperature, Heat & Flame Resistant Self-bonds / self fuses / self amalgamating tape.No residue when removed. Starts fusing withinminutes; fully bonded within hours. Excellent coldtemperature performance. Low water absorption.Tested to: ASTM D 149; provides minimum 400 V/mil. for.010” to .030” thick tape, 300 V/mil for .040”thick tape and 250 V/mil for .060” thick tape. ASTM D 412; provides minimum 700 psitensile strength and minimum 300%elongation. ASTM D 2240; Durometer (Shore A); 55.Other test data available.Excellent for sealing ends of firesleeve: preventssleeve from absorbing contamination and wickingliquids. Excellent for wrapping electrical &mechanical connections and splices. Makes cleanand neat installations of cables, wires and hoses.Makes an instant separation bumper and providesvibration dampening.Meets Mil-I-46852, AA59163 and ABS 5334specifications. Certificate of Conformity available.Cross Reference Equivalents Available to MOX600R and 600T levelwrap series; 602-1, 603-1,604-1, 605-1, 606-1, 607-1. McDonnel Douglas /Boeing DMS-2186 Type I & II, McDonnell DouglasHelicopter HS5215, General Dynamics P5384,Martin Marietta MMS 517-6 Type II, McDonnellDouglas P.S. 17115, ST0130RB0078 Type I,3003M70P01, MS70T09-S, WS1363A, PremierFarnell 810112, Safe Flight 59562-5,PLYSIL3455, TYT200-1, 66N, 67N and variousNATO / National Stock Numbers (NSN). Amalgamating time: Room temperature; 24hours / at 120 C; 120 minutes / at 150 C;35 minutes / at 200 C; 20 minutes / at250 C; 15 minutes. Tested for short durationfluid resistance: Jet Fuel (JP5), HydraulicFluid (Skydrol 500B4), Mineral Oil (NATO0142), Synthetic Oil (NATO 0156), MIL-C87836 & Foran 141B cleaning fluids, MIL-A8243 cooling fluid.These tapes are guaranteed to meet specification for 1 year from date of manufacture providing tapes are stored dry at21 C /- 3 C or 70 F /- 5 F. Standard tapes have an interleaved liner of polyethylene. Polyester liner available.Type II tapes have a center guideline stripe to assist in making 50% overwraps. The triangular profile version tape allowsfor minimal ridge lines, providing wire and cable splices and joints with an almost totally smooth surface (preventssnagging when splice is pulled through obstructions).Thermal Protection Solutions from A-B Thermal Technologies - Product Catalog & Price List #22 / Feb 2019Page 2-11

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comFlameShield MIL-I-46852 SpecificationHigh Temperature Silicone Self FusingCompression/Stretch Electrical Insulating TapeMIL-I-46852-1I0020 / MIL-I-46852-1II0020 / MIL-I-46852-1I0030 / MIL-I-46852-1II0030MIL-I-46852-1I0040 / MIL-I-46852-1II0040Class 1 – Type I and Class 1 - Type IITape WidthInchesThicknessinchesColor / Type / ProfilePrice ck or Red / Type I / Rectangular 29.37MIL-I-46852-1I0030-RXX-0.50½”0.030”Black or Red / Type I / Rectangular k / Type I / Rectangular 30.17MIL-I-46852-1I0020-RBK-0.75¾”0.020”Black / Type I / Rectangular 31.96MIL-I-46852-1I0010-RXX-1.001”0.010”Black or Red / Type I / Rectangular 29.37MIL-I-46852-1II0020-TXX-1.001”0.020”Black or Red / Type II / Triangular 33.80MIL-I-46852-1I0020-RXX-1.001”0.020”Black or Red / Type I / Rectangular 34.71MIL-I-46852-1II0040-TXX-1.001”0.040”Black or Red / Type II / Triangular 37.91MIL-I-46852-1I0040-RXX-1.001”0.040”Black or Red / Type I / Rectangular 39.64MIL-I-46852-1I0020-RXX-1.501 ½”0.020”Black or Red / Type I / Rectangular 48.77MIL-I-46852-1I0012-RXX-1.501 ½”0.012”Black or Red / Type I / Rectangular 38.47MIL-I-46852-1I0020-RXX-2.002”0.020”Black or Red / Type I / Rectangular 57.13MIL-I-46852-1II0020-TXX-2.002”0.020”Black or Red / Type II / Triangular 48.86Part NumberGuideline Color on Type II Triangular Tapes Only: .020" blue / .030” white / .040" greenType II edge thickness is .008” /- .001”Please enquire for pricing on widths and thicknessess other than those listed above. Standard roll length is 36 feet / 12 Yards / 10.9 Metres; other lengths available. For the XX value (color code): OR Oxide-Red, BK Black. Other colors available. Certificate of Conformity: Add 6.00 for individual roll CofC. Lot/Batch CofC 25.00 per order line item. Test Report: Add 75.00 per order line item.Amalgamating time: Room temperature; 24 hours / at 120 C; 120 minutes / at 150 C; 35 minutes / at 200 C; 20minutes / at 250 C; 15 minutes. Tested for short duration fluid resistance: Jet Fuel (JP5), Hydraulic Fluid (Skydrol500B4), Mineral Oil (NATO 0142), Synthetic Oil (NATO 0156), MIL-C-87836 & Foran 141B cleaning fluids, MIL-A-8243cooling fluid.These tapes are guaranteed to meet specification for 1 year from date of manufacture providing tapes are stored dry at21 C /- 3 C or 70 F /- 5 F. Standard tapes have an interleaved liner of polyethylene. Polyester liner available.Page 2-12Thermal Protection Solutions from A-B Thermal Technologies - Product Catalog & Price List # 22 / Feb 2019

High Temperature, Heat, Flame, Fire, Molten Metal & Weld Splatter Protection MaterialsFax Orders: 610-340-9054Telephone Orders: 610-906-3549orders@abthermal.comFlameShield MIL-I-46852 Specification Silicone Rubber Self FusingElectrical Insulating Tape - Technical DataSpecifications for FlameShieldTMSilicone Rubber Tape meeting MIL-I-46852Class 1 – Type I and Type IIPropertyStandardNominal TestResult orToleranceTest MethodThickness: 1” wide tape.010”.020”.030”.040” /- .002”N/AWidth0.50”, 0.625”, 0.75”,1.00”, 1.50”, 2.00” /- .020”N/ALength36 feet / 12 yards /- 6.00”N/AColorOxide-Red or BlackN/AN/AGuideline Color(Type II).020” Tapes: Blue.030” Tapes: White.040” Tapes: GreenN/AN/A-60ºC to 260ºC-76ºC to 500ºFN/AN/ABrittle Temperature-65ºC / -85ºFN/AN/AInterleave Material.002" thick MylarN/AN/A700 psi (minimum)1100ASTM D412 / D119.010” tape: 400 V/mil.020” tape: 400 V/mil.030” tape: 400 V/mil.040” tape: 300 V/mil575ASTM D-149Operating TemperatureTensile StrengthDielectric Str

ASTM D 149; provides minimum 400 V/mil. for .010” to .030” thick tape, 300 V/mil for .040” thick tape and 250 V/mil for .060” thick tape. ASTM D 412; provides minimum 700 psi tensile strength and minimum 300% elongation. ASTM D 2240; Durometer (Shore A); 55. Other test data available.File Size: 2MBPage Count: 50People also search formil i 46852a a 59163 type iimil spec a a 59163a a 59163 tapea a 59163 speca a 59163 type 2