Transcription

Oil Spill PreventionControl andCountermeasurePlan222825.00Middle Georgia StateUniversityEastman Campus71 Airport RoadEastman, Georgia 31023woodardcurran.comCOMMITMENT & INTEGRITY DRIVE RESULTSSeptember 2015

TABLE OF CONTENTSSECTIONPAGE NO.Facility Information . vRegulatory Requirement Cross Reference Table . viRecord of Changes . x1.PLAN OVERVIEW . 1-11.11.21.31.41.51.62.FACILITY DESCRIPTION . 2-12.12.23.Aboveground Tanks and Containers .3-1Storage Tanks .3-1Mobile Equipment .3-2Emergency Generators.3-2Hydraulic Elevators.3-2Electrical Transformers.3-3Drum Storage .3-3Oil Transfer and Delivery Procedures.3-3Transfer Areas .3-3Oil Transfer Procedures.3-3INSPECTION, TESTING, AND PREVENTIVE MAINTENANCE PROCEDURES . lity Location and Operations .2-1Drainage Pathway and Distance to Navigable Waters .2-1OIL STORAGE, CONTAINMENT, AND DELIVERY PROCEDURES . se of this Plan .1-1Ownership Information and Facility Contact .1-1Management Approval and Commitment of Resources .1-1Plan Review and Amendments .1-2Maintenance and Availability of Plan .1-2Engineer’s Certification. Error! Bookmark not defined.General Spill Prevention Strategy .4-1Inspection and Testing of ASTs .4-1Monthly Visual Inspections .4-1Formal External Inspections and Leak Testing .4-2Tank Integrity Tests .4-2Regular Testing of Devices.4-2Hydraulic Elevator Inspections .4-2Oil Filled Transformers .4-355-Gallon Drum Inspections .4-3Preventive Maintenance Procedures .4-3Recordkeeping Procedures .4-3OIL SPILL RESPONSE AND EQUIPMENT. 5-15.15.2Oil Spill Equipment .5-1General Oil Spill Response .5-1Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlaniiSeptember 2015

5.2.1Tank Overfill During Delivery .5-15.2.2Tank Failure.5-25.2.3Minor Spills .5-25.2.4Large Quantity Spills.5-25.3Oil SPCC Coordinator Responsibilities.5-25.4Alternate Oil SPCC Coordinator Responsibilities .5-35.5Disposal Procedures .5-36.OIL SPILL NOTIFICATION PROCEDURES . 6-16.16.27.EMPLOYEE TRAINING PROGRAMS . 7-17.17.28.Oil Releases to Water.6-1Written Notification for Oil Spills .6-2Oil SPCC Training .7-1Discharge Prevention Briefings .7-1SECURITY . 8-18.18.28.3Routine Security Measures .8-1Security During Emergencies .8-1Security for Oil Storage Facilities .8-1LIST OF FIGURESFIGUREFigure 2-1:PAGE NO.Site Locus . 2-2Figure 3-1:Main Campus Facility Diagram . 3-8Figure 3-2:Terminal Building and New Dorm Facility Diagram . 3-9LIST OF TABLESTABLETable 1-1:PAGE NO.Oil SPCC Provisions Review Log . 1-4Table 3-1:Aboveground Oil Storage Tanks and Containers . 3-5Table 3-2:Hydraulic Elevators. 3-7Table 3-3:Oil Filled Transformers . 3-7Table 6-1:Emergency Contact Phone Numbers . 6-3Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlaniiiSeptember 2015

APPENDICESAppendix A:Certification of the Applicability of the Substantial Harm Criteria ChecklistAppendix B:Monthly and Annual Inspection FormsAppendix C:Inspection and Testing RecordsAppendix D:Oil SPCC Training Program and Training RecordsAppendix E:Annual Discharge Prevention Briefing RecordsAppendix F:Georgia Environmental Protection Division Release Notification FormMiddle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanivSeptember 2015

FACILITY INFORMATIONTOPICINFORMATIONName of FacilityMiddle Georgia State University – Eastman CampusOwner/OperatorUniversity System of GeorgiaType of FacilityState UniversityLocation of Facility71 Airport Road, Eastman, Georgia, 31023Campus Telephone Number(478) 374-6980Oil SPCC CoordinatorEHS CoordinatorOffice Phone: (478) 934-3054Alternate Oil SPCC CoordinatorAviation Campus Coordinator of Plant MaintenanceOffice Phone: (478) 374-6707MGA Aviation Campus Police(478) 374-6403Maximum Oil Storage/Handling Capacity4,573 gallonsSpill HistoryThis facility has had no reportable spills in the past 20 yearsSensitive ReceptorsGum Swamp and Granny BranchMiddle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanvSeptember 2015

REGULATORY REQUIREMENTS CROSS REFERENCE TABLEAPPLICABLE REGULATORY REQUIREMENTSCHAPTER OF OIL SPCC PLANOil Spill Prevention Control and Countermeasure Plan40 C.F.R. Part 112Professional Engineer Certification§ 112.3(d)Section 1.6Maintenance and availability of complete plan§ 112.3(e)Section 1.5Amendments and plan review every 5 years§ 112.5Section 1.4Discussion of Facility’s conformance with 40 C.F.R. Part 112§ 112.7(a)(1)Section 1.1Description of physical layout of the Facility§ 112.7(a)(3)Chapter 2Facility Diagram§ 112.7(a)(3)Figure 3-1Type of oil in each container and its storage capacity§ 112.7(a)(3)(i)Chapter 3Discharge prevention measures (including procedures for routinehandling of products)§ 112.7(a)(3)(ii)Discharge/drainage controls around containers/structures§ 112.7(a)(3)(iii)Procedures for the control of a discharge§ 112.7(a)(3)(iii)Chapters 3 and 4Chapter 3Chapter 5 and Spill ResponseFlow Chart located in the QuickReference GuideCountermeasures for discharge discovery, response, and cleanup(including Facility and contractor capability)§ 112.7(a)(3)(iv)Chapter 5Methods of disposal of recovered materials in accordance withapplicable legal requirements§ 112.7(a)(3)(v)Section 5.5Contact list and phone numbers for the Facility response coordinator,National Response Center, cleanup contractors with whom the Facilityhas response agreements, and all appropriate Federal, State, and localagencies who must be contacted in case of a discharge.§ 112.7(a)(3)(vi)Chapter 6 and Table 6-1Information and procedures to enable a person to report a discharge asdescribed in 40 C.F.R.§ 112.7(a)(4)Chapter 6Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanviSeptember 2015

APPLICABLE REGULATORY REQUIREMENTSCHAPTER OF OIL SPCC PLANPrediction of direction, rate of flow and total quantity of oil as a result ofeach type of major equipment failure.§ 112.7(b)Chapter 3 and Tables 3-1 3-2,and 3-3Appropriate containment and/or diversionary structures.§ 112.7(c)Chapter 3 and Tables 3-1 3-2,and 3-3Demonstration of impracticability of secondary containment§ 112.7 (d)Inspections, Test, and RecordsN/A40 C.F.R. § 112.7(e)Inspections and tests performed in accordance with written procedures.Written procedures and records of inspections and tests signed and keptwith Plan for at least three years.Personnel Training and Discharge Prevention ProceduresChapter 4Appendices B and C40 C.F.R. § 112.7(f)(1) Oil-handling personnel trained in operation and maintenance ofequipment to prevent discharges; discharge procedure protocols;applicable pollution control laws, rules, and regulations; general Facilityoperations; and the contents of the Facility SPCC Plan.Section 7.1(2) Designated person responsible for spill prevention.Section 1.2(3) Schedule and conduct spill prevention briefings for oil-handlingpersonnel at least once each year.Section 7.2Security40 C.F.R. § 112.7 (g)(1) Each handling, processing or oil storage Facility fully fenced entrancegates are locked and/or guarded when the Facility is unattended.Chapter 8(2) Flow and drain valves that directly discharge out are locked in closedposition when not operational.Chapter 8(3) Oil pump starter controls locked in “off” position or only accessible toauthorized personnel when not in use.Chapter 8(4) Pipeline loading/unloading connections capped when not in service.Chapter 8(5) Adequate Facility lighting to discover spills and prevent vandalism.Chapter 8Facility Tank Car and Tank Truck Loading/Unloading Rack40 C.F.R. § 112.7(h)(1) Quick drainage systems used in areas without catch basins ortreatment Facility designed to handle discharges; containment designedto hold at least the maximum capacity of a single compartment of a tankcar or tank truck loaded or unloaded at the Facility.N/A(2) Warning lights, physical barriers, or other measures provided toprevent truck departure prior to line disconnection.N/A(3) Inspection of drains and outlets prior to filling and departure of tankcars and trucks.Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanviiSection 3.6September 2015

APPLICABLE REGULATORY REQUIREMENTSCHAPTER OF OIL SPCC PLANBrittle Fracture Evaluation40 C.F.R. § 112.7(i)Field-constructed aboveground containers that have undergone repair,alteration, reconstruction, a change in service, or have discharged oilhave been evaluated for risk of discharge or failure due to brittle fracture.Conformance with Applicable State RulesDiscussion of conformance with applicable requirements of anyapplicable more stringent State rules, regulations or guidelines.Facility DrainageN/A40 C.F.R. § 112.7(j)Sections 1.1, 4.3, 5.5, and 6.240 C.F.R. § 112.8(b)(1) Restrain diked drainage areas by valves.N/A(2) Use of manual open-and-closed drain valves to drain diked areas.N/A(3) Drainage of undiked areas into ponds,lagoons and catch basins to retain oil spills.Section 2.2(4) Design of in-plant ditches with diversion systems to return spilled oilto Facility.N/A(5) Engineer Facility drainage systems to prevent discharges in case ofequipment failure or human error.Section 2.2Bulk Storage Containers40 C.F.R. § 112.8(c)(1) Container materials and construction compatible with products storedand conditions of storage.Chapter 3(2) Adequate and impervious secondary containment for tanks.Chapter 3(3) Requirements for drainage of diked rainwater bypassing treatmentsystem (valve normally closed, valve opened only during drainage,inspect rainwater, records kept).N/A(4) Cathodic protection and regular leak testing for new buried metallictanks.N/A(5) Partially buried metallic tanks.N/A(6) Integrity test aboveground containers on a regular schedule andwhen material repairs are done.(7) Internal heating coils monitored or treated to prevent leakage.Section 4.2N/A(8) Containers are engineered or updated in accordance with goodengineering practices to avoid discharges: high level alarms, high levelpump cutoffs, direct signal communication between the container gaugerand the pumping station; fast response system for determining the liquidlevel of each container; regular testing of devices.Chapter 3(9) Plant effluent disposal facilities monitored regularly to detect systemupsets.N/A(10) Prompt correction of visible leaks; prompt removal of oilaccumulated in diked areas.Section 4.1Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanviiiSeptember 2015

APPLICABLE REGULATORY REQUIREMENTS(11) Portable tanks are positioned or located to prevent a discharge andhave been provided with adequate secondary containment.Transfer OperationsCHAPTER OF OIL SPCC PLANSection 3.540 C.F.R. § 112.8(d)(1) Cathodic protective coating for buried piping, exposed pipesinspected for corrosion.(2) Terminal connections on out of service piping capped and marked asto origin.Chapter 3N/A(3) Pipe supports properly designed.Chapter 3(4) Aboveground valves and piping inspected regularly, integrity andleak testing conducted for buried piping.Section 4.2(5) Aboveground piping protected by notifying vehicular traffic enteringFacility.Substantial Harm Criteria40 C.F.R. Part 112 Appendix CSubstantial harm criteria certification to exempt Facility from preparing aFacility Response PlanMiddle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanN/AixAppendix ASeptember 2015

RECORD OF CHANGESDATEDESCRIPTION OF CHANGE (S)02/01/2012Sec 3.1.2 change NW corner of main campus building to SW 3-2corner.02/01/2012Table 3.1 (For the refueler trucks) Change NW corner of main 3-5campus building to SW corner.02/01/2012Figure 3.1 diagram should show the refueler trucks as being 3-8located on the Southwest end of the campus, just beyond theoil/water separator on “alternate pavement # 4” behind the largehanger on the southwest end of the campus.09/19/2013Throughout the document, the following name changes occurred:MGC to MGSC, Middle Georgia College to Middle Georgia StateUniversity.09/19/2013Additional contacts added to Quick Reference Guide andEmergency Contact Numbers.09/28/2015Throughout the document, the following name changes occurred:MGSC to MGA, Middle Georgia State University to Middle GeorgiaState University.09/28/2015Facility Information: Added MGA Aviation Campus Police vTelephone NumberMiddle Georgia State University – Eastman Campus (222825.00)Oil SPCC PlanxPAGE NUMBERSeptember 2015

1.1.1PLAN OVERVIEWPURPOSE OF THIS PLANThe U.S. Environmental Protection Agency (USEPA) has promulgated regulations requiring the Middle Georgia StateUniversity – Eastman Campus (MGA-Eastman), located at 71 Airport Road, Eastman, Georgia, to adopt an Oil SpillPrevention Control and Countermeasure Plan (Oil SPCC Plan), because the storage capacity exceeds applicableregulatory thresholds. See 40 C.F.R. § 112.1(d)(2)(ii). Specifically, the total aboveground oil storage capacity oncampus is approximately 4,573 gallons, which exceeds 1,320-gallon aboveground planning thresholds. The campusmaintains no underground oil storage. This Plan is designed to comply with all of the applicable Oil SPCC planningprovisions of 40 C.F.R. Part 112.In accordance with 40 C.F.R. § 112.20, MGA-Eastman is also required to determine whether the campus is classifiedas a high-risk facility that poses a threat of substantial harm to the environment, thereby triggering the FacilityResponse Plan requirements and associated appendices. The campus does not meet the substantial harm criteria,and is therefore not required to prepare and submit a Facility Response Plan to USEPA. An Applicability ofSubstantial Harm Criteria Checklist and Certification for the campus is included in Appendix A.Each chapter of this Oil SPCC Plan identifies the federal and state laws and regulations it satisfies. A RegulatoryRequirements Cross Reference Table, preceding Chapter 1, identifies applicable regulatory requirements and thePlan chapter(s) or section(s) that satisfy them. MGA-Eastman has adopted this Regulatory Requirements CrossReference Table because this Plan does not follow the exact sequence specified in 40 C.F.R. § 112.7 of theregulations.1.2OWNERSHIP INFORMATION AND FACILITY CONTACTMGA-Eastman is owned and operated by the University System of Georgia. The Oil SPCC Coordinator listed in theFacility Information section is the primary contact and the designated person responsible for oil spill prevention at theMGA-Eastman Campus.1.3MANAGEMENT APPROVAL AND COMMITMENT OF RESOURCESMGA-Eastman is committed to conducting its operations in a safe and environmentally responsible manner. Allfaculty and staff are expected to promote and foster a safe work environment. Precautionary measures, including theadoption of this Oil SPCC Plan, have been taken to minimize the potential for incidents that could result in oilemergencies.MGA-Eastman fully supports the adoption and implementation of this Plan. This commitment includes providing themanpower, equipment, and materials required to expeditiously control and remove any harmful quantity of oil thatmay be discharged. The Oil SPCC Coordinator is: (1) thoroughly familiar with the facility operations, oil storagelocations, and this Plan; (2) prepared to implement this Plan during an emergency; and (3) committed to ensuring oilspill preventive measures are addressed during non-emergency times.Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan1-1September 2015

1.4PLAN REVIEW AND AMENDMENTSThis Oil SPCC Plan is intended to be an integral part of the operations at MGA-Eastman. To increase itseffectiveness, this Oil SPCC Plan will be amended whenever:1. It fails in an emergency;2. There is a significant change in design, construction, operation, or maintenance in a manner likely to impactthe effectiveness of this Plan;3. Some other circumstance significantly increases the potential for releases of oil products or other changesin the response procedures as necessary;4. An exercise or emergency response drill indicates an amendment is necessary;5. Either the Oil SPCC Coordinator, Alternate Coordinator, or emergency response contractors change;6. The Regional Administrator of the USEPA deems a change to be necessary; or7. There is a change in applicable statutes or regulations.Technical amendments will be certified by a licensed Professional Engineer (P.E.) within six months after a change indesign, construction, operation, or maintenance occurs which materially effects the potential for discharging oil into orupon the navigable waters of the United States or adjoining shorelines. Non-technical amendments, such aschanging the emergency contact list, phone numbers, or names do not necessitate P.E. certification. In addition, ifthis Oil SPCC Plan is amended, the changes will be documented in the “Record of Changes” in the front of this Plan.A complete review and evaluation of this Oil SPCC Plan will be conducted at least once every five years, as requiredby the regulations. The review and evaluation will be documented and the Oil SPCC Coordinator will sign astatement as to whether the Plan will be amended. The statement will read: “I have completed a review andevaluation of this Oil SPCC Plan on [date] and [will/will not] amend the Plan as a result.” If warranted, based on thereview and evaluation, MGA-Eastman will amend the Plan within six months of the review to include more effectiveprevention and control technology if such technology: (1) significantly reduces the likelihood of a discharge from thefacility; and (2) has been field-proven at the time of review. MGA-Eastman will implement such amendments withinsix months of the preparation of any amendments to the Plan. The review log for this Oil SPCC Plan is included asTable 1-1.1.5MAINTENANCE AND AVAILABILITY OF PLANA complete master copy of this Oil SPCC Plan is maintained in the EHS Office. Additionally, a copy of the Plan willbe kept in a location where it can be immediately accessed by oil-handling personnel. The Plan shall be madeavailable to the Regional Administrator of the USEPA, or his/her designee, if so required. This Plan is not, undertypical circumstances, submitted to the USEPA, or to Georgia Environmental Protection Division (Georgia EPD).Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan1-2September 2015

Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan1-3September 2015

Table 1-1: Oil SPCC Provisions Review LogReview #1“I have completed a review and evaluation of this Oil SPCC Plan on and [will/will not]amend the Plan as a result.”Name:Signature:Title:Review #2“I have completed a review and evaluation of this Oil SPCC Plan on and [will/will not]amend the Plan as a result.”Name:Signature:Title:Review #3“I have completed a review and evaluation of this Oil SPCC Plan on and [will/will not]amend the Plan as a result.”Name:Signature:Title:Review #4“I have completed a review and evaluation of this Oil SPCC Plan on and [will/will not]amend the Plan as a result.”Name:Signature:Title:Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan1-4September 2015

2.FACILITY DESCRIPTION2.1 FACILITY LOCATION AND OPERATIONSMiddle Georgia State University (MGA) is a coeducational University, which offers a wide range of programs of studydesigned to prepare the student for entry directly into business, industry, and other careers. The University offersassociate and select baccalaureate and master degrees. MGA has five campuses in Macon, Cochran, Dublin,Eastman and Warner Robins.The aviation campus in Eastman serves both commuting and residential students. The University offers the followingaviation programs at its Eastman campus: Aviation Maintenance TechnologyAircraft Structural TechnologyFlightAir Traffic ManagementAirport ManagementLogistics ManagementAvionicsThe campus is located at 71 Airport Road, Eastman, Georgia, shown on Figure 2-1. Airport and industrial propertyborders the site on all sides. Georgia highway 46 (Soperton Highway) borders the site to the south; Airport Roadborders the site to the east, the Heart of Georgia Regional Airport borders the site to the west and north. Thecampus is made up of a terminal building, a new student dormitory, and a main campus. Areas surrounding thebuildings are made up of paved parking areas.2.2 DRAINAGE PATHWAY AND DISTANCE TO NAVIGABLE WATERSThe MGA-Eastman Campus is situated on a ridge between Gum Swamp and Granny Branch. Runoff from thecampus drains south to Gum Swamp. Impervious surfaces such as roadways and parking lots are graded to directstormwater into the City’s stormwater collection system. The stormwater collection system consists of roof drains,trench drains, and catch basins that discharge south to Gum Swamp.Middle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan2-1September 2015

Figure 2-1: Site LocusMiddle Georgia State University – Eastman Campus (222825.00)Oil SPCC Plan2-2September 2015

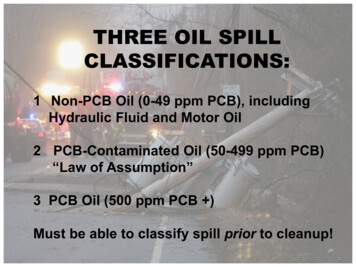

3.OIL STORAGE, CONTAINMENT, AND DELIVERY PROCEDURESThis chapter identifies and describes the MGA-Eastman Campus’ oil storage tanks and containers, including theirdesign, related secondary containment, diversionary structures, and transfer equipment. This chapter also identifiesthe most likely causes of potential spills, predicted spill pathways, probable directions, estimated maximum spillquantities, rates of flow, and satisfies many of the requirements of 40 C.F.R. §§ 112.7 and 112.8 (including 40 C.F.R.§§ 112.7(a)(3)(i)-(iii) and 112.7(h) and 112.8(b) and (c)). Tables 3-1, 3-2, and 3-3 provide a description of the oilstorage locations, capacities, means of secondary containment, and total oil quantity stored on-site. Figure 3-1illustrates the location of the bulk oil storage tanks and oil-filled equipment.3.1ABOVEGROUND TANKS AND CONTAINERSThe following subsections provide details on the ASTs located at the Eastman Campus. Potential oil releasepathways and additional AST details are provided in Table 3-1. The rate of flow of a potential spill from any of thetanks or containers would depend on several factors (e.g., the size of the leak and liquid head above the leak) and isdifficult to determine accurately until all factors associated with a specific spill are known. For all aboveground bulkstorage containers provided with secondary containment, a release from the containers would remain within thesecondary containment. However, Table 3-1 provides potential oil release pathways in the event of secondarycontainment failure or when it is not present. The maximum potential spill volumes for the aboveground tanks areequivalent to their capacities (i.e., the maximum spill quantity for a 100-gallon AST is 100 gallons). However, if anincident occurs during tank filling, the potential volume of the release is equal to the capacity of the delivery or pick upvehicle.The likelihood of a release discharging

Oil Spill Prevention Control and Countermeasure Plan 222825.00 Middle Georgia State University . and cleanup (including Facility and contractor capability) § 112.7(a)(3)(iv) . Methods of disposal of recovered materials in accordance with applicable legal requirements § 112.7(a)(3)(v) Section 5.5 Contact list and phone numbers for the .